- Server Monitoring and Management Tools

- Status LEDs and Buttons

- Preparing for Server Component Installation

- Installing or Replacing Server Components

- Replaceable Component Locations

- Replacing SAS/SATA Hard Drives or Solid State Drives

- Replacing a 2.5-Inch Form-Factor NVMe PCIe SSDs

- Replacing an HHHL Form-Factor NVMe Solid State Drive

- Replacing Fan Modules

- Replacing DIMMs

- Replacing CPUs and Heatsinks

- Replacing a SATA Interposer Board

- Replacing a Cisco Modular RAID Controller Card

- Replacing a Modular RAID Controller Transportable Memory Module (TMM)

- Replacing the Supercap Power Module (RAID Backup Battery)

- Replacing a Software RAID 5 Key Module

- Replacing the Motherboard RTC Battery

- Replacing an Internal SD Card

- Enabling or Disabling the Internal USB Port

- Replacing a PCIe Riser

- Replacing a PCIe Card

- Installing an NVIDIA GPU Card

- Replacing Internal SATA Boot Drives

- Installing a Trusted Platform Module (TPM)

- Replacing Power Supplies

- Replacing an mLOM Card

- Service DIP Switches

Maintaining the Server

This chapter describes how to diagnose server system problems using LEDs. It also provides information about how to install or replace hardware components, and it includes the following sections:

Server Monitoring and Management Tools

Cisco Integrated Management Interface

You can monitor the server inventory, health, and system event logs by using the built-in Cisco Integrated Management Controller (Cisco IMC) GUI or CLI interfaces. See the user documentation for your firmware release at the following URL:

http://www.cisco.com/en/US/products/ps10739/products_installation_and_configuration_guides_list.html

Server Configuration Utility

Cisco has also developed the Cisco Server Configuration Utility for C-Series servers, which can aid and simplify the following tasks:

- Monitoring server inventory and health

- Diagnosing common server problems with diagnostic tools and logs

- Setting the BIOS booting order

- Configuring some RAID configurations

- Installing operating systems

You can also download the ISO image from Cisco.com. See the user documentation for your version of the utility at the following URL:

http://www.cisco.com/en/US/products/ps10493/products_user_guide_list.html

Status LEDs and Buttons

This section describes the location and meaning of LEDs and buttons and includes the following topics

Front Panel LEDs

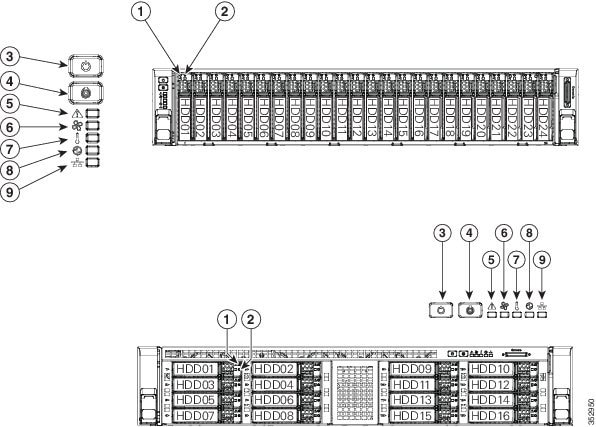

Figure 3-1 shows the front panel LEDs. Table 3-1 defines the LED states.

The small form factor (SFF) drives, 24-drive version and the SFF drives, 16-drive version are shown.

|

|

Hard drive fault LED (on each drive tray) Note: NVMe PCIe SSDs drive tray LEDs have slightly different behavior. See Table 3-1 for the LED states. |

|

|

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|---|---|---|

| Note: If your controller is a Cisco UCS RAID SAS 9300-8i or 9300-8e HBA, see Cisco UCS SAS 9300-8e HBA Considerations for differing LED behavior. |

||

|

||

– – – |

||

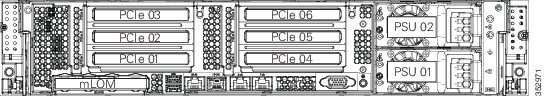

Rear Panel LEDs and Buttons

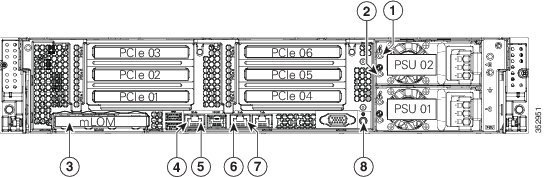

Figure 3-2 shows the rear panel LEDs and buttons. Table 3-2 defines the LED states.

Figure 3-2 Rear Panel LEDs and Buttons

|

|

|

||

|

|

|

||

|

|

Optional mLOM card LEDs |

|

|

|

|

|

|

|

|

|

|---|---|---|

| This is a summary; for advanced power supply LED information, see Table 3-3 . |

|

|

| This is a summary; for advanced power supply LED information, see Table 3-3 . |

||

In Table 3-3 , read the status and fault LED states together in each row to determine the event that cause this combination.

|

|

|

|

|---|---|---|

Internal Diagnostic LEDs

The server is equipped with a supercap voltage source that can activate internal component fault LEDs up to 30 minutes after AC power is removed. The server has internal fault LEDs for CPUs, DIMMs, fan modules, SD cards, the RTC battery, and the mLOM card.

To use these LEDs to identify a failed component, press the front or rear Unit Identification button (see Figure 3-1 or Figure 3-2) with AC power removed. An LED lights amber to indicate a faulty component.

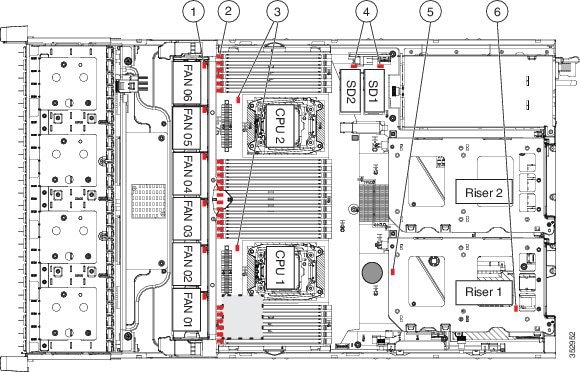

See Figure 3-3 for the locations of these internal LEDs.

Figure 3-3 Internal Diagnostic LED Locations

|

|

|

||

|

|

DIMM fault LEDs (one directly in front of each DIMM socket on the motherboard) |

|

|

|

|

|

|

|

|

|---|---|

Preparing for Server Component Installation

This section describes how to prepare for component installation, and it includes the following topics:

- Required Equipment

- Shutting Down and Powering Off the Server

- Removing and Replacing the Server Top Cover

- Serial Number Location

- Hot-Swap or Hot-Plug Replacement

Required Equipment

The following equipment is used to perform the procedures in this chapter:

Shutting Down and Powering Off the Server

The server can run in two power modes:

- Main power mode—Power is supplied to all server components and any operating system on your drives can run.

- Standby power mode—Power is supplied only to the service processor and the cooling fans and it is safe to power off the server from this mode.

You can invoke a graceful shutdown or a hard shutdown by using either of the following methods:

- Use the Cisco IMC management interface.

- Use the Power button on the server front panel. To use the Power button, follow these steps:

Step 1![]() Check the color of the Power Status LED (see the “Front Panel LEDs” section).

Check the color of the Power Status LED (see the “Front Panel LEDs” section).

- Green—The server is in main power mode and must be shut down before it can be safely powered off. Go to Step 2.

- Amber—The server is already in standby mode and can be safely powered off. Go to Step 3.

Step 2![]() Invoke either a graceful shutdown or a hard shutdown:

Invoke either a graceful shutdown or a hard shutdown:

- Graceful shutdown—Press and release the Power button. The operating system performs a graceful shutdown and the server goes to standby mode, which is indicated by an amber Power Status LED.

- Emergency shutdown—Press and hold the Power button for 4 seconds to force the main power off and immediately enter standby mode.

Step 3![]() Disconnect the power cords from the power supplies in your server to completely power off the server.

Disconnect the power cords from the power supplies in your server to completely power off the server.

Removing and Replacing the Server Top Cover

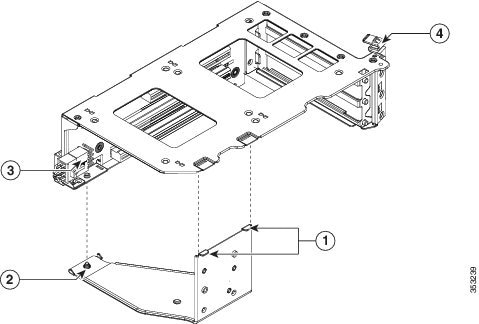

Step 1![]() Remove the top cover (see Figure 3-4).

Remove the top cover (see Figure 3-4).

a.![]() If the cover latch is locked, use a screwdriver to turn the lock 90-degrees counterclockwise to unlock it. See Figure 3-4.

If the cover latch is locked, use a screwdriver to turn the lock 90-degrees counterclockwise to unlock it. See Figure 3-4.

b.![]() Lift on the end of the latch that has the green finger grip. The cover is pushed back to the open position as you lift the latch.

Lift on the end of the latch that has the green finger grip. The cover is pushed back to the open position as you lift the latch.

c.![]() Lift the top cover straight up from the server and set it aside.

Lift the top cover straight up from the server and set it aside.

Note![]() The latch must be in the fully open position when you set the cover back in place, which allows the opening in the latch to sit over a peg that is on the fan tray.

The latch must be in the fully open position when you set the cover back in place, which allows the opening in the latch to sit over a peg that is on the fan tray.

a.![]() With the latch in the fully open position, place the cover on top of the server about one-half inch (1.27 cm) behind the lip of the front cover panel. The opening in the latch should fit over the peg that sticks up from the fan tray.

With the latch in the fully open position, place the cover on top of the server about one-half inch (1.27 cm) behind the lip of the front cover panel. The opening in the latch should fit over the peg that sticks up from the fan tray.

b.![]() Press the cover latch down to the closed position. The cover is pushed forward to the closed position as you push down the latch.

Press the cover latch down to the closed position. The cover is pushed forward to the closed position as you push down the latch.

c.![]() If desired, lock the latch by using a screwdriver to turn the lock 90-degrees clockwise.

