Safety Guidelines

Before you perform any procedure in this document, review the safety guidelines in this section to avoid injuring yourself or damaging the equipment. The following guidelines are for your safety and to protect the equipment. Because the guidelines do not include all hazards, be constantly alert.

-

Keep the work area clear, smoke and dust-free during and after installation. Do not allow dirt or debris to enter into any laser-based components.

-

Do not wear loose clothing, jewelry, or other items that could get caught in the router or other associated components.

-

Cisco equipment operates safely when used in accordance with its specifications and product-usage instructions.

-

Be sure to power down a fixed configuration PDU or modular configuration power shelf before removing it from the chassis.

-

If potentially hazardous conditions exist, do not work alone.

-

Take care when connecting multiple units to the supply circuit so that wiring is not overloaded.

-

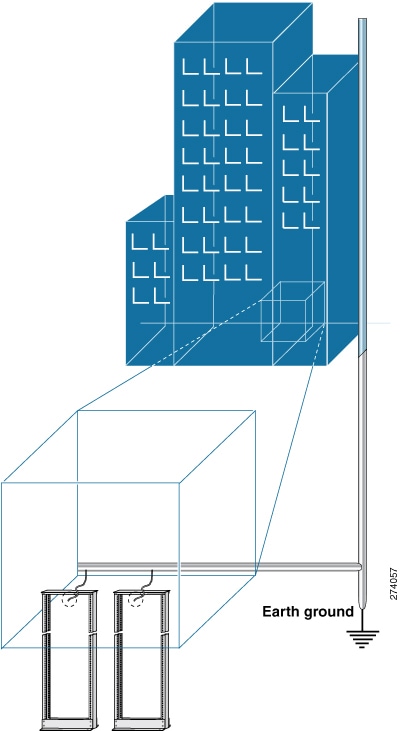

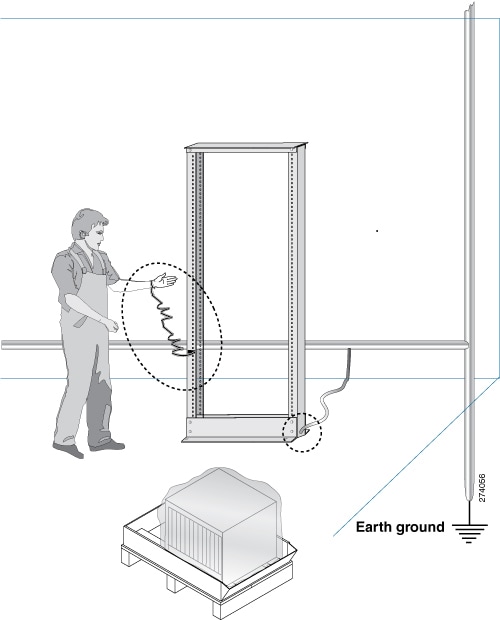

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain about whether suitable grounding is available.

-

When installing or replacing the unit, the ground connection must always be made first and disconnected last.

-

To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the handles on modules (such as power supplies, fans, or cards); these types of handles are not designed to support the weight of the unit.

-

Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing.

