Standard Warning Statements

This section describes the warning definition and then lists core safety warnings grouped by topic.

General Safety Warnings

Note |

Statement 1089—Instructed and Skilled Person Definitions An instructed person is someone who has been instructed and trained by a skilled person and takes the necessary precautions when working with equipment. A skilled person or qualified personnel is someone who has training or experience in the equipment technology and understands potential hazards when working with equipment. |

Warning |

Statement 9001—Product Disposal Ultimate disposal of this product should be handled according to all national laws and regulations. |

Warning |

Statement 1073—No User-Serviceable Parts There are no serviceable parts inside. To avoid risk of electric shock, do not open. |

Warning |

Statement 1074—Comply with Local and National Electrical Codes To reduce risk of electric shock or fire, installation of the equipment must comply with local and national electrical codes. |

Note |

Statement 407—Japanese Safety Instruction You are strongly advised to read the safety instruction before using the product. https://www.cisco.com/web/JP/techdoc/pldoc/pldoc.html When installing the product, use the provided or designated connection cables/power cables/AC adapters. 〈製品使用における安全上の注意〉 www.cisco.com/web/JP/techdoc/index.html 接続ケーブル、電源コードセット、ACアダプタ、バッテリなどの部品は、必ず添付品または 指定品をご使用ください。添付品・指定品以外をご使用になると故障や動作不良、火災の 原因となります。また、電源コードセットは弊社が指定する製品以外の電気機器には使用 できないためご注意ください。 |

Note |

Statement 438—Taiwan RoHS Restricted Substances Content Disclosure Table web address: http://www.cisco.com/go/taiwanrohs |

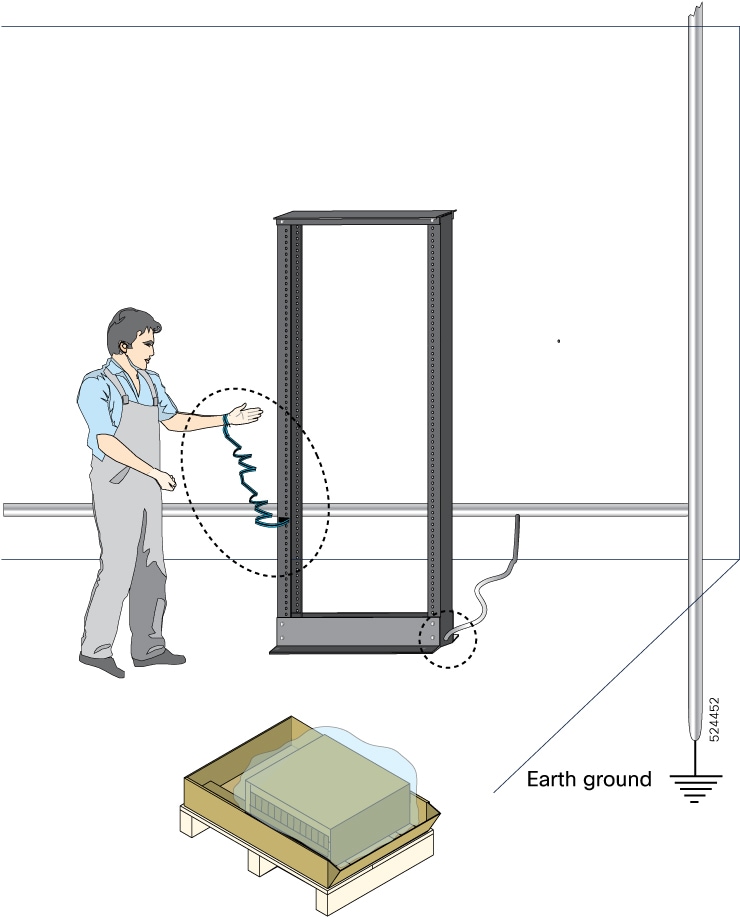

Warning |

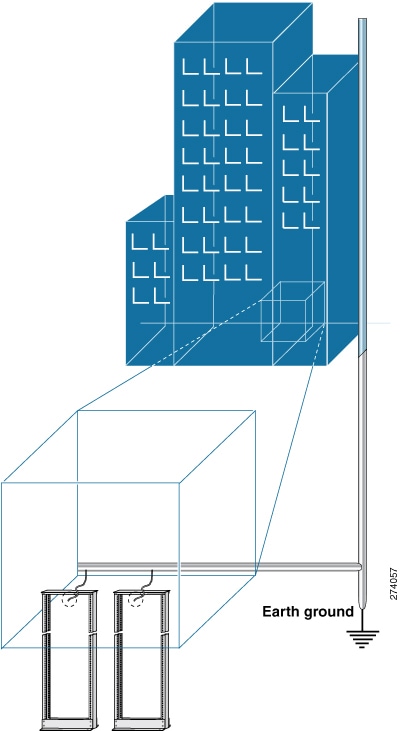

Statement 445—Connect the Chassis to Earth Ground To reduce the risk of electric shock, connect the chassis of this equipment to permanent earth ground during normal use. |

Warning |

Statement 1020—Electrical Power Outlet with Grounding In accordance with the ABNT NBR 5410 Electrical Installation Standard, this equipment must be connected to an electrical power outlet that has grounding (three pins), which protects the user against electric shocks. |

Warning |

Statement 1029—Blank Faceplates and Cover Panels Blank faceplates and cover panels serve three important functions: they reduce the risk of electric shock and fire, they contain electromagnetic interference (EMI) that might disrupt other equipment, and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. |

Warning |

Statement 1057—Hazardous Radiation Exposure Use of controls, adjustments, or performance of procedures other than those specified may result in hazardous radiation exposure. |

Warning |

Statement 1062—Remove Power Before Disconnecting Explosion Hazard—Do not connect or disconnect any connector to this equipment unless power has been removed or you have verified that the area is nonhazardous. Secure any external connections that connect to this equipment by using screws, sliding latches, threaded connectors, or other means provided with this product. |

Warning |

Statement 1071—Warning Definition IMPORTANT SAFETY INSTRUCTIONS Before you work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard practices for preventing accidents. Read the installation instructions before using, installing, or connecting the system to the power source. Use the statement number at the beginning of each warning statement to locate its translation in the translated safety warnings for this device. SAVE THESE INSTRUCTIONS  |

Note |

Statement 1089—Instructed and Skilled Person Definitions An instructed person is someone who has been instructed and trained by a skilled person and takes the necessary precautions when working with equipment. A skilled person or qualified personnel is someone who has training or experience in the equipment technology and understands potential hazards when working with equipment. |

Warning |

Statement 1093—Avoid Sharp Edges Risk of personal injury. Avoid sharp edges when installing or removing replaceable units.

|

Note |

Statement 8006—CE Mark |

Feedback

Feedback