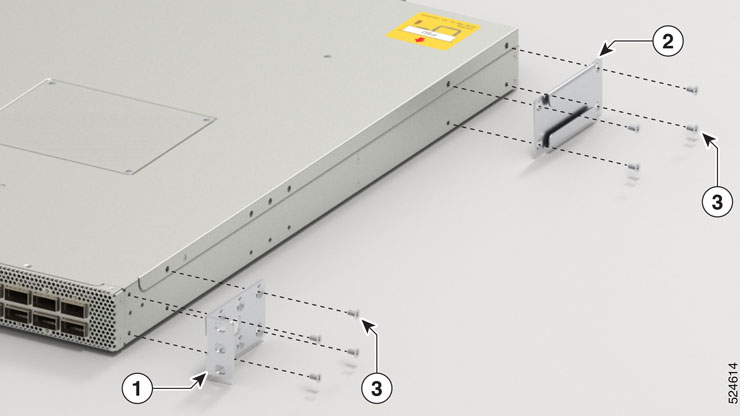

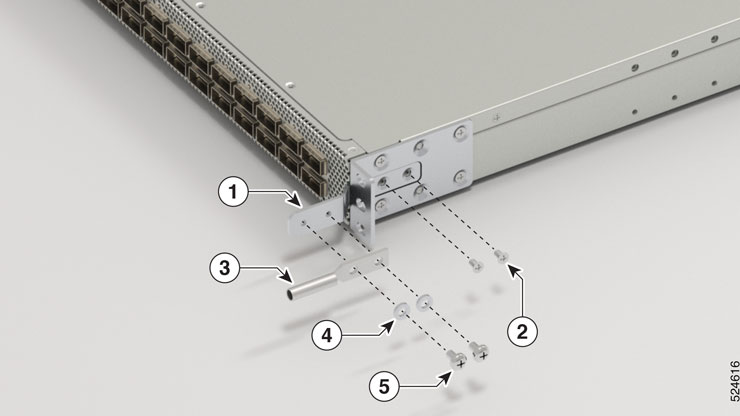

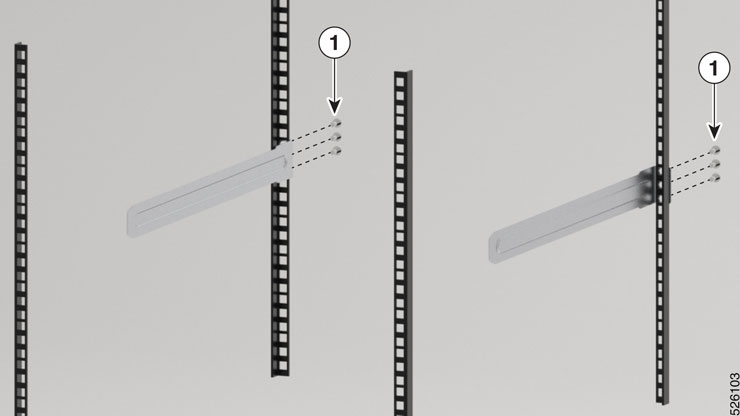

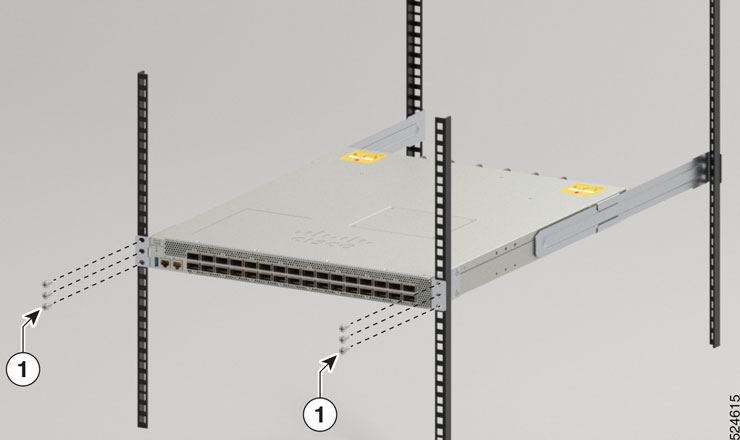

Rack mount the chassis

The switch can be mounted on a 4-post rack.

Warning |

Statement 1006—Chassis Warning for Rack-Mounting and Servicing To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

|

Warning |

Statement 1032—Lifting the Chassis To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the handles on modules, such as power supplies, fans, or cards. These types of handles are not designed to support the weight of the unit. |

Warning |

Statement 1098—Lifting Requirement people are required to lift the heavy parts of the product. To prevent injury, keep your back straight and lift with your legs, not your back. |

Note |

Statement 4023—Product Usage Restrictions This product is designed for indoor usage only. Outdoor usage is not permitted. |

Feedback

Feedback