- Preface

- Product Overview

- Preparing for Installation

- Installing the Switch

- Installing and Removing Power Supplies

- Installing the Modular Port Card

- Replacing the Fan Tray

- Technical Specifications

- Module Connectors and Cable Specifications

- Repacking the Switch

- Troubleshooting

- Installing the USB Drivers

- Installation Tasks

- Safety Warnings

- Rack-Mounting Guidelines

- Unpacking the Switch

- Chassis Installation Kits and Cable Guides

- Installing the Switch Chassis

- Installation Accessory Kits

- L Brackets on the Chassis

- Installing the Rack-Mount Shelf Kit

- Required Tools

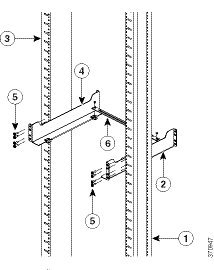

- Installing the Shelf Brackets on a rack

- Installing Shelf Brackets and Crossbar in a Four-Post Rack with 17.5-inch (44.45 cm) Opening

- Installing Shelf Brackets and Crossbar in a Four-Post Rack with 17.75 inch (45.09 cm) Opening

- Installing Shelf Brackets and Crossbar in a Two-Post Rack with 17.5-inch (44.45 cm) Opening

- Installing Shelf Brackets and Crossbar in a Two-Post Rack with 17.75 inch (45.09 cm) Opening

- Rack Mouting the Chassis

- Establishing the System Ground

- Installing the Power Supplies in the Switch Chassis

- Installing the Port Card in the Switch Chassis

- Connecting the Switch Console Port

- Connecting the Uplink Ports

- Verifying Switch Chassis Installation

- Online Diagnostics

Installing the Switch

This chapter describes how to install a Catalyst 6880-X switch. Pointers within the overall chassis installation procedures point to separate installation procedures that cover installing various components and assemblies.

- Installation Tasks

- Safety Warnings

- Rack-Mounting Guidelines

- Unpacking the Switch

- Chassis Installation Kits and Cable Guides

- Installing the Switch Chassis

Installation Tasks

The process of installing the switch can be broken down into a series of tasks, which are described in the following table.

|

Task |

Description |

||

|---|---|---|---|

|

Unpacking the switch |

Remove the switch from the packaging materials.

|

||

|

Installing the switch |

Install the switch. |

||

|

Connecting the chassis to system ground |

Construct and attach a system ground wire from the building (earth) ground to the system ground point on the chassis. |

||

|

Installing and cabling the power supply or supplies |

Power supplies that are ordered with the switch are installed in the switch. If ordered separately, install the power supplies. Connect the power supplies. |

||

|

Cabling the chassis and modules to the network |

The various ports on the chassis must be connected to the network. This process can involve only attaching a network interface cable to the port or it can include the installation of a transceiver of some type in port and then attaching the network interface cable to the transceiver. |

||

|

Powering up the chassis |

After completing the network cabling and making sure that system ground is connected, the power supplies can be turned on. The system powers up and runs through a set of built-in diagnostics. |

Safety Warnings

Warning | Class 1 laser product. Statement 1008 |

Warning | This unit is intended for installation in restricted access areas. A restricted access area can be accessed only through the use of a special tool, lock and key, or other means of security. Statement 1017 |

Warning | This unit might have more than one power supply connection. All connections must be removed to de-energize the unit. Statement 1028 |

Warning | Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030 |

Warning | To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the handles on modules (such as power supplies, fans, or cards); these types of handles are not designed to support the weight of the unit. Statement 1032 |

Warning | Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034 |

Warning | This product requires short-circuit (overcurrent) protection, to be provided as part of the building installation. Install only in accordance with national and local wiring regulations. Statement 1045 |

Warning | When installing or replacing the unit, the ground connection must always be made first and disconnected last. Statement 1046 |

Warning | Installation of the equipment must comply with local and national electrical codes.. Statement 1074 |

Warning | Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051 |

Before starting the installation procedures in this chapter, see the “Site Preparation Checklist” section on page 2-15 to verify that all site planning activities were completed.

Rack-Mounting Guidelines

Note | The switch is designed to be installed in standard 19-inch racks. |

Before rack-mounting the switch, ensure that the equipment rack complies with the following guidelines:

-

The width of the rack, measured between the two front-mounting strips or rails, must be one of the following measurements:

-

The depth of the rack, measured between the front- and rear-mounting strips, must be at least 19.25 inches (48.9 cm).

