Rack Mount the Chassis

The chassis can be mounted on a 4-post or a 2-post rack based on the type of the chassis and the rack requirement.

-

4-Post Rack-The following sections explain the mounting of the chassis on a 4-post rack:

-

Rack-Mount the Chassis in a 4-Post Rack — Procedure 1- Contains the procedures for mounting the Cisco NCS-55A1-24H, Cisco NCS 5501, Cisco NCS 5501-SE, Cisco NCS-55A1-48Q6H, Cisco NCS-55A1-24Q6H-S, Cisco NCS-55A1-24Q6H-SS, Cisco NCS 55A1-36H-S, Cisco NCS 55A1-36H-SE-S, Cisco NCS 5502, and Cisco NCS 5502-SE chassis.

To mount the Cisco NCS 55A2-MOD-S, Cisco 55A2-MOD-HD-S, Cisco NCS 55A2-MOD-SE-S, Cisco NCS-55A2-MOD-HX-S, and Cisco NC55A2-MOD-SE-H-S chassis on the front post of the 4-post rack, follow the steps in Rack Mount the Chassis in a 2 Post Rack — Procedure 2.

-

Rack Mount the Chassis in a 4-Post Rack — Procedure 2- Contains the procedures for mounting the Cisco NCS-55A2-MOD-HD-S, Cisco NCS-55A2-MOD-HX-S and Cisco NC55A2-MOD-SE-H-S chassis.

-

-

2-Post Rack-The following sections explain the mounting of the chassis on a 2-post rack:

-

Rack-Mount the Chassis in a 2-Post Rack — Procedure 1- Contains procedures for mounting the Cisco NCS-55A1-24H, Cisco NCS 5501, Cisco NCS 5501-SE, Cisco NCS-55A1-24Q6H-S, and Cisco NCS-55A1-24Q6H-SS,

-

Rack Mount the Chassis in a 2 Post Rack — Procedure 2- Contains procedures for mounting the Cisco NCS-55A2-MOD-S, Cisco NCS-55A2-MOD-HD-S, Cisco NCS-55A2-MOD-SE-S, Cisco NCS-55A2-MOD-HX-S, and Cisco NC55A2-MOD-SE-H-S

-

Rack-Mount the Chassis in a 4-Post Rack — Procedure 1

This section describes how to use the rack-mount kit that is provided with the router to install the router in a 4-post rack.

Caution |

If the rack is on wheels, ensure that the brakes are engaged or that the rack is otherwise stabilized. |

Note |

To mount the Cisco NCS 55A2-MOD-S, Cisco 55A2-MOD-HD-S, Cisco NCS 55A2-MOD-SE-S, Cisco NCS-55A2-MOD-HX-S, and Cisco NC55A2-MOD-SE-H-S chassis on the front post of the 4-post rack, follow the steps in Rack Mount the Chassis in a 2 Post Rack — Procedure 2. |

The following table lists the items that are contained in the rack-mount kit.