If desired, lock the latch by using a screwdriver to turn the lock 90-degrees clockwise.

Figure 3-4 Removing the Top Cover

|

|

|

||

|

|

|

Serial Number Location

The serial number (SN) for the server is printed on a label on the top of the server, near the front.

Hot-Swap or Hot-Plug Replacement

Some components can be removed and replaced without powering off and removing AC power from the server.

- Hot-swap replacement—You do not have to precondition or shut down the component in the software before you remove it for the following components:

–![]() SAS/SATA hard drives or SSDs

SAS/SATA hard drives or SSDs

Installing or Replacing Server Components

Warning![]() Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place.

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place.

Statement 1029

Tip![]() You can press the Unit Identification button on the front panel or rear panel to turn on a flashing Unit Identification LED on the front and rear panels of the server. This button allows you to locate the specific server that you are servicing when you go to the opposite side of the rack. You can also activate these LEDs remotely by using the Cisco IMC interface. See the “Status LEDs and Buttons” section for locations of these LEDs.

You can press the Unit Identification button on the front panel or rear panel to turn on a flashing Unit Identification LED on the front and rear panels of the server. This button allows you to locate the specific server that you are servicing when you go to the opposite side of the rack. You can also activate these LEDs remotely by using the Cisco IMC interface. See the “Status LEDs and Buttons” section for locations of these LEDs.

This section describes how to install and replace server components, and it includes the following topics:

- Replaceable Component Locations

- Replacing SAS/SATA Hard Drives or Solid State Drives

- Replacing a 2.5-Inch Form-Factor NVMe PCIe SSDs

- Replacing an HHHL Form-Factor NVMe Solid State Drive

- Replacing Fan Modules

- Replacing DIMMs

- Replacing CPUs and Heatsinks

- Replacing a SATA Interposer Board

- Replacing a Cisco Modular RAID Controller Card

- Replacing a Modular RAID Controller Transportable Memory Module (TMM)

- Replacing the Supercap Power Module (RAID Backup Battery)

- Replacing a Software RAID 5 Key Module

- Replacing the Motherboard RTC Battery

- Replacing an Internal SD Card

- Enabling or Disabling the Internal USB Port

- Replacing a PCIe Riser

- Replacing a PCIe Card

- Installing an NVIDIA GPU Card

- Replacing Internal SATA Boot Drives

- Installing a Trusted Platform Module (TPM)

- Replacing Power Supplies

- Replacing an mLOM Card

Replaceable Component Locations

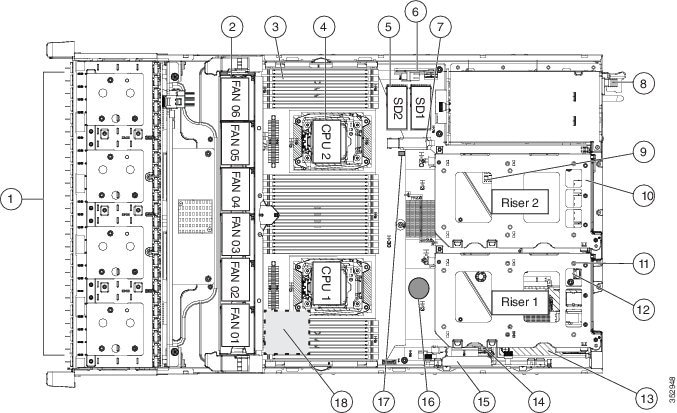

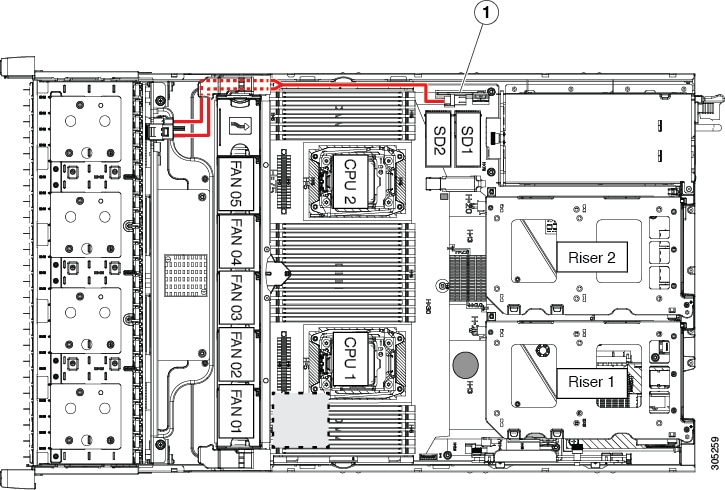

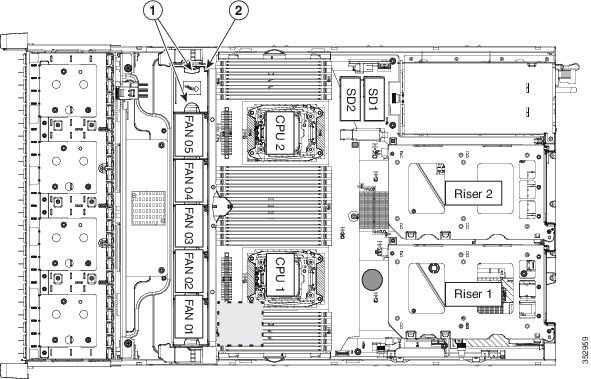

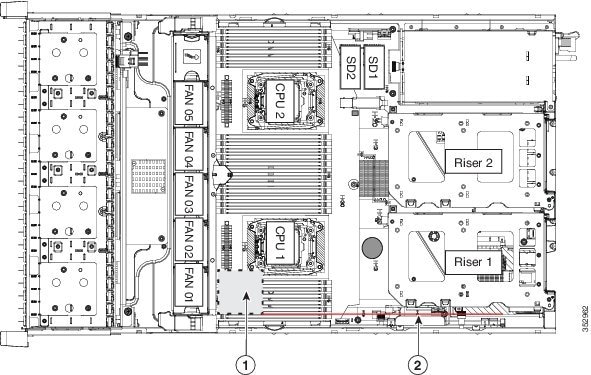

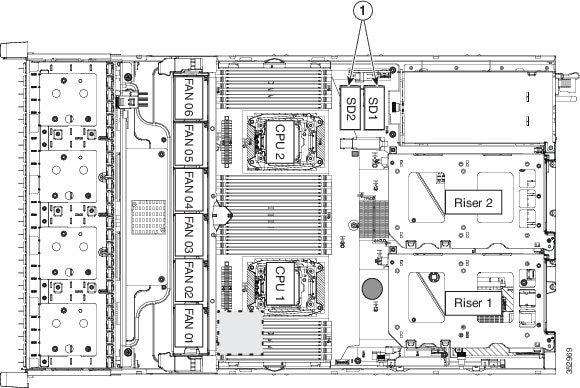

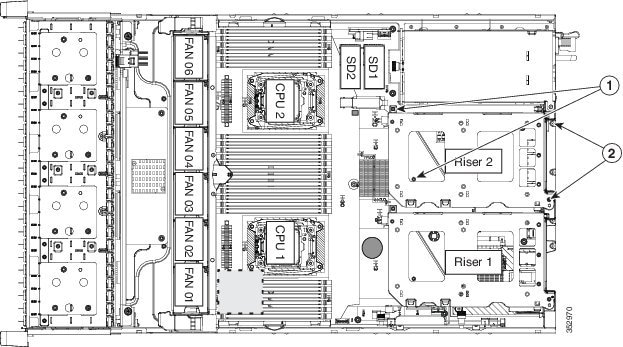

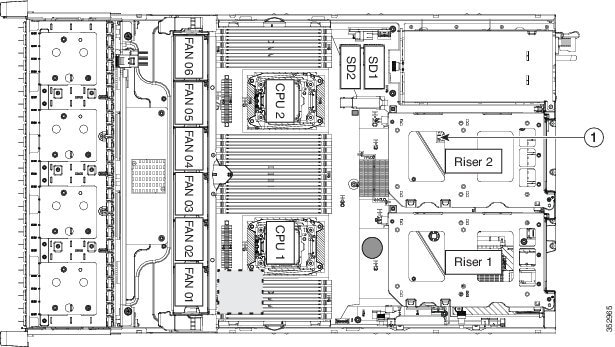

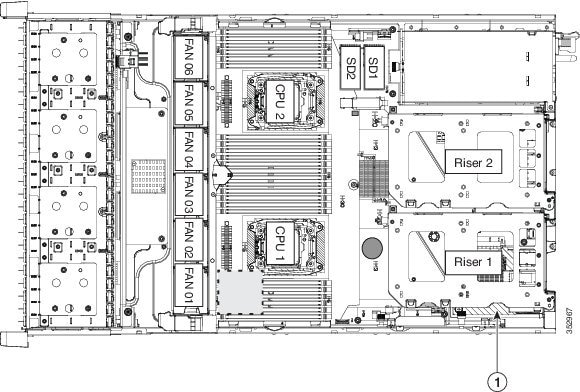

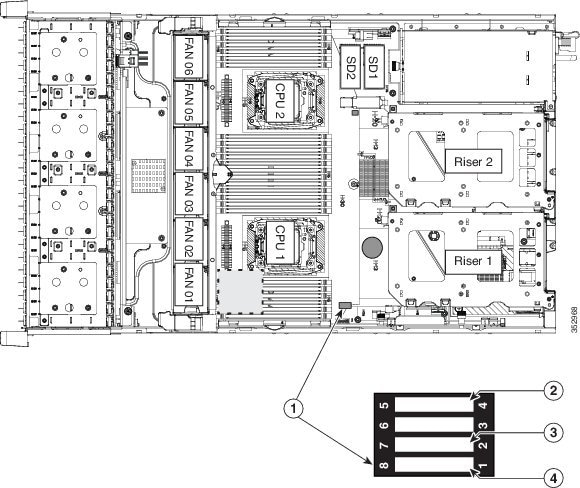

Figure 3-5 shows the locations of the components that are supported as field-replaceable. The view shown is from the top down, with the top covers and air baffle removed.