-

The rack must have sufficient vertical clearance to insert the chassis: 8.75 inches (22.23 cm) (5 RU)

Note | Chassis height is sometimes measured in rack units (RU or just U) where 1 RU or 1 U equals 1.75 in (44.45 mm). A typical server rack is 42 RU or 42 U in height. |

Caution | If the rack is on wheels, ensure that the brakes are engaged and that the rack is stabilized. |

Warning | Stability hazard. The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor before you slide the unit out for servicing. Failure to stabilize the rack can cause the rack to tip over. Statement 1048 |

Note | To maintain proper air circulation through the Catalyst switch chassis, you should maintain a recommended separation of a minimum of 6 inches (15 cm) between a wall and the chassis air intake or a wall and the chassis air exhaust. You should also allow a minimum separation of 12 inches (30.5 cm) between the hot air exhaust on one chassis and the air intake on another chassis. Failure to maintain adequate air space can cause the chassis to overheat and the system to fail. |

Unpacking the Switch

Note | Do not discard the shipping container when you unpack the switch. Flatten the shipping cartons and store them with the pallet. You will need these containers if you need to move or ship the switch in the future. |

Check the contents of the accessory kit. Verify that you received all listed equipment, which should include the following:

- Grounding lug and disposable ESD strap.

-

Optional equipment that you ordered, such as console cables, transceivers, or special connectors.

-

Blank covers are installed for the port card slots and power supply slots on the chassis.

-

Rack-mount shelf kit is provided that includes brackets and a tray to support the chassis when it is installed on a rack.

Chassis Installation Kits and Cable Guides

The chassis ships with an accessory kit, which includes chassis installation kits and cable guides:

Installing the Switch Chassis

Installation Accessory Kits

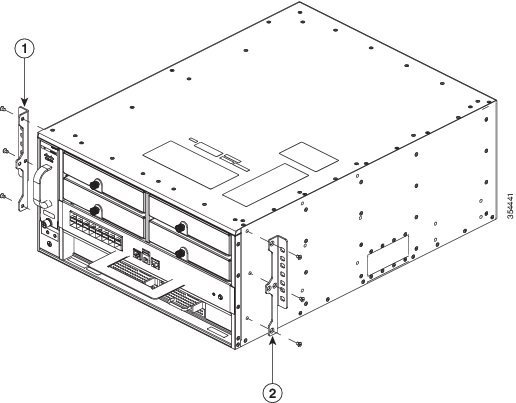

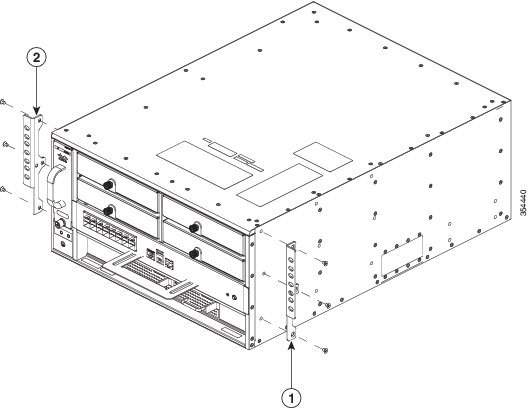

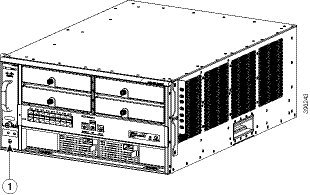

The switch chassis is designed to be installed in a standard 19-inch rack, either open or enclosed. The chassis is shipped with the 19-inch rack-mount L brackets that are factory installed on the left-front and right-front of the chassis. Screws are included with the accessory kit that are used to secure the chassis in the rack enclosure.

Note | Depending on the manufacturer, the rack posts might be prethreaded to accept either 10-32 or 12-24 screws. If the rack posts are not prethreaded, you must install 10-32 or 12-24 clip nuts or cage nuts to secure the rack-mount screws. The clip nuts or the cage nuts are not included as part of the accessory kit and must be obtained on your own. |

The accessory kit also contains the following chassis installation kits:

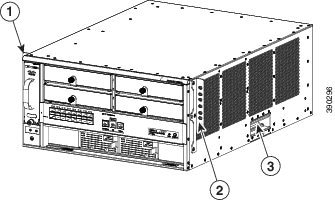

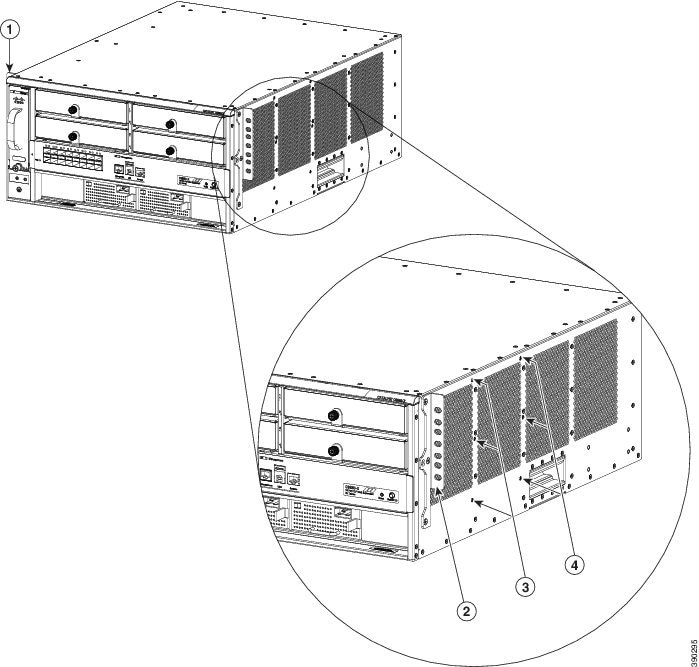

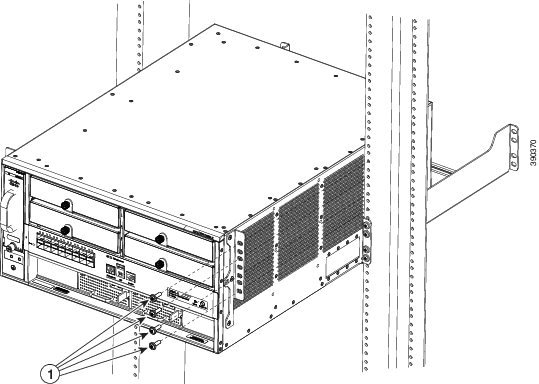

L Brackets on the Chassis

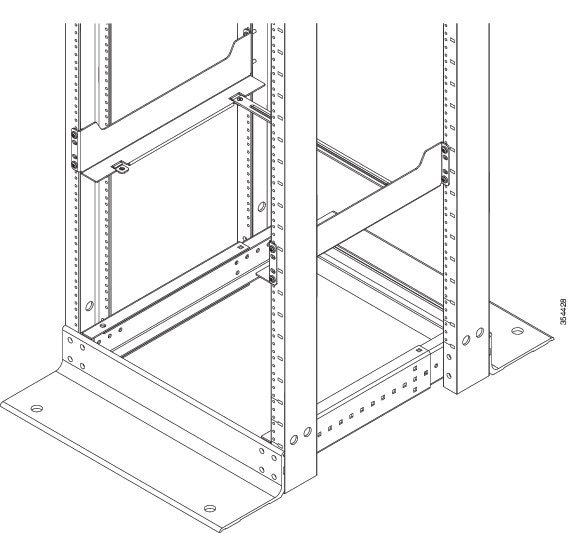

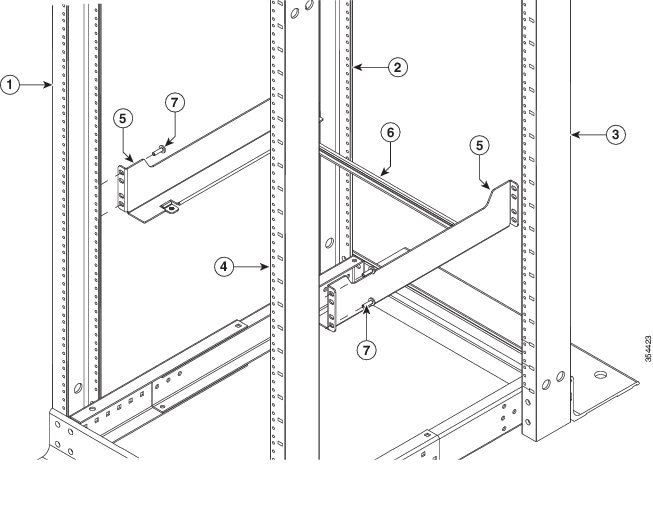

The switch chassis is shipped with two L brackets installed toward the front of each side of the chassis, as shown in the following figure.

