Safety Guidelines

Before you begin the installation of the Cisco ASR 903 Router as a satellite shelf, review the safety guidelines in this chapter to avoid injuring yourself or damaging the equipment.

In addition, before replacing, configuring, or maintaining the Cisco ASR 903 Router as a satellite shelf, review the safety warnings listed in Regulatory Compliance and Safety Information for the Cisco ASR 903 Router .

Standard Warning Statements

To see translations of the warnings that appear in this publication, see the Regulatory Compliance and Safety Information document that accompanied this device.

Warning |

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to ensure that the system remains stable. The following guidelines are provided to ensure your safety:This unit should be mounted at the bottom of the rack if it is the only unit in the rack.When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack.When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack.If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack. Statement 1006 |

Warning |

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only through the use of a special tool, lock and key, or other means of security. Statement 1017 |

Warning |

Ultimate disposal of this product should be handled according to all national laws and regulations. Statement 1040 |

Warning |

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of 149°F (65°C). Statement 1047 |

Warning |

The chassis should be mounted on a rack that is permanently affixed to the building. Statement 1049 |

Warning |

IMPORTANT SAFETY INSTRUCTIONS: This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard practices for preventing accidents. Use the statement number provided at the end of each warning to locate its translation in the translated safety warnings that accompanied this device. Statement 1071 |

Warning |

This is a Class A Device and is registered for EMC requirements for industrial use. The seller or buyer should be aware of this. If this type was sold or purchased by mistake, it should be replaced with a residential-use type. Statement 294 |

Warning |

This is a class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures. Statement 340 |

Warning |

This equipment is in compliance with the essential requirements and other relevant provisions of Directive 1999/5/EC. Statement 287. |

Safety Guidelines for Personal Safety and Equipment Protection

The following guidelines help ensure your safety and protect the equipment. This list does not include all the potentially hazardous situations. Therefore, you should be on alert.

- Before moving the system, always disconnect all the power cords and interface cables.

- Never assume that power is disconnected from a circuit; always check.

- Before and after installation, keep the chassis area clear and dust-free.

- Keep tools and assembly components away from walk areas where you or others could trip over them.

- Do not work alone if potentially hazardous conditions exist.

- Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

- Do not wear loose clothing that may get caught in the chassis.

- When working under conditions that may be hazardous to your eyes, wear safety glasses.

Safety Precautions for Module Installation and Removal

Be sure to observe the following safety precautions when you work on the router.

To see translations of the warnings that appear in this publication, see the Regulatory Compliance and Safety Information document that accompanied this device.

Warning |

Class 1 laser product. Statement 1008 |

Warning |

Do not stare into the beam or view it directly with optical instruments. Statement 1011 |

Warning |

Invisible laser radiation present. Statement 1016 |

Warning |

Hazardous network voltages are present in WAN ports regardless of whether power to the unit is OFF or ON. To avoid electric shock, use caution when working near WAN ports. When detaching cables, detach the end away from the unit first. Statement 1026 |

Warning |

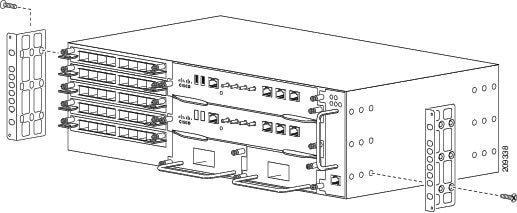

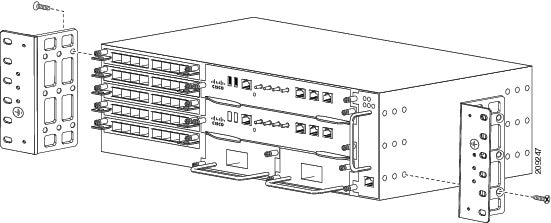

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029 |

Warning |

Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034 |

Warning |

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051 |

Safety with Electricity

Warning |

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect the power at the circuit breaker on DC units. Statement 12 |

Warning |

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces, and watches). Metal objects will heat up when connected to power and ground and can cause serious burns or weld the metal object to the terminals. Statement 43 |

Warning |

Avoid using or servicing any equipment that has outdoor connections during an electrical storm. There may be a risk of electric shock from lightning. Statement 1088 |

