Preparing for Installation

Warnings

These warnings are translated into several languages in the Regulatory Compliance and Safety Information for this switch.

Warning |

Statement 1003—DC Power Disconnection To reduce risk of electric shock or personal injury, disconnect DC power before removing or replacing components or performing upgrades. |

Warning |

Statement 1017—Restricted Area This unit is intended for installation in restricted access areas. Only skilled, instructed, or qualified personnel can access a restricted access area. |

Warning |

Statement 1033—Safety Extra-Low Voltage (SELV)—IEC 60950/ES1–IEC 62368 DC Power Supply To reduce the risk of electric shock, connect the unit only to a DC power source that complies with the SELV requirements in the IEC 60950-based safety standards or the ES1 requirements in the IEC 62368-based safety standards. |

Warning |

Statement 1074—Comply with Local and National Electrical Codes To reduce risk of electric shock or fire, installation of the equipment must comply with local and national electrical codes. |

Warning |

Statement 1079—Hot Surface This icon is a hot surface warning. To avoid personal injury, do not touch without proper protection.  |

Note |

Statement 1089—Instructed and Skilled Person Definitions An instructed person is someone who has been instructed and trained by a skilled person and takes the necessary precautions when working with equipment. A skilled person or qualified personnel is someone who has training or experience in the equipment technology and understands potential hazards when working with equipment. |

Warning |

Statement 1091—Installation by an Instructed Person Only an instructed person or skilled person should be allowed to install, replace, or service this equipment. See statement 1089 for the definition of an instructed or skilled person. |

Warning |

Statement 9001—Product Disposal Ultimate disposal of this product should be handled according to all national laws and regulations. |

Note |

Statement 407—Japanese Safety Instruction You are strongly advised to read the safety instruction before using the product. https://www.cisco.com/web/JP/techdoc/pldoc/pldoc.html When installing the product, use the provided or designated connection cables/power cables/AC adapters. 〈製品使用における安全上の注意〉 www.cisco.com/web/JP/techdoc/index.html 接続ケーブル、電源コードセット、ACアダプタ、バッテリなどの部品は、必ず添付品または 指定品をご使用ください。添付品・指定品以外をご使用になると故障や動作不良、火災の 原因となります。また、電源コードセットは弊社が指定する製品以外の電気機器には使用 できないためご注意ください。 |

Caution |

Airflow around the switch must be unrestricted. To prevent the switch from overheating, there must be the following minimum clearances:– Top and bottom: 1.0 in. (25 mm)– Sides: 1.0 in. (25 mm)– Front: 1.0 in. (25 mm) |

Caution |

If installer is providing cabling for an IP66/IP67 and Type-4 rated environment, the cables must be suitably rated for IP66/IP67 and Type-4 requirements |

EMC Environmental Conditions for Products Installed in the European Union

This section applies to products to be installed in the European Union.

The equipment is intended to operate under the following environmental conditions with respect to EMC:

-

A separate defined location under the user’s control.

-

Earthing and bonding shall meet the requirements of ETS 300 253 or CCITT K27.

-

AC-power distribution shall be one of the following types, where applicable: TN-S and TN-C as defined in IEC 364-3.

In addition, if equipment is operated in a domestic environment, interference could occur.

Installation Guidelines

When determining where to place the switch, observe these guidelines.

Environment and Enclosure Guidelines

Review these environmental and enclosure guidelines before installation:

-

This equipment is considered Group 1, Class A industrial equipment, according to IEC/CISPR Publication 11. Without appropriate precautions, there may be potential difficulties ensuring electromagnetic compatibility in other environments due to conducted as well as radiated disturbance.

Caution |

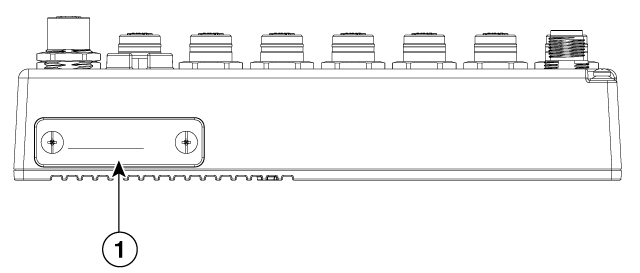

To meet IP67 Compliance, all cables, dust caps, or the captive screws on the SD card cover must be torqued to the recommended spec before operating the unit. |

Caution |

Use caution when removing dust caps. Dust caps in an over-tightened state may adhere to the connector O-ring seal. Ensure that the O-ring remains in place when dust caps are removed and follow all torque specs here: |

General Guidelines

Before installation, observe these general guidelines:

Caution |

Proper ESD protection is required whenever you handle Cisco equipment. Installation and maintenance personnel should be properly grounded by using ground straps to eliminate the risk of ESD damage to the switch.Do not touch connectors or pins on component boards. Do not touch circuit components inside the switch. When not in use, store the equipment in appropriate static-safe packaging. |

-

If you are responsible for the application of safety-related programmable electronic systems (PES), you need to be aware of the safety requirements in the application of the system and be trained in using the system.

When determining where to place the switch, observe these guidelines:

-

Before installing the switch, first verify that the switch is operational by powering it on and observing boot fast.

-

For 10/100 ports and 10/100/1000 ports, the cable length from a switch to an attached device cannot exceed 328 feet (100 meters).

-

Operating environment is within the ranges listed in Appendix F, “Technical Specifications.”

-

Clearance to front and rear panels meets these conditions:

-

Front-panel LEDs can be easily read.

-

Access to ports is sufficient for unrestricted cabling.

-

Front-panel direct current (DC) power connectors are within reach of the connection to the DC power source.

-

-

Airflow around the switch must be unrestricted. To prevent the switch from overheating, you must have the following minimum clearances:

-

Top and bottom: 1.0 in. (25 mm)

-

Sides: 1.0 in. (25 mm)

-

Front: 1.0 in. (25 mm)

-

-

Ambient temperature does not exceed 140°F (60°C).

-

Cabling is away from sources of electrical noise, such as radios, power lines, and fluorescent lighting fixtures.

Verifying Package Contents

Included in the box is the switch itself and it’s installation documentation. If any item is missing or damaged, contact your representative or reseller for support.

Tools and Equipment

Obtain these necessary tools and equipment:

-

A single or a pair of stud size 6 ring terminals (Hollingsworth part number R3456B or equivalent) for use as a protective ground connector.

-

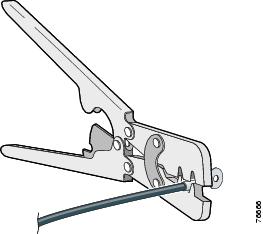

Crimping tool (Thomas & Bett part number WT2000, ERG-2001 or equivalent).

-

10-gauge copper ground wire.

-

UL- and CSA-rated, style 1007 or 1569 twisted-pair copper appliance wiring material (AWM) wire for DC power connections.

-

Wire-stripping tools for stripping 10-, 16-, and 18-gauge wires.

-

Number-2 Phillips screwdriver.

-

Flat-blade screwdriver.

-

Torque Driver (Such as a Torqueleader TT500 or equivalent)

Feedback

Feedback