Switch Installation

This chapter describes how to install your switch, verify the boot fast, and connect the switch to other devices. It also includes information specifically for installations in hazardous environments.

We recommend performing a preliminary configuration of the switch before it is installed in a permanent location.

Preparing for Installation

Warnings

These warnings are translated into several languages in the Regulatory Compliance and Safety Information for this switch.

Warning |

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces, and watches). Metal objects will heat up when connected to power and ground and can cause serious burns or weld the metal object to the terminals. Statement 43 |

Warning |

Do not work on the system or connect or disconnect cables during periods of lightning activity. Statement 1001 |

Warning |

Before performing any of the following procedures, ensure that power is removed from the DC circuit. Statement 1003 |

Warning |

Read the installation instructions before you connect the system to its power source. Statement 1004 |

Warning |

This unit is intended for installation in restricted access areas. A restricted access area can be accessed only through the use of a special tool, lock and key, or other means of security. Statement 1017 |

Warning |

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. Statement 1024 |

Warning |

Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030 |

Warning |

Connect the unit only to DC power source that complies with the safety extra-low voltage (SELV) requirements in IEC 60950 based safety standards. Statement 1033 |

Warning |

Ultimate disposal of this product should be handled according to all national laws and regulations. Statement 1040 |

Warning |

For connections outside the building where the equipment is installed, the following ports must be connected through an approved network termination unit with integral circuit protection.10/100/1000 Ethernet, Console, and Alarm Statement 1044 |

Warning |

To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of: 140°F (60°C) Statement 1047 |

Warning |

Installation of the equipment must comply with local and national electrical codes. Statement 1074 |

Caution |

Airflow around the switch must be unrestricted. To prevent the switch from overheating, there must be the following minimum clearances:– Top and bottom: 2.0 in. (50.8 mm)– Sides: 2.0 in. (50.8 mm)– Front: 2.0 in. (50.8 mm) |

Caution |

If installer is providing cabling for an IP66/IP67 and Type 4X rated environment, the cables must be suitably rated for IP66/IP67 and Type 4X requirements |

EMC Environmental Conditions for Products Installed in the European Union

This section applies to products to be installed in the European Union.

The equipment is intended to operate under the following environmental conditions with respect to EMC:

-

A separate defined location under the user’s control.

-

Earthing and bonding shall meet the requirements of ETS 300 253 or CCITT K27.

-

AC-power distribution shall be one of the following types, where applicable: TN-S and TN-C as defined in IEC 364-3.

In addition, if equipment is operated in a domestic environment, interference could occur.

Installation Guidelines

When determining where to place the switch, observe these guidelines.

Environment and Enclosure Guidelines

Review these environmental and enclosure guidelines before installation:

-

This equipment is considered Group 1, Class A industrial equipment, according to IEC/CISPR Publication 11. Without appropriate precautions, there may be potential difficulties ensuring electromagnetic compatibility in other environments due to conducted as well as radiated disturbance.

Caution |

To meet IP67 Compliance, all cables, dust caps, or the captive screws on the SD card cover must be torqued to the recommended spec before operating the unit. For torque specs see “Cisco IE 2000 IP67 Series Switches Technical Specifications” |

Caution |

Use caution when removing dust caps. Dust caps in an over-tightened state may adhere to the connector O-ring seal. Ensure that the O-ring remains in place when dust caps are removed and follow all torque specs here: “Cisco IE 2000 IP67 Series Switches Technical Specifications” |

General Guidelines

Before installation, observe these general guidelines:

Caution |

Proper ESD protection is required whenever you handle Cisco equipment. Installation and maintenance personnel should be properly grounded by using ground straps to eliminate the risk of ESD damage to the switch.Do not touch connectors or pins on component boards. Do not touch circuit components inside the switch. When not in use, store the equipment in appropriate static-safe packaging. |

-

If you are responsible for the application of safety-related programmable electronic systems (PES), you need to be aware of the safety requirements in the application of the system and be trained in using the system.

When determining where to place the switch, observe these guidelines:

-

Before installing the switch, first verify that the switch is operational by powering it on and observing boot fast. Follow the procedures in the “Where to Go Next” section on page 14 .

-

For 10/100 ports and 10/100/1000 ports, the cable length from a switch to an attached device cannot exceed 328 feet (100 meters).