|

Quantity |

Part Description |

|---|---|

|

2 |

Rack-mount brackets |

|

12 |

M4 x 6-mm Phillips flat-head screws |

|

2 |

M5 x 12mm Phillips pan-head screws |

|

2 |

Rack-mount guides |

|

2 |

Rack-mount slider rails |

|

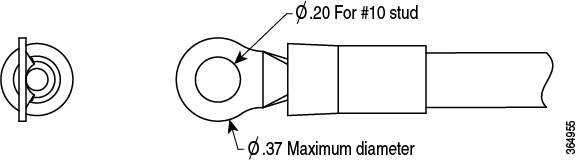

1 |

Grounding lug |

|

Quantity |

Part Description |

|---|---|

|

2 |

Rack-mount brackets |

|

14 |

M4 x 6-mm Phillips flat-head screws |

|

2 |

M4 x 6-mm Phillips pan-head screws |

|

2 |

Rack-mount guides |

|

2 |

Rack-mount slider rails |

|

1 |

Grounding cover plate |

|

1 |

Grounding lug |

|

Quantity |

Part Description |

|---|---|

|

2 |

Rack-mount brackets |

|

18 |

M4 x 8-mm Phillips flat-head screws |

|

2 |

M4 x 8mm Phillips pan-head screws |

|

2 |

Rack-mount guides |

|

2 |

Rack-mount slider rails |

|

1 |

Grounding cover plate |

|

1 |

Grounding lug |

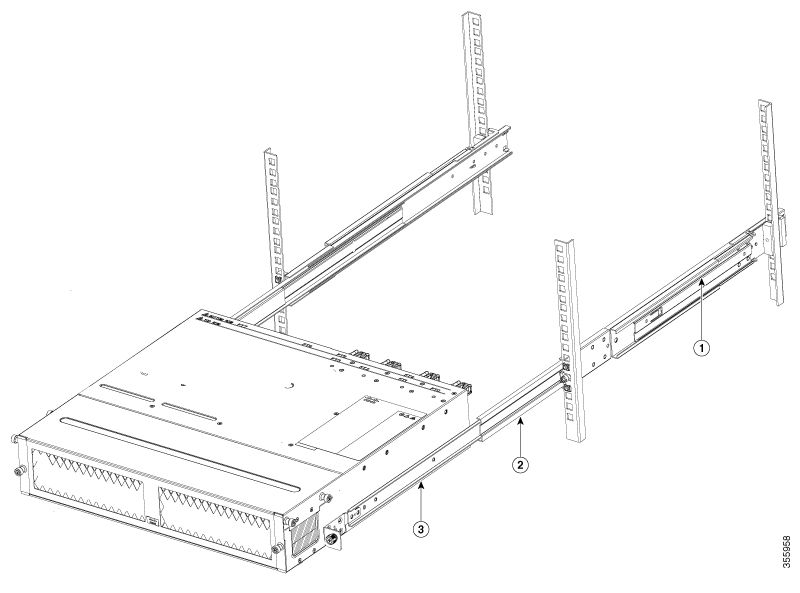

Procedure

|

Step 1 |

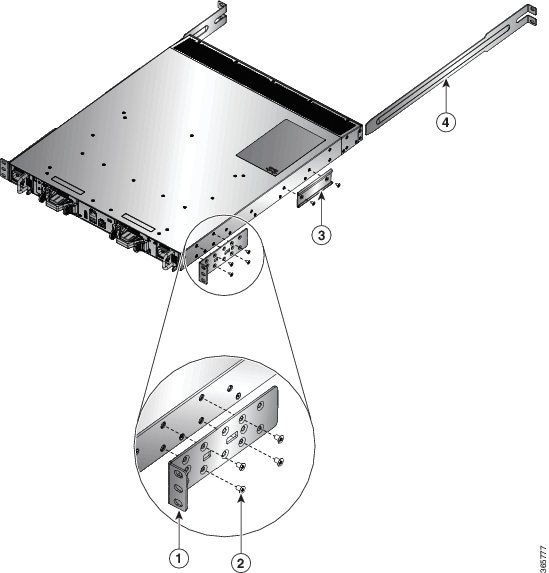

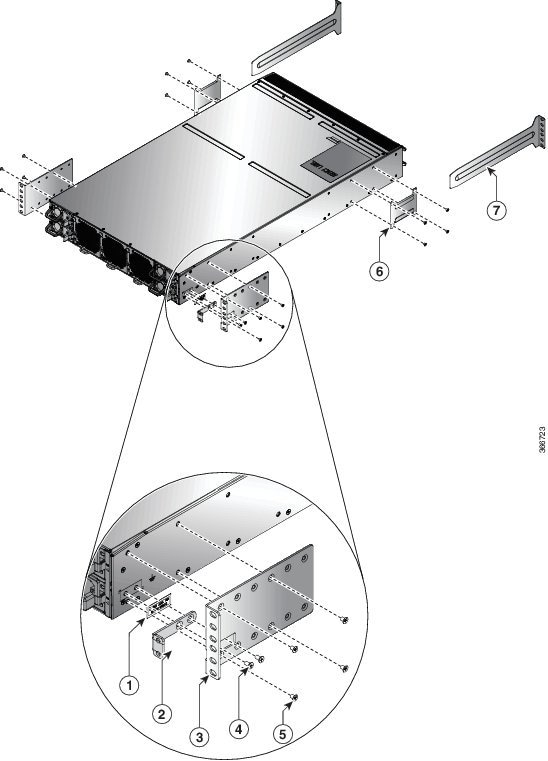

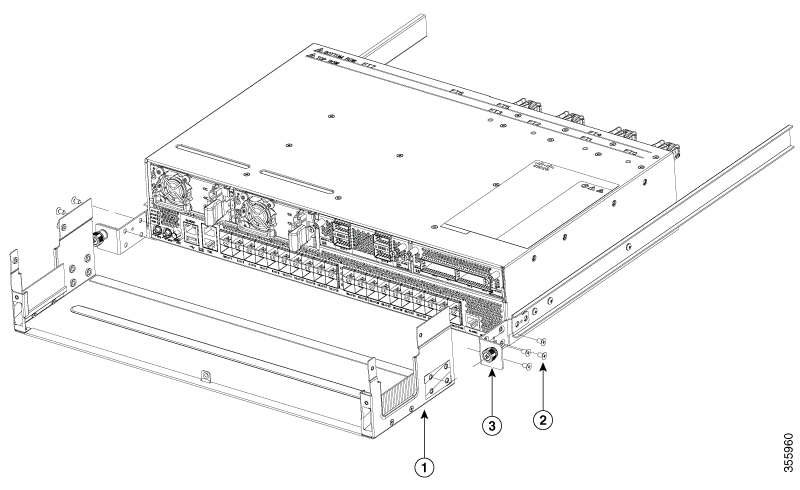

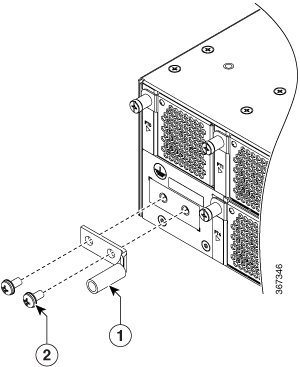

Install the rack-mount brackets to the router as follows: |

||

|

Step 2 |

Cisco NCS-55A1-24H, Cisco NCS 55A1-36H-S, Cisco NCS 55A1-36H-SE-S, NCS 5501, and NCS 5501-SE: The top plate is required for NEBS compliance when the router is installed with the ports in the cold aisle (port-side air intake). Install the top plate by pressing the ends of the plate on to the rack-mount brackets.