|

1 |

Left L bracket |

3 |

Handhold (one on each side of chassis) |

|

2 |

Right L bracket |

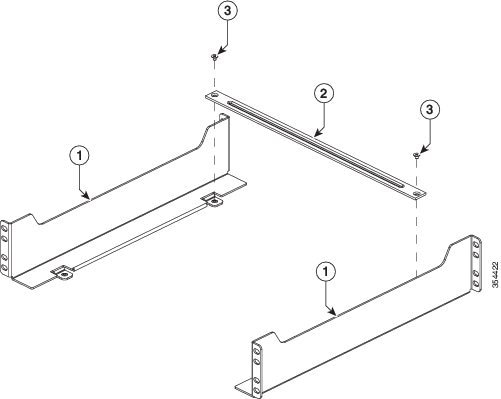

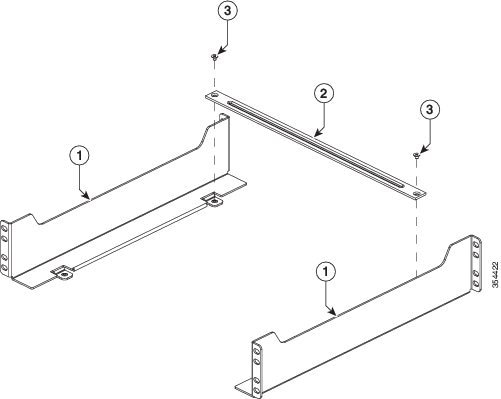

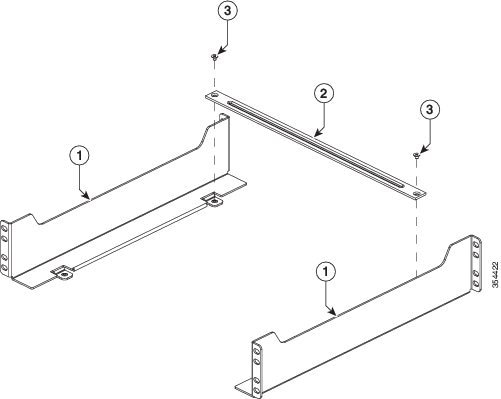

Installing the Rack-Mount Shelf Kit

Before installing the chassis, you should install the rack-mount shelf kit that is included as part of the accessory kit. The rack-mount shelf kit is shipped as part of the switch accessory kit. It contains two shelf brackets, a crossbar, and screws. The shelf brackets attach directly to the rack and help support the weight of the chassis.

Required Tools

These tools and equipment are required to install the rack-mount shelf kit:

Installing the Shelf Brackets on a rack

Note | On many older equipment racks, the rack posts are prethreaded to accept either 10-32 or 12-24 screws. Newer rack enclosure posts might not be prethreaded. These rack enclosure posts require that you install 10-32 or 12-24 clip nuts or cage nuts to secure the rack-mount screws. The clip nuts or the cage nuts are not included as part of the accessory kit and must be obtained on your own. |

Before you install the Shelf brackets, determine the clearance between the insides of the left and right rails of your rack system:

- Installing Shelf Brackets and Crossbar in a Four-Post Rack with 17.5-inch (44.45 cm) Opening

- Installing Shelf Brackets and Crossbar in a Four-Post Rack with 17.75 inch (45.09 cm) Opening

- Installing Shelf Brackets and Crossbar in a Two-Post Rack with 17.5-inch (44.45 cm) Opening

- Installing Shelf Brackets and Crossbar in a Two-Post Rack with 17.75 inch (45.09 cm) Opening

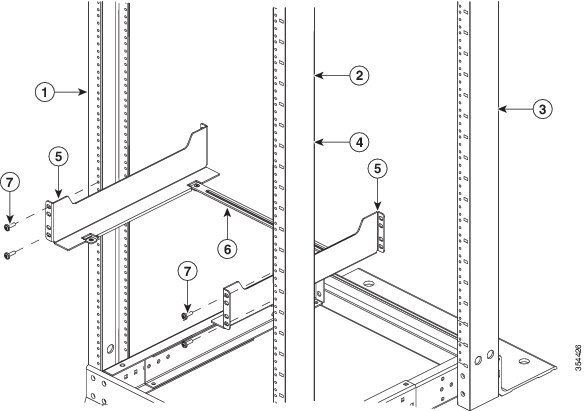

Installing Shelf Brackets and Crossbar in a Four-Post Rack with 17.5-inch (44.45 cm) Opening

You have to rear-mount the shelf brackets and the crossbar in a rack with a 17.5-inch rail-to-rail opening.

Perform these steps:

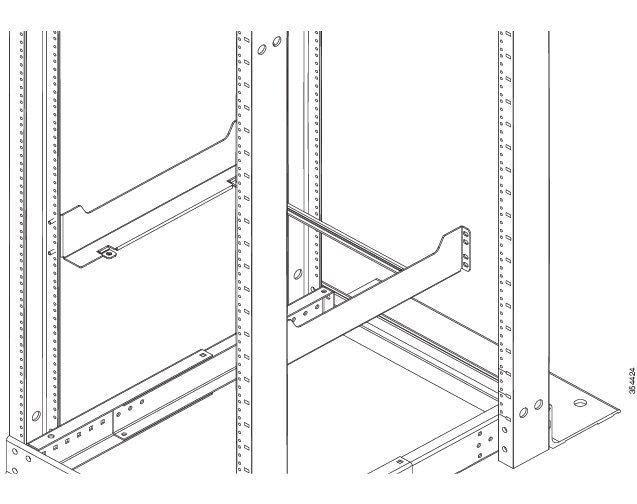

Installing Shelf Brackets and Crossbar in a Four-Post Rack with 17.75 inch (45.09 cm) Opening

You have to front-mount the shelf brackets and crossbar on a rack with a 17.75-inch rail-to-rail opening.