-

Operating environment is within the ranges listed in Appendix F, “Technical Specifications.”

-

Clearance to front and rear panels meets these conditions:

-

Front-panel LEDs can be easily read.

-

Access to ports is sufficient for unrestricted cabling.

-

Front-panel direct current (DC) power connectors and the alarm connector are within reach of the connection to the DC power source.

-

-

Airflow around the switch must be unrestricted. To prevent the switch from overheating, you must have the following minimum clearances:

-

Top and bottom: 2.0 in. (50.8 mm)

-

Sides: 2.0 in. (50.8 mm)

-

Front: 2.0 in. (50.8 mm)

-

-

Ambient temperature does not exceed 140°F (60°C).

-

Cabling is away from sources of electrical noise, such as radios, power lines, and fluorescent lighting fixtures.

Verifying Package Contents

Included in the box is the switch itself and it’s installation documentation. If any item is missing or damaged, contact your representative or reseller for support.

Tools and Equipment

Obtain these necessary tools and equipment:

-

A single or a pair of stud size 6 ring terminals (Hollingsworth part number R3456B or equivalent) for use as a protective ground connector.

-

Crimping tool (Thomas & Bett part number WT2000, ERG-2001 or equivalent).

-

10-gauge copper ground wire.

-

UL- and CSA-rated, style 1007 or 1569 twisted-pair copper appliance wiring material (AWM) wire for DC power connections.

-

Wire-stripping tools for stripping 10-, 16-, and 18-gauge wires.

-

Number-2 Phillips screwdriver.

-

Flat-blade screwdriver.

-

15mm 12pt socket for IP67 dust caps

-

Torque Driver (Such as a Torqueleader TT500 or equivalent)

Installing or Removing the Memory Card (Optional)

The switch supports a hot-swappable SD memory card (SD-IE-4GB) firmware and the startup configuration are stored, making it possible to replace a failed switch without reconfiguring the replacement switch.

The SD memory card cover protects the flash card against shock and vibration by holding the card in place. The cover is attached via lanyard, and secured with captive screws. The slot for the SD memory card is located on the side of the switch.

To install or replace the SD memory card, follow these steps:

Procedure

| Step 1 |

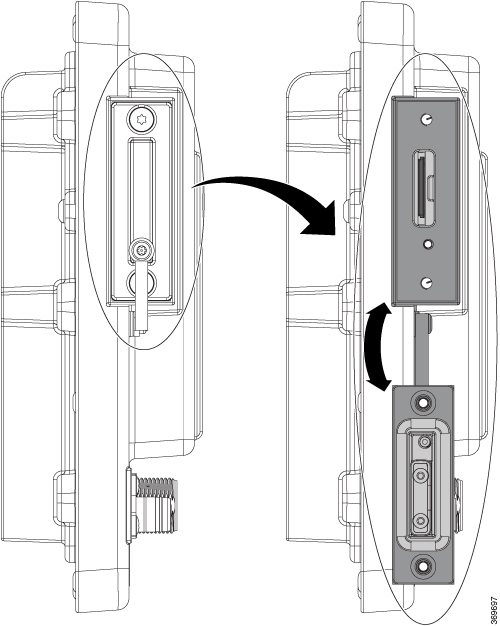

On the side of the switch, loosen the captive screws until they are free of the chassis. See the following figure.  |

| Step 2 |

Install or remove the card:

|

| Step 3 |

Close the guard door and fasten the captive screws to 15.93 to 19.47 in/lbs (1.8 -2.2Nm) to maintain IP67 compliance. |

Connecting a PC or Terminal to the Console Port

To configure the device, you can connect a PC or terminal to the console port and enter Cisco IOS commands through the CLI. This section describes the procedure for connecting a PC to the console port and using a terminal emulator application, such as PuTTy or Hyperterminal, to configure the device.