Figure 3-5 Replaceable Component Locations

|

|

Drives bays. All drive bays support SAS/SATA drives. SFF, 8-, 16-, and 24-drive versions only: Drive bays 1 and 2 support SAS/SATA drives and NVMe PCIe SSDs. NVMe drives require a PCIe interposer board for PCIe bus connection (see item 6). |

|

|

|

|

|

PCIe riser 1 (PCIe slots 1, 2, 3*) *Slot 3 not present in all versions. See Replacing a PCIe Card for riser options and slot specifications. |

|

|

|

|

SATA boot drives (two sockets available only on PCIe riser 1 option 1C) |

|

|

|

|

||

|

|

|

||

|

|

|

Cisco modular RAID controller PCIe slot |

|

|

|

|

||

|

|

|

||

|

|

Trusted platform module (TPM) socket on motherboard, under PCIe riser 2 |

|

Supercap power module (RAID backup) mounting location on air baffle (not shown) |

The Technical Specifications Sheets for all versions of this server, which include supported component part numbers, are at Cisco UCS Servers Technical Specifications Sheets.

Replacing SAS/SATA Hard Drives or Solid State Drives

SAS/SATA Drive Population Guidelines

The server is orderable in four different versions, each with one of four different front panel/backplane configurations:

- Cisco UCS C240 M4—Small form-factor (SFF) drives with 24-drive backplane and expander.

This version holds up to 24 2.5-inch SAS/SATA hard drives or solid state drives (SSDs). SAS/SATA drives are hot-swappable. - Cisco UCS C240 M4—SFF drives, with 16-drive backplane and integrated expander.

This version holds up to 16 2.5-inch SAS/SATA hard drives or solid state drives. SAS/SATA drives are hot-swappable. - Cisco UCS C240 M4—SFF drives, with 8-drive direct-connect backplane and no expander.

This version holds up to 8 2.5-inch SAS/SATA hard drives or solid state drives. SAS/SATA drives are hot-swappable. - Cisco UCS C240 M4—Large form-factor (LFF) drives, with 12-drive backplane and integrated expander. This version holds up to 12 3.5-inch SAS/SATA hard drives. SAS/SATA drives are hot-swappable.

Note![]() You cannot change the backplane type after-factory. To change a front panel/backplane configuration, a chassis replacement is required.

You cannot change the backplane type after-factory. To change a front panel/backplane configuration, a chassis replacement is required.

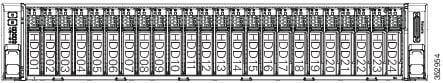

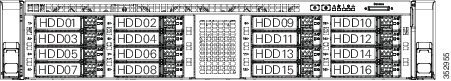

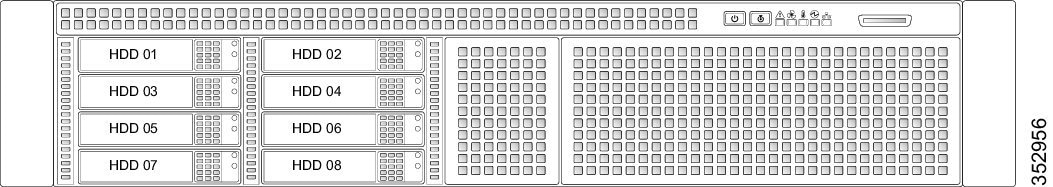

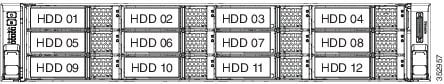

The drive-bay numbering for all server versions is shown in Figure 3-6 through Figure 3-9.

Figure 3-6 Drive Numbering, SFF Drives, 24-Drive Version

Figure 3-7 Drive Numbering, SFF Drives, 16-Drive Version

Figure 3-8 Drive Numbering, SFF Drives, 8-Drive Version

Figure 3-9 Drive Numbering, LFF Drives, 12-Drive Version

Observe these drive population guidelines for optimal performance:

- When populating drives, add drives in the lowest numbered bays first.

- Keep an empty drive blanking tray in any unused bays to ensure optimal airflow and cooling.

- You can mix hard drives and solid state drives in the same server. However, you cannot configure a logical volume (virtual drive) that contains a mix of hard drives and SSDs. That is, when you create a logical volume, it must contain all hard drives or all SSDs.

4K Sector Format Drives Considerations

- You must boot 4K sector format drives in UEFI mode, not legacy mode. See Setting Up Booting in UEFI Mode in the BIOS Setup Utility or Setting Up Booting in UEFI Mode in the Cisco IMC GUI.

- Do not configure 4K sector format and 512-byte sector format drives as part of the same RAID volume.

- Operating system support on 4K sector drives is as follows: Windows: Win2012 and Win2012R2; Linux: RHEL 6.5, 6.6, 6.7, 7.0, 7.2; SLES 11 SP3, and SLES 12. ESXi/Vmware is not supported.

Setting Up Booting in UEFI Mode in the BIOS Setup Utility

Step 1![]() Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Step 2![]() Go to the Boot Options tab.

Go to the Boot Options tab.

Step 3![]() Set UEFI Boot Options to Enabled.

Set UEFI Boot Options to Enabled.

Step 4![]() Under Boot Option Priorities, set your OS installation media (such as a virtual DVD) as your

Under Boot Option Priorities, set your OS installation media (such as a virtual DVD) as your

Boot Option #1.

Step 5![]() Go to the Advanced tab.

Go to the Advanced tab.

Step 6![]() Select LOM and PCIe Slot Configuration.

Select LOM and PCIe Slot Configuration.

Step 7![]() Set the PCIe Slot ID: HBA Option ROM to UEFI Only.

Set the PCIe Slot ID: HBA Option ROM to UEFI Only.

Step 8![]() Press F10 to save changes and exit the BIOS setup utility. Allow the server to reboot.

Press F10 to save changes and exit the BIOS setup utility. Allow the server to reboot.

Step 9![]() After the OS installs, verify the installation:

After the OS installs, verify the installation:

a.![]() Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

b.![]() Go to the Boot Options tab.

Go to the Boot Options tab.

c.![]() Under Boot Option Priorities, verify that the OS you installed is listed as your Boot Option #1.

Under Boot Option Priorities, verify that the OS you installed is listed as your Boot Option #1.

Setting Up Booting in UEFI Mode in the Cisco IMC GUI

Step 1![]() Use a web browser and the IP address of the server to log into the Cisco IMC GUI management interface.

Use a web browser and the IP address of the server to log into the Cisco IMC GUI management interface.

Step 2![]() Navigate to Server > BIOS.

Navigate to Server > BIOS.

Step 3![]() Under Actions, click Configure BIOS.

Under Actions, click Configure BIOS.

Step 4![]() In the Configure BIOS Parameters dialog, select the Advanced tab.

In the Configure BIOS Parameters dialog, select the Advanced tab.

Step 5![]() Go to the LOM and PCIe Slot Configuration section.

Go to the LOM and PCIe Slot Configuration section.

Step 6![]() Set the PCIe Slot: HBA Option ROM to UEFI Only.

Set the PCIe Slot: HBA Option ROM to UEFI Only.

Step 7![]() Click Save Changes. The dialog closes.

Click Save Changes. The dialog closes.

Step 8![]() Under BIOS Properties, set Configured Boot Order to UEFI.

Under BIOS Properties, set Configured Boot Order to UEFI.

Step 9![]() Under Actions, click Configure Boot Order.

Under Actions, click Configure Boot Order.

Step 10![]() In the Configure Boot Order dialog, click Add Local HDD.

In the Configure Boot Order dialog, click Add Local HDD.

Step 11![]() In the Add Local HDD dialog, enter the information for the 4K sector format drive and make it first in the boot order.

In the Add Local HDD dialog, enter the information for the 4K sector format drive and make it first in the boot order.

Step 12![]() Save changes and reboot the server. The changes you made will be visible after the system reboots.

Save changes and reboot the server. The changes you made will be visible after the system reboots.

Replacing SAS/SATA Drives

Tip![]() You do not have to shut down or power off the server to replace SAS/SATA hard drives or solid state drives (SSDs) because they are hot-swappable. To replace an NVMe PCIe SSD drive, which must be shut down before removal, see Replacing a 2.5-Inch Form-Factor NVMe PCIe SSDs.

You do not have to shut down or power off the server to replace SAS/SATA hard drives or solid state drives (SSDs) because they are hot-swappable. To replace an NVMe PCIe SSD drive, which must be shut down before removal, see Replacing a 2.5-Inch Form-Factor NVMe PCIe SSDs.

Step 1![]() Remove the drive that you are replacing or remove a blank drive tray from an empty bay:

Remove the drive that you are replacing or remove a blank drive tray from an empty bay:

a.![]() Press the release button on the face of the drive tray. See Figure 3-10.

Press the release button on the face of the drive tray. See Figure 3-10.

b.![]() Grasp and open the ejector lever and then pull the drive tray out of the slot.

Grasp and open the ejector lever and then pull the drive tray out of the slot.

c.![]() If you are replacing an existing drive, remove the four drive-tray screws that secure the drive to the tray and then lift the drive out of the tray.

If you are replacing an existing drive, remove the four drive-tray screws that secure the drive to the tray and then lift the drive out of the tray.

a.![]() Place a new drive in the empty drive tray and replace the four drive-tray screws.

Place a new drive in the empty drive tray and replace the four drive-tray screws.

b.![]() With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

c.![]() Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

|

|

|

||

|

|

|

Replacing a 2.5-Inch Form-Factor NVMe PCIe SSDs

This section is for replacing 2.5-inch small form-factor (SFF) NVMe PCIe SSDs in front-panel drive bays. To replace HHHL form-factor NVMe PCIe SSDs in the PCIe slots, see Replacing an HHHL Form-Factor NVMe Solid State Drive.

2.5-Inch Form-Factor NVMe PCIe SSD Population Guidelines

The SFF versions of the server (8-, 16-, and 24-drive) support up to two NVMe SFF 2.5-inch SSDs in drive bays 1 and 2 only.

2.5-Inch Form-Factor NVME PCIe SSD Requirements and Restrictions

Observe these requirements for NVMe SFF 2.5-inch SSDs:

- The SFF drives versions of the server (8-drives, 16-drives, or 24-drives).

- The server must have two CPUs. The PCIe interposer board is not available in a single-CPU system.

