General Precautions

Observe the following general precautions when using and working with your router:

-

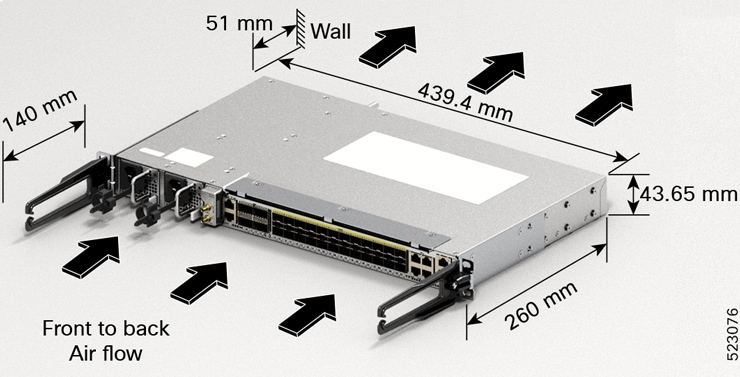

Keep your system components away from radiators and heat sources, and do not block cooling vents.

-

Do not spill food or liquids on your system components, and never operate the product in a wet environment.

-

Do not push any objects into the openings of your system components. Doing so can cause fire or electric shock by shorting out interior components.

-

Position system cables and power supply cable carefully. Route system cables, the power supply cable, and plug so that they are not stepped on or tripped over. Be sure that nothing else rests on your system component cables or power cable.

-

Do not modify power cables or plugs. Consult a licensed electrician or your power company for site modifications. Always follow your local and national wiring rules.

-

If you turn off your system, wait at least 30 seconds before turning it on again to avoid damage to the system components.

Feedback

Feedback