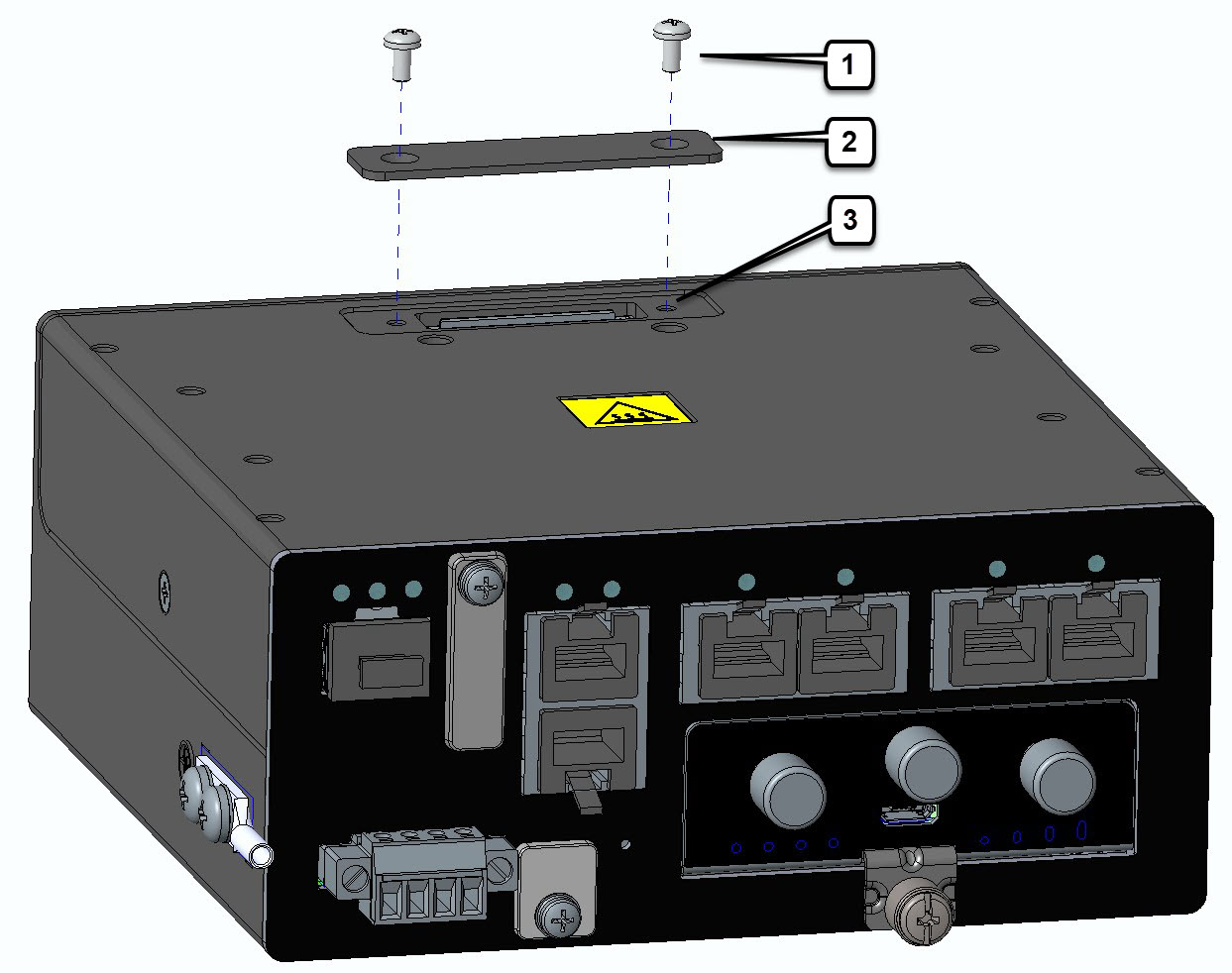

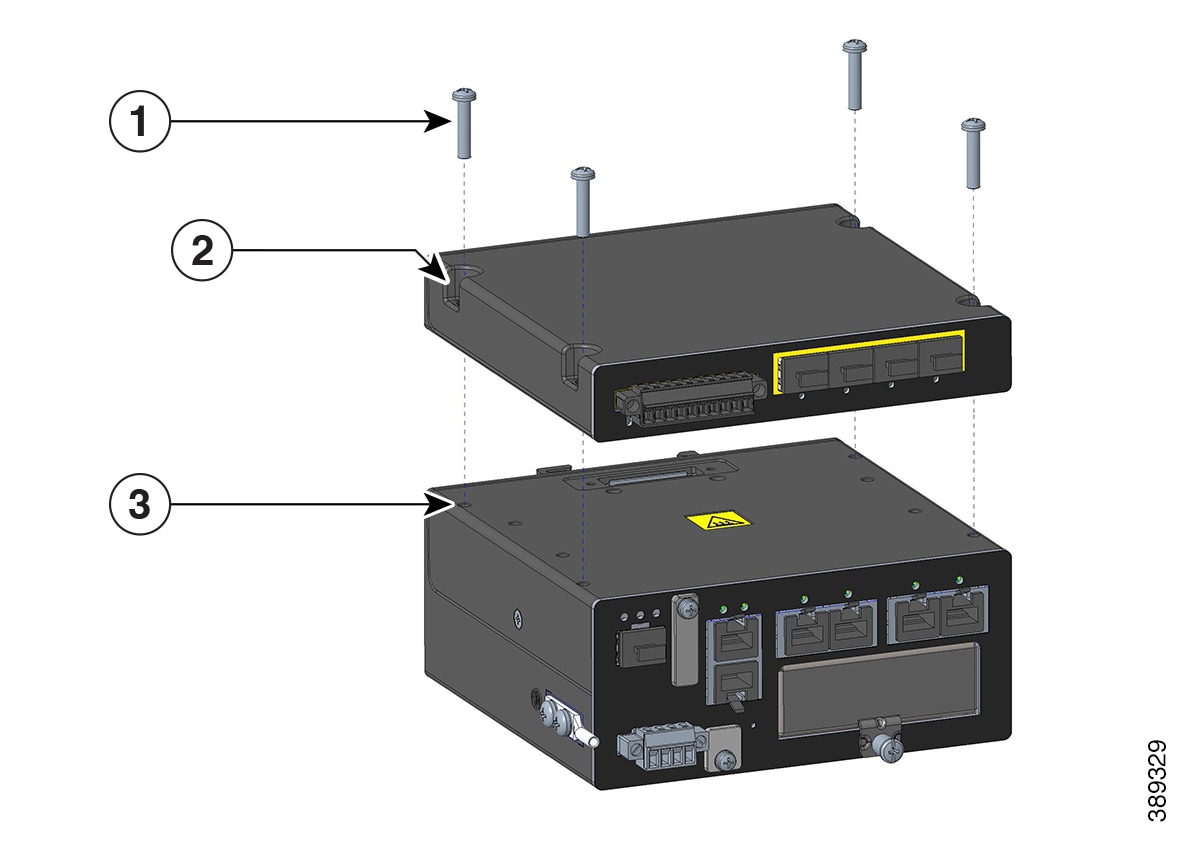