- The PCIe interposer board with bundled cables for your server version:

–![]() SFF 8- or SFF 16-drives server: UCSC-IP-SSD-240M4

SFF 8- or SFF 16-drives server: UCSC-IP-SSD-240M4

–![]() SFF 24-drives server: UCSC-IP-SSD-240M4B

SFF 24-drives server: UCSC-IP-SSD-240M4B

Observe these restrictions for NVMe SFF 2.5-inch SSDs:

- You can boot (UEFI only) from an NVMe SFF 2.5-inch SSD only with Cisco IMC 2.0(13) or later server firmware. For Cisco UCS Manager-integrated servers, booting is supported only with Cisco UCS Manager 3.1(2) or later software.

- NVMe SFF 2.5-inch SSDs support booting only in UEFI mode. Legacy boot is not supported.

- You cannot control an NVMe SFF 2.5-inch SSD with a SAS RAID controller because they communicate with the server via the PCIe bus.

- You can combine NVMe SFF 2.5-inch SSDs and HHHL form-factor SSDs in the same system, but the same partner brand must be used. For example, two Intel NVMe SFF 2.5-inch SSDs and six HHHL form-factor HGST SSDs is an invalid configuration. A valid configuration is two HGST NVMe SFF 2.5-inch SSDs and six HGST HHHL form-factor SSDs.

- UEFI boot is supported in the five operating systems listed in Table 3-5 , when your server is running Cisco IMC 2.0(13) or later firmware. Refer to this table for OS-informed hot-insertion and hot-removal support by operating system:

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

Enabling Hot-Plug Support in the System BIOS

In Cisco IMC 2.0(13) and later, hot-plug (OS-informed hot-insertion and hot-removal) is disabled in the system BIOS by default.

Enabling Hot-Plug Support in the BIOS Setup Utility

Step 1![]() Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Enter the BIOS setup utility by pressing the F2 key when prompted during bootup.

Step 2![]() Locate the setting: Advanced > PCI Subsystem Settings > NVMe SSD Hot-Plug Support.

Locate the setting: Advanced > PCI Subsystem Settings > NVMe SSD Hot-Plug Support.

Step 3![]() Set the value to Enabled.

Set the value to Enabled.

Step 4![]() Save your changes and exit the utility.

Save your changes and exit the utility.

Enabling Hot-Plug Support in the Cisco IMC GUI

Step 1![]() Use a browser to log into the Cisco IMC GUI for the system.

Use a browser to log into the Cisco IMC GUI for the system.

Step 2![]() Navigate to Compute > BIOS > Advanced > PCI Configuration.

Navigate to Compute > BIOS > Advanced > PCI Configuration.

Step 3![]() Set NVME SSD Hot-Plug Support to Enabled.

Set NVME SSD Hot-Plug Support to Enabled.

Step 4![]() Save your changes and exit the software.

Save your changes and exit the software.

Replacing an NVMe SFF 2.5-Inch PCIe SSD

Note![]() OS-surprise removal is not supported. OS-informed hot-insertion and hot-removal are supported only with Cisco IMC release 2.0(13) and later and they depend on your OS version. See Table 3-5 for support by OS.

OS-surprise removal is not supported. OS-informed hot-insertion and hot-removal are supported only with Cisco IMC release 2.0(13) and later and they depend on your OS version. See Table 3-5 for support by OS.

Note![]() OS-informed hot-insertion and hot-removal must be enabled in the system BIOS. See Enabling Hot-Plug Support in the System BIOS.

OS-informed hot-insertion and hot-removal must be enabled in the system BIOS. See Enabling Hot-Plug Support in the System BIOS.

For information about drive tray LEDs, see Front Panel LEDs.

Step 1![]() Remove an existing NVMe SFF 2.5-inch SSD:

Remove an existing NVMe SFF 2.5-inch SSD:

a.![]() Shut down the NVMe SFF 2.5-inch SSD to initiate an OS-informed removal. Use your operating system interface to shut down the drive, and then observe the drive-tray LED:

Shut down the NVMe SFF 2.5-inch SSD to initiate an OS-informed removal. Use your operating system interface to shut down the drive, and then observe the drive-tray LED:

–![]() Green—The drive is in use and functioning properly. Do not remove.

Green—The drive is in use and functioning properly. Do not remove.

–![]() Green, blinking—the driver is unloading following a shutdown command. Do not remove.

Green, blinking—the driver is unloading following a shutdown command. Do not remove.

–![]() Off—The drive is not in use and can be safely removed.

Off—The drive is not in use and can be safely removed.

b.![]() Press the release button on the face of the drive tray. See Figure 3-10.

Press the release button on the face of the drive tray. See Figure 3-10.

c.![]() Grasp and open the ejector lever and then pull the drive tray out of the slot.

Grasp and open the ejector lever and then pull the drive tray out of the slot.

d.![]() If you are replacing an existing SSD, remove the four drive tray screws that secure the SSD to the tray and then lift the SSD out of the tray.

If you are replacing an existing SSD, remove the four drive tray screws that secure the SSD to the tray and then lift the SSD out of the tray.

Note![]() If this is the first time that NVMe SFF 2.5-inch SSDs are being installed in the server, you must install a PCIe interposer board and connect its cables before installing the drive. See Installing a PCIe Interposer Board For NVMe SFF 2.5-inch SSDs.

If this is the first time that NVMe SFF 2.5-inch SSDs are being installed in the server, you must install a PCIe interposer board and connect its cables before installing the drive. See Installing a PCIe Interposer Board For NVMe SFF 2.5-inch SSDs.

Step 2![]() Install a new NVMe SFF 2.5-inch SSD:

Install a new NVMe SFF 2.5-inch SSD:

a.![]() Place a new SSD in the empty drive tray and replace the four drive tray screws.

Place a new SSD in the empty drive tray and replace the four drive tray screws.

b.![]() With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

With the ejector lever on the drive tray open, insert the drive tray into the empty drive bay.

c.![]() Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

Push the tray into the slot until it touches the backplane, and then close the ejector lever to lock the drive in place.

Step 3![]() Observe the drive-tray LED and wait until it returns to solid green before accessing the drive:

Observe the drive-tray LED and wait until it returns to solid green before accessing the drive:

- Off—The drive is not in use.

- Green, blinking—the driver is initializing following hot-plug insertion.

- Green—The drive is in use and functioning properly.

Installing a PCIe Interposer Board For NVMe SFF 2.5-inch SSDs

A PCIe interposer board is used to provide communication with the PCIe bus from the NVMe SFF 2.5-inch SSDs in the front panel bays. Use the correct interposer board, with bundled cables, for your version of the server:

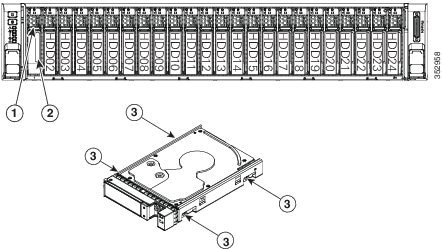

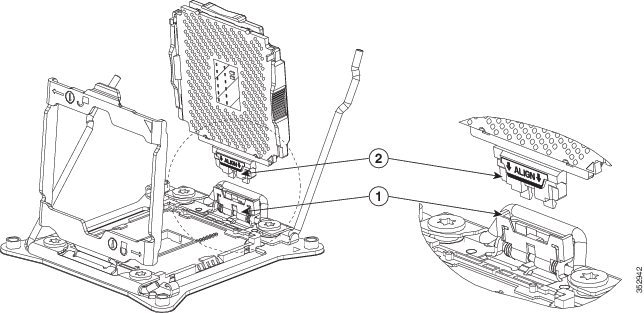

Figure 3-11 PCIe Interposer Board

|

|

|

||

|

|

|

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Install a new PCIe interposer board:

Install a new PCIe interposer board:

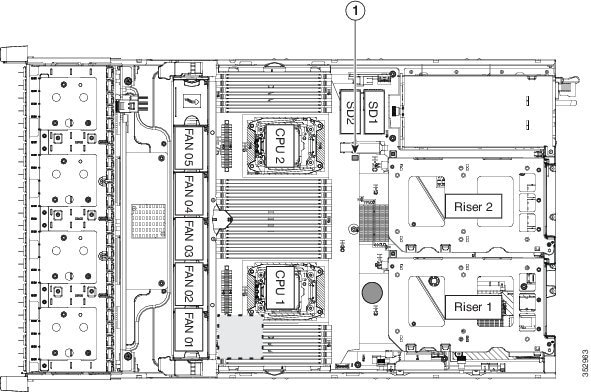

a.![]() Locate the PCIe interposer board socket on the motherboard (see Figure 3-12).

Locate the PCIe interposer board socket on the motherboard (see Figure 3-12).

b.![]() Pinch the securing clip on the board while you insert the board to the socket as shown in Figure 3-11.

Pinch the securing clip on the board while you insert the board to the socket as shown in Figure 3-11.

c.![]() Carefully push down to seat the board, then release the securing clip.

Carefully push down to seat the board, then release the securing clip.

Step 5![]() Connect the two cables that come with the interposer board:

Connect the two cables that come with the interposer board:

a.![]() Connect the double-connector end of the cable to the interposer board (see Figure 3-11).

Connect the double-connector end of the cable to the interposer board (see Figure 3-11).

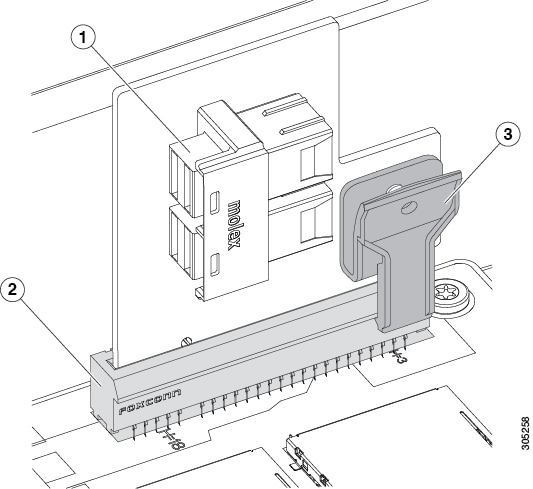

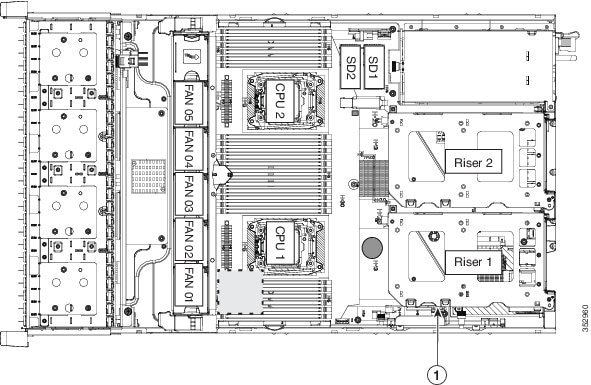

b.![]() Route the cables to the front of the server using the recommended path through the chassis cable guides as shown in Figure 3-12.

