Product Transportation and Handling Considerations

Be aware of the following transporting and safe handling requirements for this product:

-

Although not a requirement, it is a best practice to secure the product into a shipping container, such as the original packaging that came with the product.

-

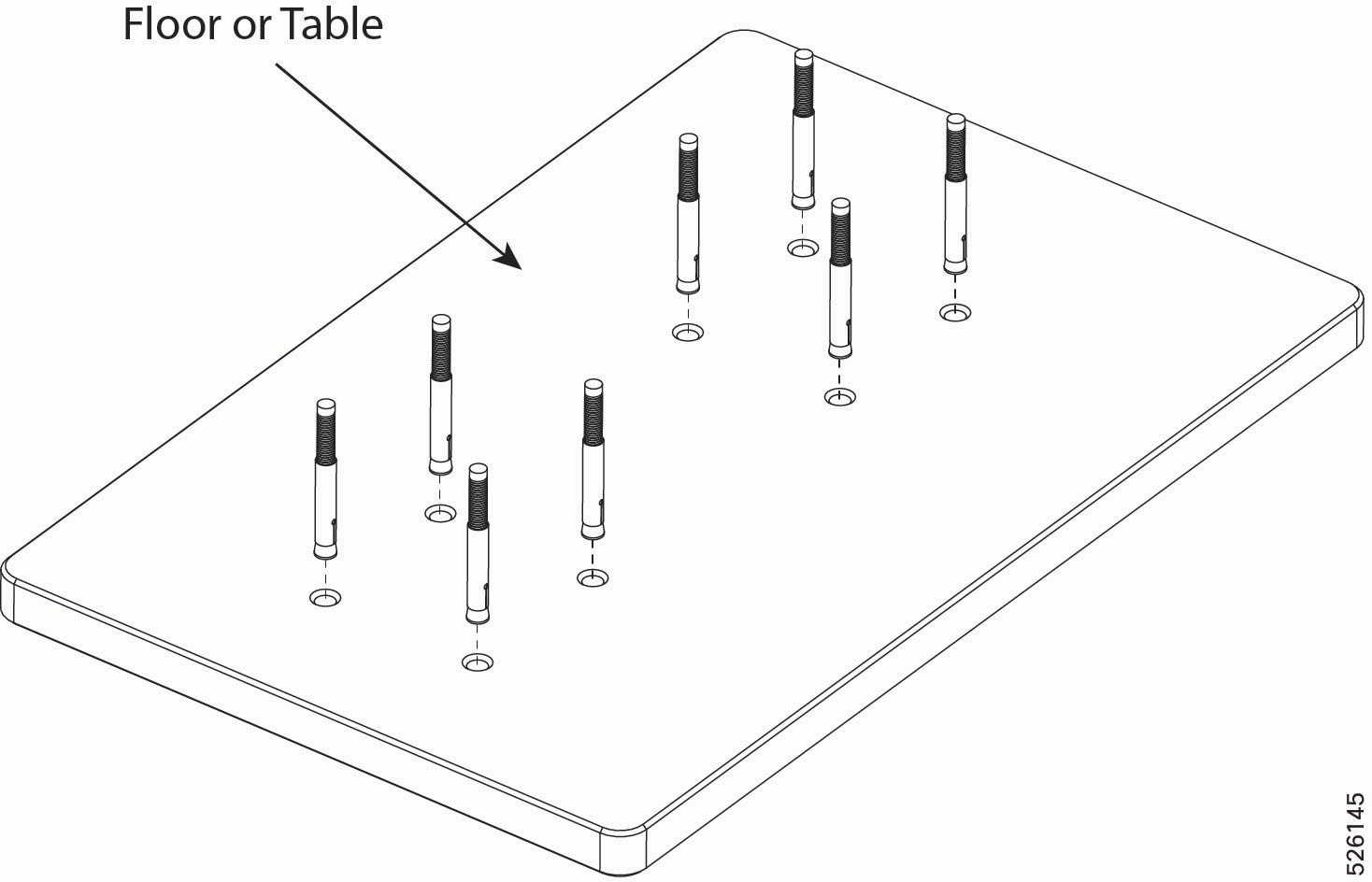

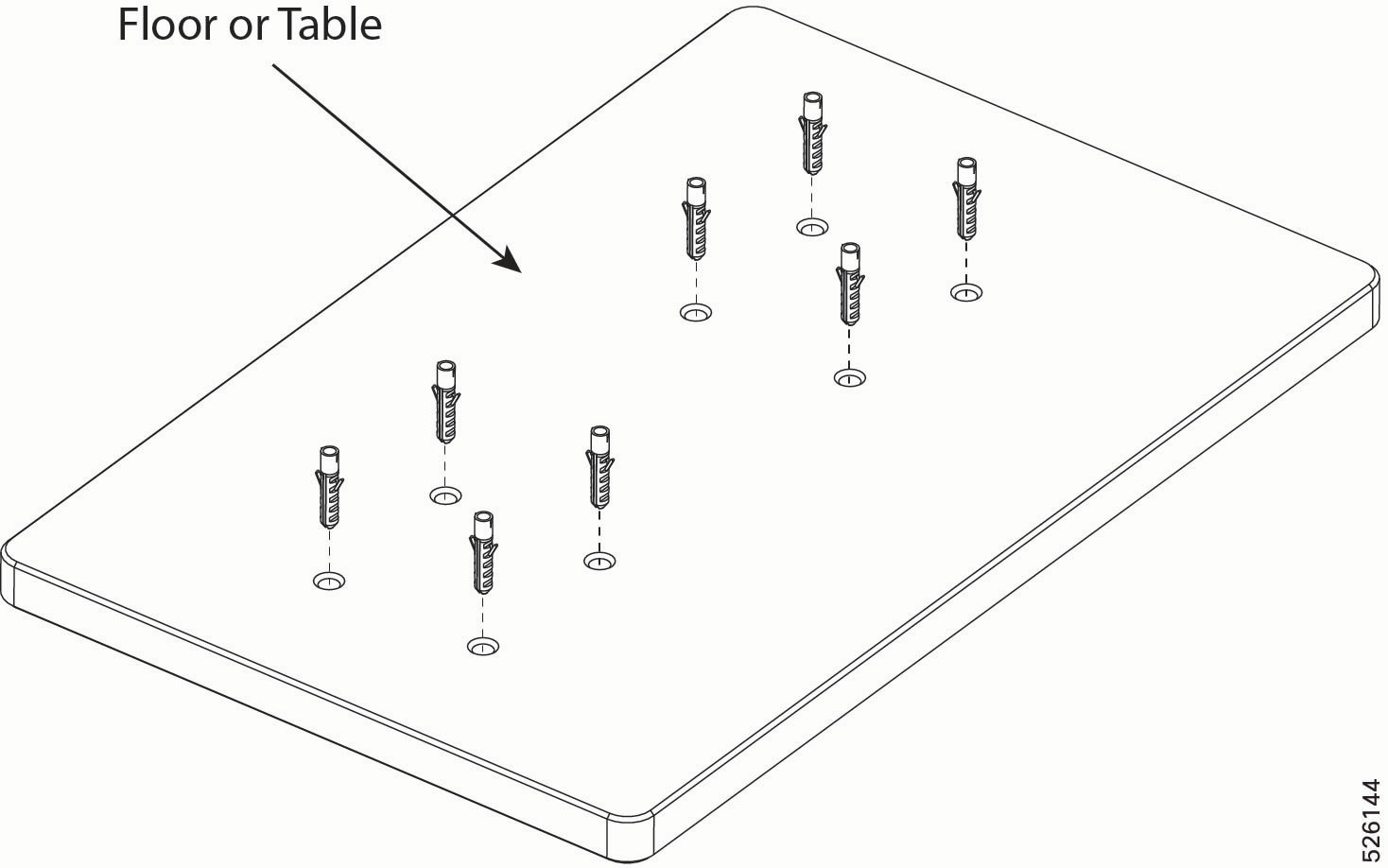

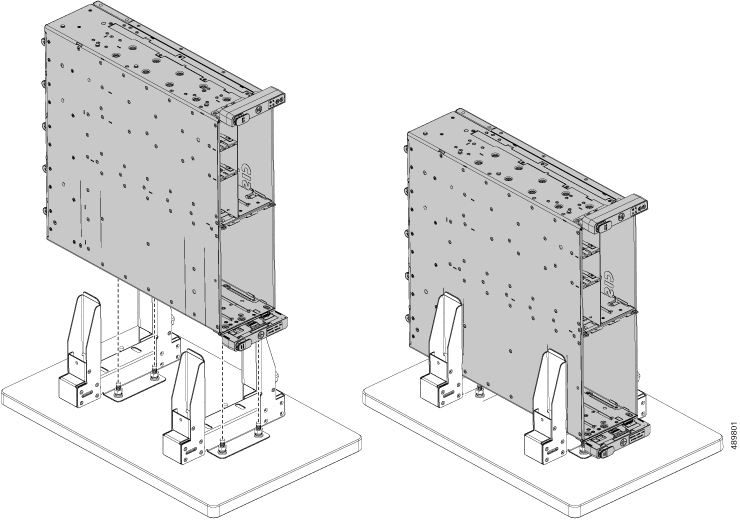

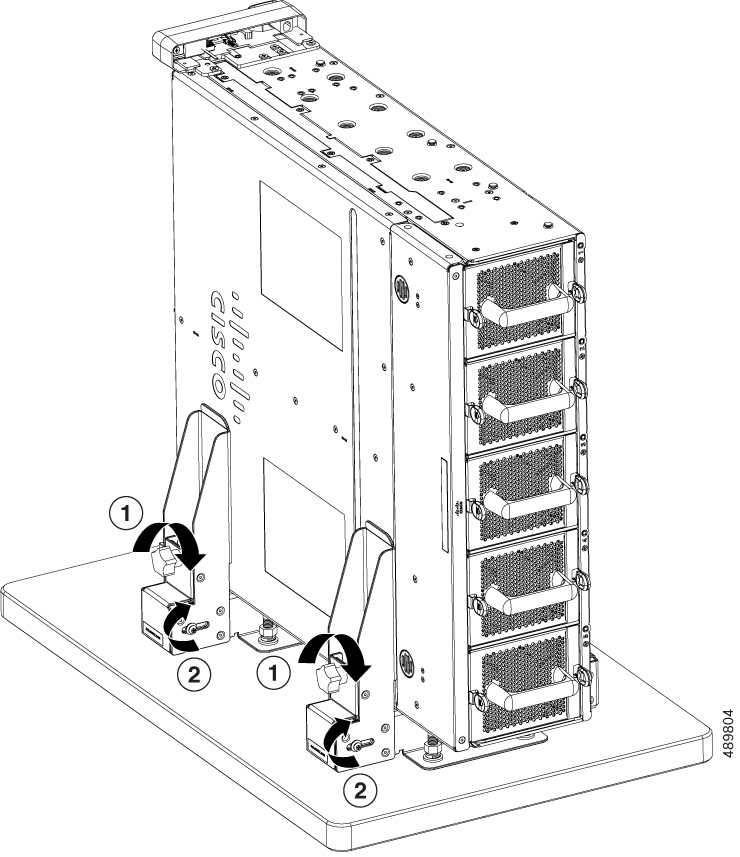

