Chapter 7: Cisco Multi-Switch Router Maintenance

Available Languages

Table Of Contents

Maintaining the Cisco Catalyst 5500 Multiswitch Router

Ethernet Switching Module (10BaseT 24 Port) LEDs

10/100 Mbps Fast Ethernet Switching Module (10/100BaseTX 12 Port) LEDs

Using the Command Line Interface to Check Status

Avoiding Problems When Inserting and Removing Modules

Removing the Supervisor Engine

Replacing the Supervisor Engine

Using Flash Memory (PCMCIA) Cards (Supervisor Engine III)

Removing and Replacing the Power Supply

Removing an AC-Input Power Supply

Installing an AC-Input Power Supply

Removing a DC-Input Power Supply

Installing a DC-Input Power Supply

Removing and Replacing the Chassis Fan Assembly

Maintaining the Cisco Catalyst 5500 Multiswitch Router

This chapter contains recommended hardware maintenance procedures for the Cisco Catalyst 5500 Multiswitch Routers (MSRs), which provide an Ethernet backbone for connections between the Cisco Signaling Link Terminals (SLTs), Cisco Media Gateway Controllers (MGCs), and Cisco Media Gateways (MGWs). You can configure several virtual LANs (VLANs) on the Catalyst 5500s and the route switch modules (RSMs) provide inter-VLAN routing when necessary. If your solution includes two Catalyst 5500s, they are connected through an Inter-Switch Link (ISL) trunk, enabling them to share VLAN data and provide ensured availability.

This chapter describes hardware maintenance; for information on upgrading and maintaining Catalyst 5500 software, refer to the Cisco Media Gateway Controller Software Release 7 Installation and Configuration Guide.

This chapter includes the following sections:

•

Replacing Hardware Components

Checking Equipment Status

Check the status of the Cisco Catalyst 5500, using the following methods:

•

Reading the Cisco Catalyst 5500 LEDs

•

Querying the status using the Catalyst command line interface (CLI)

•

Querying the system using CiscoWorks 2000 and Cisco WAN Manager (CWM)

Cisco Catalyst 5500 LEDs

LEDs of the Catalyst 5500 may vary, depending on which components are installed. The LEDs described in this section are factory default.

Supervisor Engine Module LEDs

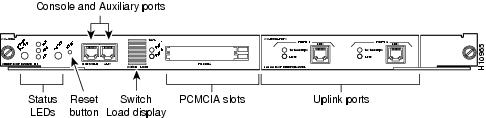

The front panel of the supervisor engine III (product number WS X5530-E3) is shown in Figure 7-1.

Figure 7-1 Supervisor Engine III Front Panel

The LEDs on the supervisor engine front panel indicate the status of the system, which includes the supervisor engine, the power supplies, and the fan assembly. Table 7-1 describes LED operation.

Ethernet Switching Module (10BaseT 24 Port) LEDs

Each switching module (Prod # WS-X5013) contains a STATUS LED. When on, this LED indicates that the switching module is operational and is powered up. It does not necessarily mean that the interface ports are functional or enabled.

The LEDs on the faceplate of the Ethernet switching module (10BaseT 24 Port) are described in Table 7-2 and shown in Figure 7-2.

Figure 7-2 Ethernet Switching Module (10BaseT 24 Port) LEDs

10/100 Mbps Fast Ethernet Switching Module (10/100BaseTX 12 Port) LEDs

The faceplate of each 10/100 Mbps Fast Ethernet Switching Module (Prod # WS-X5203) contains a module STATUS LED, and two LEDs for each switching port. The LEDs provide status information for the module and individual Fast Ethernet interface connections. The LEDs are described in Table 7-3 and are shown in Figure 7-3.

Figure 7-3 10/100 Mbps Fast Ethernet Switching Module (10/100BaseTX 12 Port) LEDs

Route Switch Module LEDs

The RSM (product number WS-X5302) LEDs, shown in Figure 7-4, are described in Table 7-3.

Figure 7-4 RSM (WS-X5302) LEDs

Table 7-4 RSM (WS-X5302) STATUS LED Descriptions

STATUS

Green

All the self-tests have been passed.

Red

A test other than an individual port test has been failed.

Orange

System boot, self-test diagnostics running, or the module is disabled.

CPU HALT

On

Indicates normal RSM operation.

Off

The system detected a processor hardware failure.

ENABLED

On

Indicates IP microcode is loaded and the RSM is operational.

PCMCIA SLOTs 0 and 1

On

Indicates PCMCIA devices in slot 0 and 1 are being accessed by the RSM.

TX1

Green

The port is transmitting a packet (LED is lit for approximately 50 ms).