|

||

|

Step 3 |

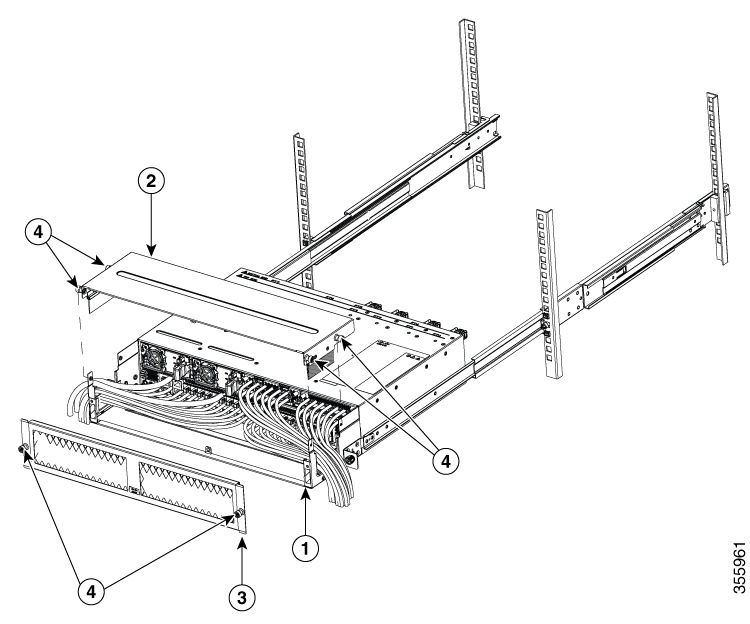

Install the two rack-mount guides on the chassis as follows:

|

||

|

Step 4 |

Install the slider rails to the rack as follows: |

||

|

Step 5 |

Insert the router into the rack and attach it as follows: |

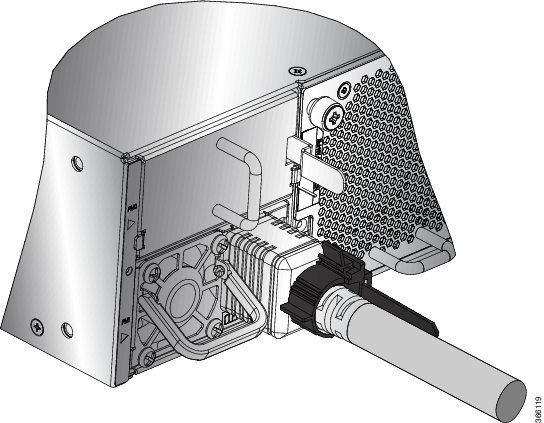

Rack Mount the Chassis in a 4-Post Rack — Procedure 2

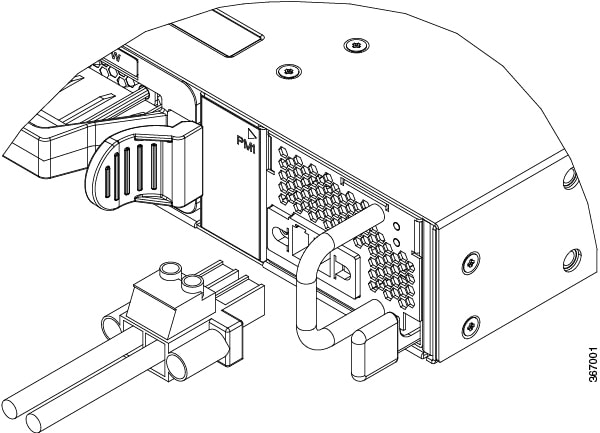

This section describes how to install the Cisco NCS-55A2-MOD-HD-S, Cisco NCS-55A2-MOD-HX-S and Cisco NC55A2-MOD-SE-H-S chassis on the 4-post rack, using sliders.

Sliders

The sliders are used to install the Cisco NCS-55A2-MOD-HX-S and Cisco NC55A2-MOD-SE-H-S chassis on a 4-post outdoor rack. Sliders are used to access the fan trays in the chassis easily during maintenance.

The sliders are designed such that the air filters (NCS-55A2-FLTR-FW) can also be accomodated in the chassis installation. There are two types of sliders:

-

NC55-2RU-ACC-SL1: Designed for custom made cabinets that are 476 mm wide (min. 650 x650 mm), or for cabinets with equivalent specifications.

Rack Requirements to Install NC55-2RU-ACC-SL1:

-

4-post rack

-

476 cm wide center to center rail mounting.

-

The width between the front rack-mounting rails must be at least 17.75 inches (45.0 cm)

-

The minimum spacing for the bend radius for fiber-optic cables should have the front-mounting rails of the cabinet offset from the front door by a minimum of 4.7 inches (12.0 cm).

-

The minimum spacing between the front-mounting rails of the cabinet to the inner surface of the front door shall be min. 5.8 inches (14.7 cm). Depend on cabinet ambient thermal set-point this distance can change.

-

The distance between the outside face of the front mounting rail and the outside face of the back-mounting rail should be 16.0 to 19.9 inches (40.7to 50.5 cm) to allow for rear-bracket installation.