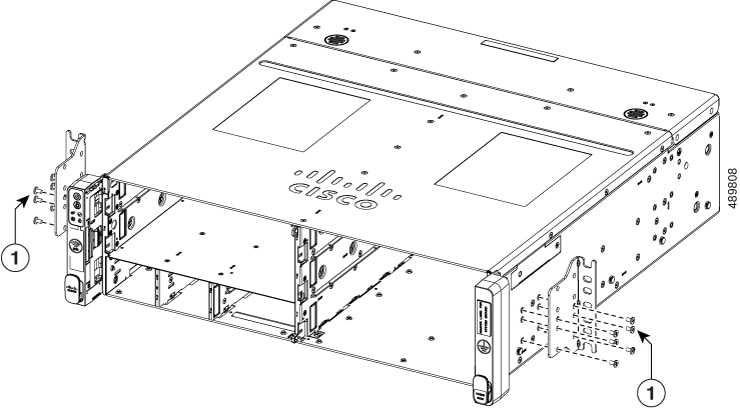

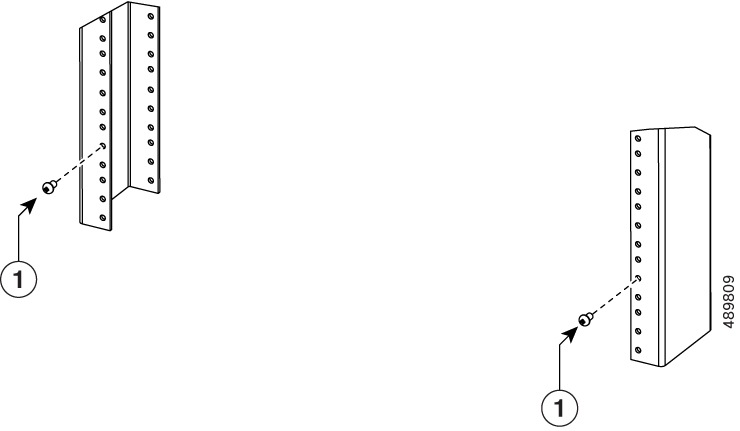

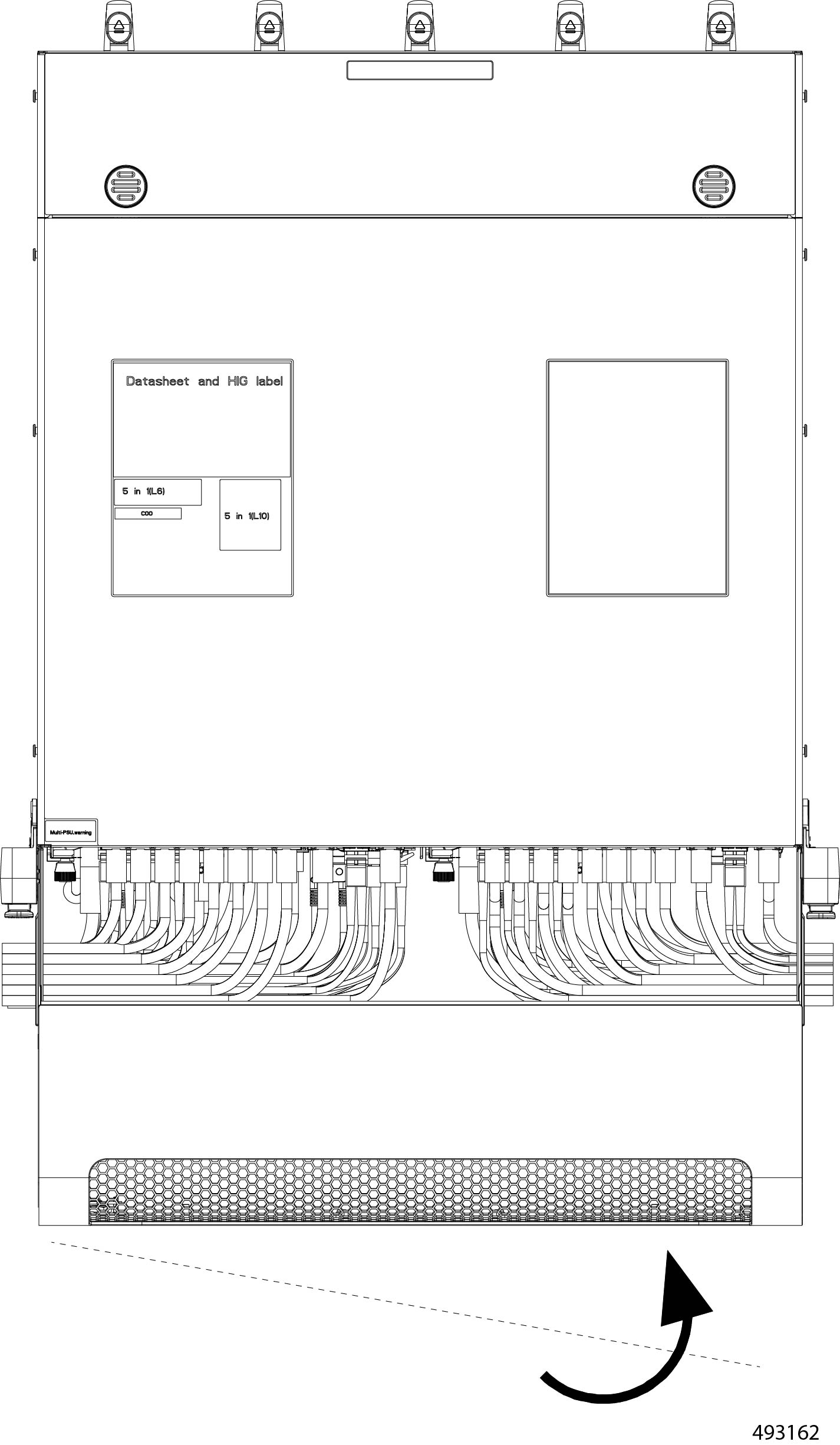

Whenever the product is shipped or transported, it is a requirement that the product is loaded onto a pallet.

Caution

Before loading the product onto a pallet, inspect the pallet for damage, missing screws, nails, or other fasteners. Only use undamaged pallets that are not missing any fasteners to ship the product.