Route the cables to the front of the server using the recommended path through the chassis cable guides as shown in Figure 3-12.

c.![]() Connect the two ends of the cable to the PCIe connectors on the drive backplane.

Connect the two ends of the cable to the PCIe connectors on the drive backplane.

Connect the cable labeled Port A to the Port A connector; connect the cable labeled Port B to the Port B connector.

Step 7![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

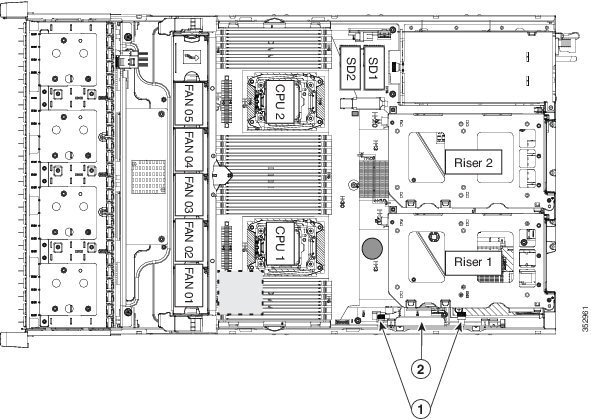

Figure 3-12 PCIe Interposer Board Cabling

|

|

|

Replacing an HHHL Form-Factor NVMe Solid State Drive

The half-height, half-length- (HHHL-) format NVMe PCIe SSDs install to the PCIe riser slots. To install a 2.5-inch form-factor NVME SSD in the front-panel drive bays, see Replacing a 2.5-Inch Form-Factor NVMe PCIe SSDs.

HHHL Form-Factor NVMe SSD Population Guidelines

Observe the following population guidelines when installing HHHL form-factor NVMe SSDs:

- Two-CPU systems—You can populate up to 6 HHHL form-factor SSDs, using PCIe slots 1 – 6.

- One-CPU systems—In a single-CPU system, PCIe riser 2, which has slots 4–6, is not available. Therefore, the maximum number of HHHL form-factor SSDs you can populate is 3, in PCIe slots 1–3.

|

|

|

|---|---|

HHHL Form-Factor NVME SSD Requirements and Restrictions

Observe these requirements for HHHL form-factor NVMe SSDs:

- All versions of the server support HHHL form-factor NVMe SSDs (LFF 12-drives or SFF 8-drives, 16-drives, or 24-drives server).

Observe these restrictions for HHHL form-factor NVMe PCIe SSDs:

- You cannot boot from an HHHL form-factor NVMe SSD.

- You cannot control an HHHL form-factor NVMe PCIe SSD with a SAS RAID controller because they communicate with the server via the PCIe bus.

- You can combine NVMe SFF 2.5-inch SSDs and HHHL form-factor SSDs in the same system, but the same partner brand must be used. For example, two Intel NVMe SFF 2.5-inch SSDs and six HHHL form-factor HGST SSDs is an invalid configuration. A valid configuration is two HGST NVMe SFF 2.5-inch SSDs and six HGST HHHL form-factor SSDs.

Replacing an HHHL Form-Factor NVMe SSD

Note![]() In a single-CPU server, PCIe riser 2 (PCIe slots 4–6) is not available.

In a single-CPU server, PCIe riser 2 (PCIe slots 4–6) is not available.

Step 1![]() Shut down and power off the server as described in Shutting Down and Powering Off the Server.

Shut down and power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

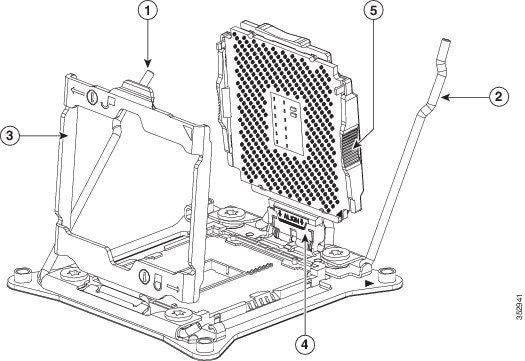

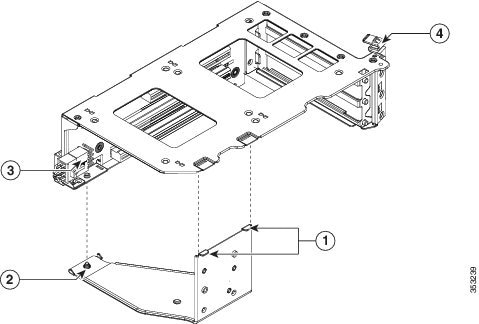

Step 4![]() Remove an existing HHHL form-factor NVMe drive (or a blanking panel) from the PCIe riser:

Remove an existing HHHL form-factor NVMe drive (or a blanking panel) from the PCIe riser:

a.![]() Lift straight up on both ends of the riser to disengage its circuit board from the socket on the motherboard. Set the riser on an antistatic mat.

Lift straight up on both ends of the riser to disengage its circuit board from the socket on the motherboard. Set the riser on an antistatic mat.

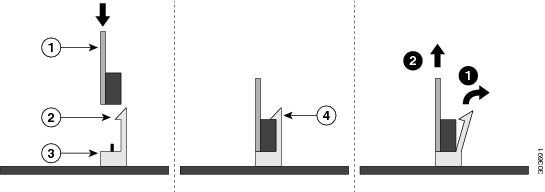

b.![]() On the bottom of the riser, loosen the single thumbscrew that holds the securing plate (see Figure 3-13).

On the bottom of the riser, loosen the single thumbscrew that holds the securing plate (see Figure 3-13).

c.![]() Swing open the securing plate and remove it from the riser to provide access.

Swing open the securing plate and remove it from the riser to provide access.

d.![]() Swing open the card-tab retainer that secures the back-panel tab of the card (see Figure 3-13).

Swing open the card-tab retainer that secures the back-panel tab of the card (see Figure 3-13).

e.![]() Pull evenly on both ends of the HHHL form-factor NVMe SSD to disengage it from the socket on the PCIe riser (or remove a blanking panel) and then set the card aside.

Pull evenly on both ends of the HHHL form-factor NVMe SSD to disengage it from the socket on the PCIe riser (or remove a blanking panel) and then set the card aside.

Step 5![]() Install an HHHL form-factor NVMe SSD:

Install an HHHL form-factor NVMe SSD:

a.![]() Align the new HHHL form-factor NVMe SSD with the empty socket on the PCIe riser.

Align the new HHHL form-factor NVMe SSD with the empty socket on the PCIe riser.

b.![]() Push down evenly on both ends of the card until it is fully seated in the socket.

Push down evenly on both ends of the card until it is fully seated in the socket.

c.![]() Close the card-tab retainer (see Figure 3-13).

Close the card-tab retainer (see Figure 3-13).

d.![]() Return the securing plate to the riser. Insert the two hinge-tabs into the two slots on the riser, and then swing the securing plate closed.

Return the securing plate to the riser. Insert the two hinge-tabs into the two slots on the riser, and then swing the securing plate closed.

e.![]() Tighten the single thumbscrew on the bottom of the securing plate.

Tighten the single thumbscrew on the bottom of the securing plate.

f.![]() Position the PCIe riser over its socket on the motherboard and over its alignment features in the chassis (see Figure 3-27).

Position the PCIe riser over its socket on the motherboard and over its alignment features in the chassis (see Figure 3-27).

g.![]() Carefully push down on both ends of the PCIe riser to fully engage its circuit board connector with the socket on the motherboard.

Carefully push down on both ends of the PCIe riser to fully engage its circuit board connector with the socket on the motherboard.

Step 7![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Figure 3-13 PCIe Riser Securing Features (Three-Slot Riser Shown)

|

|

|

||

|

|

Securing plate thumbscrew (knob not visible on underside of plate) |

|

Replacing Fan Modules

The six hot-swappable fan modules in the server are numbered as follows when you are facing the front of the server.

Figure 3-14 Fan Module Numbering

Tip![]() A fault LED is on the top of each fan module that lights amber if the fan module fails. To operate these LEDs from the SuperCap power source, remove AC power cords and then press the Unit Identification button. See also Internal Diagnostic LEDs.

A fault LED is on the top of each fan module that lights amber if the fan module fails. To operate these LEDs from the SuperCap power source, remove AC power cords and then press the Unit Identification button. See also Internal Diagnostic LEDs.

Step 1![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 2![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 3![]() Identify a faulty fan module by looking for a fan fault LED that is lit amber (see Figure 3-15).

Identify a faulty fan module by looking for a fan fault LED that is lit amber (see Figure 3-15).

Step 4![]() Remove a fan module that you are replacing (see Figure 3-15):

Remove a fan module that you are replacing (see Figure 3-15):

a.![]() Grasp the top of the fan and pinch the green plastic latch toward the center.

Grasp the top of the fan and pinch the green plastic latch toward the center.

b.![]() Lift straight up to remove the fan module from the server.

Lift straight up to remove the fan module from the server.

Step 5![]() Install a new fan module:

Install a new fan module:

a.![]() Set the new fan module in place, aligning the connector on the bottom of the fan module with the connector on the motherboard.

Set the new fan module in place, aligning the connector on the bottom of the fan module with the connector on the motherboard.

Note![]() The arrow label on the top of the fan module, which indicates the direction of airflow, should point toward the rear of the server.

The arrow label on the top of the fan module, which indicates the direction of airflow, should point toward the rear of the server.

b.![]() Press down gently on the fan module until the latch clicks and locks in place.

Press down gently on the fan module until the latch clicks and locks in place.

Step 7![]() Replace the server in the rack.

Replace the server in the rack.

