Status LEDs and Buttons

This section contains information for interpreting LED states.

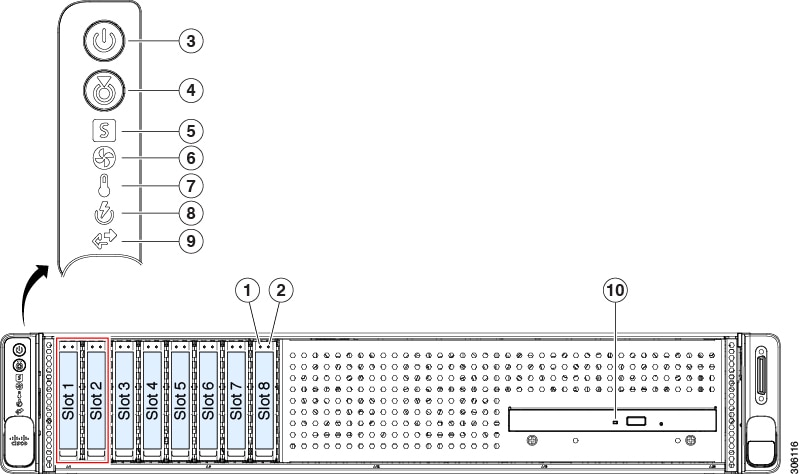

Front-Panel LEDs

|

LED Name |

States |

|||

|

1 SAS |

SAS/SATA drive fault

|

|

||

|

2 SAS |

SAS/SATA drive activity LED |

|

||

|

1 NVMe |

NVMe SSD drive fault

|

|

||

|

2 NVMe |

NVMe SSD activity |

|

||

|

3 |

Power button/LED |

|

||

|

4 |

Unit identification |

|

||

|

5 |

System health |

|

||

|

6 |

Fan status |

|

||

|

7 |

Temperature status |

|

||

|

8 |

Power supply status |

|

||

|

9 |

Network link activity |

|

||

|

10 |

DVD drive activity |

|

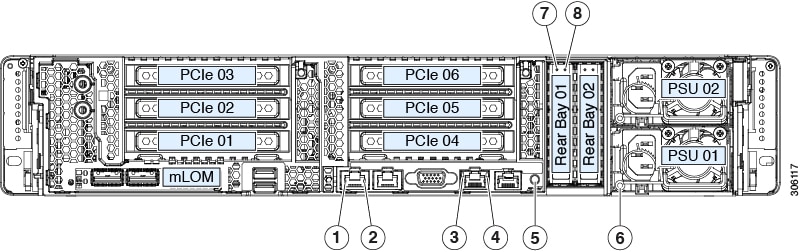