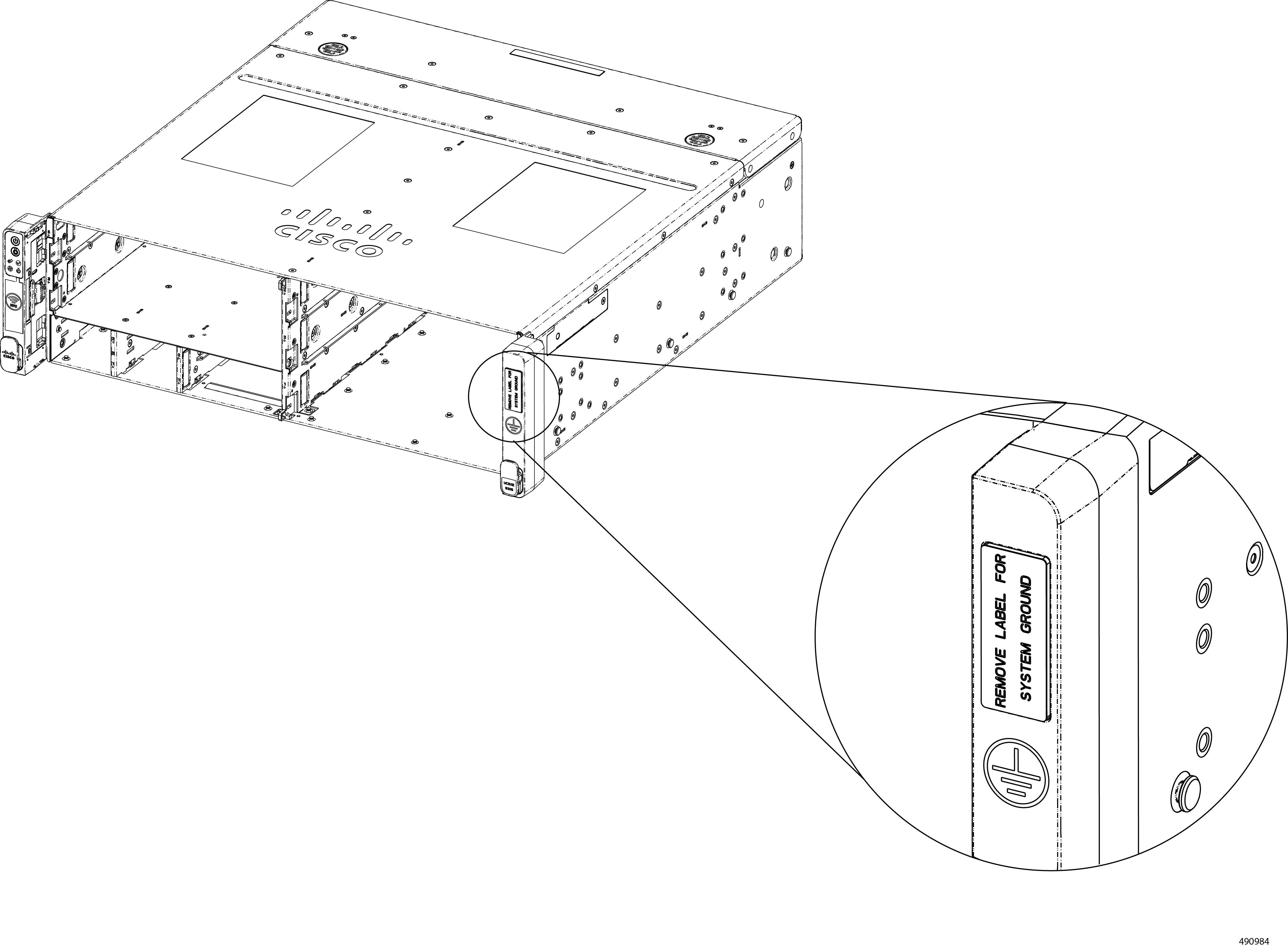

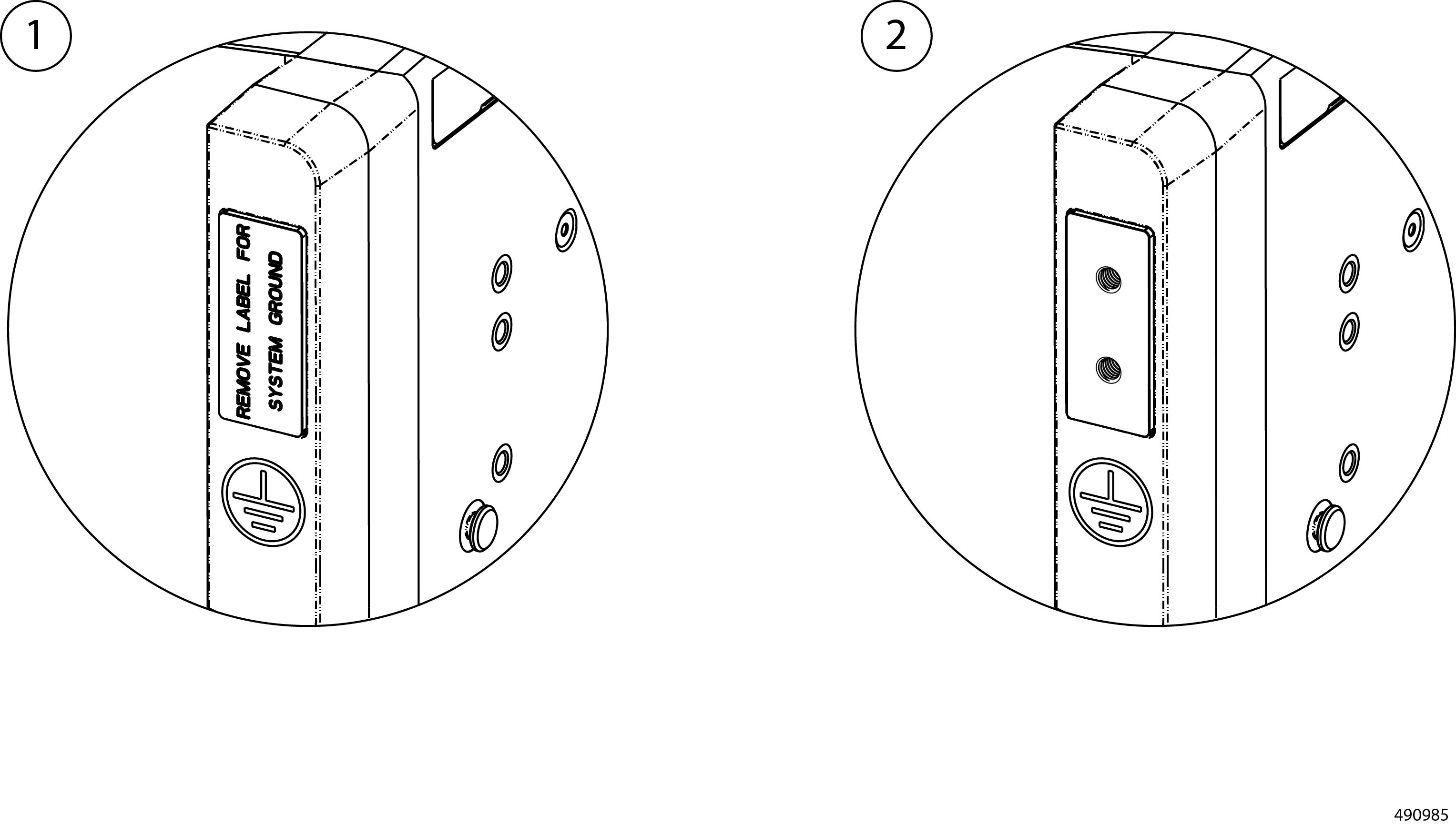

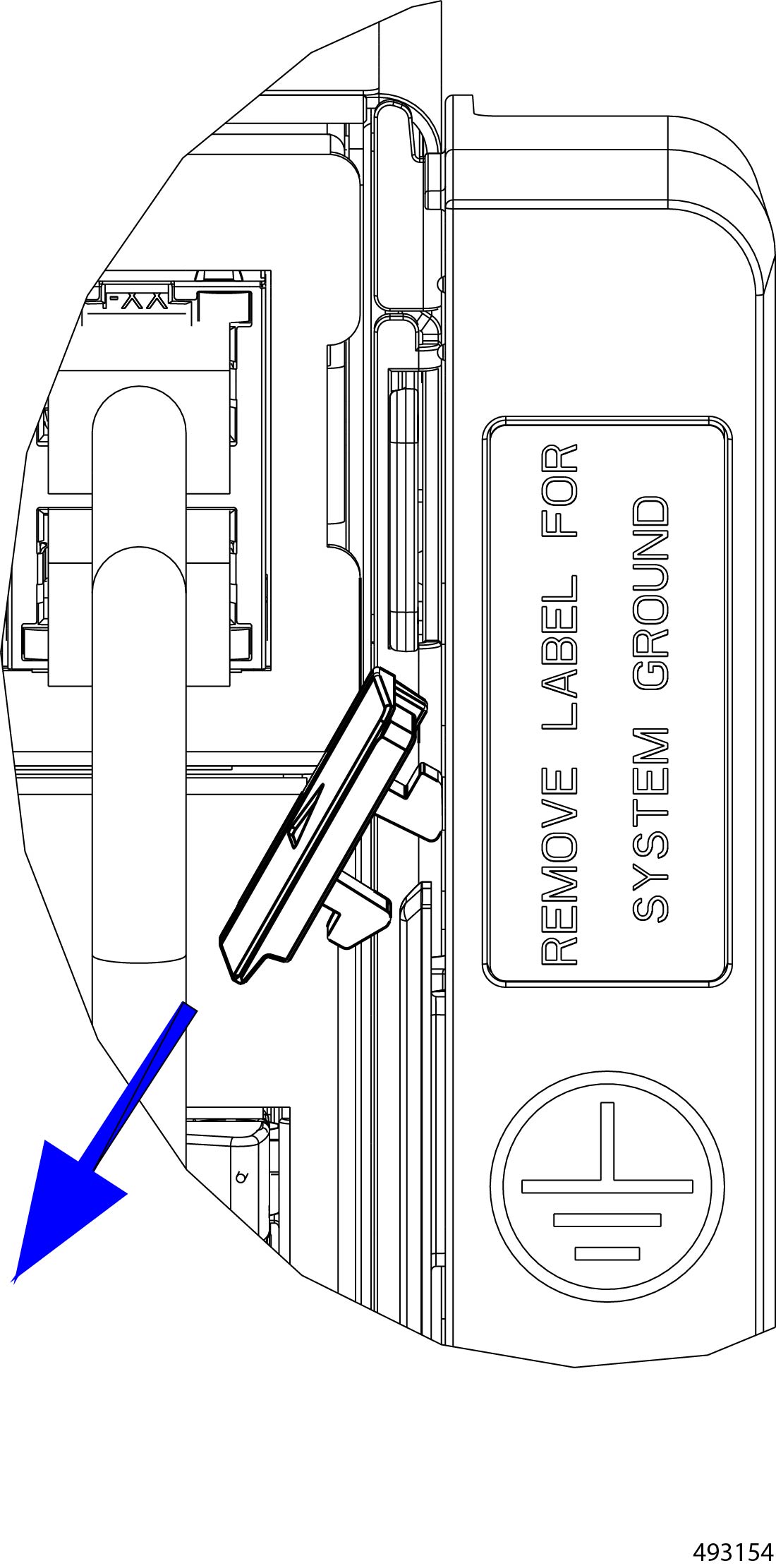

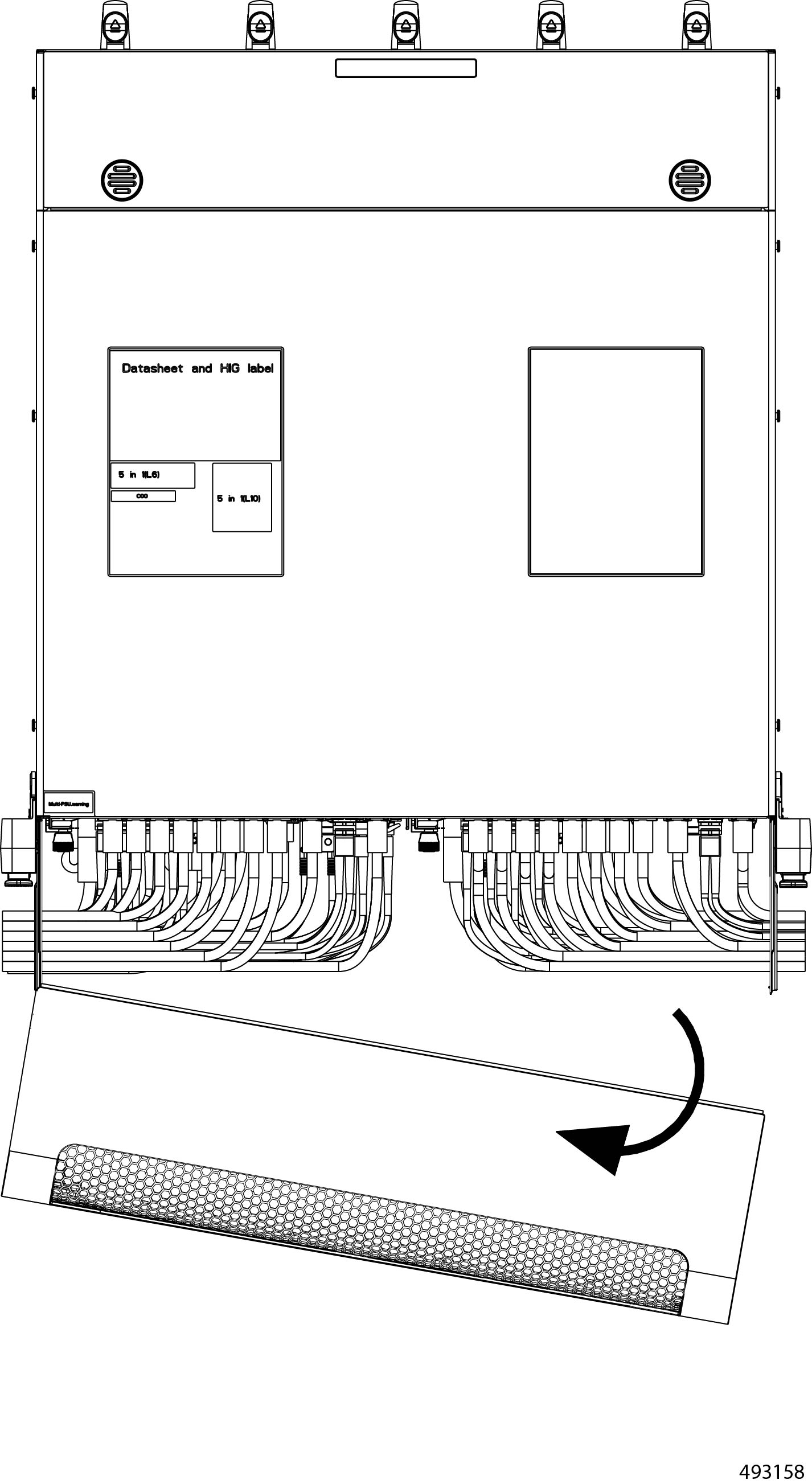

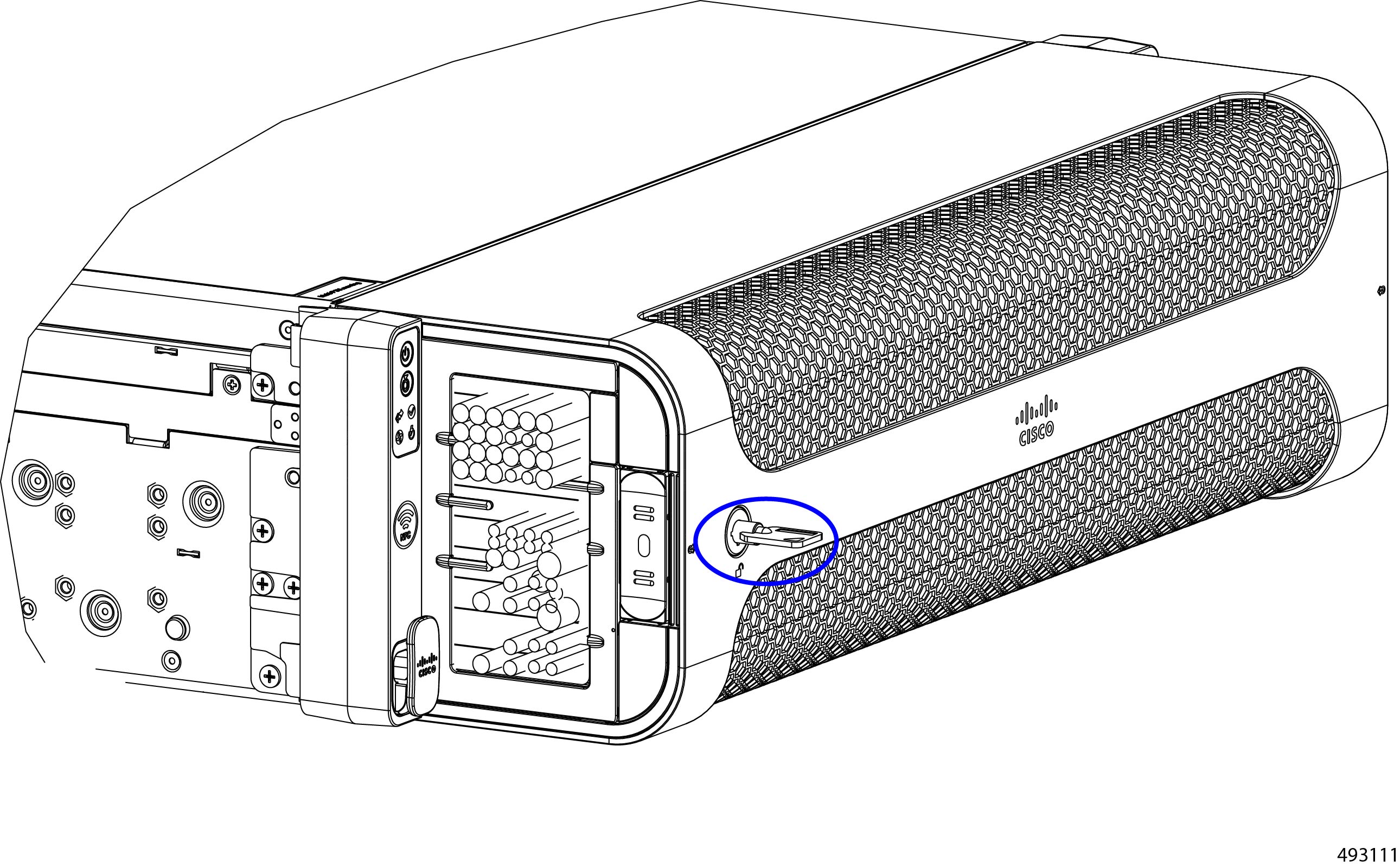

This requirement is also indicated by the following label which is directly affixed to the product.

You must use these transportation and handling considerations for shipping or transporting the product to or from any customer or order fulfillment site, or when return shipping the product to Cisco Systems, for example, due to an RMA.

If you do not have access to a pallet that can support the product's weight and size, you can order one from Cisco Systems by ordering UCSXE-PKG-MINIPLT=

Note |

The Cisco pallet (UCSXE-PKG-MINIPLT=) does not include any product packaging or shipping container. |

Caution |

Shipping the product without using an appropriate pallet can void your product warranty. |

Feedback

Feedback