Figure 3-15 Fan Modules Latch and Fault LED

|

|

|

Replacing DIMMs

This section includes the following topics:

Note![]() To ensure the best server performance, it is important that you are familiar with memory performance guidelines and population rules before you install or replace the memory.

To ensure the best server performance, it is important that you are familiar with memory performance guidelines and population rules before you install or replace the memory.

Memory Performance Guidelines and Population Rules

This section describes the type of memory that the server requires and its effect on performance. The section includes the following topics:

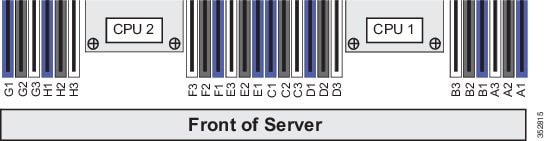

DIMM Socket Numbering

Figure 3-16 shows the numbering of the DIMM sockets and CPUs.

Figure 3-16 CPUs and DIMM Socket Numbering on Motherboard

DIMM Population Rules

Observe the following guidelines when installing or replacing DIMMs:

–![]() CPU1 supports channels A, B, C, and D.

CPU1 supports channels A, B, C, and D.

–![]() CPU2 supports channels E, F, G, and H.

CPU2 supports channels E, F, G, and H.

–![]() A channel can operate with one, two, or three DIMMs installed.

A channel can operate with one, two, or three DIMMs installed.

–![]() If a channel has only one DIMM, populate slot 1 first (the blue slot).

If a channel has only one DIMM, populate slot 1 first (the blue slot).

–![]() Fill blue #1 slots in the channels first: A1, E1, B1, F1, C1, G1, D1, H1

Fill blue #1 slots in the channels first: A1, E1, B1, F1, C1, G1, D1, H1

–![]() Fill black #2 slots in the channels second: A2, E2, B2, F2, C2, G2, D2, H2

Fill black #2 slots in the channels second: A2, E2, B2, F2, C2, G2, D2, H2

–![]() Fill white #3 slots in the channels third: A3, E3, B3, F3, C3, G3, D3, H3

Fill white #3 slots in the channels third: A3, E3, B3, F3, C3, G3, D3, H3

- Any DIMM installed in a DIMM socket for which the CPU is absent is not recognized. In a single-CPU configuration, populate the channels for CPU1 only (A, B, C, D).

- Memory mirroring reduces the amount of memory available by 50 percent because only one of the two populated channels provides data. When memory mirroring is enabled, you must install DIMMs in sets of 4, 6, 8, or 12 as described in Memory Mirroring and RAS.

- NVIDIA K-Series and M-Series GPUs can support only less-than 1 TB memory in the server.

- NVIDIA P-Series GPUs can support 1 TB or more memory in the server.

- AMD FirePro S7150 X2 can support only less-than 1 TB memory in the server.

- Observe the DIMM mixing rules shown in Table 3-6 .

Memory Mirroring and RAS

The Intel E5-2600 CPUs within the server support memory mirroring only when an even number of channels are populated with DIMMs. If one or three channels are populated with DIMMs, memory mirroring is automatically disabled. Furthermore, if memory mirroring is used, DRAM size is reduced by 50 percent for reasons of reliability.

For details on populating recommended memory mirroring configurations, see the specification sheet for the server:

Lockstep Channel Mode

When you enable lockstep channel mode, each memory access is a 128-bit data access that spans four channels.

Lockstep channel mode requires that all four memory channels on a CPU must be populated identically with regard to size and organization. DIMM socket populations within a channel (for example, A1, A2, A3) do not have to be identical but the same DIMM slot location across all four channels must be populated the same.

For example, DIMMs in sockets A1, B1, C1, and D1 must be identical. DIMMs in sockets A2, B2, C2, and D2 must be identical. However, the A1-B1-C1-D1 DIMMs do not have to be identical with the A2-B2-C2-D2 DIMMs.

DIMM Replacement Procedure

Identifying a Faulty DIMM

Each DIMM socket has a corresponding DIMM fault LED, directly in front of the DIMM socket. See Figure 3-3 for the locations of these LEDs. The LEDs light amber to indicate a faulty DIMM. To operate these LEDs from the SuperCap power source, remove AC power cords and then press the Unit Identification button.

Replacing DIMMs

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove the air baffle that sits over the DIMM sockets and set it aside.

Remove the air baffle that sits over the DIMM sockets and set it aside.

Step 5![]() Identify the faulty DIMM by observing the DIMM socket fault LEDs on the motherboard (see Figure 3-3).

Identify the faulty DIMM by observing the DIMM socket fault LEDs on the motherboard (see Figure 3-3).

Step 6![]() Remove the DIMMs that you are replacing. Open the ejector levers at both ends of the DIMM socket, and then lift the DIMM out of the socket.

Remove the DIMMs that you are replacing. Open the ejector levers at both ends of the DIMM socket, and then lift the DIMM out of the socket.

Note![]() Before installing DIMMs, see the population guidelines. See Memory Performance Guidelines and Population Rules.

Before installing DIMMs, see the population guidelines. See Memory Performance Guidelines and Population Rules.

a.![]() Align the new DIMM with the empty socket on the motherboard. Use the alignment key in the DIMM socket to correctly orient the DIMM.

Align the new DIMM with the empty socket on the motherboard. Use the alignment key in the DIMM socket to correctly orient the DIMM.

b.![]() Push down evenly on the top corners of the DIMM until it is fully seated and the ejector levers on both ends lock into place.

Push down evenly on the top corners of the DIMM until it is fully seated and the ejector levers on both ends lock into place.

Step 8![]() Replace the air baffle.

Replace the air baffle.

Step 10![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replacing CPUs and Heatsinks

Special Information For Upgrades to Intel Xeon v4 CPUs

The minimum software and firmware versions required for the server to support Intel v4 CPUs are as follows:

|

|

|

|---|---|

Note![]() Cisco UCS Manager Release 2.2(4) introduced a server pack feature that allows Intel v4 CPUs to run with Cisco UCS Manager Release 2.2(4) or later.

Cisco UCS Manager Release 2.2(4) introduced a server pack feature that allows Intel v4 CPUs to run with Cisco UCS Manager Release 2.2(4) or later.

The UCS Manager Capability Catalog must be updated to 2.2(7c) or later.

The server Cisco IMC/BIOS must be running the minimum version or later as described in Table 3-7.

Do one of the following actions:

- If your server’s firmware and/or Cisco UCS Manager software are already at the required levels shown in Table 3-7 , you can replace the CPU hardware by using the procedure in this section.

- If your server’s firmware and/or Cisco UCS Manager software is earlier than the required levels, use the instructions in the Cisco UCS C-Series Servers Upgrade Guide for Intel Xeon v4 CPUs to upgrade your software. After you upgrade the software, return to the procedure in this section as directed to replace the CPU hardware.

CPU Configuration Rules

This server has two CPU sockets. Each CPU supports four DIMM channels (12 DIMM sockets). See Figure 3-16.

- The server can operate with one CPU or with two identical CPUs installed.

- The minimum configuration is that the server must have at least CPU1 installed. Install CPU1 first, and then CPU2.

- The following restrictions apply when using a single-CPU configuration:

–![]() The maximum number of DIMMs is 12 (only CPU1 channels A, B, C, and D).

The maximum number of DIMMs is 12 (only CPU1 channels A, B, C, and D).

–![]() PCIe riser 2, which contains PCIe slots 4, 5, and 6 is unavailable.

PCIe riser 2, which contains PCIe slots 4, 5, and 6 is unavailable.

Replacing a CPU and Heatsink

Note![]() This server uses the new independent loading mechanism (ILM) CPU sockets, so no Pick-and-Place tools are required for CPU handling or installation. Always grasp the plastic frame on the CPU when handling.

This server uses the new independent loading mechanism (ILM) CPU sockets, so no Pick-and-Place tools are required for CPU handling or installation. Always grasp the plastic frame on the CPU when handling.

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove the plastic air baffle that sits over the CPUs.

Remove the plastic air baffle that sits over the CPUs.

Step 5![]() Remove the heatsink that you are replacing:

Remove the heatsink that you are replacing:

a.![]() Use a Number 2 Phillips-head screwdriver to loosen the four captive screws that secure the heatsink.

Use a Number 2 Phillips-head screwdriver to loosen the four captive screws that secure the heatsink.

Note![]() Alternate loosening each screw evenly to avoid damaging the heatsink or CPU.

Alternate loosening each screw evenly to avoid damaging the heatsink or CPU.

b.![]() Lift the heatsink off of the CPU.

Lift the heatsink off of the CPU.

Step 6![]() Open the CPU retaining mechanism:

Open the CPU retaining mechanism:

a.![]() Unclip the first retaining latch labeled with the

Unclip the first retaining latch labeled with the  icon, and then unclip the second retaining latch labeled with the

icon, and then unclip the second retaining latch labeled with the  icon. See Figure 3-17.

icon. See Figure 3-17.

b.![]() Open the hinged CPU cover plate.

Open the hinged CPU cover plate.

|

|

|

||

|

|

|

||

|

|

|

Step 7![]() Remove any existing CPU:

Remove any existing CPU:

a.![]() With the latches and hinged CPU cover plate open, swing the CPU in its hinged seat up to the open position, as shown in Figure 3-17.

With the latches and hinged CPU cover plate open, swing the CPU in its hinged seat up to the open position, as shown in Figure 3-17.

b.![]() Grasp the CPU by the finger-grips on its plastic frame and lift it up and out of the hinged CPU seat.

Grasp the CPU by the finger-grips on its plastic frame and lift it up and out of the hinged CPU seat.

c.![]() Set the CPU aside on an antistatic surface.

Set the CPU aside on an antistatic surface.

a.![]() Grasp the new CPU by the finger-grips on its plastic frame and align the tab on the frame that is labeled “ALIGN” with the hinged seat, as shown in Figure 3-18.

Grasp the new CPU by the finger-grips on its plastic frame and align the tab on the frame that is labeled “ALIGN” with the hinged seat, as shown in Figure 3-18.

b.![]() Insert the tab on the CPU frame into the seat until it stops and is held firmly.

Insert the tab on the CPU frame into the seat until it stops and is held firmly.

The line below the word “ALIGN” should be level with the edge of the seat, as shown in Figure 3-18.

c.![]() Swing the hinged seat with the CPU down until the CPU frame clicks in place and holds flat in the socket.