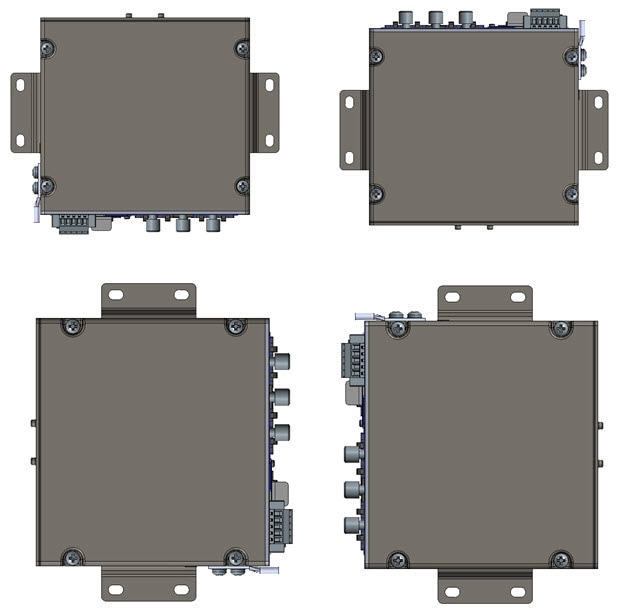

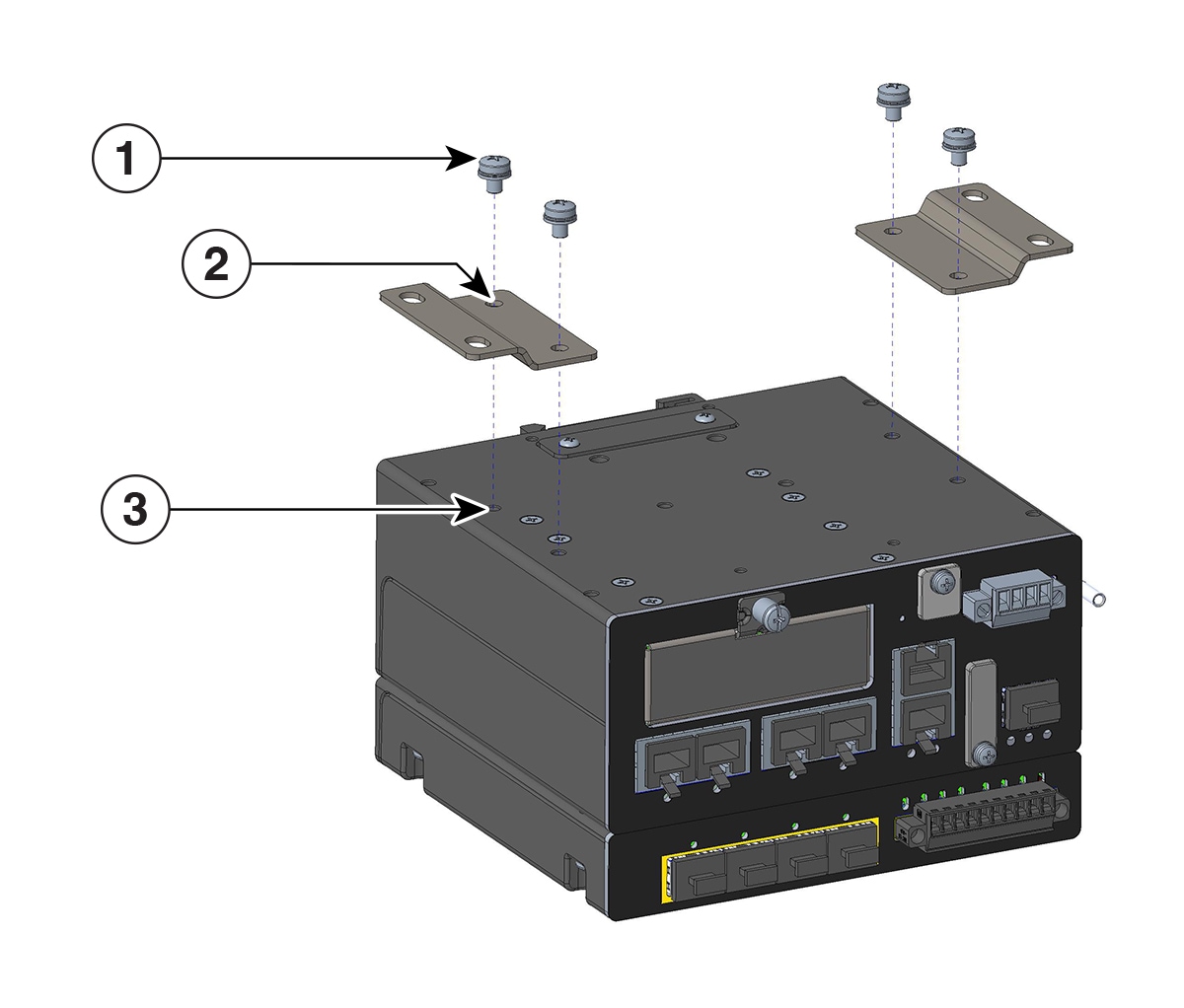

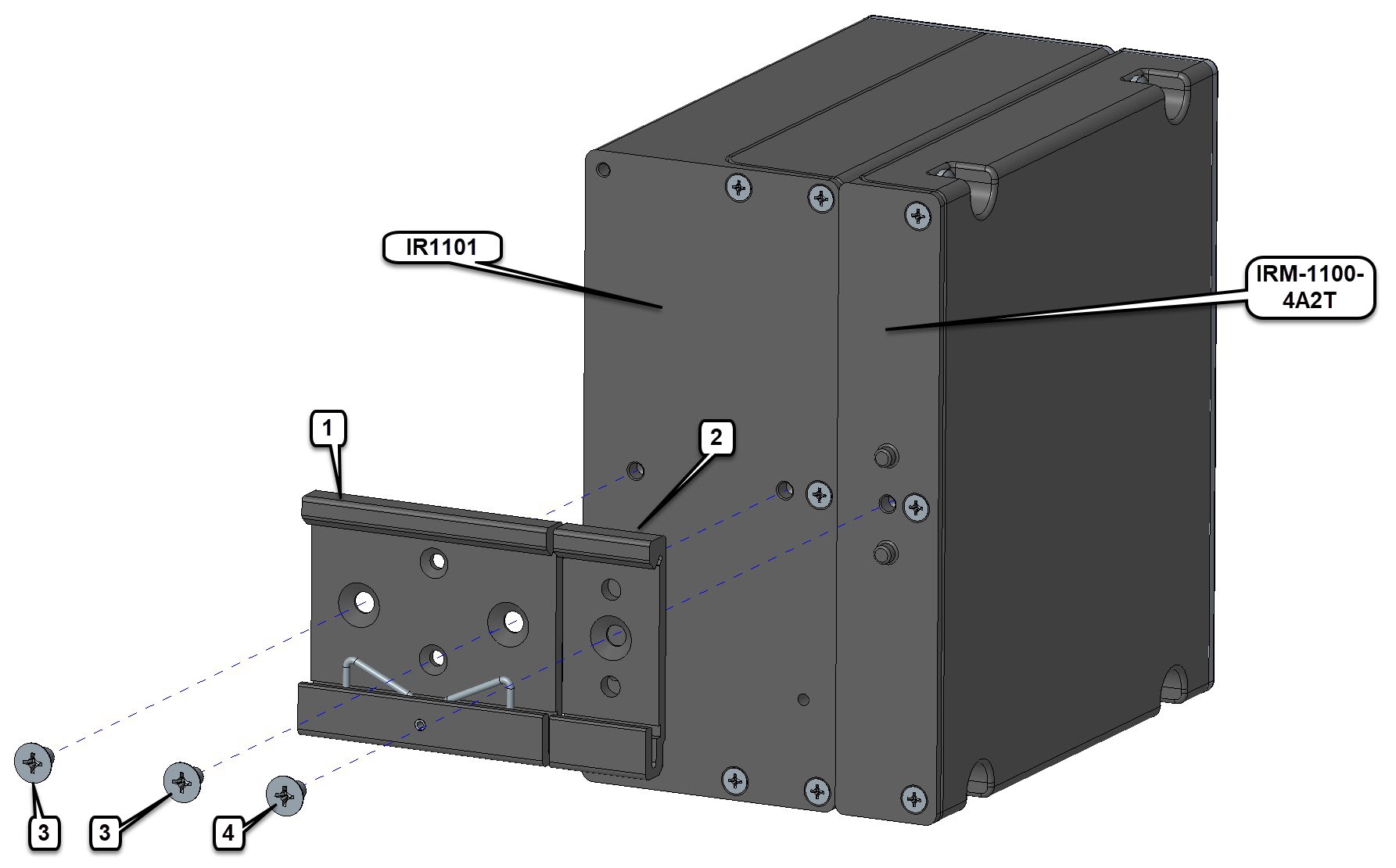

Items shipped with your Expansion Module

Unpack the box and verify that all items listed on the invoice were shipped with the Cisco IRM-1100-4S8I.

The following items are shipped in the box:

