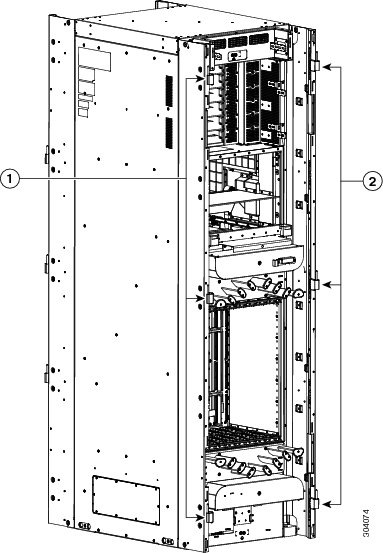

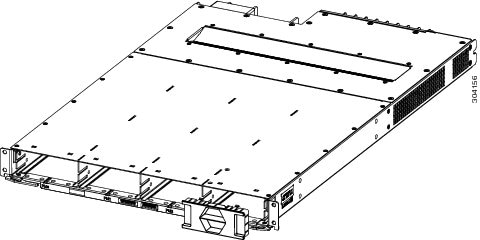

Removing the Exterior Cosmetics

This section describes how to remove the front-side and rear side exterior cosmetics on the Cisco NCS 6008 LCC. We recommend that you remove the cosmetics in the order outlined in this section.

Prerequisites

Ensure that you have all the original packaging material for the cosmetic components available.

Required Tools and Equipment

8-inch, number-1 Phillips screwdriver (magnetic head preferable)

Removing the Front Exterior Cosmetics

Steps

To remove the front exterior cosmetics, perform the following steps:

Procedure

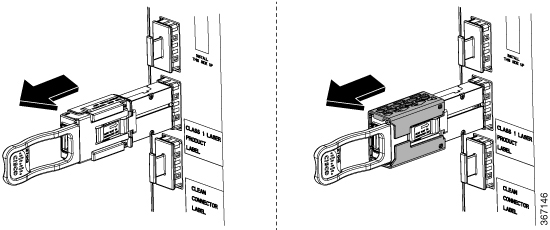

| Step 1 |

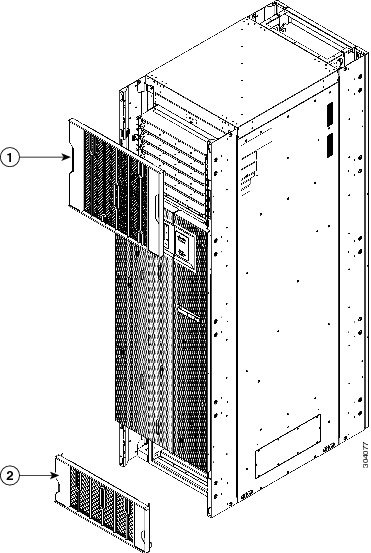

Remove the top and bottom front grilles by unsnapping them from the snap joiners on the LCC.

