Replacing a Fan Module

You can replace a fan module while the switch is operating, as long as you perform the replacement within one minute. If you cannot perform the replacement within one minute, leave the original fan module in the chassis to maintain the designed airflow until you have the replacement fan module on hand and can perform the replacement.

Caution |

If you are replacing a module during operations, verify the replacement fan module has the correct direction of airflow. This means that it has the same airflow direction as the other modules in the chassis. Also, verify that the airflow direction takes in air from a cold aisle and exhausts air to a hot aisle. Otherwise, the switch can overheat and shutdown. If you are changing the airflow direction of all the modules in the chassis, shutdown the switch before replacing all the fan and power supply modules with modules using the other airflow direction. During operations, all of the modules must have the same direction of airflow. |

Removing a Fan Module

Caution |

The fans might still be turning when you remove the fan assembly from the chassis. Keep fingers, screwdrivers, and other objects away from the openings in the fan assembly's housing. |

Procedure

|

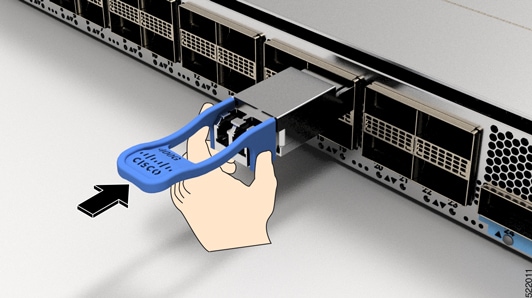

Step 1 |

On the fan module that you are removing, press the two sides of the fan module handle together, and pull on the handles enough to unseat it from its connectors. |

||

|

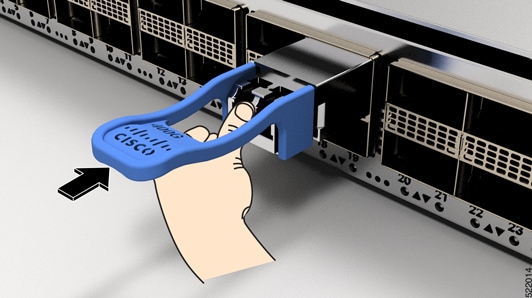

Step 2 |

Holding the handle, pull the module out of the chassis.

|

Installing a Fan Module

Before you begin

-

A fan slot must be open and ready for the new fan module to be installed.

-

If the switch is operating, you must have a new fan module on hand and ready to install within one minute of removing the original fan module.

-

The new fan module must have the same airflow direction as the other fan and power supply modules installed in the switch.

Procedure

|

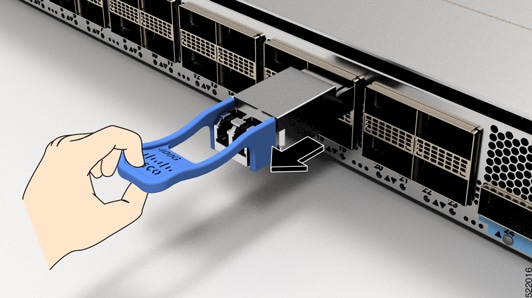

Step 1 |

Holding the fan module by its handle, align the back of the fan module (the side with the electrical connectors) to the open fan slot in the chassis. |

|

Step 2 |

Slide the fan module into the slot until it clicks in place. |

|

Step 3 |

Verify that the Status (STS) LED turns on and becomes green. |

Feedback

Feedback