-

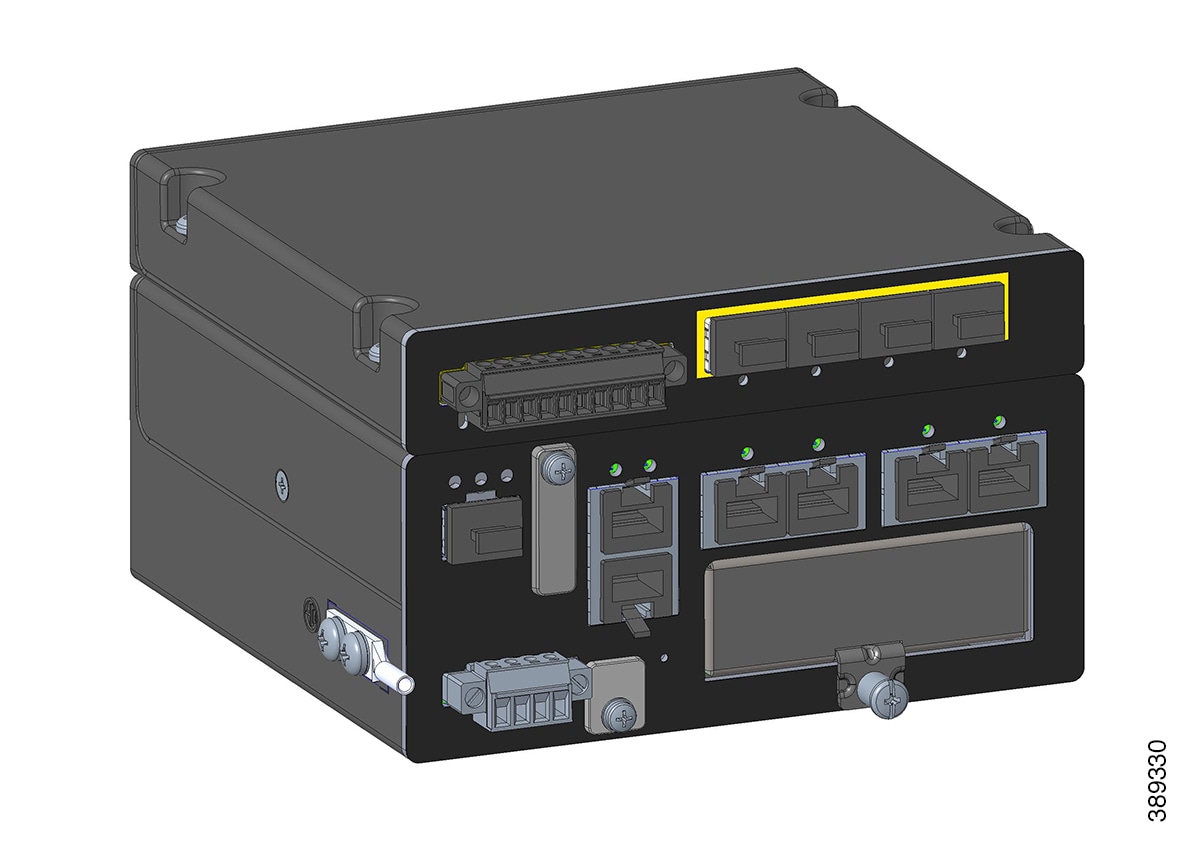

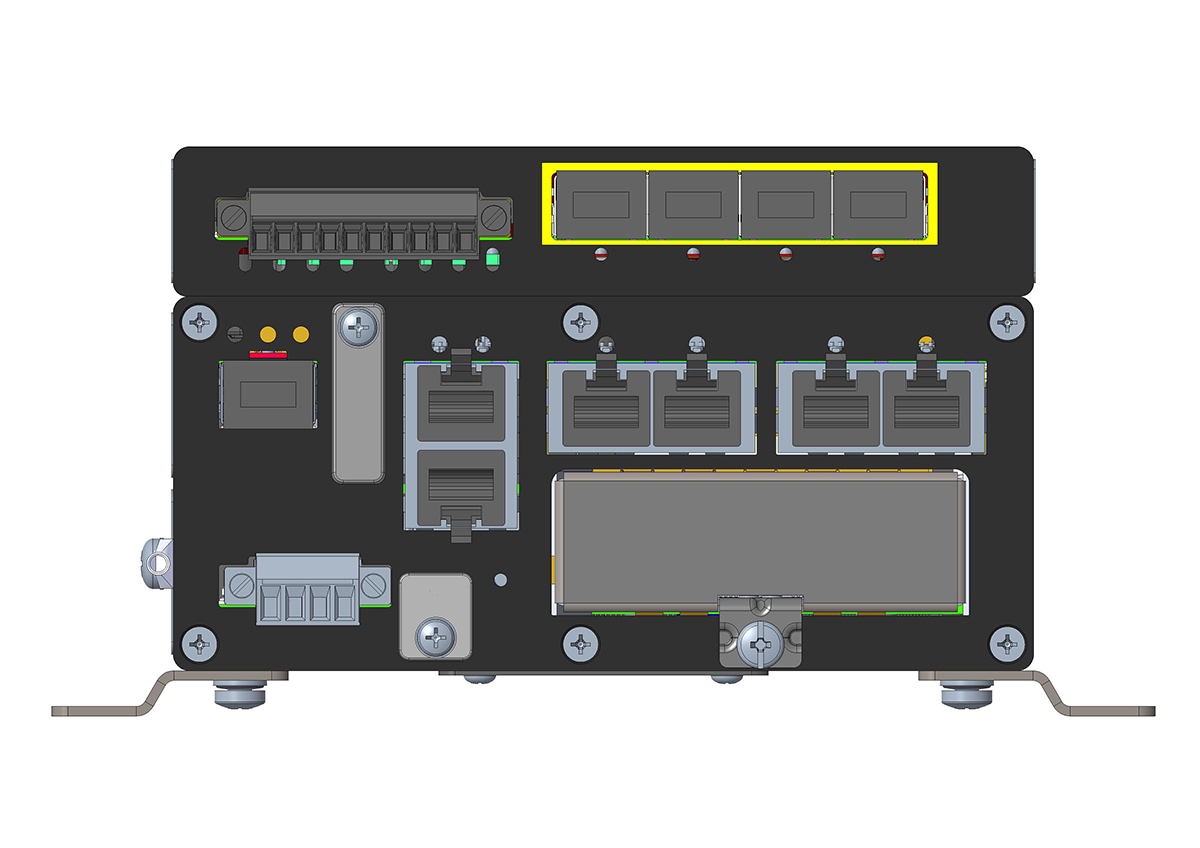

