Power-Supply Modules

|

Model |

Description |

|---|---|

|

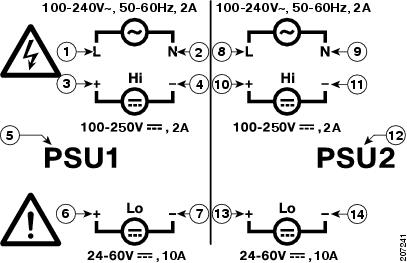

PWR-RGD-LOW-DC-H |

Low-voltage DC. For detailed specifications, see the IE 4010 Data Sheet. |

|

PWR-RGD-AC-DC-H |

High-voltage AC or DC. For detailed specifications, see the Cisco Industrial Ethernet 4010 Series Switches Data Sheet. |

|

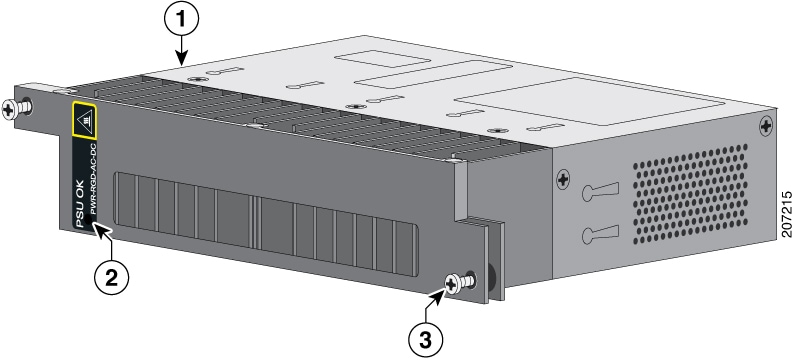

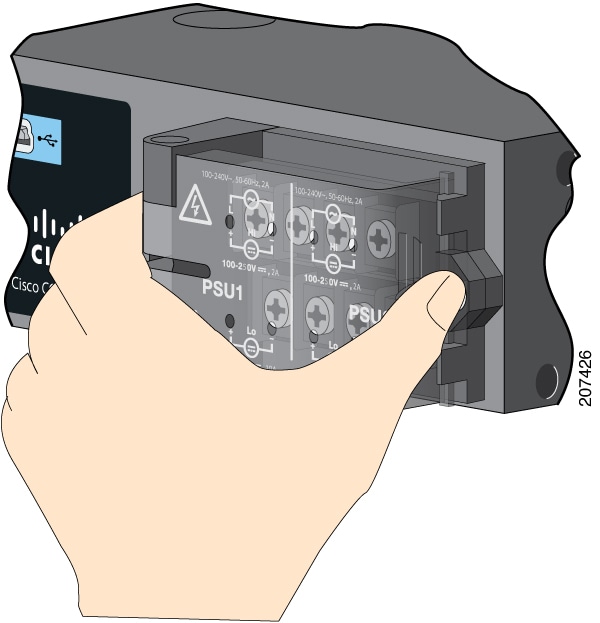

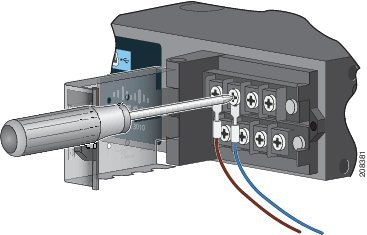

1 |

Power-supply module |

|

2 |

PSU OK LED |

|

3 |

Captive screw |

|

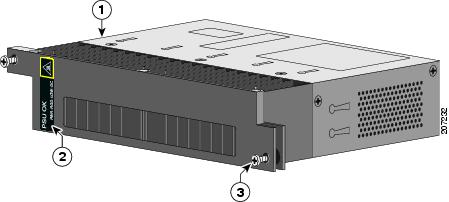

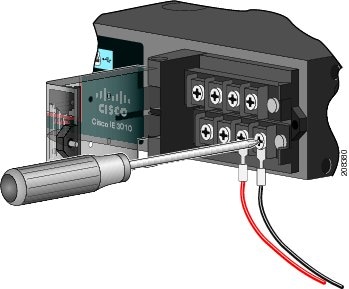

1 |

Power-supply module |

|

2 |

PSU OK LED |

|

3 |

Captive screw |

Note |

Power Supplies with the -H suffix are required for hazardous environment installations. Non hazardous environments may use either -H or non -H supplies. |

For a description of the PSU OK LEDs, see Power-Supply Module LEDs.

Feedback

Feedback