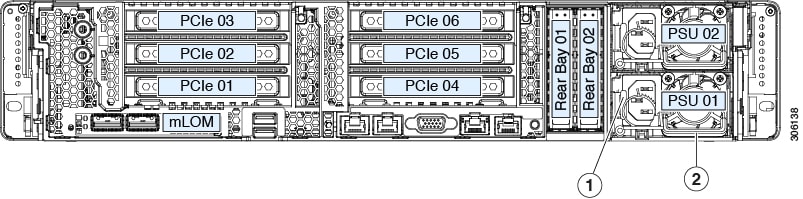

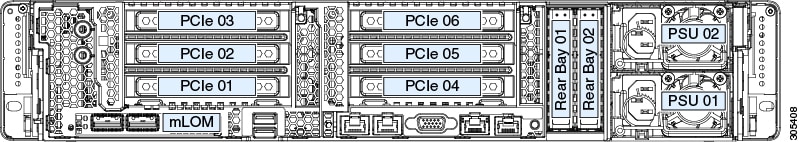

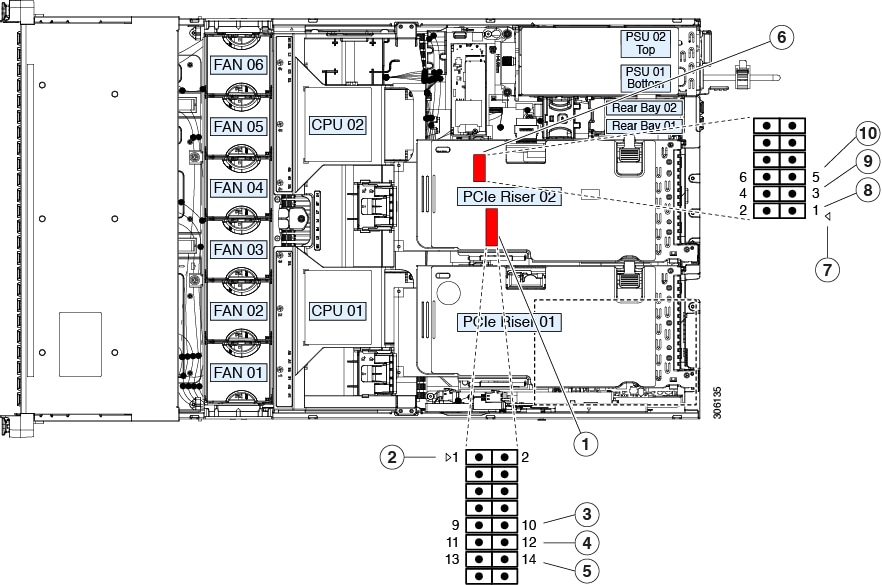

Rear-Panel LEDs

|

LED Name |

States |

|||

|

1 |

1-Gb/10-Gb Ethernet link speed (on both LAN1 and LAN2) |

|

||

|

2 |

1-Gb/10-Gb Ethernet link status (on both LAN1 and LAN2) |

|

||

|

3 |

1-Gb Ethernet dedicated management link speed |

|

||

|

4 |

1-Gb Ethernet dedicated management link status |

|

||

|

5 |

Rear unit identification |

|

||

|

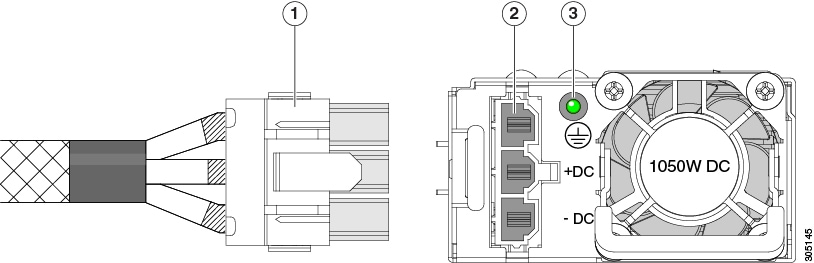

6 |

Power supply status (one LED each power supply unit) |

AC power supplies:

DC power supply (UCSC-PSUV2-1050DC):