|

||||||

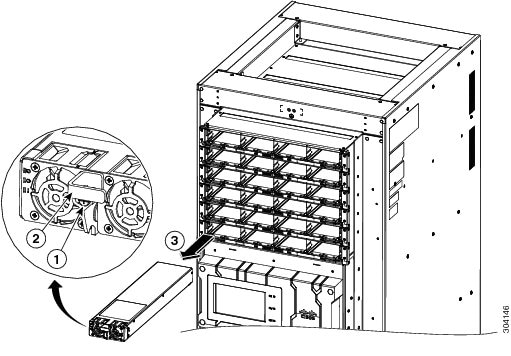

| Step 2 |

Remove the front doors. |

||||||

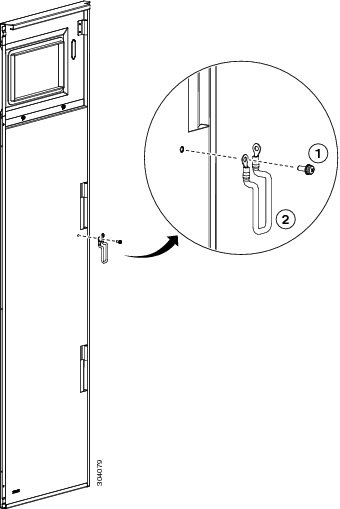

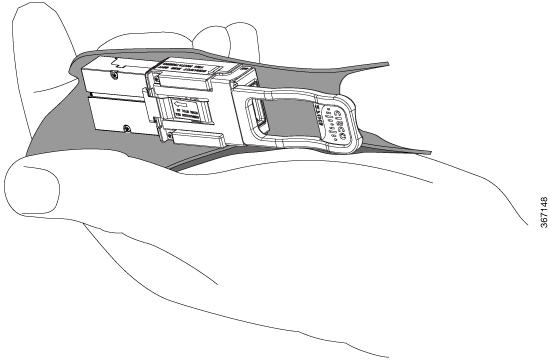

| Step 3 |

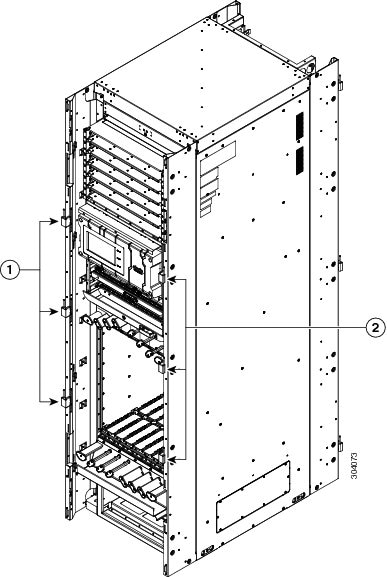

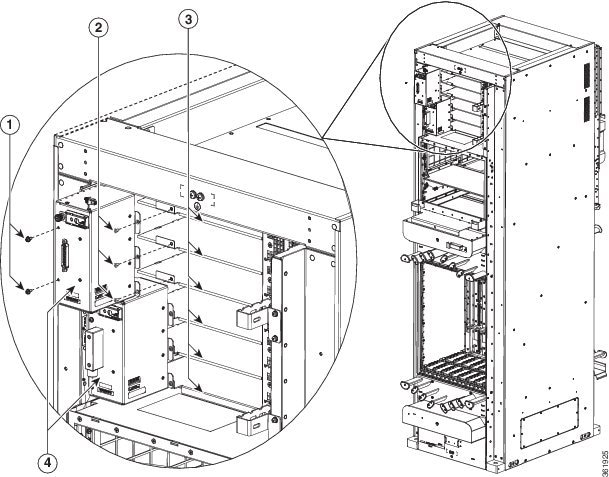

Remove the door hinge attachments, three left and three right, by removing two pan-head screws each (See below figure).

|

||||||

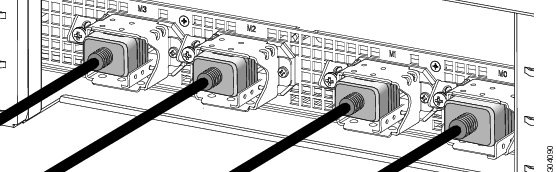

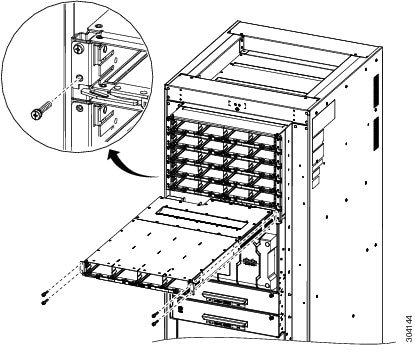

| Step 4 |

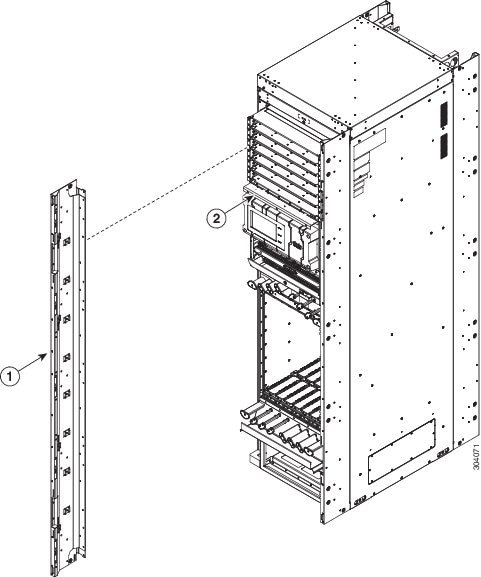

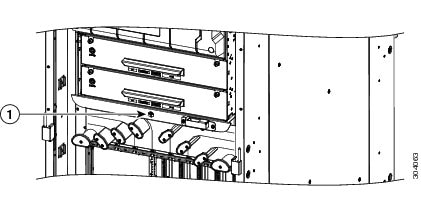

Remove the left and right vertical cable troughs from the front of the LCC (See figure below)) by using the screwdriver to loosen the pan-head screws counterclockwise and remove them from the cable troughs.

|

||||||

| Step 5 |

If necessary, remove the craft panel located on the front of the LCC (see above figure). Usually it is not necessary to remove this panel. The craft panel (Cisco PID NCS-CRFT=) is a field replaceable unit.

|

Removing the Rear Exterior Cosmetics

Note |

While it is possible to remove most of the rear cosmetic parts on the fabric chassis separately, some parts (such as a vertical cable trough) require that other parts be removed first. |

Steps

To remove the rear cosmetics, perform the following steps:

Procedure

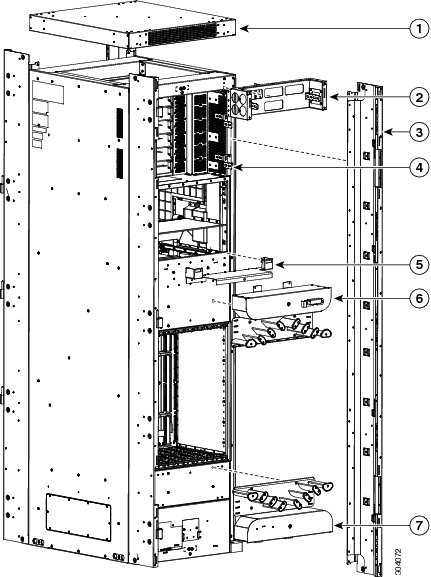

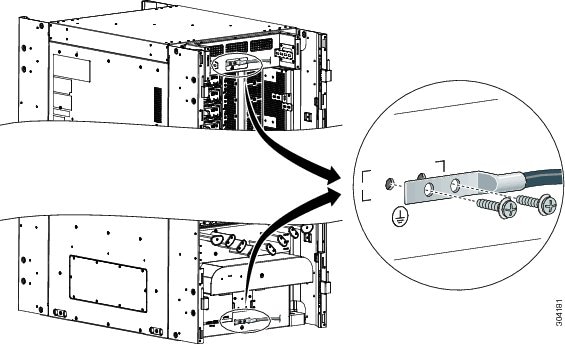

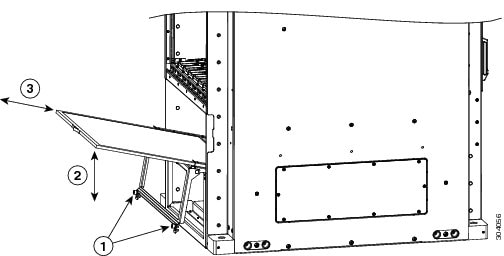

| Step 1 |

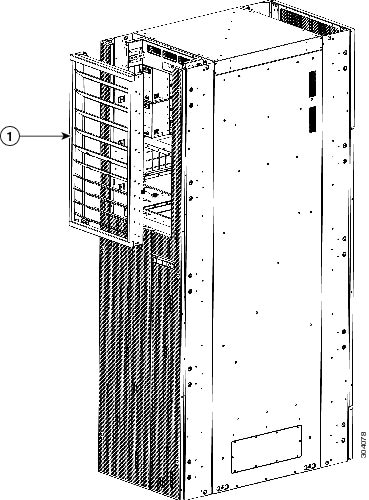

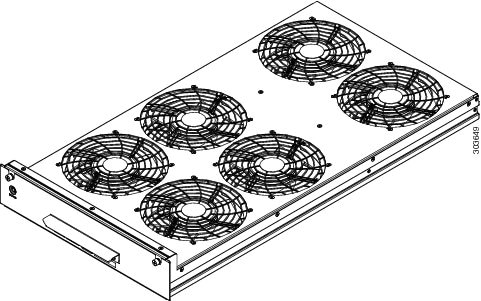

Remove the exhaust air deflector by carefully pulling its mounting tabs away from the brackets on the vertical cable troughs.

|

||||||||

| Step 2 |

Remove the Rear Doors |

||||||||

| Step 3 |

Remove the door hinge attachments, three left and three right, by removing the two pan-head screws each.

|

||||||||

| Step 4 |

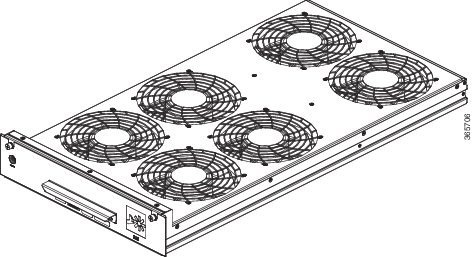

Remove the exhaust plenum bracket by removing the eight pan-head screws (four on each side).

|

||||||||

| Step 5 |

Remove the top cap from the top of the LCC by removing the four screws from the tops of the vertical cable troughs. |

||||||||

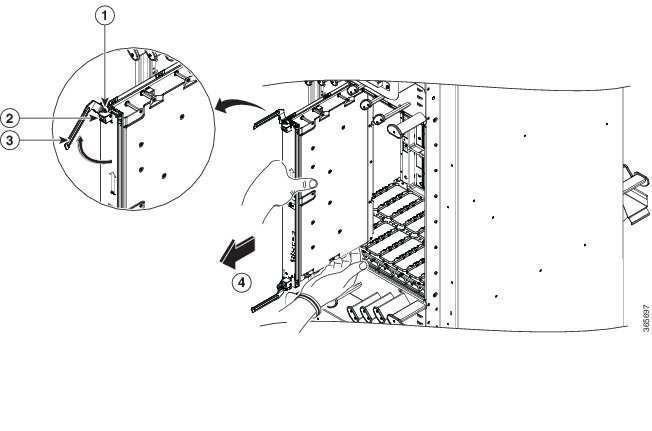

| Step 6 |

Remove the left and right vertical cable troughs by using the screwdriver to loosen the 16 pan-head screws counterclockwise and remove them from the cable troughs.

|

Feedback

Feedback