Warning |

Before performing any of the following procedures, ensure that power is removed from the DC circuit. Statement 1003 |

Warning |

Read the installation instructions before connecting the system to the power source. Statement 1004 |

Warning |

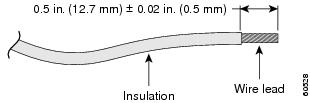

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the protective device is rated: For a -48/-60 VDC installation, the wire shall be 12 AWG minimum with a 20 A branch circuit breaker. For a 24 VDC installation, the wire shall be 8 AWG minimum with a 40 A branch circuit breaker. Statement 1005 |

Warning |

This product relies on the building’s installation for short-circuit (overcurrent) protection. For an AC installation, ensure that the branch circuit breaker is rated a maximum 20A. Statement 1005 |

Warning |

There is the danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer’s instructions. Statement 1015 |

Warning |

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only through the use of a special tool, lock and key, or other means of security. Statement 1017 |

Warning |

When you connect or disconnect the power and/or alarm connector with power applied, an electrical arc can occur. This could cause an explosion in hazardous area installations. Be sure that all power is removed from the switch and any other circuits. Be sure that power cannot be accidentally turned on or verify that the area is nonhazardous before proceeding. Statement 1058 |

Warning |

Take care when connecting units to the supply circuit so that wiring is not overloaded. Statement 1018 |

Warning |

The plug-socket combination must be accessible at all times, because it serves as the main disconnecting device. Statement 1019 |

Warning |

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some LAN and WAN ports both use RJ-45 connectors. Use caution when connecting cables. Statement 1021 |

Warning |

A readily accessible two-poled disconnect device must be incorporated in the fixed wiring. Statement 1022 |

Warning |

To reduce the risk of fire, use only 26 AWG or larger telecommunication line cord. Statement 1023 |

Warning |

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. Statement 1024 |

Warning |

Use copper conductors only. Statement 1025 |

Warning |

This unit might have more than one power supply connection. All connections must be removed to de-energize the unit. Statement 1028 |

Warning |

To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the handles on modules (such as power supplies, fans, or cards); these types of handles are not designed to support the weight of the unit. Statement 1032 |

Warning |

Connect the unit only to DC power source that complies with the safety extra-low voltage (SELV) requirements in IEC 60950 based safety standards. Statement 1033 |

Warning |

Do not use this product near water; for example, near a bath tub, wash bowl, kitchen sink or laundry tub, in a wet basement, or near a swimming pool. Statement 1035 |

Warning |

Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations. Statement 1036 |

Warning |

Before opening the unit, disconnect the telephone-network cables to avoid contact with telephone-network voltages. Statement 1041 |

Warning |

This product requires short-circuit (overturned) protection, to be provided as part of the building installation. Install only in accordance with national and local wiring regulations. Statement 1045 |

Warning |

When installing or replacing the unit, the ground connection must always be made first and disconnected last. Statement 1046 |

Warning |

Never install an AC power module and a DC power module in the same chassis. Statement 1050 |

Warning |

When you connect or disconnect the power and/or alarm connector with power applied, an electrical arc can occur. This could cause an explosion in hazardous area installations. Be sure that all power is removed from the switch and any other circuits. Be sure that power cannot be accidentally turned on or verify that the area is nonhazardous before proceeding. Statement 1058 |

Warning |

This equipment is intended to be grounded to comply with emission and immunity requirements. Ensure that the switch functional ground lug is connected to earth ground during normal use. Statement 1064 |

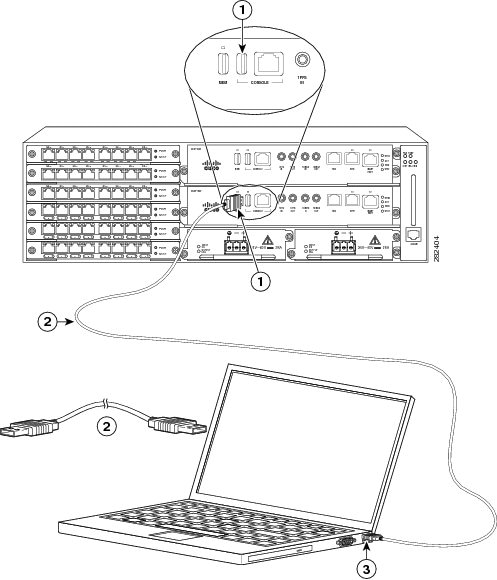

Warning |

If you connect or disconnect the console cable with power applied to the switch or any device on the network, an electrical arc can occur. This could cause an explosion in hazardous location installations. Be sure that power is removed or the area is nonhazardous before proceeding. Statement 1080 |

