About Installing Cards and Associated Components

Preventing Electrostatic Discharge

Electrostatic discharge (ESD) damage, which can occur when electronic cards or components are improperly handled, results in complete or intermittent failures. We recommend use of an ESD-preventive wrist strap whenever you handle network equipment or one of its components.

-

Always use an ESD-preventive wrist or ankle strap, and ensure that it makes good skin contact. Connect the equipment end of the connection cord to an ESD jack ( Figure 2-4 ) or a bare metal surface on the chassis (ensure that the chassis is grounded).

-

Handle a card by its ejector levers, when applicable, or its metal carrier only; avoid touching the board or connector pins (see the Guidelines for Installing and Removing a Card section).

-

Place a removed card board-side-up on an antistatic surface or in a static-shielding bag. If you plan to return the component to the factory, immediately place it in a static-shielding bag.

-

Avoid contact between a card and clothing. The wrist strap protects the board from only ESD voltage on the body; ESD voltage on clothing can still cause damage.

-

Be careful not to lay any tools on the aluminum honeycomb panel, or insert your fingers into the panel.

Guidelines for Installing and Removing a Card

-

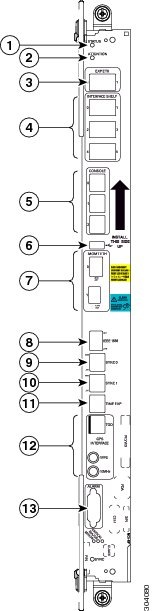

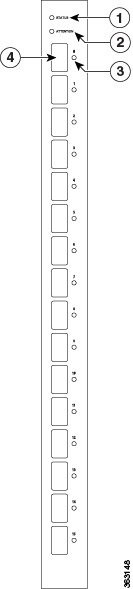

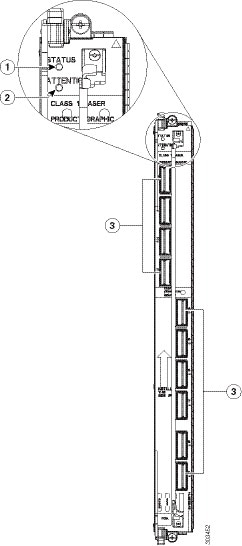

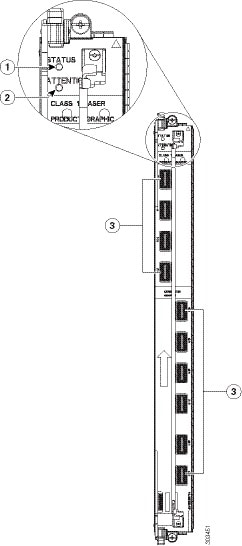

Every card has a label with an arrow on its faceplate showing which side is up for installation.

-

The card connector of every FC, LC, and RP card is keyed to ensure that the card is installed correctly in the slot.

Note

RP card faceplates and the RP card slots on the LCC are labeled with the square symbol. FC faceplates and the FC slots on the LCC are labeled with the circle symbol.

-

Online insertion and removal (OIR) is supported enabling you to install a card while the LCC is operating. OIR removes power to a specific slot before the card is replaced. The power remains on for all other card slots.

OIR is seamless to users on the network, maintains all routing information, and ensures session preservation. We recommend that you perform a graceful shutdown to shut down an FC, LC, or RP card prior to removing it from the LCC. See the Steps for OIR Card Removal section.

Note

Graceful shutdown is critical to prevent file system corruption on the SSD in the RP or LC.