-

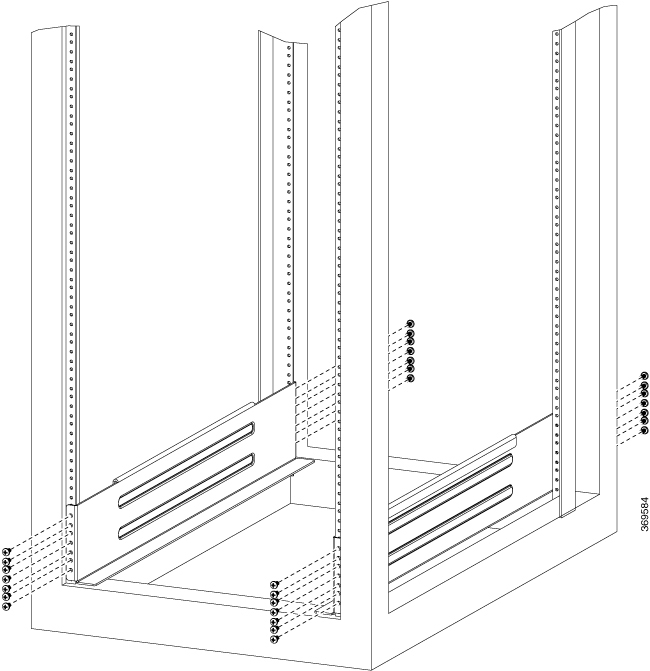

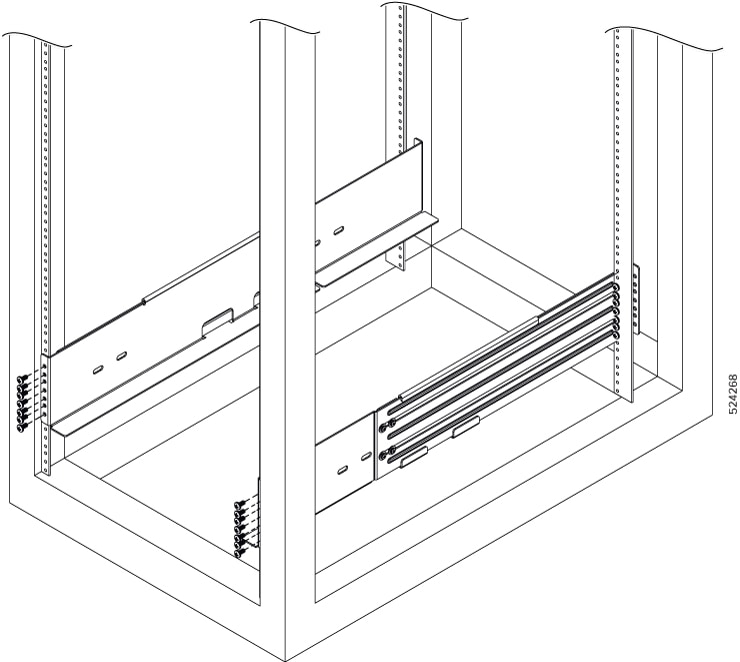

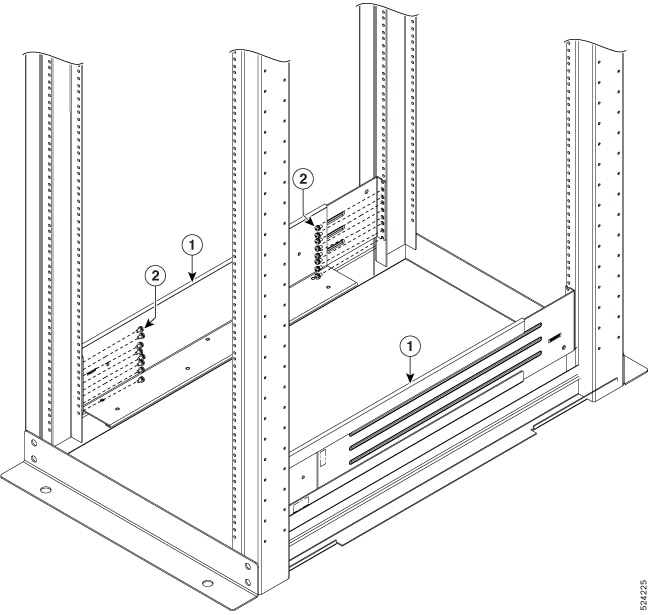

The rack stabilizing mechanism must be in place, or the rack must be bolted to the floor before you slide out the unit for servicing. Failure to stabilize the rack may cause the rack to tip over.

Feedback

Feedback