Swing the hinged seat with the CPU down until the CPU frame clicks in place and holds flat in the socket.

d.![]() Close the hinged CPU cover plate.

Close the hinged CPU cover plate.

e.![]() Clip down the CPU retaining latch with the

Clip down the CPU retaining latch with the  icon, and then clip down the CPU retaining latch with the

icon, and then clip down the CPU retaining latch with the  icon. See Figure 3-17.

icon. See Figure 3-17.

Figure 3-18 CPU and Socket Alignment Features

|

|

|

a.![]() Apply the cleaning solution, which is included with the heatsink cleaning kit (UCSX-HSCK=, shipped with spare CPUs), to the old thermal grease on the heatsink and CPU and let it soak for a least 15 seconds.

Apply the cleaning solution, which is included with the heatsink cleaning kit (UCSX-HSCK=, shipped with spare CPUs), to the old thermal grease on the heatsink and CPU and let it soak for a least 15 seconds.

b.![]() Wipe all of the old thermal grease off the old heat sink and CPU using the soft cloth that is included with the heatsink cleaning kit. Be careful to not scratch the heat sink surface.

Wipe all of the old thermal grease off the old heat sink and CPU using the soft cloth that is included with the heatsink cleaning kit. Be careful to not scratch the heat sink surface.

Note![]() New heatsinks come with a pre-applied pad of thermal grease. If you are reusing a heatsink, you must apply thermal grease from a syringe (UCS-CPU-GREASE3=).

New heatsinks come with a pre-applied pad of thermal grease. If you are reusing a heatsink, you must apply thermal grease from a syringe (UCS-CPU-GREASE3=).

c.![]() Align the four heatsink captive screws with the motherboard standoffs, and then use a Number 2 Phillips-head screwdriver to tighten the captive screws evenly.

Align the four heatsink captive screws with the motherboard standoffs, and then use a Number 2 Phillips-head screwdriver to tighten the captive screws evenly.

Note![]() Alternate tightening each screw evenly to avoid damaging the heatsink or CPU.

Alternate tightening each screw evenly to avoid damaging the heatsink or CPU.

Step 10![]() Replace the air baffle.

Replace the air baffle.

Step 11![]() Replace the top cover.

Replace the top cover.

Step 12![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Additional CPU-Related Parts to Order with RMA Replacement Motherboards

When a return material authorization (RMA) of the motherboard or CPU is done on a Cisco UCS C-series server, additional parts might not be included with the CPU or motherboard spare bill of materials (BOM). The TAC engineer might need to add the additional parts to the RMA to help ensure a successful replacement.

Note![]() This server uses the new independent loading mechanism (ILM) CPU sockets, so no Pick-and-Place tools are required for CPU handling or installation. Always grasp the plastic frame on the CPU when handling.

This server uses the new independent loading mechanism (ILM) CPU sockets, so no Pick-and-Place tools are required for CPU handling or installation. Always grasp the plastic frame on the CPU when handling.

–![]() Heat sink cleaning kit (UCSX-HSCK=)

Heat sink cleaning kit (UCSX-HSCK=)

–![]() Thermal grease kit for C240 M4 (UCS-CPU-GREASE3=)

Thermal grease kit for C240 M4 (UCS-CPU-GREASE3=)

–![]() Heat sink cleaning kit (UCSX-HSCK=)

Heat sink cleaning kit (UCSX-HSCK=)

A CPU heatsink cleaning kit is good for up to four CPU and heatsink cleanings. The cleaning kit contains two bottles of solution, one to clean the CPU and heatsink of old thermal interface material and the other to prepare the surface of the heatsink.

New heatsink spares come with a pre-applied pad of thermal grease. It is important to clean the old thermal grease off of the CPU prior to installing the heatsinks. Therefore, when you are ordering new heatsinks, you must order the heatsink cleaning kit.

Replacing a SATA Interposer Board

The server uses a SATA interposer board and cable to connect the embedded RAID (PCH SATA) controller on the motherboard to the drive backplane. See Figure 3-19 for the socket location.

Note![]() The SATA interposer board and embedded RAID can be used only with the SFF, 8-drive backplane version of the server. It does not operate with an expander. You cannot use the embedded RAID controller and a hardware RAID controller card at the same time.

The SATA interposer board and embedded RAID can be used only with the SFF, 8-drive backplane version of the server. It does not operate with an expander. You cannot use the embedded RAID controller and a hardware RAID controller card at the same time.

See Embedded SATA RAID Controller for more information about using the embedded RAID controller and options.

Step 1![]() Power off the server as described in the Shutting Down and Powering Off the Server.

Power off the server as described in the Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove the plastic air baffle that sits over the CPUs to gain access to the interposer cables.

Remove the plastic air baffle that sits over the CPUs to gain access to the interposer cables.

Step 5![]() Remove PCIe riser 1 from the server to provide clearance. See Replacing a PCIe Riser.

Remove PCIe riser 1 from the server to provide clearance. See Replacing a PCIe Riser.

Step 6![]() Remove any existing PCH SATA interposer board:

Remove any existing PCH SATA interposer board:

a.![]() Disconnect both cable connectors from the interposer board.

Disconnect both cable connectors from the interposer board.

b.![]() Lift straight up on the board to remove it from its motherboard socket.

Lift straight up on the board to remove it from its motherboard socket.

Step 7![]() Install a new interposer board and cables:

Install a new interposer board and cables:

Note![]() The required Y-cable and SATA interposer board are bundled as UCSC-IP-PCH-C240M4=.

The required Y-cable and SATA interposer board are bundled as UCSC-IP-PCH-C240M4=.

a.![]() Align the board with the socket, and then gently press down on both top corners to seat it evenly.

Align the board with the socket, and then gently press down on both top corners to seat it evenly.

b.![]() Connect the single mini-SAS HD cable connector to the single connector on the backplane.

Connect the single mini-SAS HD cable connector to the single connector on the backplane.

c.![]() Route the cables through the plastic clips on the chassis wall.

Route the cables through the plastic clips on the chassis wall.

d.![]() Connect PORT A and PORT B cable connectors to their corresponding connectors on the new interposer board.

Connect PORT A and PORT B cable connectors to their corresponding connectors on the new interposer board.

Step 8![]() Replace PCIe riser 1 to the server.

Replace PCIe riser 1 to the server.

Step 9![]() Replace the air baffle.

Replace the air baffle.

Step 10![]() Replace the top cover.

Replace the top cover.

Step 11![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Figure 3-19 SATA Interposer Board Socket Location

|

|

|

Replacing a Cisco Modular RAID Controller Card

The server has an internal, dedicated PCIe slot on the motherboard for a Cisco modular RAID controller card (see Figure 3-20).

- Replacing a Modular RAID Controller Transportable Memory Module (TMM)

- Replacing the Supercap Power Module (RAID Backup Battery)

Note![]() You cannot use a hardware RAID controller card and the embedded RAID controller at the same time. See RAID Controller Considerations for details about RAID support.

You cannot use a hardware RAID controller card and the embedded RAID controller at the same time. See RAID Controller Considerations for details about RAID support.

RAID Card Firmware Compatibility

If the PCIe card that you are installing is a RAID controller card, firmware on the RAID controller must be verified for compatibility with the current Cisco IMC and BIOS versions that are installed on the server. If not compatible, upgrade or downgrade the RAID controller firmware accordingly using the Host Upgrade Utility (HUU) for your firmware release to bring it to a compatible level.

See the HUU guide for your Cisco IMC release for instructions on downloading and using the utility to bring server components to compatible levels: HUU Guides

Replacement Procedure

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove an existing RAID controller card:

Remove an existing RAID controller card:

a.![]() Disconnect the data cable from the card. Depress the tab on the cable connector and pull.

Disconnect the data cable from the card. Depress the tab on the cable connector and pull.

b.![]() Disconnect the supercap power module cable from the transportable memory module (TMM), if present.

Disconnect the supercap power module cable from the transportable memory module (TMM), if present.

c.![]() Lift straight up on the metal bracket that holds the card. The bracket lifts off of two pegs on the chassis wall.

Lift straight up on the metal bracket that holds the card. The bracket lifts off of two pegs on the chassis wall.

d.![]() Loosen the two thumbscrews that hold the card to the metal bracket and then lift the card from the bracket.

Loosen the two thumbscrews that hold the card to the metal bracket and then lift the card from the bracket.

Step 5![]() Install a new RAID controller card:

Install a new RAID controller card:

a.![]() Set the new card on the metal bracket, aligned so that the thumbscrews on the card enter the threaded standoffs on the bracket. Tighten the thumbscrews to secure the card to the bracket.

Set the new card on the metal bracket, aligned so that the thumbscrews on the card enter the threaded standoffs on the bracket. Tighten the thumbscrews to secure the card to the bracket.

b.![]() Align the two slots on the back of the bracket with the two pegs on the chassis wall.

Align the two slots on the back of the bracket with the two pegs on the chassis wall.

The two slots on the bracket must slide down over the pegs at the same time that you push the card into the motherboard socket.

c.![]() Gently press down on both top corners of the metal bracket to seat the card into the socket on the motherboard.

Gently press down on both top corners of the metal bracket to seat the card into the socket on the motherboard.

d.![]() Connect the supercap power module cable to its connector on the TMM, if present.

Connect the supercap power module cable to its connector on the TMM, if present.

e.![]() Connect the single data cable to the card.

Connect the single data cable to the card.

Step 7![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Figure 3-20 Modular RAID Controller Card Location

|

|

|

Replacing a Modular RAID Controller Transportable Memory Module (TMM)

The transportable memory module (TMM) that attaches to the modular RAID controller card can be installed or replaced after-factory.

- Replacing a Cisco Modular RAID Controller Card

- Replacing the Supercap Power Module (RAID Backup Battery)

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove the modular RAID controller card from the server:

Remove the modular RAID controller card from the server:

a.![]() Lift straight up on the metal bracket that holds the card. The bracket lifts off of two pegs on the chassis wall (see Figure 3-20).

Lift straight up on the metal bracket that holds the card. The bracket lifts off of two pegs on the chassis wall (see Figure 3-20).

b.![]() Disconnect the supercap power module cable from the TMM that is attached to the card.

Disconnect the supercap power module cable from the TMM that is attached to the card.