-

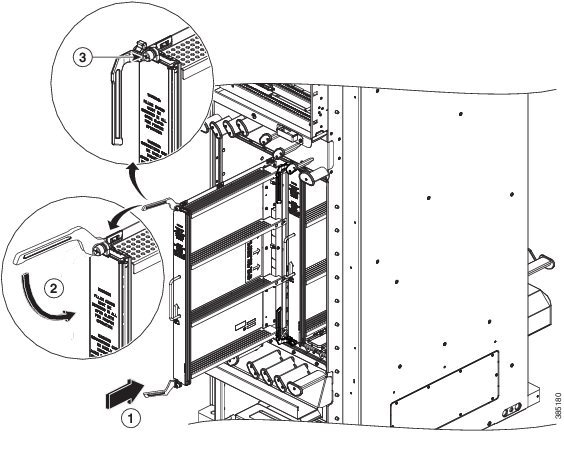

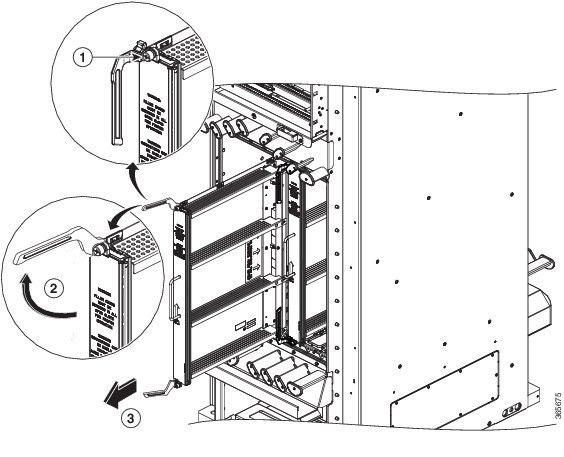

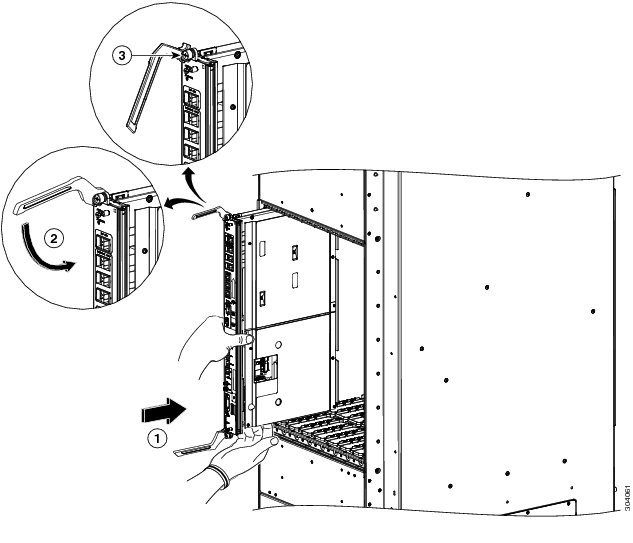

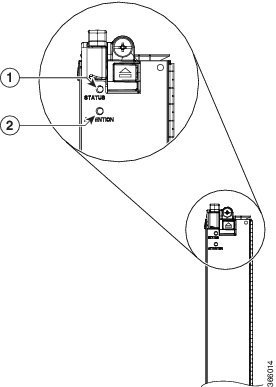

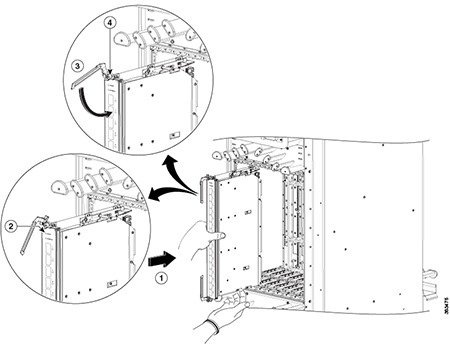

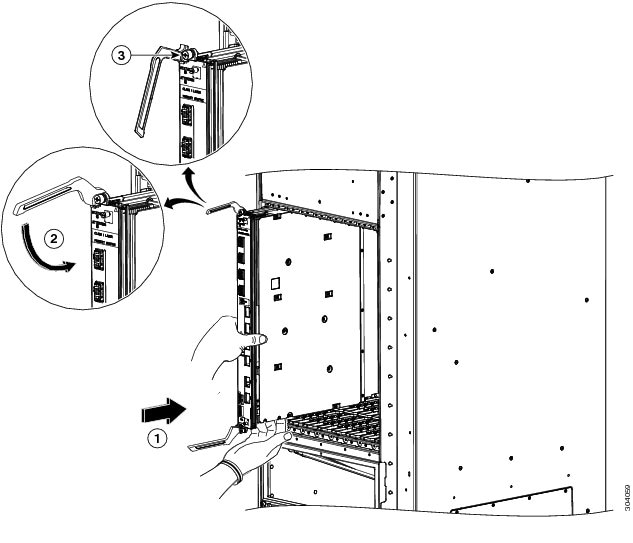

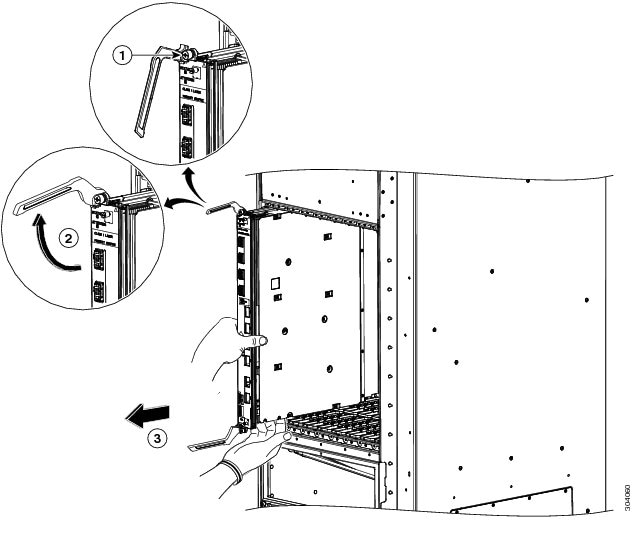

Prior to installing a fabric card, you must push the OIR button on both the upper and lower ejectors to release the mechanical latches.

-

The ejector levers and captive screws on the cards secure the cards to the LCC and ensure proper electrical connection. The ejector levers and captive screws are located at the upper and bottom ends of the faceplate.

