Chassis Overview

The Cisco NCS 6008 LCC is a single-chassis system that provides 8 Tbps of full-duplex network bandwidth through eight line cards. Each card delivers up to 1 Tbps throughput using a mix of 10-Gbps or 100-Gbps interfaces per card. The Cisco NCS 6008 LCC also provides modular optics options to meet a wide range of distance requirements. In a back-to-back configuration, the LCC can be expanded to support up to 16 Tbps of full-duplex forwarding throughput. In a multi-chassis configuration, the LCC can be expanded to support up to 128 Tbps of full-duplex forwarding throughput.

The Cisco NCS 6008 LCC is a highly scalable routing system with redundancy and reliability features that allow for nonstop operation even during service upgrades of equipment, with no single points of failure in hardware or software. The routing system has the potential to expand from a single-chassis to a back-to-back or multi-chassis configuration for even greater routing capacity. For information about setting up a back-to-back and multi-chassis configurations, refer to the Cisco Network Convergence System 6000 Series Routers Migration Guide.

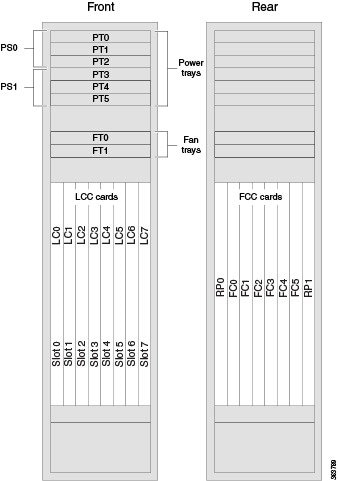

The LCC contains a chassis midplane and packet interfaces on line cards cross-connected to each other through a switch fabric. The chassis has eight slots at the front for Line Cards (LCs), two slots at the rear for Route Processor (RP) cards, and six slots at the rear for Fabric Cards (FCs).

The LCC has an integrated rack and does not require an external rack. It is bolted to the facility floor. It contains its own power and cooling systems. Power systems are available using AC or DC power.

Note |

The installation of a Cisco NCS 6008 LCC may require space, floor loading, power, and cooling modifications to a facility. Therefore, you should plan the site well in advance of the scheduled delivery of the chassis system. For site preparation information, see the Cisco Network Convergence System 6000 Series Routers Site Planning Guide. |

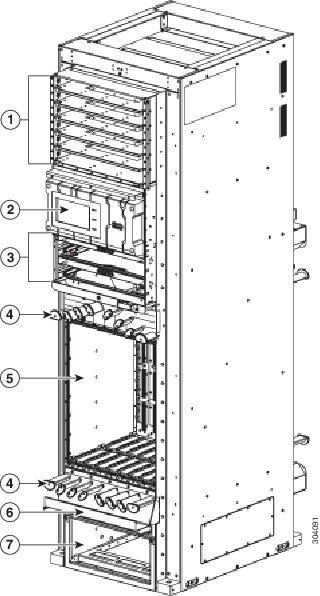

The following figure shows the front view of the Cisco NCS 6008 LCC.

|

1 |

Six power trays |

5 |

One card cage with eight LC slots |

|

2 |

Craft panel display |

6 |

Air filter access |

|

3 |

Two fan trays |

7 |

Air inlet plenum |

|

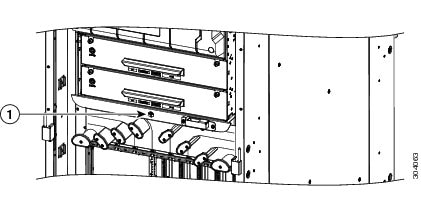

4 |

Cable management brackets |

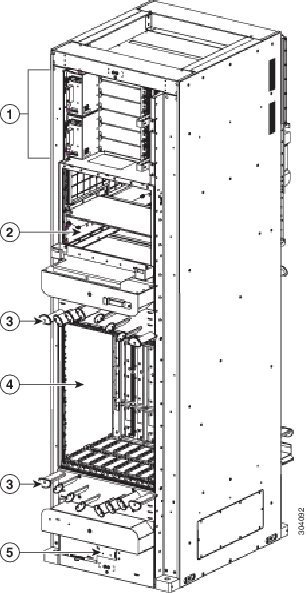

The following figure shows the rear view of the Cisco NCS 6008 LCC.

|

1 |

Power input feeds (AC or DC) |

4 |

One card cage with slots for FCs and RP cards |

|

2 |

Air exhaust plenum |

5 |

Temperature sensor |

|

3 |

Cable management bracket |

Feedback

Feedback