Preparing for Installation

Before you install a Cisco Catalyst IE9300 Rugged Series Switch, you must read, understand, and observe the warnings and guidelines in this section. You also must verify the switch package contents, gather the required tools and equipment, and verify the switch operations.

Warnings

These warnings are translated into several languages in the Regulatory Compliance and Safety Information for Cisco Catalyst IE9300 Rugged Series Switch. They apply to all the switch models.

Warning |

Statement 1074—Comply with Local and National Electrical Codes To reduce risk of electric shock or fire, installation of the equipment must comply with local and national electrical codes. |

Warning |

Statement 1017—Restricted Area This unit is intended for installation in restricted access areas. Only skilled, instructed, or qualified personnel can access a restricted access area. |

Warning |

Statement 1024—Ground Conductor This equipment must be grounded. To reduce the risk of electric shock, never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. |

Warning |

Statement 1028—More Than One Power Supply This unit might have more than one power supply connection. To reduce risk of electric shock, remove all connections to de-energize the unit.  |

Warning |

Statement 9001—Product Disposal Ultimate disposal of this product should be handled according to all national laws and regulations. |

Installation Guidelines

Before installing the Cisco Catalyst IE9300 Rugged Series Switch, be sure to meet the following guidelines:

-

Ensure that cabling is away from sources of electrical noise, such as radios, power lines, and fluorescent lighting fixtures. Also ensure that the cabling is away from other devices that might damage the cables.

-

Ensure that the operating environment is within the ranges that are listed in Technical Specifications.

-

Ensure that relative humidity around the switch does not exceed 95 percent (noncondensing).

-

Ensure that the altitude at the installation site is no higher than 15,000 feet (4572 m).

-

For 10/100/1000 fixed ports, ensure that cable lengths from the switch to connected devices are not more than 328 feet (100 meters).

-

For more information about SFP/SFP+ modules and cables, see Transceiver Modules.

-

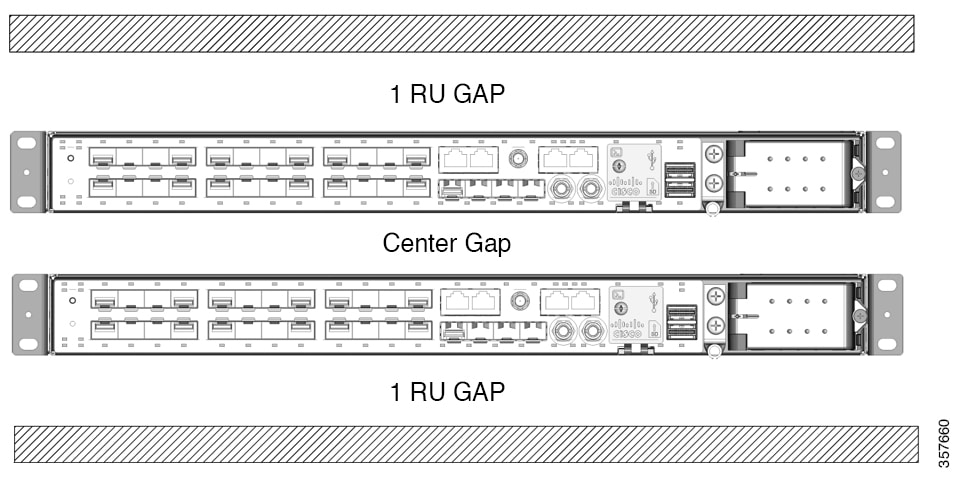

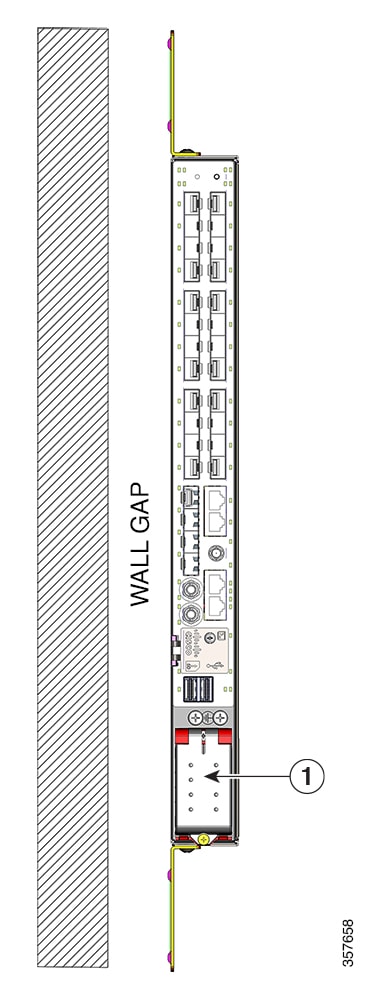

Ensure that airflow around the switch and through the vents is unrestricted. To prevent overheating, the switch must meet the minimum clearance of 1.75 in. (4.4 cm) at the top, bottom, and sides.