Procedure

| Step 1 |

Connect the 5-pole-to-DB-9 adapter cable (Cisco PID CAB-CONSOLE-M12=) to a 9-pin serial port on a PC. Connect the other end of the cable to the switch console port. |

||

| Step 2 |

Start a terminal-emulation program on the PC or the terminal. The program, frequently a PC application such as PuTTy or HyperTerminal, makes communication between the switch and your PC or terminal possible. |

||

| Step 3 |

Configure the baud rate and character format of the PC or terminal to match the console port characteristics:

|

||

| Step 4 |

Connect power to the switch as described in Connecting to Power. |

||

| Step 5 |

The PC or terminal shows the status of the bootup sequence. The switch will auto boot. When the IOS XE software has completed the bootup process the words "Press RETURN to get started!".

|

||

| Step 6 |

To ensure IP67 compliance, make sure all console dust caps and cables are in place and torqued to 4.43 to 7.08 in/lbs (0.5 to 0.8 Nm). |

Connecting to Power

You must supply a power solution for the device. The input voltage should be between 9.6V and 60Vdc

If a custom power supply is used, use the power cable with pig tail ends. Connect the female end of the circular mini-change cable to the power connector on the switch (torque = 10in/lbs) and connect the pigtail to the non-standard power supply.

Warning |

This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the protective device is rated not greater than: 10 A Statement 1005 |

The recommended torque to achieve IP67 compliance is 10 in-lbs (1.13 Nm) for the power input connector on the switch, power output and input connector on the Cisco IP67 power supply.

Grounding the Switch

Follow any grounding requirements at your site.

DANGER |

This equipment is intended to be grounded to comply with emission and immunity requirements. Ensure that the switch functional ground lug is connected to earth ground during normal use. Statement 1064 |

Caution |

To make sure that the equipment is reliably connected to earth ground, follow the grounding procedure instructions, and use a UL-listed ring terminal lug suitable for number 10AWG wire (Hollingsworth part number R3456B or equivalent). |

Caution |

Use at least a 4 mm 2 conductor to connect to the external grounding screw. |

A ground lug is not supplied with the switch. You can select from these options:

-

Single ring terminal

-

Two single ring terminals

To ground the switch to earth ground by using the ground screw, follow these steps:

Procedure

| Step 1 |

Use a standard Phillips screwdriver or a ratcheting torque screwdriver with a Phillips head to remove the ground screw from the switch. Store the ground screw for later use. |

| Step 2 |

Use the manufacturer guidelines to determine the wire length to be stripped. |

| Step 3 |

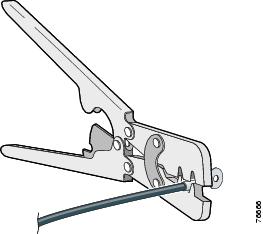

Insert the ground wire into the ring terminal lug, and using a crimping tool, crimp the terminal to the wire. See the following figure. If two ring terminals are being used, repeat this action for a second ring terminal.  |

| Step 4 |

Slide the ground screw through the terminal. |

| Step 5 |

Insert the ground screw into the ground screw opening. |

| Step 6 |

Use a ratcheting torque screwdriver to tighten the ground screws and ring terminal to the switch front panel to 3.5 in-lb (0.4 N-m). The torque must not exceed 3.5 in-lb (0.4 N-m). |

| Step 7 |

Attach the other end of the ground wire to a grounded, bare metal surface, such as a ground bus, a grounded DIN rail, or a grounded bare rack. |

Connecting the earth ground wire

Procedure

| Step 1 |

Measure a single length of stranded copper wire long enough to connect the power supply to the earth ground. The wire color might differ depending on the country that you are using it in.

|

||

| Step 2 |

Connect one end of the stranded copper wire to a grounded bare metal surface, such as a ground bus, a grounded DIN rail, or a grounded bare rack. Connect the other end of the wire to the grounding screw on the power supply. Only wire with insulation should extend from the connection.

|

||

| Step 3 |

Tighten the earth-ground wire connection screw.

|

Running Express Setup

Use Express Setup to enter the initial IP management information. You can then access WebUI on the switch by pointing your broswer to the switch IP address to complete the Day 1 configuration.

You need this equipment to set up the switch:

-

Computer running Windows or a Mac.

-

A web browser with JavaScript enabled.

Google Chrome 38 or later, Mozilla Firefox 35 or later, or Apple Safari 7 or later.

-

Straight-through or crossover Category 5 or 6 cable

-

A small paper clip to reach the button.

