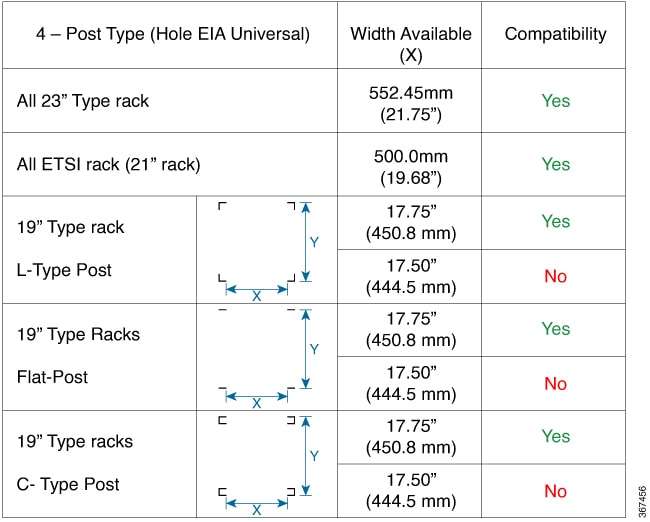

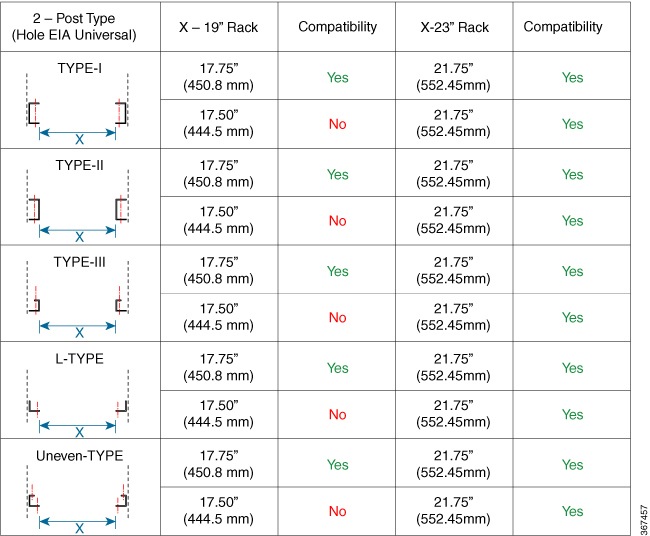

Rack Compatibility

We recommend that you follow these rack specifications.

Rack Types

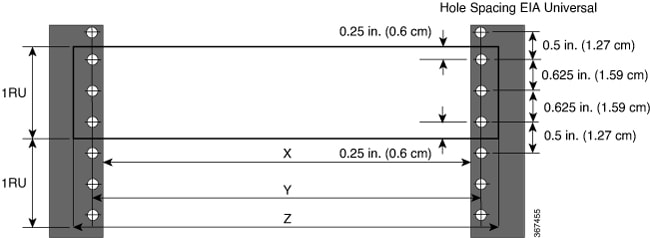

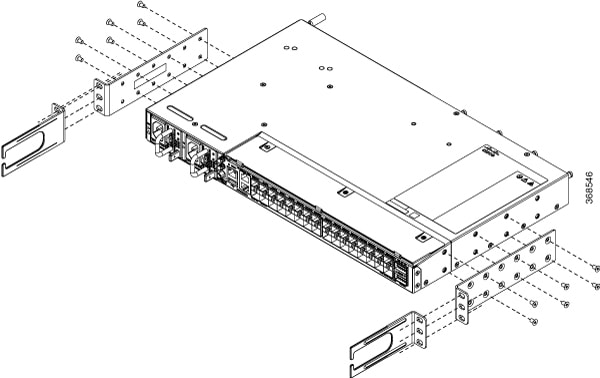

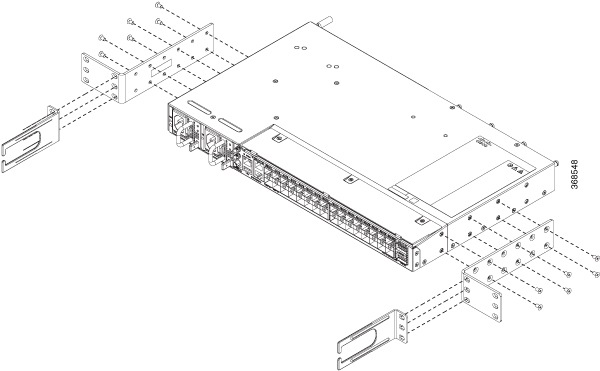

|

Post Type |

Rack Type |

Rack Front Opening (X) |

Rack Mounting Hole Centre-Centre (Y) |

Mounting Flange Dimension (Z) |

|---|---|---|---|---|

|

4 Post |

19 inches (48.3 centimeters) |

17.75 inches (45 centimeters) |

18.31 inches (46.5 centimeters) |

19 inches (48.2 centimeters) |

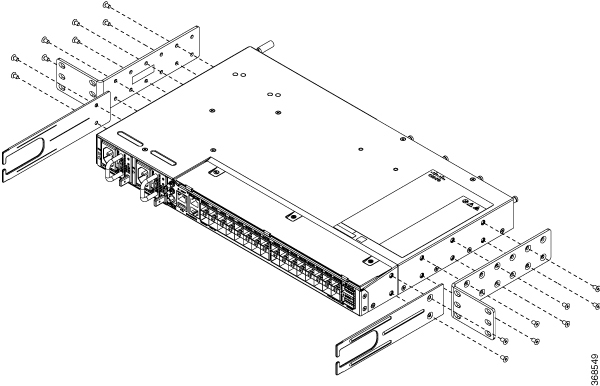

|

2 Post |

||||

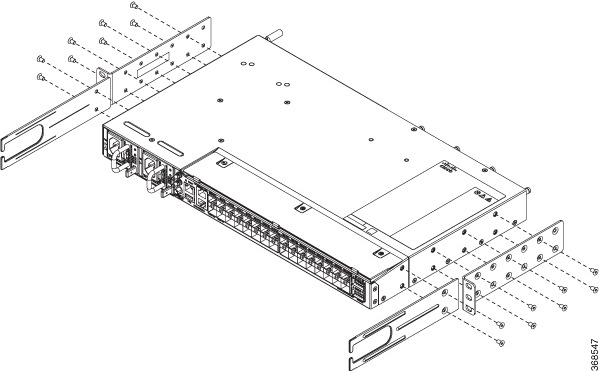

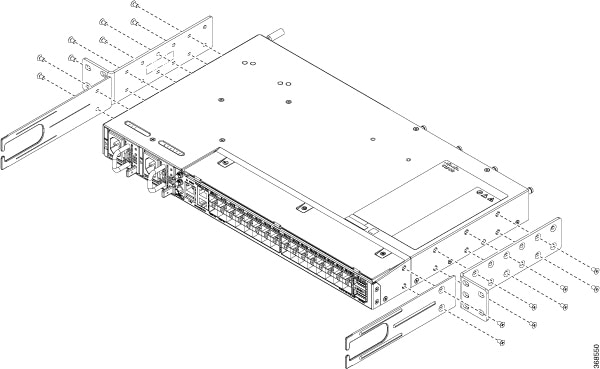

|

4 Post |

23 inches (58.4 centimeters) |

21.75 inches (55.24 centimeters) |

22.31 inches (56.6 centimeters) |

23 inches (58.4 centimeters) |

|

2 Post |

Feedback

Feedback