-

-

NC55-2RU-ACC-SL2: Designed for 19-inch (min. 650 x650 mm) EIA cabinet standard 4-post rack.

Rack Requirements to Install NC55-2RU-ACC-SL2:

-

Standard 19-inch (48.3 cm) (four-post EIA cabinet, with mounting rails that conform to English universal hole spacing per section 1 of ANSI/EIA-310-D-1992.)

-

The width between the front rack-mounting rails must be at least 17.75 inches (45.0 cm.)

-

The minimum spacing between the front-mounting rails of the cabinet to the inner surface of the front door shall be min. 5.8 inches (14.7 cm). Depending on the cabinet ambient thermal set-point this minimum distance can change.

-

The minimum spacing for the bend radius for fiber-optic cables should have the front-mounting rails of the cabinet offset from the front door by a minimum of 4.7 inches (12.0 cm).

-

The distance between the outside face of the front mounting rail and the outside face of the back-mounting rail should be 16.5 to 19 inches (41.9 to 48.26 cm) to allow for rear-bracket installation.

-

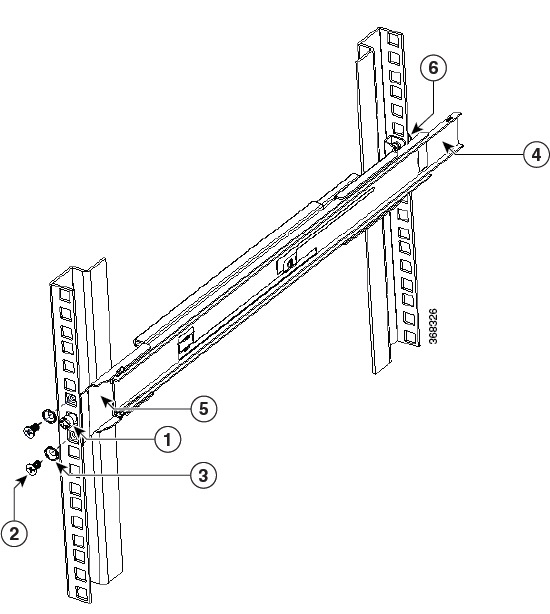

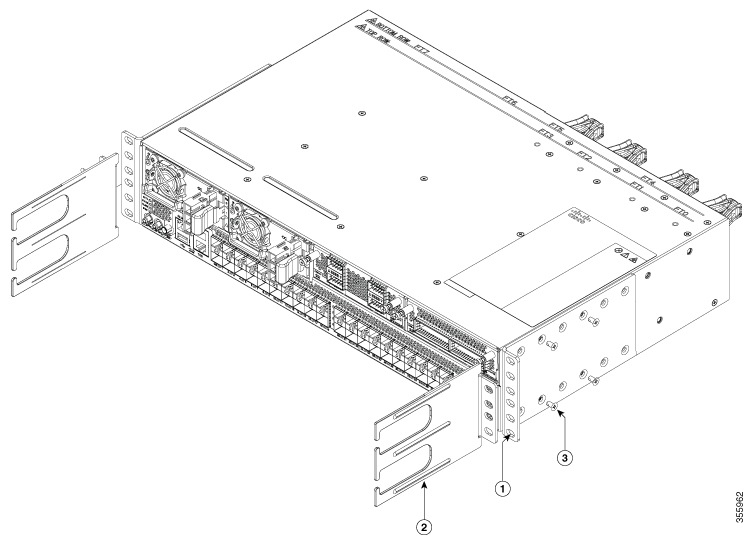

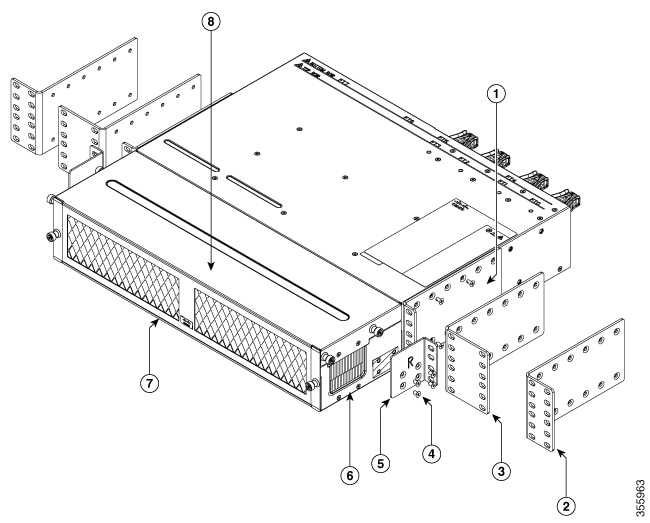

The slider assembly consists of three parts:

-

Inner Slider Member

-

Middle Slider Member

-

Outer Slider Member

Note |

The front end of the outer slider member may vary between NC55-2RU-ACC-SL1 and NC55-2RU-ACC-SL2. The outer slider member of NC55-2RU-ACC-SL2 is mounted to the front post with 2 screws, whereas, the outer slider member of NC55-2RU-ACC-SL1 is passed through the rack holes of the front post and latched to the rack. |

|

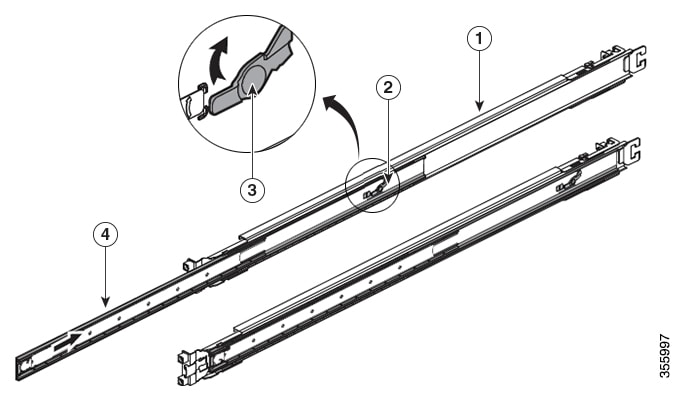

1 |

Outer Slider Member |

2 |

Middle Slider Member |

|

3 |

Unlock Feature on the Middle Slider Member |

4 |

Inner Slider Member |

|

Quantity |

Part Description |

|---|---|

|

2 |

Rack-mount brackets |

|

2 |

Rack-mount slider rails |

|

8 |

M4 x 8-mm Phillips counter sink screws |

|

2 |

M4 x 8-mm Phillips pan-head screws |

|

1 |

Grounding lug |

|

6 |

(Only NC55-2RU-ACC-SL1) M4 x 10-mm Phillips pan-head screws |

|

6 |

(Only NC55-2RU-ACC-SL2) M4 x 8-mm Phillips flat-head screws |

|

4 |

(Only NC55-2RU-ACC-SL2) washers |

|

4 |

(Only NC55-2RU-ACC-SL2) 10-32 counter sink screws |

|

4 |

(Only NC55-2RU-ACC-SL2) 9.1 mm rack mount pins |

|

4 |

(Only NC55-2RU-ACC-SL2) 8.8 mm rack mount pins |

Procedure

|

Step 1 |

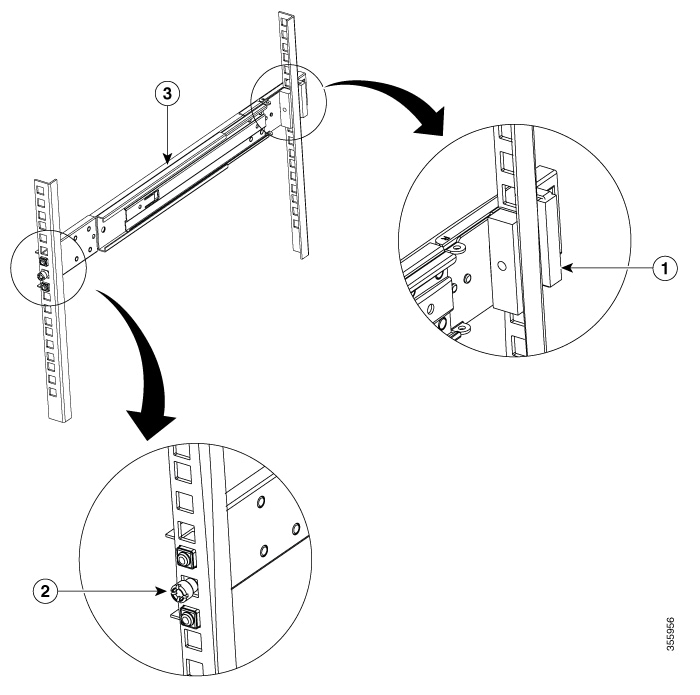

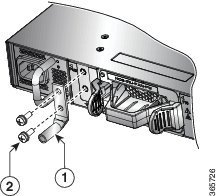

Remove the inner slider member from the slider assembly, by depressing the white tab present at the front of the slider assembly (on the outer slider member).

|

||||||||||||||||||||||||||||

|

Step 2 |

Push the unlock feature of the middle slider member and slide the middle slider member back to the slider assembly. |