Note |

The cable should have M12 Xcode or Dcode connector on one end and RJ45 on the other. Xcode cable is for Models IE-3400H-8T, IE-3400H-16T, and IE-3400H-24T. The Dcode cable is for models IE-3400H-8FT, IE-3400H-16FT, and IE-3400H-24FT. |

Note |

Before running Express Setup, disable any pop-up blockers or proxy settings on your browser and any wireless client running on your PC. |

To run Express Setup:

Procedure

| Step 1 |

Make sure that nothing is connected to the switch, and the cover for the SD card has been removed (see Installing or Removing the Memory Card (Optional)). During Express Setup, the switch acts as a DHCP server. If your PC has a static IP address, write down the PC static IP address and temporarily configure your PC settings to use DHCP before going to the next step. |

| Step 2 |

Connect power to the switch. See the instructions in the Connecting to Power. The boot sequence begins. This process can take up to 90 seconds. During boot fast, the SYS LED blinks green, and the other LEDs turn steady green. When boot fast is complete, the SYS LED turns steady green, and the Express Setup LED starts to blink green. If the SYS LED is off (system not powered on), continues to blink green (POST in progress), or is solid red (Fault), contact the Cisco Technical Assistance Center (TAC). |

| Step 3 |

Press the Express Setup button (located next to the SD Card slot, under the cover) for 2 to 3 seconds. This button is recessed behind the panel, so you can use a simple tool, such as a paper clip. When you press the Express Setup button, switch port 1/1 begins blinking green. |

| Step 4 |

Connect a Category 5 Ethernet cable (not provided) to the top left port on the switch to the Ethernet port on your PC. on the switch its always the top left port regardless of model. The port LEDs on your PC and on the switch blink green while the switch configures the connection. The steady green port LEDs indicate a successful connection. If the port LEDs do not turn green after about 30 seconds, make sure that:

|

| Step 5 |

Start a browser session on the PC. A login prompt appears. |

| Step 6 |

Enter IP address 192.168.1.254 into the browser URL bar. If a security warning appears, click to accept the risk and proceed. A login prompt appears. |

| Step 7 |

Username is 'admin', and password is the system serial number found on the side of the switch next to the SD card cover. The Configuration Setup Wizard Setup web page appears. If it does not appear, make sure that any pop-up blockers or proxy settings on your browser are disabled and that any wireless client is disabled on your PC. |

| Step 8 |

The first of four web pages appears. You need to navigate through all four web pages to complete express setup. In the Account Settings page, provide values for all fields with "*" .

|

| Step 9 |

Click Basic Settings once the settings are correct. The Basic Settings window is displayed.

|

| Step 10 |

Click Switch Wide Settings. The Switch Wide Settings window is displayed (No required fields on this page). |

| Step 11 |

Click Summary. The Summary window is displayed. |

| Step 12 |

Verify the information displayed in the summary is correct, and when ready click Submit. |

-

Verify connectivity:

-

Open a command prompt, type ping 192.168.1.254, all replies should be received.

-

Do not unplug PC from the switch

-

-

In case of error or to return IE switch to Manufacturing defaults:

-

The IE Switch can be returned to mfg defaults by inserting paper clip (or equivalent) into Express Setup recess for 15-20 seconds, observe the Express Setup LED, remove the paper clip when it flashes alternating orange/green.

-

After 15 seconds release paper clip, IE switch will auto reload.

-

After reboot, IE switch will be in factory defaults. Wait approximately 120 seconds.

-

Express Setup LED blinks orange, which means reloading factory defaults.

-

When Express Setup LED blinks green, restart the Express Setup procedure.

Note

The Express setup long press (pressing the button for 15 seconds to reset the switch to use factory default settings) deletes the configurations (nvram_config and vlan.dat) from the flash and removable media (SD card). Remove any removable media if you do not want any files to be deleted from the SD card.

-

-

Reset procedure

-

Screen naming vs power page naming

-

PC disconnect, start over

What to do next

You can now manage the switch by using WebUI, or CLI.

Launching WebUI

Display WebUI by following these steps:

Procedure

| Step 1 |

Start a web browser on your PC or laptop. |

| Step 2 |

Enter the switch IP address, username, and password (assigned previously in Step 8) in the web browser, and press Enter . The WebUI page appears. If the WebUI page does not appear:

|

Connecting Alarm Circuits

After the switch is installed, you can connect the alarm.

For instructions on grounding the switch and connecting it to power, see the Connecting to Power.