Note

If the switch is installed in a closed or multirack assembly, the temperature around it might be greater than normal room temperature. Ensure that the internal temperature does not exceed the maximum ambient temperature specifications for the switch.

Required Tools and Equipment

Obtain the necessary tools and equipment:

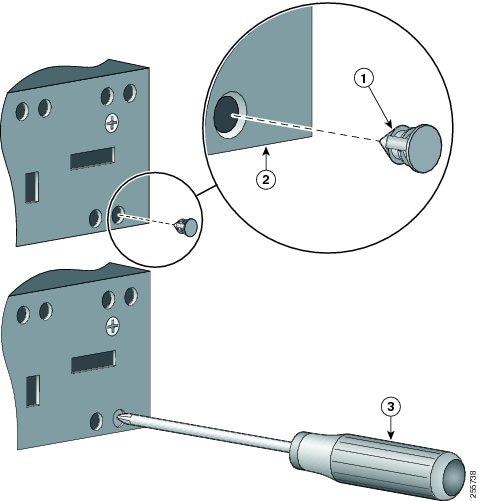

-

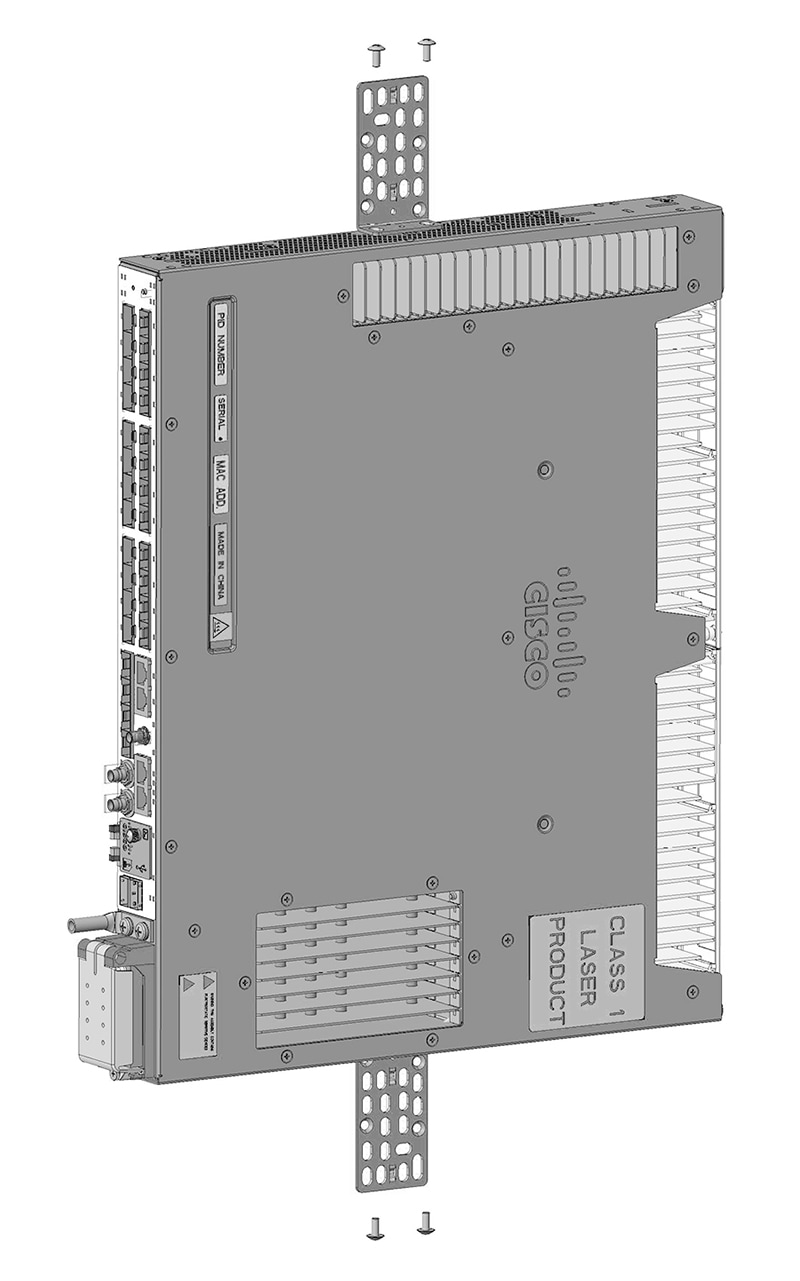

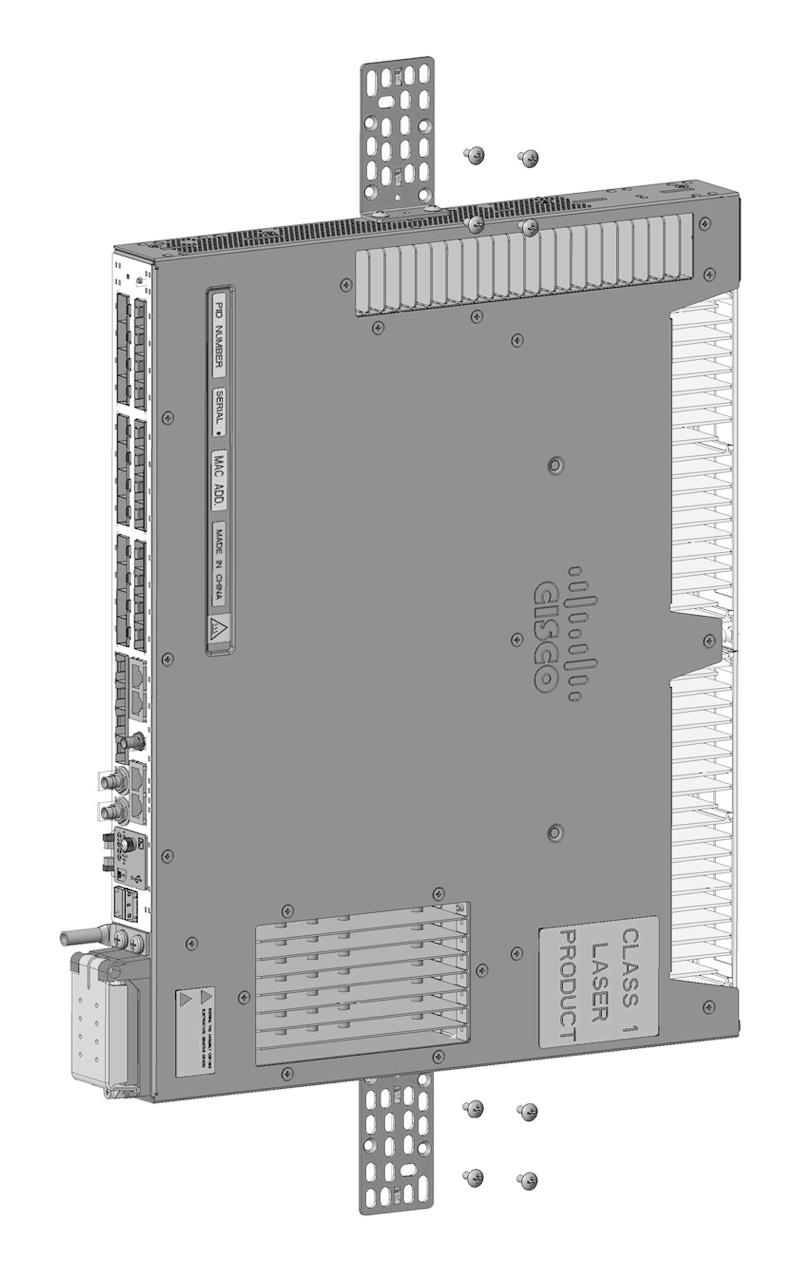

Phillips screwdriver

Verifying the Package Contents

The shipping box contains the model of the switch you ordered and other components that you need for installation. Some components are optional, depending on your order.

Note |

Verify that you have received these items. If any item is missing or damaged, contact your Cisco representative or reseller for instructions. |

Verifying the Switch Operation

Before installing the switch in a rack or on a wall, you should power the switch and verify that the switch passes the power-on self-test (POST).

To wire the switch to the power source, see Power-Supply Module Installation.

When the switch begins POST, the SYS LED blinks green, and the other LEDs stay green. When the switch passes POST, the SYS LED turns green. The other LEDs turn off and return to their operating status. If the switch fails POST, the SYS LED is red.

Note |

Contact Cisco Systems immediately if your switch fails POST. |

After a successful POST, disconnect the power from the switch. For more information, see Wiring the Power Source. See the Installing the Switch to install the switch in a rack or on a wall.

Feedback

Feedback