Perform these steps:

| Step 1 | Secure the

crossbar to the shelf brackets by using two M4 screws, with one screw on each

side.

| ||||||||||||||||||

| Step 2 | Position the

rear side of the support flanges of the shelf brackets on the front side of the

fixed front-left and front-right posts of the rack. Align and secure the

bracket to the rack by using the four EA screws (Two EA screws on each side).

| ||||||||||||||||||

| Step 3 | Adjust the

adjustable rear-left and rear-right rack posts until it touches the shelf

brackets flange surface and secure by using four EA screws, with two EA screws

on each side.

|

Installing Shelf Brackets and Crossbar in a Two-Post Rack with 17.5-inch (44.45 cm) Opening

You have to rear-mount the shelf brackets and the crossbar for a rack with a 17.5-inch rail-to-rail opening.

Perform these steps:

| Step 1 | Secure the

crossbar to the shelf brackets by using two M4 screws, with one screw on each

side.

| ||||||||||||||

| Step 2 | Position the

front side of the support flanges of the shelf brackets on the rear side of the

left and the right posts of the rack. Align and secure the bracket to the rack

by using the eight EA screws (four EA screws on each side).

|

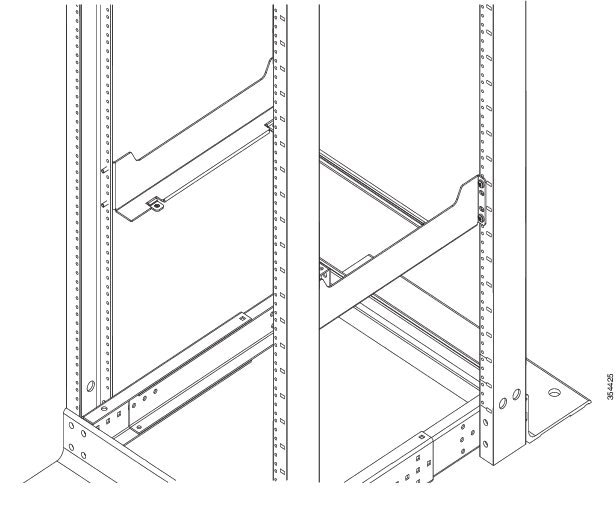

Installing Shelf Brackets and Crossbar in a Two-Post Rack with 17.75 inch (45.09 cm) Opening

You have to front-mount the shelf brackets and crossbar in a rack with a 17.75-inch rail-to-rail opening.

Perform these steps:

| Step 1 | Secure the

crossbar to the shelf brackets by using two M4 screws, with one screw on each

side.

| ||||||||||||

| Step 2 | Position the

rear side of the support flanges of the shelf brackets on the front side of the

left and the right posts of the rack. Align and secure the bracket to the rack

by using the four EA screws (two EA screws on each side).

|

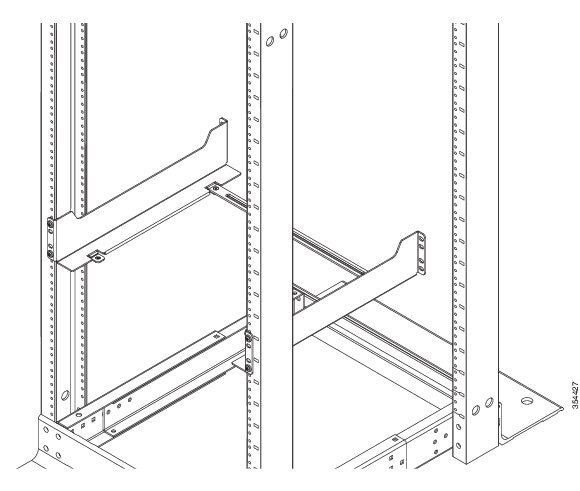

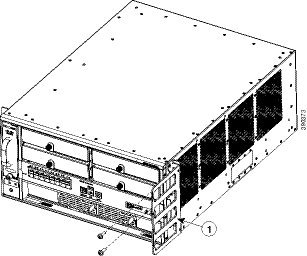

Rack Mouting the Chassis

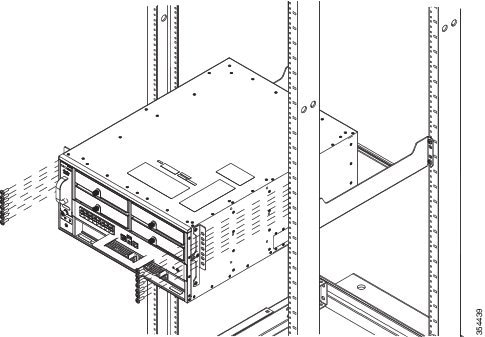

Installing the Chassis in a Four-Post Rack

Note | The chassis are designed to be mounted in equipment racks that meet ANSI/EIA 310-D and ETS 300-119 standards. |

| Step 1 | Based on the

type of rack (closed (cabinet) rack or open rack), you can install the left and

the right L brackets of the chassis in one of the following ways:

| ||||||||||

| Step 2 | With a person standing at each side of the chassis, each person supports the chassis by placing one hand in the handhold on the side of the chassis (see figure above) and using the other hand under the back of the chassis for balance. Slowly lift the chassis together. Avoid sudden twists or moves to prevent injury. | ||||||||||

| Step 3 | Rest the back end of the chassis on the rack-mount shelf and carefully slide the chassis into the rack until the L brackets meet the front rails of the rack system. | ||||||||||

| Step 4 | Locate the rack

post holes that align with the chassis L bracket holes. If the rack post holes

are prethreaded, determine if the threads are 10-32 or 12-24. If the rack post

holes are unthreaded, install fourteen (seven on each side) either 10-32 or

12-24 clip or cage nuts over the rack post holes to accept the installation

screws.