||||||||||||||||||||||||||||

|

Step 3 |

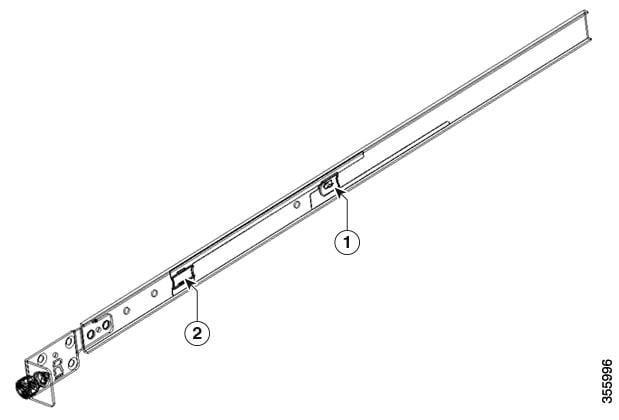

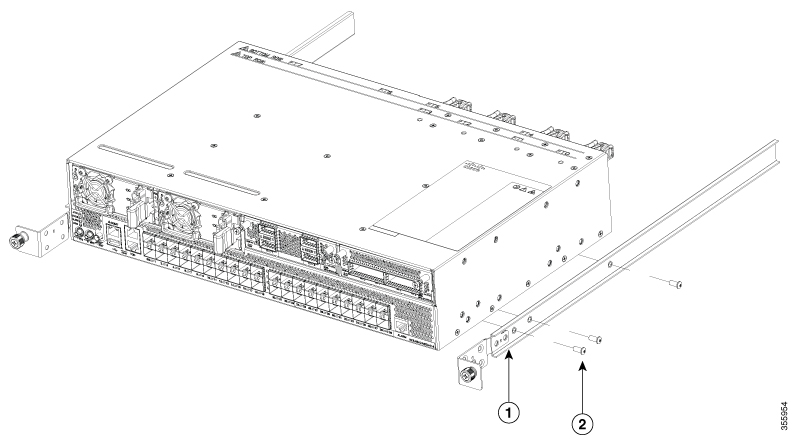

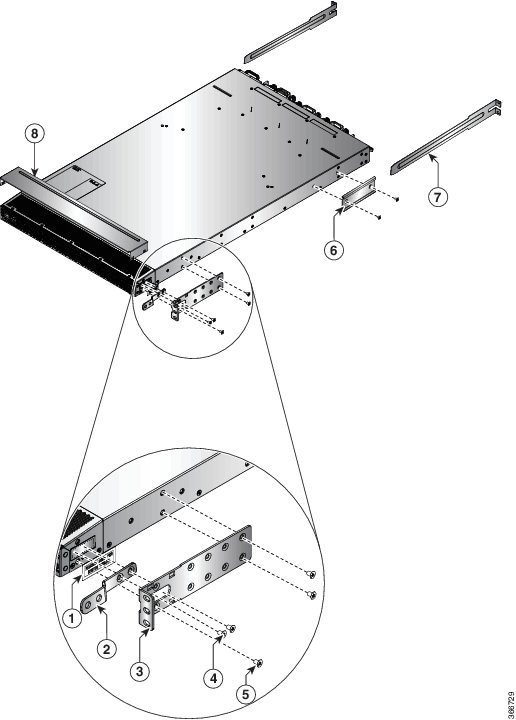

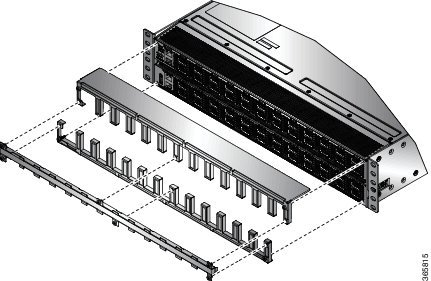

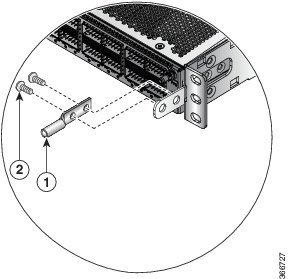

Attach the inner slider member to the sides of the chassis:

|

||||||||||||||||||||||||||||

|

Step 4 |

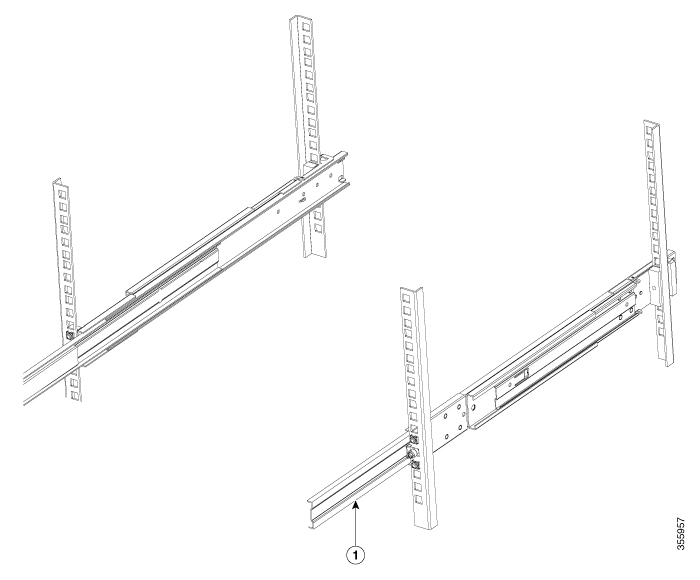

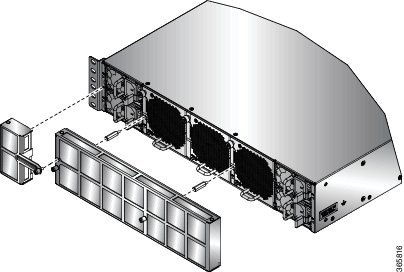

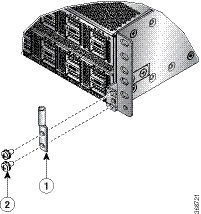

Install the outer slider member to the rack:

|

||||||||||||||||||||||||||||

|

Step 5 |

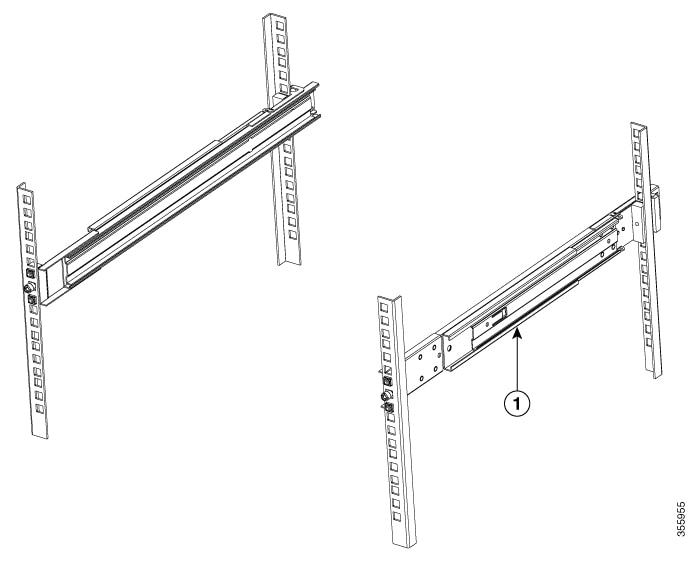

Pull the middle slider member from the slider assembly to an extended position.

|

||||||||||||||||||||||||||||

|

Step 6 |

Insert the chassis that already has the inner slider members attached, to the middle slider member on the rack. |

||||||||||||||||||||||||||||

|

Step 7 |

Slide the chassis into middle slider member until it cannot be pushed further.

|

||||||||||||||||||||||||||||

|

Step 8 |

Pull the blue release tab on the inner slider member on both sides simultaneously to release the lock position. Continue to push the chassis to the rack.  |

||||||||||||||||||||||||||||

|

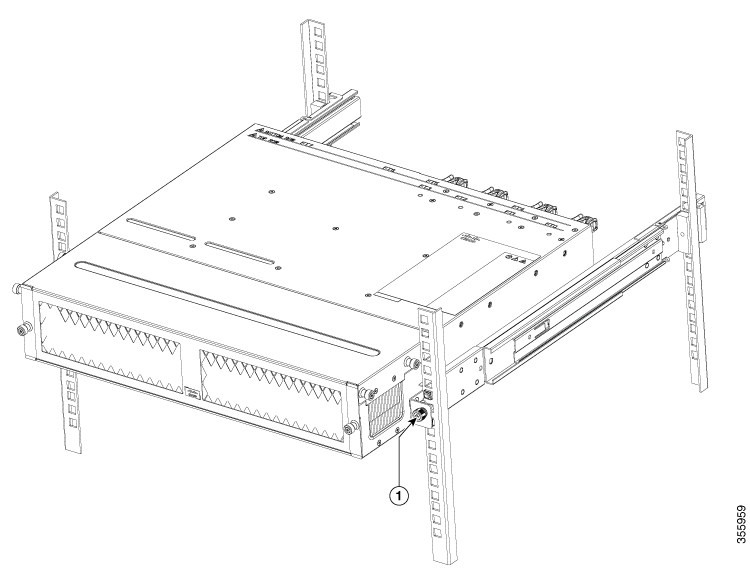

Step 9 |

Tighten the thumbscrews on either side of the chassis, that is aligned with the screw thread adapter of the outer slider member through the rack holes. |

What to do next

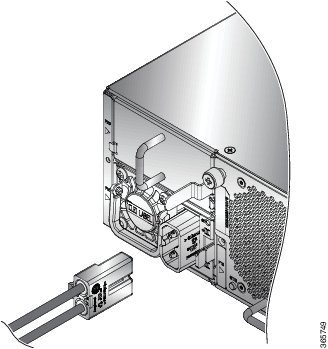

Rack-Mount the Chassis in a 2-Post Rack — Procedure 1

This section describes how to use the rack-mount kit provided with the router to install the following routers into a cabinet or 2-post rack:

-

Cisco NCS-55A1-24H

-

Cisco NCS 5501

-

Cisco NCS 5501-SE

-

Cisco NCS-55A1-24Q6H-S

-

Cisco NCS-55A1-24Q6H-SS

Caution |

If the rack is on wheels, ensure that the brakes are engaged or that the rack is otherwise stabilized. |

The following table lists the items contained in the rack-mount kit provided with the routers.