|

||

|

7 SAS |

SAS/SATA drive fault

|

|

||

|

8 SAS |

SAS/SATA drive activity LED |

|

||

|

7 NVMe |

NVMe SSD drive fault

|

|

||

|

8 NVMe |

NVMe SSD activity |

|

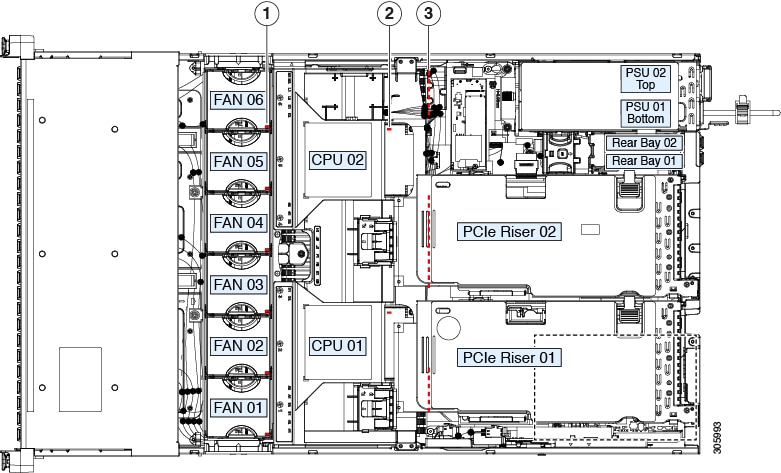

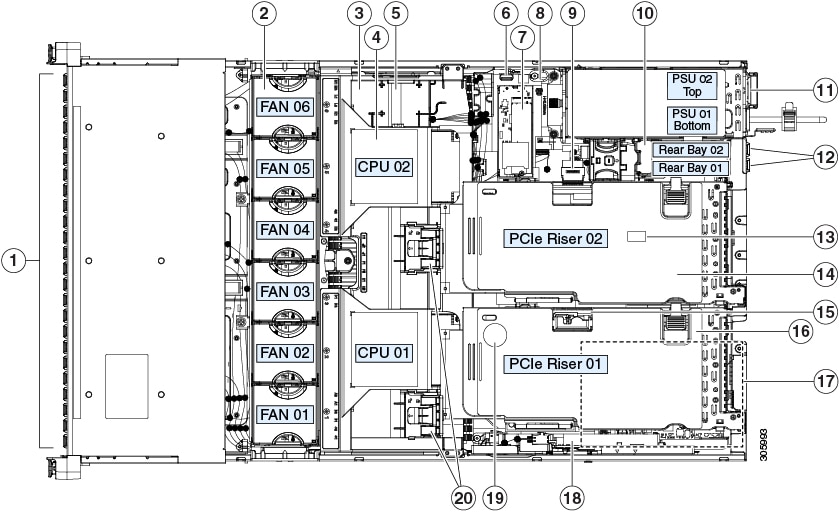

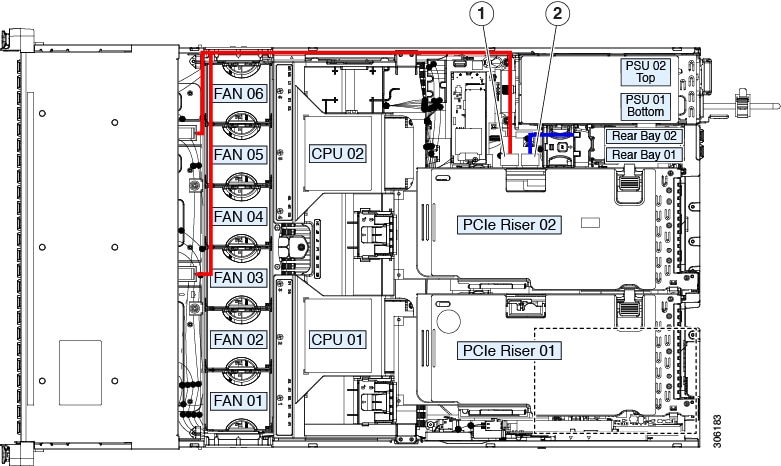