RX2

Green

The port is receiving a packet (LED is lit for approximately 50 ms3 )

1 TX = transmit

2 RX = receive

3 ms = milliseconds

Using the Command Line Interface to Check Status

The Cisco Catalyst 5500 command line interface includes a series of commands that enable you to determine if the MSR is functioning correctly or where problems have occurred. Relevant commands for checking status include ping, traceroute, test snmp trap, and show. There are more than 100 show commands, many of which can be used to check status. To learn how to find more information concerning these and other commands, refer to the Command Reference Manual that came with the Cisco Catalyst 5500 MSR.

Replacing Hardware Components

This section describes how to perform the following removal and replacement procedures for

Cisco Catalyst 5000 series field-replaceable units (FRUs):•

Removing the Supervisor Engine

•

Using Flash Memory (PCMCIA) Cards (Supervisor Engine III)

•

Removing and Replacing the Power Supply

•

Removing and Replacing the Chassis Fan Assembly

For instructions on installing and replacing switching modules, refer to the Catalyst 5000 Series Module Installation Guide.

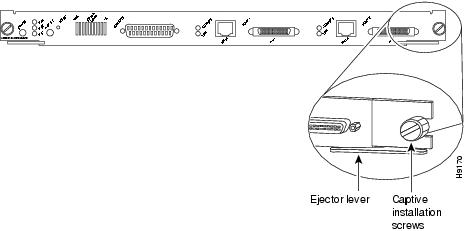

Avoiding Problems When Inserting and Removing Modules

The ejector levers on the supervisor engine and switching modules align and seat the module connectors in the backplane (see Figure 7-5). Failure to use the ejector levers to insert the module can disrupt the order in which the pins make contact with the backplane. Follow the installation and removal instructions carefully.

When removing a module, use the ejector levers to ensure that the module connector pins disconnect from the backplane properly. Any supervisor engine or switching module that is only partially connected to the backplane can disrupt the system. Detailed instructions for removing and installing switching modules are described in the Catalyst 5000 Series Module Installation Guide.

Figure 7-5 Ejector Levers and Captive Installation Screws (Supervisor Engine II Shown)

Tools Required

Use a flat-blade screwdriver to remove any filler (blank) modules and to tighten the captive installation screws that secure the modules in their slots. When you handle modules, use an ESD-preventive wrist strap or other grounding device to prevent electrostatic discharge (ESD) damage.

Removing the Supervisor Engine

Before you remove a supervisor engine, you should first upload the current configuration to a server. This saves time when bringing the module back online. You can recover the configuration by downloading it from the server to the nonvolatile memory of the supervisor engine.

To remove a supervisor engine, perform the following steps:

Step 1

If you do not plan to immediately reinstall the supervisor engine you are removing, disconnect any network interface cables attached to the module ports.

Step 2

Use a screwdriver to loosen the captive installation screws at the left and right sides of the module.

Step 3

Grasp the left and right ejector levers and simultaneously pull the left lever to the left and the right lever to the right to release the module from the backplane connector.

Step 4

Grasp the handle of the module with one hand and place your other hand under the carrier to support and guide the module out of the slot. Avoid touching the module.

Step 5

Carefully pull the module straight out of the slot, keeping your other hand under the carrier to guide it. Keep the module at a 90-degree orientation to the backplane.

Step 6

Place the removed module on an antistatic mat or antistatic foam.

Step 7

If the slot is to remain empty, install a module filler plate to keep dust out of the chassis and to maintain proper airflow through the module compartment.

CautionAlways install a switching module filler plate in empty switching module slots to maintain the proper flow of cooling air across the modules.

Note

When you remove and replace the supervisor engine, the system provides status messages on the console screen. The messages are for information only. Enter the show system and show module commands to view specific information. For additional information, refer to the Catalyst 5000 Series Software Configuration Guide and the Catalyst 5000 Series Command Reference. Also, refer to the Preface for a description of Cisco Connection Online (CCO).

Replacing the Supervisor Engine

To replace the supervisor engine, perform the following steps. Note that the supervisor engine must go in slot 1 and the redundant supervisor engine in slot 2.

Step 1

Remove the module filler plate, if any.

Step 2

Grasp the handle of the module with one hand and carefully align the module with the slot, keeping your other hand under the carrier to support it. Keep the module at a 90-degree orientation to the backplane.

Step 3

Carefully push the module straight into the slot, keeping one hand under the carrier to guide it. Avoid touching the module.

Step 4

Make sure that the ejector levers are pushed in, holding the module to the backplane connector.

Step 5

Use a screwdriver to tighten the captive installation screws at the left and right sides of the module.