Wiring the External Alarms

Use M12 A-coded cable to connect to the alarm connector on the switch. Recommended torque is 4.43 to 7.08 in/lbs (0.5 to 0.8 Nm).

The recommended cable part number from Molex is 1200650523. One end of the cable has M12 A-coded connector and the other end is open.

The labels for the alarm connector are on the switch panel and are displayed in the following table.

|

Pin |

Label |

Connection |

|---|---|---|

|

1 |

NO |

Alarm Output Normally Open (NO) connection |

|

2 |

NC |

Alarm Output Normally Closed (NC) connection |

|

3 |

UNCONNECTED |

Unused |

|

4 |

UNCONNECTED |

Unused |

|

5 |

COMMON |

Alarm Common connection |

Caution |

The input voltage source of the alarm output relay circuit must be an isolated source and limited to less than or equal to 24 VDC, 1.0 A or 48 VDC, 0.5 A. |

Connecting Destination Ports

These section provides information about connecting to the destination ports.

Caution |

IP66/IP67 UL50E Type 4X compliant only when all cables are mated and torqued appropriately or with the supplied dust caps attached. |

Connecting to 10/100 and 10/100/1000 Ports

The 10/100 and 10/100/1000 ports automatically configure themselves to operate at the speed of attached devices. If the attached ports do not support autonegotiation, you can explicitly set the speed and duplex parameters. Connecting devices that do not autonegotiate or that have their speed and duplex parameters manually set can reduce performance or result in no linkage.

To maximize performance, choose one of these methods for configuring the Ethernet ports:

-

Let the ports autonegotiate both speed and duplex.

-

Set the port speed and duplex parameters on both ends of the connection.

-

For connecting Ethernet cables to models IE-3400H-8FT, 16FT, & 24FT use cables with D-code M12 connectors.

-

To connect Ethernet cables to Models IE-3400H-8T, 16T, & 24T use cables with X-code M12 connectors.

Caution |

To prevent electrostatic-discharge (ESD) damage, follow your normal board and component handling procedures. |

To connect to 10BASE-T, 100BASE-TX or 1000BASE-T devices, follow these steps:

Procedure

| Step 1 |

When connecting to workstations, servers, routers, and Cisco IP phones, connect a straight-through cable to a M12 connector (IP67 Torque: 4.43 to 7.08 in/lbs or 0.5 to 0.8 Nm) on the front panel. See Figure 1-2 . When connecting to 1000BASE-T-compatible devices, use a twisted four-pair, Category 5 or higher cable. The auto-MDIX feature is enabled by default. |

| Step 2 |

Connect the other end of the cable to a M12 connector on the other device. The port LED turns on when both the switch and the connected device have established a link. The port LED is amber while Spanning Tree Protocol (STP) discovers the topology and searches for loops. This can take up to 30 seconds, and then the port LED turns green. If the port LED does not turn on:

|

| Step 3 |

Reconfigure and reboot the connected device if necessary. |

| Step 4 |

Repeat Steps 1 through 3 to connect each device. |

| Step 5 |

To ensure IP67 compliance, make sure all alarm dust caps and cables are in place and torqued to 4.43 to 7.08 in/lbs (0.5 to 0.8 Nm). |

Where to Go Next

If the default configuration is satisfactory, the switch does not need further configuration. You can use any of these management options to change the default configuration:

-

WebUI

You can use WebUI web interface to manage and monitor individual switches. Device Manager can be accessed from anywhere in your network through a web browser by using the management IP address of the switch. For more information, see the Device Manager online help.

-

Cisco IOS-XE CLI

The switch CLI is a version of Cisco iOS firmware that can be used to configure and monitor the switch. You can access the CLI either by connecting your management station directly to the switch console port or by using Telnet from a remote management station.

-

Cisco DNA Center that can be found at: https://www.cisco.com/c/en/us/products/cloud-systems-management/dna-center/index.html

-

SNMP

Switches can be managed by using a SNMP-compatible management station running platforms such as HP OpenView or SunNet Manager. The switch supports a comprehensive set of Management Information Base (MIB) extensions and four Remote Monitoring (RMON) groups.

-

Common Industrial Protocol

Common Industrial Protocol (CIP) management objects are supported by the switch, allowing you to manage an entire industrial automation system with one tool.

Feedback

Feedback