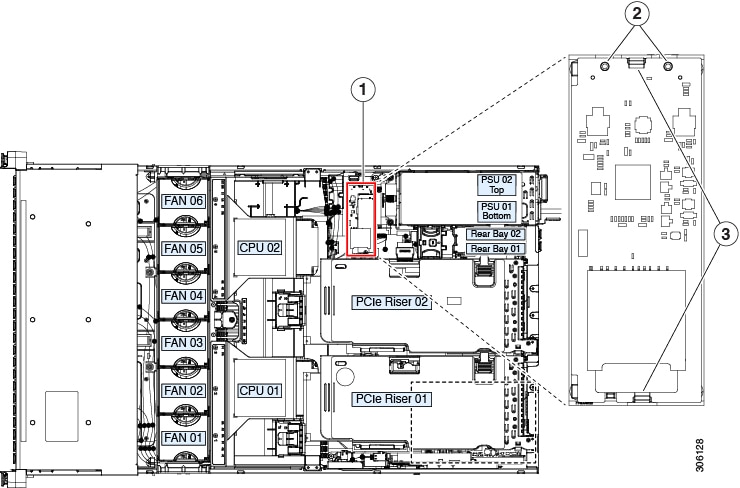

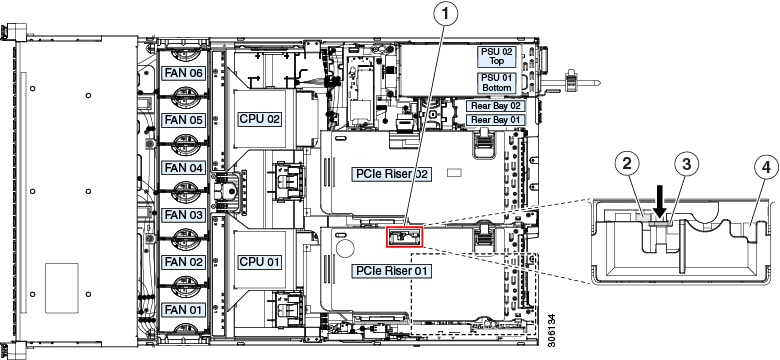

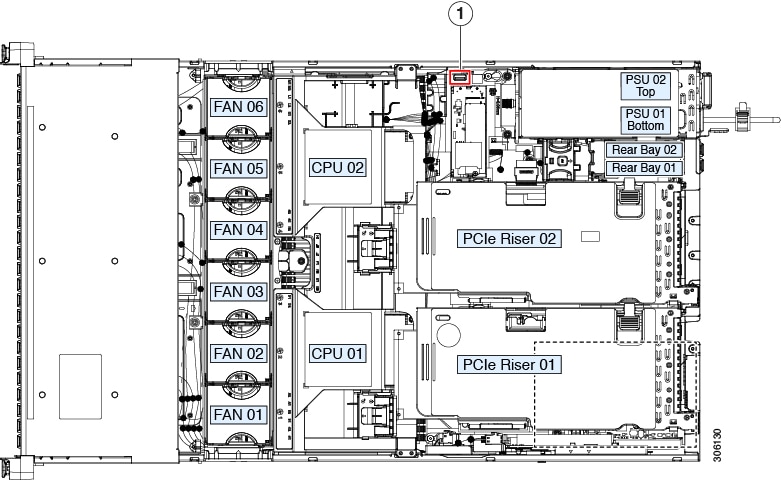

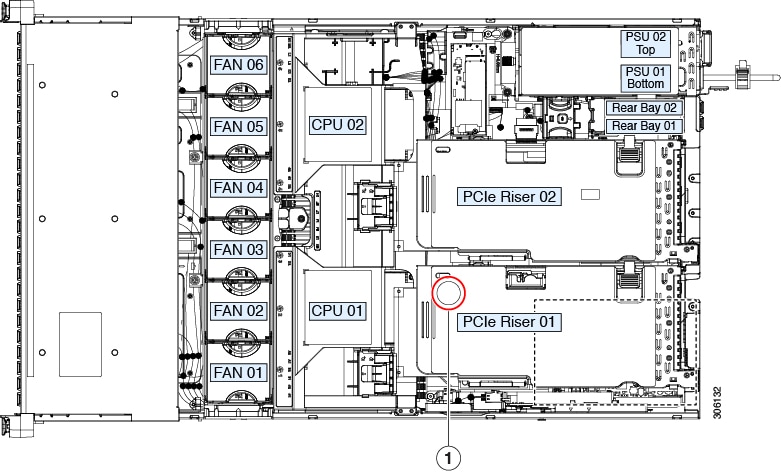

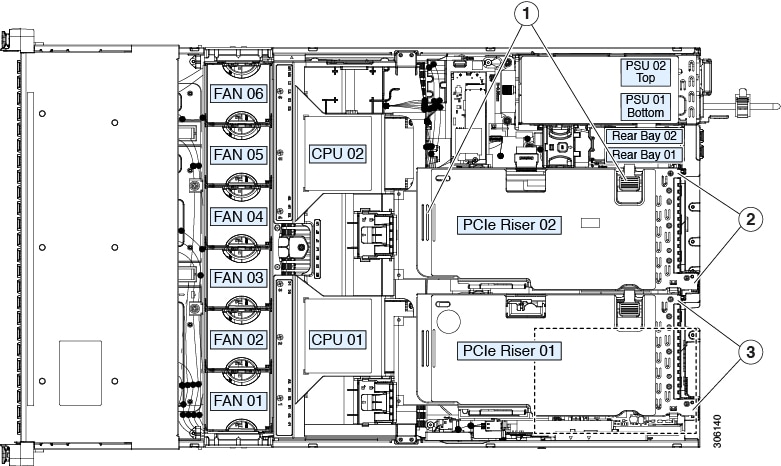

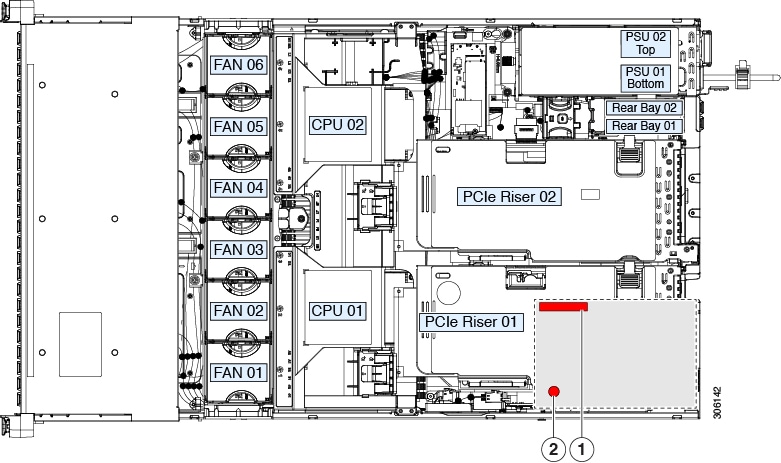

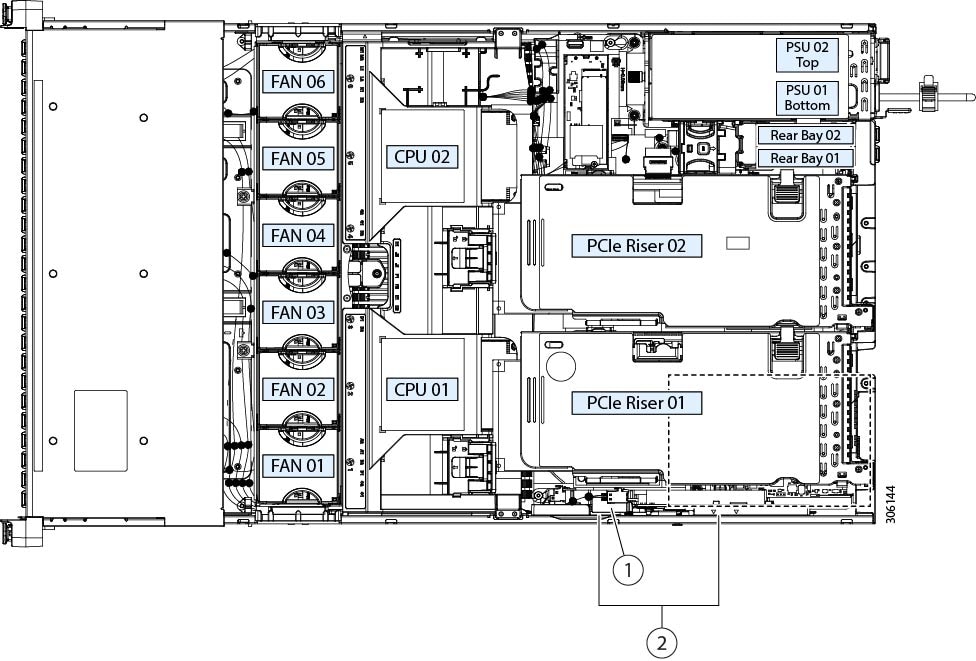