-

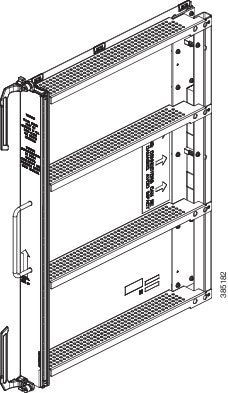

The chassis is shipped with all card slots containing either impedance carriers or a plastic cover to help maintain chassis stiffness and prevent any damage to the chassis during shipment.

Note |

The NC6-LC-BLANK impedance carrier is no longer supported. Replace the NC6-LC-BLANK with the NC6-LC-BLANK2 impedance carrier (front of the LCC) when installing new FCs or performing OIR on existing FCs (rear of the LCC). |

-

All unused card slots must be covered to ensure proper air circulation and cooling within the chassis. Install NC6-LC-BLANK2 impedance carriers in all slots that are not being used. This ensures proper air flow and maintains system EMC and safety compliance. See the Installing an Impedance Carrier section.

-

Install LCs and NC6-LC-BLANK2 impedance carriers (front of the LCC) before installing the FCs and RP cards (rear of the LCC).

-

Fully insert all FCs and RP cards into the chassis before tightening their captive screws.

-

For information about the slot numbers, see the section.

Caution |

The chassis may indicate a hardware failure if you do not follow proper procedures. Remove or install only one card at a time. Allow at least 15 seconds for the chassis to complete its tasks before removing or installing another card. |

Steps for OIR Card Removal

Follow these steps to perform a graceful OIR on the FC, LC, or RP card.

Procedure

| Step 1 |

If you are removing an FC, shut down the fabric plane X (where X is in the range of 0 to 5). If you are removing an LC or RP, go to Step 2. Example: |

| Step 2 |

Shut down the FC, LC, or RP card location rack /slot (where rack is the rack number in the range of 0 to 15 and F0 to F3, and slot is the slot in the range of 0 to 7 for an LC, FC0 to FC5 for an FC, and RP0 to RP1 for an RP). Confirm the shutdown. Example: |

| Step 3 |

Before you remove the card, use the show platform command to verify that it is powered off. Do not remove the card until the output of the show platform command indicates that the card has been powered off. Example: |

| Step 4 |

Remove the card using the appropriate procedure: |

| Step 5 |

Reinstall the card using the appropriate procedure: |

| Step 6 |

Use the show platform command to verify that the card is operational . Example: |

| Step 7 |

If you are installing a fabric card, unshut the fabric plane X . Example: |

About Cable Management Brackets

The Cisco NCS 6008 LCC has cable management features for both the front and rear sides of the chassis. These features organize the interface cables entering and exiting the different cards, keeping them out of the way and free of sharp bends that may damage the cables.

-

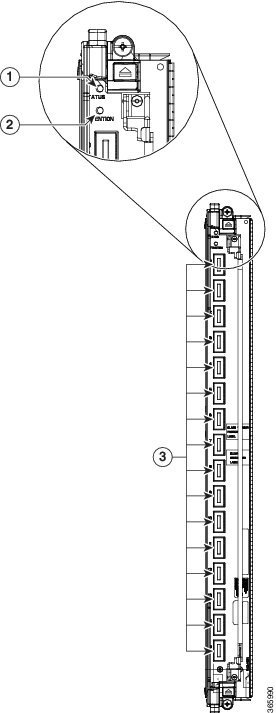

The front and rear sides have horizontal cable management brackets above and below the card cages (see Front View of the Cisco NCS 6008 LCC and Rear View of the Cisco NCS 6008 LCC).

-

The front and rear sides have vertical cable troughs on the left and right of the chassis.

-

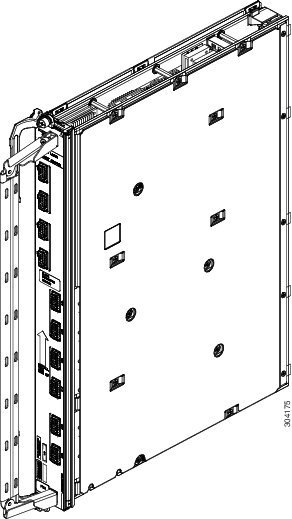

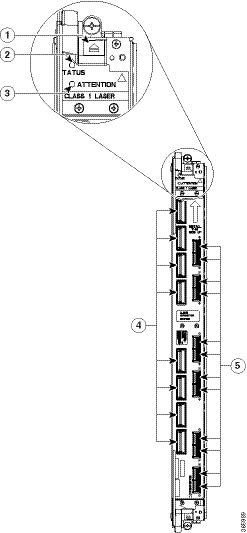

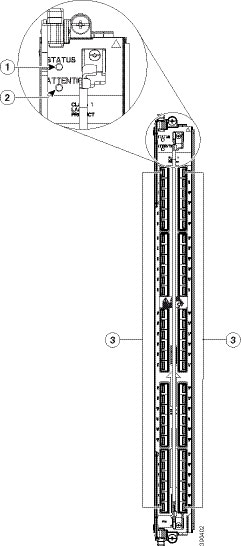

A vertical cable management bracket is preattached to the faceplate of a LC, FC, and RP card (see figure below).

Feedback

Feedback