Step 6

Reattach network interface cables to the module ports.

Using Flash Memory (PCMCIA) Cards (Supervisor Engine III)

The Flash memory (PCMCIA) card slots on the front panel of Supervisor Engine III are for additional PCMCIA-based Flash memory. You can use this Flash memory to store and run Cisco IOS images, or to serve as an I/O device. Occasionally, it might be necessary to remove and replace Flash memory cards; however, removing Flash memory cards is not required and is not recommended after the cards are installed in the slots.

Supervisor Engine III has two PCMCIA slots: slot 0 (bottom) and slot 1 (top). The following procedure is generic and can be used for a Flash memory card in either slot position.

Note

You can insert and remove the Flash memory card with the power on.

Before you install a card, verify that the Flash memory card is set with write protection off. The write-protect switch is located on the front edge of the card when oriented with the printing right side up and the edge connector end away from you. (See Figure 7-6.)

Figure 7-6 Locating the Flash Memory Card Write-Protection Switch

Use the following procedure for installing and removing a Flash memory card:

Step 1

Face the front panel of the switch and hold the Flash memory card with the connector end of the card toward the slot. The connector end of the card is opposite the end with the write-protection switch, which is shown in Figure 7-6.

Step 2

Insert the card into the appropriate slot until the card completely seats in the connector at the back of the slot and the eject button pops out toward you. Note that the card does not insert all the way into the slot; a portion of the card remains outside the slot. Do not attempt to force the card past this point.

Step 3

To eject a card, press the appropriate ejector button until the card is free of the connector at the back of the slot.

Step 4

Remove the card from the slot and place it in an antistatic bag.

Removing and Replacing the Power Supply

This section describes the procedure you use to remove and install power supplies for the Cisco Catalyst 5500 switches. Use a flat-blade screwdriver to perform these procedures.

•

Removing an AC-Input Power Supply

•

Installing an AC-Input Power Supply

•

Removing a DC-Input Power Supply

•

Installing a DC-Input Power Supply

Removing an AC-Input Power Supply

Follow these steps to remove an AC-input power supply:

Note

In systems with redundant power supplies, the faulty supply can be replaced while the system is operating.

Step 1

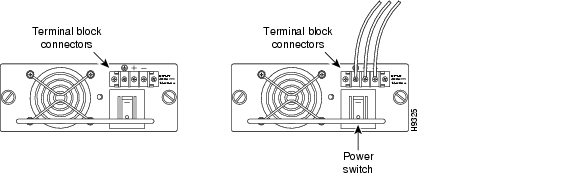

Turn off the power switch on the power supply you are removing (see Figure 7-7).

Warning

Do not touch the power supply when the power cord is connected. For systems with a power switch, line voltages are present within the power supply even when the power switch is off and the power cord is connected. For systems without a power switch, line voltages are present within the power supply when the power cord is connected.

CautionFailure to turn off the power supply could result in equipment damage.

Figure 7-7 AC-Input Power Supply Front Panels

Step 2

Disconnect the power cord from the power source.

Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect the power at the circuit breaker on DC units.

Step 3

Disconnect the power cord from the power supply being removed.

Step 4

Using a flat-blade screwdriver, loosen and remove the captive installation screws (see Figure 7-7).

CautionUse both hands to install and remove power supplies.

Step 5

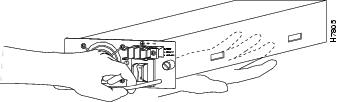

Grasp the power supply handle with one hand and place your other hand underneath to support the bottom of the supply, as shown in Figure 7-8 (Cisco Catalyst 5000 supply shown).

Figure 7-8 Handling an AC-Input Power Supply

Warning

Keep your hands and fingers out of the power supply bays. High current is present on the power backplane when the system is operating.

Step 6

Pull the supply out of the bay and put it aside.

Step 7

If the power supply bay is to remain empty, install a blank power supply filler plate over the opening; secure it with the mounting screws.

CautionAlways install a filler plate over an empty power supply bay, not only to protect the inner chassis and connectors from dust or other contamination, but to prevent possible contact with the high current levels of those connectors when the chassis is powered on.

Installing an AC-Input Power Supply

Warning

Before installing a Cisco Catalyst 5500 AC-input power supply, read the warning in the "Removing an AC-Input Power Supply" section.

Follow these steps to install an AC-input power supply:

Step 1

Turn off the power switch on the power supply you are installing (see Figure 7-9).

CautionFailure to turn off the power supply could result in equipment damage.

CautionUse both hands to install and remove power supplies. The Cisco Catalyst 5500 power supply weighs 22 lb. (9.9 kg).