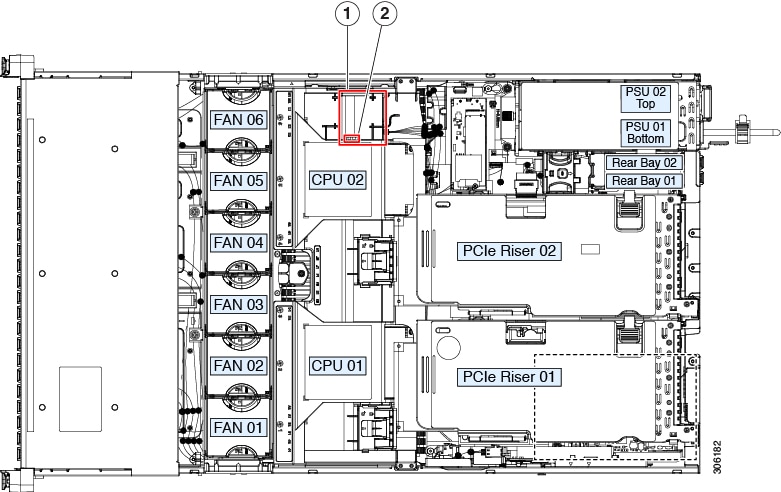

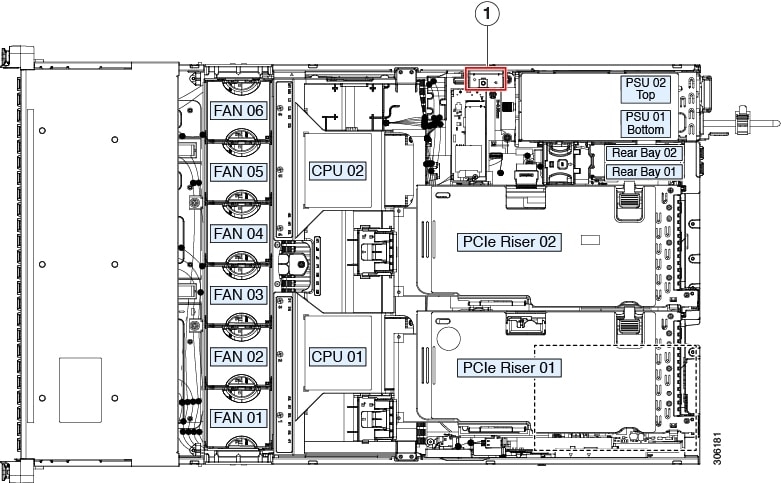

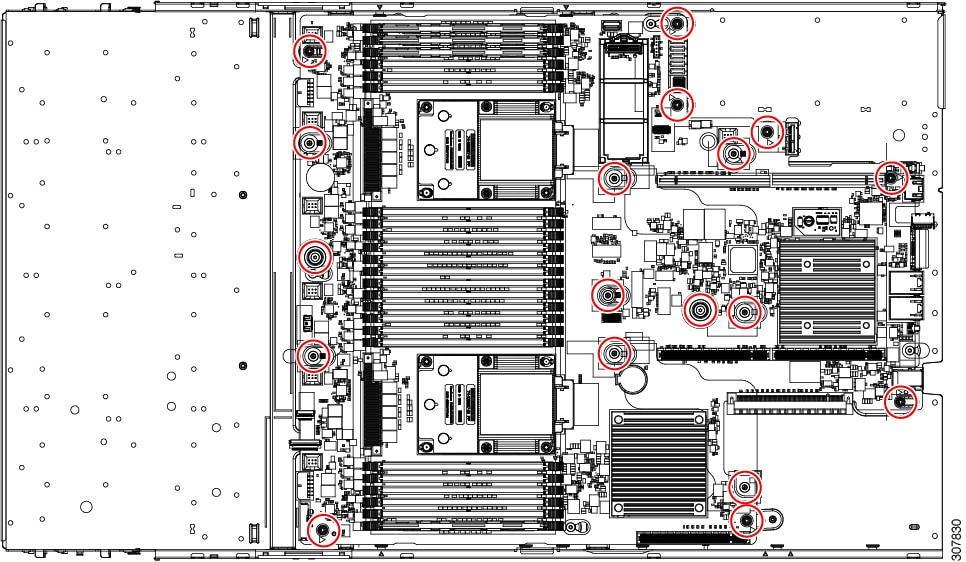

Internal Diagnostic LEDs

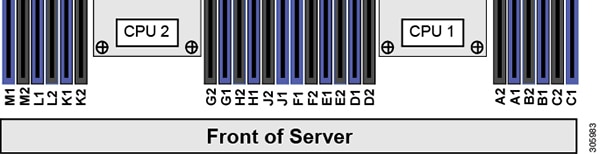

The server has internal fault LEDs for CPUs, DIMMs, and fan modules.

|

1 |

Fan module fault LEDs (one on the top of each fan module)

|

3 |

DIMM fault LEDs (one behind each DIMM socket on the motherboard) These LEDs operate only when the server is in standby power mode.

|

|

2 |

CPU fault LEDs (one behind each CPU socket on the motherboard). These LEDs operate only when the server is in standby power mode.

|

- |

Feedback

Feedback