| ||||||||||

| Step 5 | If you want to

install one or both of the optional cable guide assemblies, position the cable

guides so that the cable guide mounting holes are aligned with L bracket holes

as shown in figure below.

| ||||||||||

| Step 6 | Install all fourteen 10-32 or 12-24 screws (seven on each side) through the cable guide mounting holes, rack-mount L bracket holes, rack post holes, and into the clip nuts to secure the cable guides and the chassis to the rack post. Tighten the screws securely. | ||||||||||

| Step 7 | Secure the

chassis using fourteen screws through the holes in the L bracket and into the

rack post holes.

|

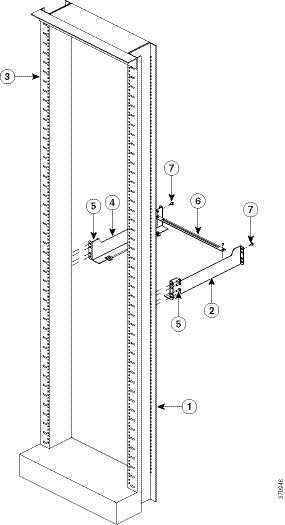

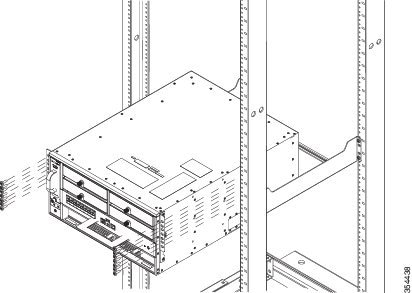

Installing the Chassis in a Two-Post Rack

Note | The chassis are designed to be mounted in equipment racks that meet ANSI/EIA 310-D and ETS 300-119 standards. |

| Step 1 | Before

rack-mounting the chassis, determine if you need to move the L brackets so that

the chassis is installed in one of the recommended positions:

| ||||||||

| Step 2 | With a person standing at each side of the chassis, each person supports the chassis by placing one hand in the handhold on the side of the chassis (see figure above) and using the other hand under the back of the chassis for balance. Slowly lift the chassis together. Avoid sudden twists or moves to prevent injury. | ||||||||

| Step 3 | Rest the back end of the chassis on the rack-mount shelf and carefully slide the chassis into the rack until the L brackets meet the front rails of the rack system. | ||||||||

| Step 4 | Locate the rack

post holes that align with the chassis L bracket holes. If the rack post holes

are prethreaded, determine if the threads are 10-32 or 12-24. If the rack post

holes are unthreaded, install eight or ten (four or five on each side) either

10-32 or 12-24 clip or cage nuts over the rack post holes to accept the

installation screws.

| ||||||||

| Step 5 | If you want to

install one or both of the optional cable guide assemblies, position the cable

guides so that the cable guide mounting holes are aligned with L bracket holes

as shown in figure below.

| ||||||||

| Step 6 | Install all eight 10-32 or 12-24 screws (four on each side) through the cable guide mounting holes, rack-mount L bracket holes, rack post holes, and into the clip nuts to secure the cable guides and the chassis to the rack post. Tighten the screws securely. | ||||||||

| Step 7 | Secure the

chassis using four screws through the holes in the L bracket and into the rack

post holes.

|

What to Do Next

After installing the chassis in its location, complete the installation process by following these procedures:

-

Connecting the chassis to system ground. See Establishing the System Ground.

-

Installing and connecting the power supplies to source power. For information on how to install and cable power supplies, see the Installing Power Supplies.

-

Connecting to the switch console port. See Connecting the Switch Console Port.

-

Connecting to the uplink ports. Installing SFP and SFP+ Transceiver Modules

-

Powering-up the chassis and verifying the installation. See Verifying Switch Chassis Installation.

Establishing the System Ground

This section describes how to connect a system ground to the switch.

Caution | Installations that rely solely on system grounding using only an AC third-prong ground run a substantially greater risk of equipment problems and data corruption than those installations that use both the AC third-prong ground and a properly installed system ground. |

The system ground provides additional grounding for EMI shielding requirements and grounding for the low voltage supplies (DC-DC converters) on the modules. You must observe the following system grounding guidelines for your chassis:

-

You must install the system ground connection with any other rack or system power ground connections that you make. The system ground connection is required if FXS modules are installed or if this equipment is installed in a U.S. or European Central Office.