Warning

Keep your hands and fingers out of the power supply bays. High current is present on the power backplane when the system is operating.

Step 2

Grasp the power supply handle with one hand and place your other hand underneath to support the bottom of the supply, as shown in Figure 7-11.

Step 3

Slide the power supply all the way into the power supply bay.

Step 4

Using a flat-blade screwdriver, tighten the captive installation screws (see Figure 7-10).

Step 5

Before connecting the power supply to a power source, ensure that all site power and grounding requirements described in the Cisco Media Gateway Controller Hardware Installation Guide have been met.

Step 6

Plug the power cord into the power supply.

Step 7

Connect the other end of the power cord to an AC-power input source.

Note

Each AC-input power supply operating at 120 VAC requires a dedicated 20A service and 20A plug and receptacle. It is not acceptable to power the Cisco Catalyst 5500 from a 15A line cord because of the safety ratings under which the Cisco Catalyst 5500 is certified.

CautionIn a system with dual power supplies, connect each power supply to a separate input source. In case of a power source failure, the second source will probably still be available and can maintain maximum overcurrent protection for each power connection.

Step 8

Turn the power switch to the ON position on the power supply.

Step 9

Verify that power supply operation and the front panel LEDs are in the following states:

AC OK LED is green.

FAN OK LED is green.

OUTPUT FAIL LED is off.

Step 10

Verify that the appropriate supervisor engine module PS1 and PS2 LEDs are on (green).

Step 11

Enter the show system command to display the power supply and system status.

If the LEDs or show system command indicate a power or other system problem, refer to "Troubleshooting Cisco Catalyst 5500 Multiswitch Routers Signaling," for troubleshooting information.

Removing a DC-Input Power Supply

Follow these steps to remove a DC-input power supply (product number WS-C5568):

Step 1

Verify that power is off to the DC circuit on the power supply you are removing.

Warning

Before performing the following procedures, ensure that power is removed from the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect the power at the circuit breaker on DC units.

Step 2

Turn the power switch to the OFF (0) position on the power supply you are removing (see Figure 7-9).

Step 3

Remove the two screws securing the terminal block cover and slide the cover straight off the terminal block (see Figure 7-9).

Figure 7-9 DC-Input Power Supply Front Panels

Step 4

Disconnect the DC-input wires from the terminal block. Disconnect the ground wire last.

Step 5

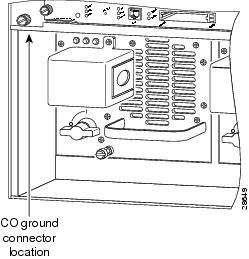

Disconnect the central office (CO) ground from the CO ground connector (Figure 7-10).

Figure 7-10 DC-Input Power Supply CO Ground

Step 6

Loosen and remove the captive screws on the power supply (see Figure 7-9).

CautionUse both hands to remove and install power supplies.

Step 7

Grasp the power supply handle with one hand and place your other hand underneath as you slowly pull the power supply out of the bay (see Figure 7-11).

Warning

Keep hands and fingers out of the power supply bays. High voltage is present on the power backplane when the system is operating.

Figure 7-11 Handling a DC Power Supply

Step 8

If the bay is to remain empty, install a blank power supply filler plate (Cisco part number 700-00177-01) over the opening and secure it with the mounting screws. This protects the inner chassis from dust and prevents accidental contact with live voltage at rear of the bay.

CautionAlways install a filler plate over an empty power supply bay to protect the inner chassis and connectors from dust or other contamination and to prevent possible contact with the high current levels of those connectors when the chassis is powered on.

Step 9

Reinstall the power supply terminal block cover.

Installing a DC-Input Power Supply

Follow these steps to install a DC-input power supply:

Step 1

Verify that power is off to the DC circuit on the power supply you are installing.

Warning

Before performing any of the following procedures, ensure that power is removed from the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel board that services the DC circuit, switch the circuit breaker to the OFF position, and tape the switch handle of the circuit breaker in the OFF position.

Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect the power at the circuit breaker on DC units.

Step 2

Connect the switch to the CO ground through the CO ground connector shown in Figure 7-10. Remove the adhesive strip covering the CO ground connector on the switch.

Use the following guidelines when connecting the switch to the CO ground:

•

The ground wire lug must be less than or equal to 0.320 in. (8.1 mm) to fit within the ground connector.

•

The ground wire must be 10 to 12 AWG. Use the larger gauge ground wire when the switch is further away from the ground location.

Step 3

Turn the power switch to the OFF (0) position on the power supply you are installing

(see Figure 7-10).

CautionUse both hands to remove and install power supplies.