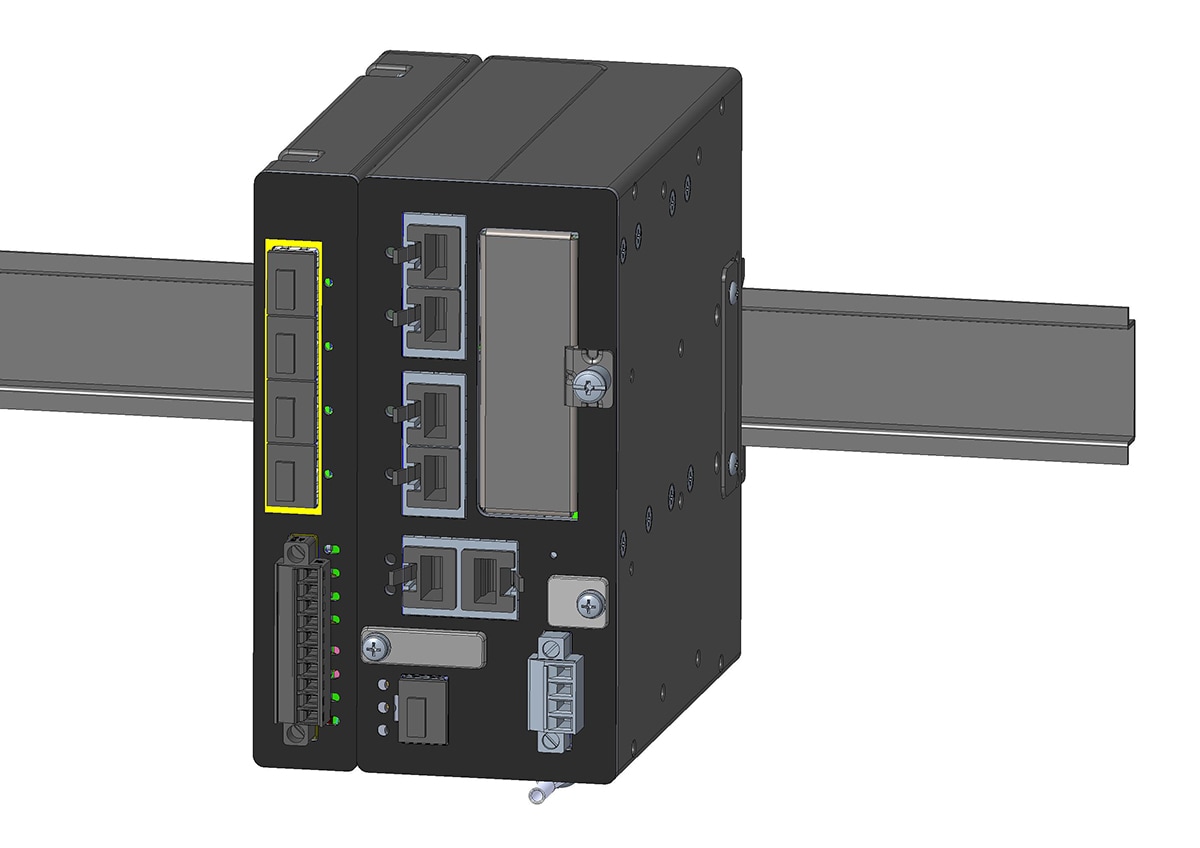

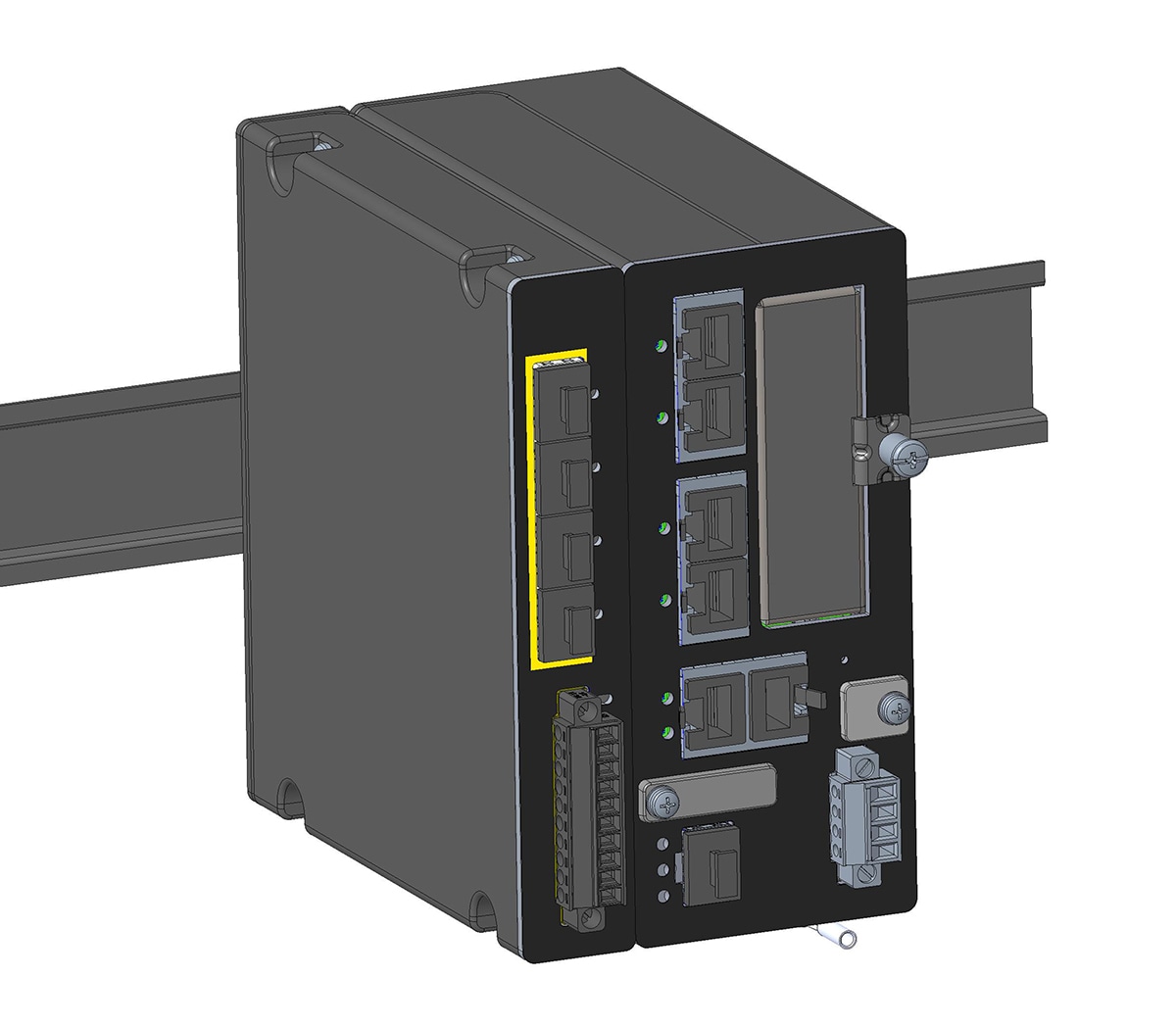