-

You must connect both the system ground connection and the power supply ground connection to an earth ground. The system ground connection is required if FXS modules are installed or if this equipment is installed in a U.S. or European Central Office.

-

When using DC-input power supplies, you must install the system (ground before you attach the source DC power cables to the DC PEM. Power down the chassis before attaching the system ground.

Note | In all situations, grounding practices must comply with Section 250 of the National Electric Code (NEC) requirements or local laws and regulations. A 6 AWG grounding wire is preferred from the chassis to the rack ground or directly to the common bonding network (CBN). The equipment rack should also be connected to the CBN with 6 AWG grounding wire. |

Note | The system ground serves as the primary safety ground for chassis that are equipped with DC-input power supplies. The DC-input power supplies for these chassis do not have a separate ground. |

Required Tools and Equipment

To connect the system ground, you need the following tools and materials:

-

Grounding lug—A two-hole standard barrel lug. Supports up to 6 AWG wire. Supplied as part of accessory kit.

-

Grounding screws—Two M4 x 8 mm (metric) pan-head screws. Supplied as part of the accessory kit.

-

Grounding wire—Not supplied as part of accessory kit. The grounding wire should be sized according to local and national installation requirements. Depending on the power supply and system, a 12 AWG to 6 AWG copper conductor is required for U.S. installations. Commercially available 6 AWG wire is recommended. The length of the grounding wire depends on the proximity of the switch to proper grounding facilities.

-

No. 1 Phillips screwdriver.

-

Crimping tool to crimp the grounding wire to the grounding lug.

-

Wire-stripping tool to remove the insulation from the grounding wire.

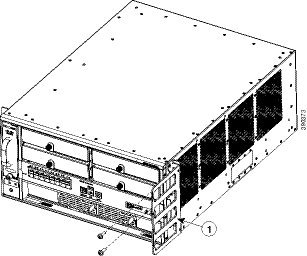

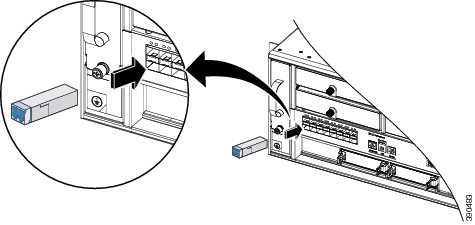

Connecting the System Ground

To establish an earth ground for the chassis, you must attach a grounding cable from the chassis’ grounding lug to the rack.

Review the following illustration and table.

|

1 |

Location of system ground lug |

| Step 1 | Use a wire-stripping tool to remove approximately 0.75 inch (19 mm) of the covering from the end of the grounding wire. |

| Step 2 | Insert the stripped end of the grounding wire into the open end of the grounding lug. |

| Step 3 | Crimp the grounding wire in the barrel of the grounding lug. Verify that the ground wire is securely attached to the ground lug. |

| Step 4 | Place the grounding wire lug against the grounding pad, making sure that there is solid metal-to-metal contact. |

| Step 5 | Secure the grounding lug to the chassis with two M4 screws. Ensure that the grounding lug and the grounding wire will not interfere with other switch hardware or rack equipment. |

| Step 6 | Prepare the other end of the grounding wire with a ring lug, and secure it to the rack with a screw. |

Installing the Power Supplies in the Switch Chassis

The chassis power supplies (AC or DC) might be shipped separately from the switch chassis. Remove the power supply from its shipping packaging, and then install and connect it to the site power by referring to Installing Power Supplies.

Note | AC-input and DC-input power supplies can be mixed in a chassis. |

Installing the Port Card in the Switch Chassis

The modular port card is optional and might be shipped separately from the switch chassis. Remove the port card from its shipping packaging, and then install it, see the Installing a Modular Port Card section.

Connecting the Switch Console Port

This section describes how to connect to the supervisor engine console port from a terminal or modem. The console port on the supervisor engine allows you to perform the following functions:

- Configure the switch from the CLI.

- Monitor network statistics and errors.

- Configure SNMP agent parameters.

- Download software updates to the switch, or distribute software images residing in flash memory to attached devices.

The console port is located on the front panel of the chassis.

The accessory kit that shipped with your switch might contain the necessary cable and adapters (depending on if you ordered them) to connect a terminal or modem to the console port. To connect a terminal to the console port using the cable and adapters provided, follow these steps:

| Step 1 |

Connect to the port using the RJ-45-to-RJ-45 cable and RJ-45-to-DB-25 DTE adapter or RJ-45-to-DB-9 DTE adapter (labeled "Terminal"). |

| Step 2 |

Position the cable in the cable guide (if installed). Make sure there are no sharp bends in the cable. |

| Step 3 |

Check the terminal documentation to determine the baud rate. The baud rate of the terminal must match the default baud rate (9600 baud) of the console port. Set up the terminal as follows: |

Connecting the Uplink Ports

SFP and SFP+ Transceiver Modules

The SFP and SFP+ transceiver modules provide copper or fiber-optic connections to other devices. These transceiver modules are field-replaceable and provide the uplink interfaces when installed in an SFP module slot. The SFP modules have LC connectors for fiber-optic connections or RJ-45 connectors for copper connections.