Warning |

Installation of the equipment must comply with local and national electrical codes. Statement 1074 |

Warning |

Hazardous voltage or energy may be present on power terminals. Always replace cover when terminals are not in service. Be sure uninsulated conductors are not accessible when cover is in place. Statement 1086 |

When working on equipment powered by electricity, follow these guidelines:

- Locate the room’s emergency power-off switch. If an electrical accident occurs, you will be able to quickly turn off the power.

- Before working on the system, turn off the DC main circuit breaker and disconnect the power terminal block cable.

- Before doing the following,

disconnect all power:

- Working on or near power supplies

- Installing or removing a router chassis or network processor module

- Performing most hardware upgrades

- Never install equipment that appears damaged.

- Carefully examine your work area for possible hazards, such as moist floors, ungrounded power extension cables, and missing safety grounds.

- Never assume that power is disconnected from a circuit; always check.

- Never perform any action that creates a potential hazard to people or makes the equipment unsafe.

- If an electrical

accident occurs, proceed as follows:

- Use caution, and do not become a victim yourself.

- Turn off power to the router.

- If possible, send another person to get medical aid. Otherwise, determine the condition of the victim, and then call for help.

- Determine whether the person needs rescue breathing or external cardiac compressions; then take appropriate action.

In addition, use the following guidelines when working with any equipment that is disconnected from a power source, but still connected to telephone wiring or network cabling:

- Never install telephone wiring during a lightning storm.

- Never install telephone jacks in wet locations unless the jack is specifically designed for it.

- Never touch uninsulated telephone wires or terminals unless the telephone line is disconnected at the network interface.

- When installing or modifying telephone lines, use caution.

Power Supply Considerations

Check the power at your site to ensure that you are receiving clean power (free of spikes and noise). Install a power conditioner if necessary.

Warning |

This equipment has been designed for connection to TN and IT power systems. Statement 1007 |

Preventing ESD Damage

Warning |

This equipment needs to be grounded. Use a green and yellow 6 AWG ground wire to connect the host to earth ground during normal use. Statement 383 |

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD can occur when electronic printed circuit cards are improperly handled and can cause complete or intermittent failures. When removing and replacing modules, always follow ESD prevention procedures:

- Ensure that the router chassis is electrically connected to earth ground.

- Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. To channel unwanted ESD voltages safely to ground, connect the clip to an unpainted surface of the chassis frame. To guard against ESD damage and shocks, the wrist strap and cord must operate effectively.

- If no wrist strap is available, ground yourself by touching a metal part of the chassis.

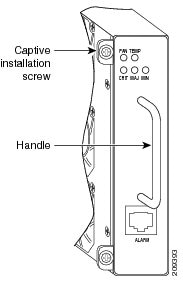

- When installing a component, use any available ejector levers or captive installation screws to properly seat the bus connectors in the backplane or midplane. These devices prevent accidental removal, provide proper grounding for the system, and help to ensure that bus connectors are properly seated.

- When removing a component, use available ejector levers or captive installation screws, if any, to release the bus connectors from the backplane or midplane.

- Handle components by their handles or edges only; do not touch the printed circuit boards or connectors.

- Place a removed component board side up on an antistatic surface or in a static-shielding container. If you plan to return the component to the factory, immediately place it in a static-shielding container.

- Avoid contact between the printed circuit boards and clothing. The wrist strap only protects components from ESD voltages on the body; ESD voltages on clothing can still cause damage.

- Never attempt to remove the printed circuit board from the metal carrier.

Note |

For the safety of your equipment, periodically check the resistance value of the antistatic wrist strap. It should be between 1 and 10 Mohm. |

Feedback

Feedback