Warning

Keep hands and fingers out of the power supply bays. High voltage is present on the power backplane when the system is operating.

Step 4

Grasp the power supply handle with one hand and place your other hand underneath as you slowly insert the power supply into the bay (see Figure 7-11).

Step 5

Using a screwdriver, tighten the captive screws on the power supply (see Figure 7-9).

Step 6

Remove the terminal block cover (see Figure 7-9). Remove the two screws securing the terminal block cover and slide the cover straight off the terminal block.

Step 7

Attach the appropriate lugs to the DC-input wires. Maximum width of the lugs is 0.300 inch (7.6 mm). Suggested lugs are AMP 322985 or 52941. Suggested DC-input wires are 10 AWG.

CautionWhen stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type with upturned lugs. These terminations must be the appropriate size for the wires and clamp both the insulation and conductor.

Step 8

Connect the DC-input wires to the terminal block.

If not already done, route the DC-input power cable through the conduit from your power source, through the conduit bracket on the power supply, and make a sufficient length of wire available to attach to the three terminal block connections.

Attach and tighten the conduit to the conduit bracket. How this conduit is attached depends on your site; its attachment is beyond the scope of this document.

CautionConnect the ground wire first.

Step 9

Connect the DC-input wires to the terminal block (see Figure 7-12). The proper wiring sequence is ground to ground, positive to positive (line to L), and negative to negative (neutral to N). Note that the ground wire should always be connected first and disconnected last.

Step 10

After ensuring that all wire connections are secure, reinstall the terminal block cover.

CautionTo prevent a short-circuit or shock hazard after wiring the DC-input power supply, reinstall the terminal block cover.

Figure 7-12 DC-Input Power Supply Connectors

CautionIn a system with dual power supplies, use the modular power cord to connect each power supply to a separate input line. In case of a line failure, the second source will most likely still be available and can maintain maximum overcurrent protection for each power connection.

Step 11

Remove the tape from the circuit breaker switch handle and restore power by moving the circuit breaker switch handle to the on position.

Step 12

Turn the power switch to the on position on the power supply.

Step 13

Verify power supply operation.

Verify that the power supply front panel LEDs are in the following states:

DC OK LED is green.

FAN OK LED is green.

OUTPUT FAIL LED is off.

Verify that the appropriate supervisor engine module PS1 and PS2 LEDs are on and green.

Enter the show system command to display the power supply and system status.

Removing and Replacing the Chassis Fan Assembly

This section describes how to remove and install chassis fan assemblies. Use a flat-blade screwdriver to perform this procedure.

Removing the Fan Assembly

Perform the following steps to remove the existing chassis fan assembly:

CautionNever operate the system if the fan assembly is removed or if it is not functioning properly. An overtemperature condition can result in severe equipment damage.

Note

The fan assembly is designed to be removed and replaced while the system is operating without presenting an electrical hazard or damage to the system.

Step 1

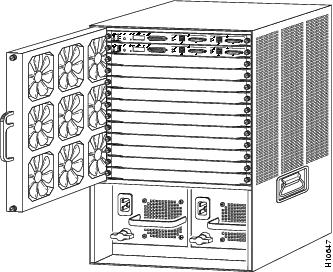

Locate the fan assembly to the left of the card cage (see Figure 7-13).

Step 2

Loosen the two captive installation screws by turning them counterclockwise.

Step 3

Grasp the fan assembly with both hands and pull it outward, joggling it if necessary to unseat it from the backplane. Pull it clear of the chassis and place it in a safe location.

Installing the Fan Assembly

Perform the following steps to install the new fan assembly:

Step 1

Hold the fan assembly with the fans facing to the right.

Step 2

Place the fan assembly into the front chassis cavity so that it rests on the chassis, and then lift the fan assembly up slightly, aligning the top and bottom guides.

Step 3

Push the fan assembly into the chassis until the captive installation screws meet the chassis.

Step 4

Tighten the captive installation screws by turning them clockwise.

Figure 7-13 Cisco Catalyst 5500 Chassis Fan Assembly

Checking the Installation

Perform the following steps to verify that the new fan assembly is installed correctly:

Step 1

Listen for the fans; you should immediately hear them operating. If you do not hear them, ensure that the fan assembly is completely inserted in the chassis and that the faceplate is flush with the switch back panel.

Step 2

If after several attempts the fans do not operate, or if you experience trouble with the installation (for instance, if the captive installation screws do not align with the chassis holes), contact the Cisco Technical Assistance Center (TAC) for assistance. Refer to the "Obtaining Technical Assistance" section for information on contacting the Cisco TAC.

Feedback

Feedback