|

Quantity |

Part Description |

|---|---|

|

2 |

Rack-mount brackets |

|

8 |

M4 x 0.7 x 6-mm Phillips flat-head screws |

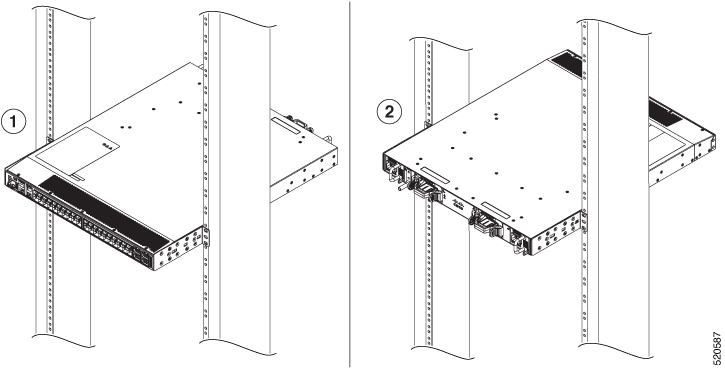

Procedure

|

Step 1 |

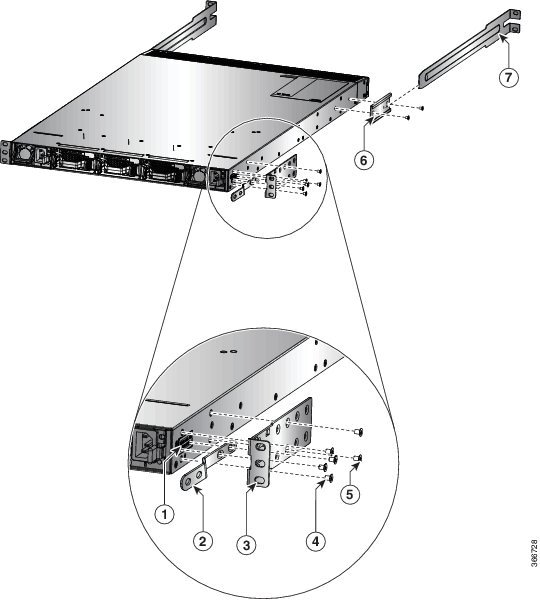

Install two rack-mount brackets to the router as follows:

|

||||

|

Step 2 |

Install the router onto the 2-post rack as follows:

|

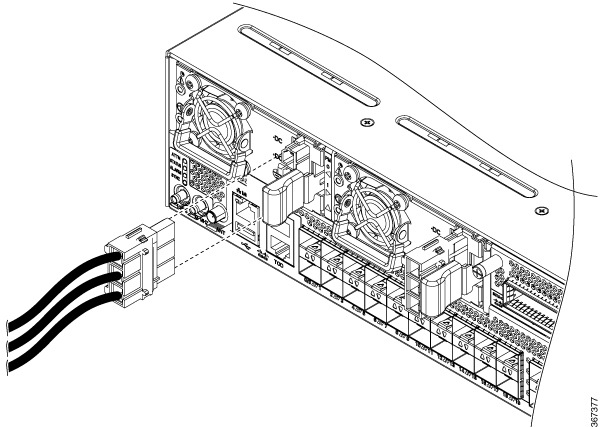

Rack Mount the Chassis in a 2 Post Rack — Procedure 2

This section describes how to use the rack-mount kit provided with the chassis, to install the following chassis into a cabinet or a 2-post rack:

-

Cisco NCS-55A2-MOD-S

-

Cisco NCS-55A2-MOD-HD-S

-

Cisco NCS-55A2-MOD-SE-S

-

Cisco NCS-55A2-MOD-HX-S

-

Cisco NC55A2-MOD-SE-H-S

Caution |

If the rack is on wheels, ensure that the brakes are engaged or that the rack is otherwise stabilized. |

The following table lists the items contained in the rack-mount kit provided with the routers.

|

Quantity |

Part Description |

|---|---|

|

2 |

Rack-mount brackets |

|

8 |

M4 x 8-mm Phillips counter sink screws |

Depending on the type of the rack, the following rack mount brackets can be used:

-

19-inch Rack: NC55A2-RCKMNT-19 brackets

-

23-inch Rack: NC55A2-RCKMNT-23 brackets

-

ETSI Rack: N55A2-RCKMNT-ETSI brackets

Note |

In addition, use the cable guide bracket (NCS-55A2-CAB-MGMT) for managing the cables in Cisco NCS 55A2-MOD-SE-S, Cisco NCS-55A2-MOD-HX-S and Cisco NC55A2-MOD-SE-H-S. The cable guide bracket is optional and is obtained in the accessory kit (NC55-2RU-ACCX-KIT). |

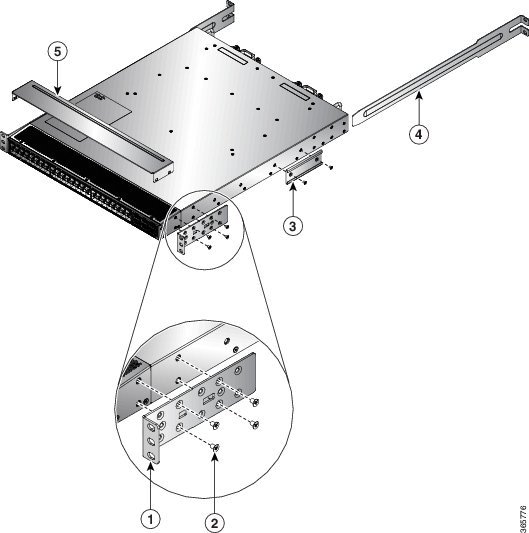

Procedure

|

Step 1 |

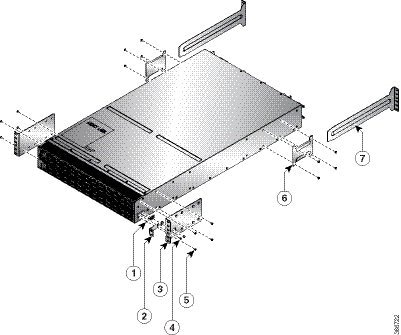

Install two rack-mount brackets to the router as follows: |

|

Step 2 |

Install the router onto the 2-post rack as follows:

|

Feedback

Feedback