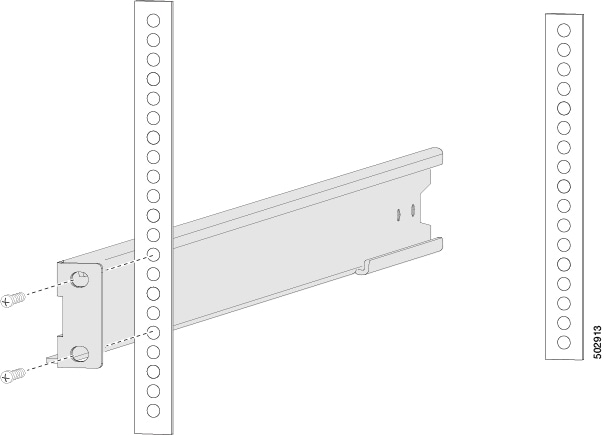

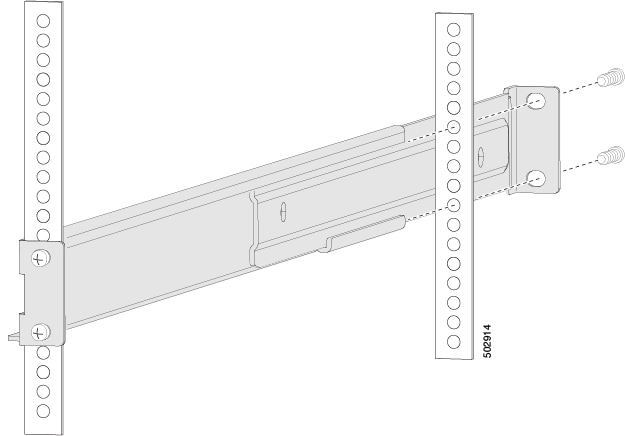

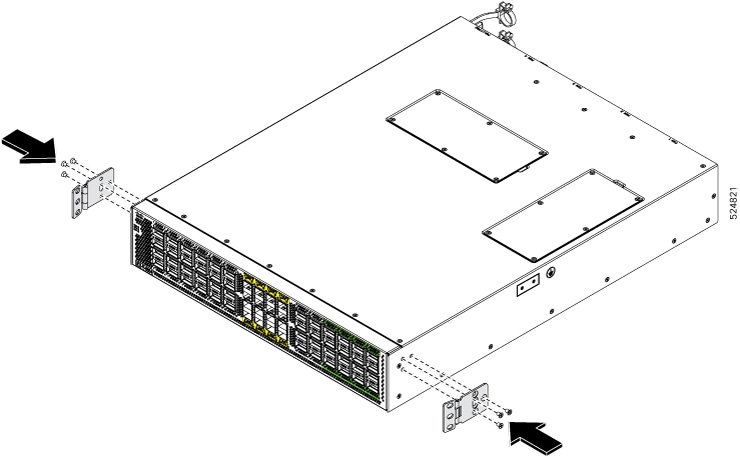

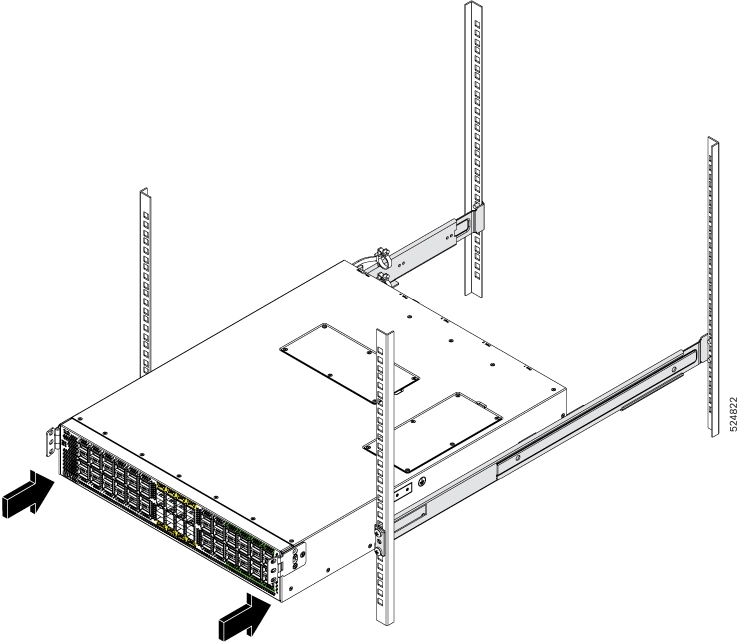

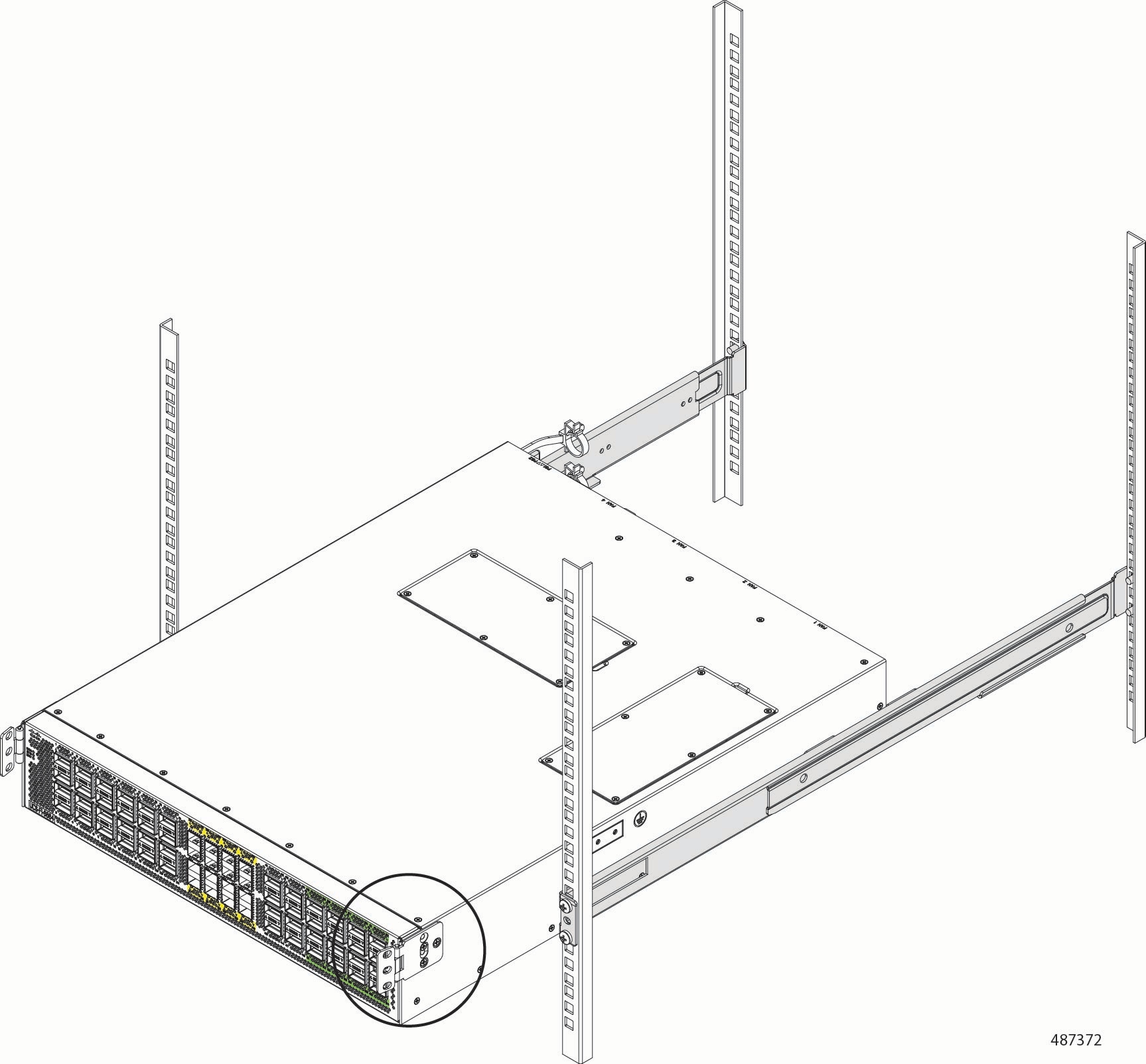

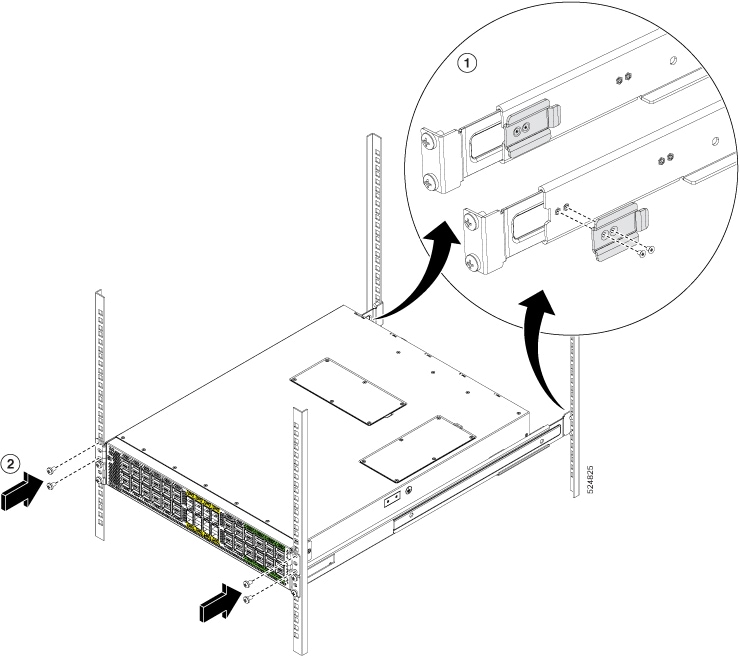

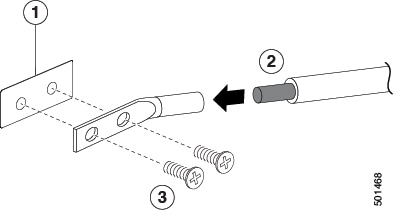

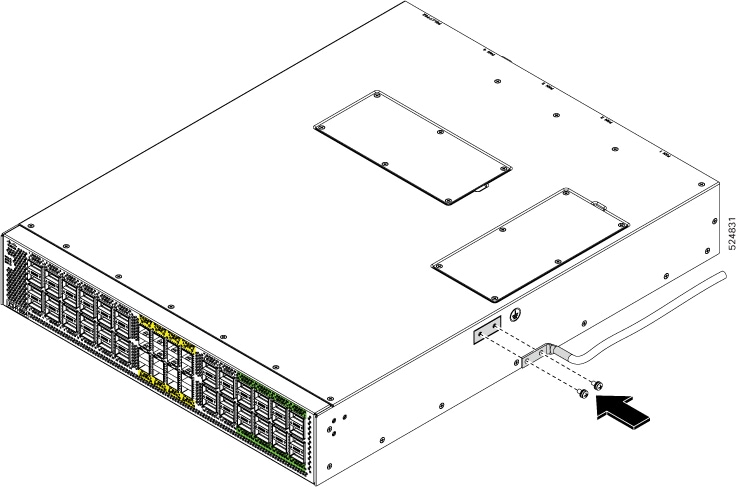

Installation Options with Rack-Mount Kits

The rack-mount kit enables you to install the fabric interconnect into racks of varying depths. Position the fabric interconnect with easy access to either the port connections or the fan and power supply modules.

Install the fabric interconnect using rack-mount kit UCS-ACC-6664, which you can order from Cisco. This option offers you easy installation, greater stability, increased weight capacity, added accessibility, and improved removability with front and rear removal.

The rack or cabinet that you use must meet the requirements listed the in General Requirements for Cabinets and Racks.

Note |

You are responsible for verifying that your rack and rack-mount hardware comply with the guidelines that are described in this document. |

Feedback

Feedback