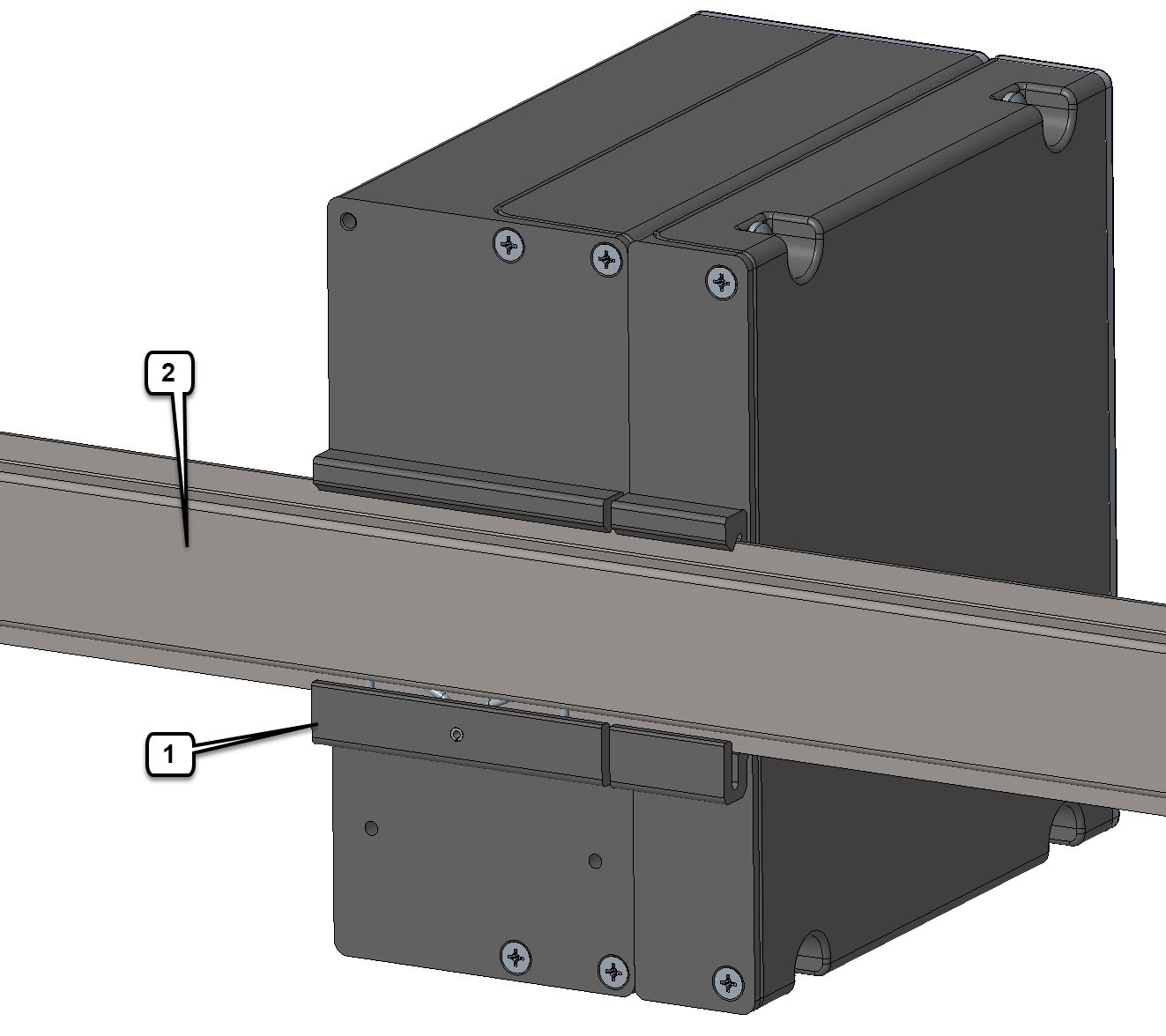

Cisco IRM-1100-4S8I expansion module

-

Four mating screws to connect the IRM-1100-4S8I to the IR1101

Feedback

Feedback