For Cisco SFP and SFP+ transceiver modules documentation, including compatibility matrixes, refer to this URL: http://www.cisco.com/en/US/products/hw/modules/ps5455/products_device_support_tables_list.html

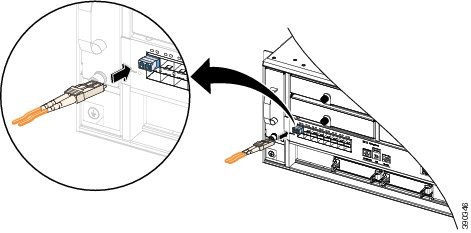

Installing SFP and SFP+ Transceiver Modules

For cable specifications, see Appendix B, “Connector and Cable Specifications.”

Observe these precautions:

Warning | Class 1 laser product. Statement 1008 |

-

Do not remove the dust plugs from the SFP transceiver modules or the rubber caps from the fiber-optic cable until you are ready to connect the cable. The plugs and caps protect the module ports and cables from contamination and ambient light.

-

Removing and installing an SFP transceiver module can shorten its useful life. Do not remove and insert any SFP transceiver module more often than is necessary.

-

To prevent ESD damage, follow your normal board and component handling procedures when connecting cables to the switch and other devices.

Note | For installing SFP or SFP+ modules from the modular port card, see the Installing SFP and SFP+ Transceiver Modules in the Port Card section. |

| Step 1 | Attach an ESD-preventive wrist strap to your wrist and to an earth ground surface. | ||

| Step 2 | Find the send (Tx) and receive

(Rx) markings that identify the top of the SFP module.

On some SFP transceiver modules, the send and receive (Tx and Rx) markings might be shown by arrows that show the direction of the connection. | ||

| Step 3 | If the SFP transceiver module has a bale-clasp latch, move it to the open, unlocked position. | ||

| Step 4 | Align the module in front of

the slot opening, and push until you feel the connector snap into place.

| ||

| Step 5 | If the module has a bale-clasp

latch, close it to lock the SFP transceiver module in place.

| ||

| Step 6 | Remove the SFP dust plugs and save. | ||

| Step 7 | Connect the SFP cables.

|

Removing SFP or SFP+ Transceiver Modules

Note | For removing SFP or SFP+ modules from the modular port card, see the Removing SFP or SFP+ Modules from the Modular Port Card section. |

| Step 1 | Attach an ESD-preventive wrist strap to your wrist and to an earth ground surface. |

| Step 2 | Disconnect the cable from the SFP transceiver module. For reattachment, note which cable connector plug is send (Tx) and which is receive (Rx). |

| Step 3 | Insert a dust plug into the optical ports of the SFP transceiver module to keep the optical interfaces clean. |

| Step 4 | If the module has a bale-clasp latch, pull the bale out and down to eject the module. If you cannot use your finger to open the latch, use a small, flat-blade screwdriver or other long, narrow instrument to open it. |

| Step 5 | Grasp the SFP transceiver module, and carefully remove it from the slot. |

| Step 6 | Place the SFP transceiver module in an antistatic bag or other protective environment. |

Verifying Switch Chassis Installation

| Step 1 |

Verify that all empty module slots have blank faceplates installed and that the screws holding the plates in place are tight. The blank faceplates optimize the air flow through the chassis and contain electromagnetic interference.

| ||

| Step 2 | Ensure that the unused power supply unit has a metal cover plate installed. | ||

| Step 3 |

Turn on the power supply switches to power up the system. During the power-up sequence, the system performs a series of bootup diagnostic tests. Additional system diagnostic tests are available. These tests allow you to perform a complete sanity check on the system prior to inserting the system into your network and to monitor the health of the system while the system is running. Refer to the “Online Diagnostics” section on page 3-19 for further information.

|

Online Diagnostics

The switch running Cisco IOS has many levels of online diagnostic capabilities. The online diagnostics are divided into four categories:

-

Bootup—Bootup diagnostics automatically run during bootup, module OIR, or switchover to a backup supervisor engine.

-

Background health—Monitoring diagnostic tests are continuously run by the system to monitor system health.

-

On-demand online diagnostics—On-demand online diagnostics can be used to run any test from the CLI. You can also run on-demand online diagnostics to perform a sanity check on the system hardware. Some of these tests are disruptive and will impact traffic flow.You must follow the on-demand diagnostic guidelines exactly to avoid false failures.

-

Scheduled diagnostics—Scheduled diagnostics can be used to run any of the above tests at user-designated intervals.

For complete information on the online diagnostic tests and how to run them, refer to the software configuration guide.

Feedback

Feedback