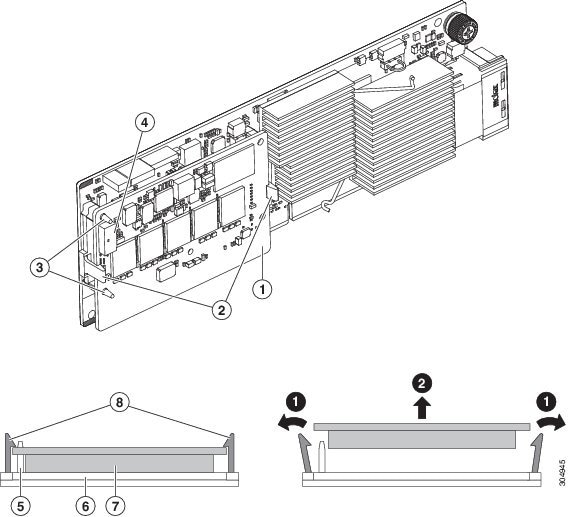

Step 5![]() Remove the TMM from the modular RAID controller card (see Figure 3-21):

Remove the TMM from the modular RAID controller card (see Figure 3-21):

a.![]() The plastic bracket on the card has a securing plastic clip at each end of the TMM. Gently spread each clip away from the TMM.

The plastic bracket on the card has a securing plastic clip at each end of the TMM. Gently spread each clip away from the TMM.

b.![]() Pull straight up on the TMM to lift it off the two plastic guide pegs and the socket on the card.

Pull straight up on the TMM to lift it off the two plastic guide pegs and the socket on the card.

Step 6![]() Install a TMM to the modular RAID controller card (see Figure 3-21):

Install a TMM to the modular RAID controller card (see Figure 3-21):

a.![]() Align the TMM over the bracket on the card. Align the connector on the underside of the TMM with the socket on the card. Align the two guide holes on the TMM over the two guide pegs on the card.

Align the TMM over the bracket on the card. Align the connector on the underside of the TMM with the socket on the card. Align the two guide holes on the TMM over the two guide pegs on the card.

b.![]() Gently lower the TMM so that the guide holes on the TMM go over the guide pegs on the card.

Gently lower the TMM so that the guide holes on the TMM go over the guide pegs on the card.

c.![]() Press down on the TMM until the plastic clips on the bracket close over each end of the TMM.

Press down on the TMM until the plastic clips on the bracket close over each end of the TMM.

d.![]() Press down on the TMM to fully seat its connector with the socket on the card.

Press down on the TMM to fully seat its connector with the socket on the card.

Step 7![]() Install the modular RAID controller card back into the server:

Install the modular RAID controller card back into the server:

Note![]() If this is a first-time installation of your TMM, you must also install a supercap power module (SCPM). The SCPM cable attaches to a connector on the TMM. See Replacing the Supercap Power Module (RAID Backup Battery).

If this is a first-time installation of your TMM, you must also install a supercap power module (SCPM). The SCPM cable attaches to a connector on the TMM. See Replacing the Supercap Power Module (RAID Backup Battery).

a.![]() Connect the cable from the supercap power module (RAID battery) to the connector on the TMM (see Figure 3-21).

Connect the cable from the supercap power module (RAID battery) to the connector on the TMM (see Figure 3-21).

b.![]() Align the two slots on the back of the RAID card bracket with the two pegs on the chassis wall.

Align the two slots on the back of the RAID card bracket with the two pegs on the chassis wall.

The two slots on the bracket must slide down over the pegs at the same time that you push the card into the motherboard socket.

c.![]() Gently press down on both top corners of the metal bracket to seat the card into the socket on the motherboard.

Gently press down on both top corners of the metal bracket to seat the card into the socket on the motherboard.

Figure 3-21 TMM on Modular RAID Controller Card

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

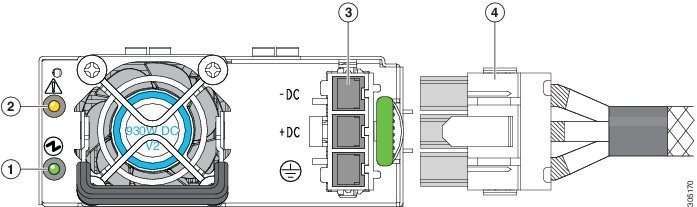

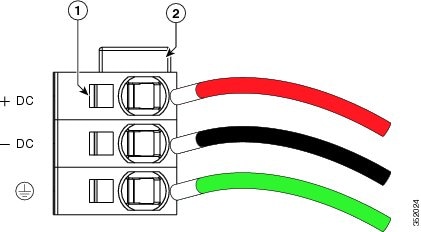

Replacing the Supercap Power Module (RAID Backup Battery)

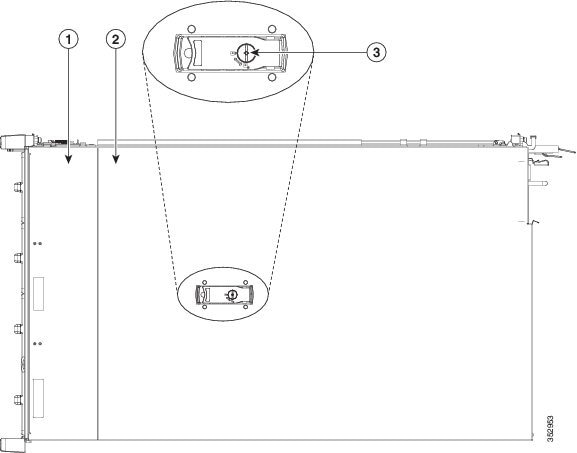

This server supports installation of one supercap power module (SCPM). The unit mounts to a clip on the removable air baffle (see Figure 3-22). The SCPM requires that you have a transportable memory module (TMM) attached to your RAID controller card because the connector for the SCPM cable is on the TMM.

- Replacing a Cisco Modular RAID Controller Card

- Replacing a Modular RAID Controller Transportable Memory Module (TMM)

The SCPM provides approximately three years of backup for the disk write-back cache DRAM in the case of a sudden power loss by offloading the cache to the NAND flash.

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove an existing SCPM:

Remove an existing SCPM:

a.![]() Disconnect the existing SCPM cable from the transportable memory module (TMM) that is attached to the modular RAID controller card.

Disconnect the existing SCPM cable from the transportable memory module (TMM) that is attached to the modular RAID controller card.

b.![]() Pull back the plastic clip that closes over the SCPM slightly, and then slide the SCPM free of the clips on the air baffle mounting point (see Figure 3-22).

Pull back the plastic clip that closes over the SCPM slightly, and then slide the SCPM free of the clips on the air baffle mounting point (see Figure 3-22).

a.![]() Slide the new backup unit into the holder on the air baffle mounting point until the clip clicks over the top edge of the SCPM.

Slide the new backup unit into the holder on the air baffle mounting point until the clip clicks over the top edge of the SCPM.

b.![]() Connect the cable from the SCPM to the TMM that is attached to the modular RAID controller card.

Connect the cable from the SCPM to the TMM that is attached to the modular RAID controller card.

Note![]() Put the cable through the opening on the rear of the air baffle (rather than over the air baffle) to keep the cable from interfering with the top cover of the server.

Put the cable through the opening on the rear of the air baffle (rather than over the air baffle) to keep the cable from interfering with the top cover of the server.

Step 7![]() Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Replace the server in the rack, replace cables, and then power on the server by pressing the Power button.

Figure 3-22 SCPM (RAID Backup Unit) Mounting Point and Cable Path

|

|

SCPM mounting point on removable air baffle (air baffle not shown) |

|

Replacing a Software RAID 5 Key Module

The server has a two-pin header on the motherboard for a RAID 5 key module. This module upgrades the embedded SATA RAID controller options (see Embedded SATA RAID Controller).

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.

Step 2![]() Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Slide the server out the front of the rack far enough so that you can remove the top cover. You might have to detach cables from the rear panel to provide clearance.

Step 3![]() Remove the top cover as described in Removing and Replacing the Server Top Cover.

Remove the top cover as described in Removing and Replacing the Server Top Cover.

Step 4![]() Remove any existing software RAID key module:

Remove any existing software RAID key module:

a.![]() Locate the module on the motherboard (see Figure 3-23).

Locate the module on the motherboard (see Figure 3-23).

b.![]() Hold the retention clips on the header open while you grasp the RAID key board and pull straight up (see Figure 3-24).

Hold the retention clips on the header open while you grasp the RAID key board and pull straight up (see Figure 3-24).

Figure 3-23 RAID 5 Key Header Location on Motherboard

|

|

|

Step 5![]() Install a new software RAID key module:

Install a new software RAID key module:

a.![]() Align the module with the pins in the motherboard header.

Align the module with the pins in the motherboard header.

b.![]() Gently press down on the module until it is seated and the retention clip locks over the module (see Figure 3-24).

Gently press down on the module until it is seated and the retention clip locks over the module (see Figure 3-24).

Figure 3-24 Software RAID 5 Key Module Retention Clip

|

|

|

||

|

|

|

Replacing the Motherboard RTC Battery

Warning![]() There is danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions. [Statement 1015]

There is danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions. [Statement 1015]

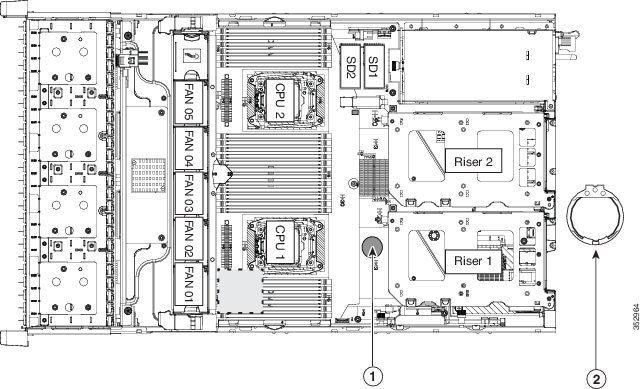

The real-time clock (RTC) battery retains system settings when the server is disconnected from power. The battery type is CR2032. Cisco supports the industry-standard CR2032 battery, which can be purchased from most electronic stores.

Step 1![]() Power off the server as described in Shutting Down and Powering Off the Server.

Power off the server as described in Shutting Down and Powering Off the Server.