Power Supply Overview

|

Hardware |

Release Information |

Description |

|---|---|---|

|

PSU4.3KW-HVPI Power Supply Unit for Cisco 8608 Router |

Release 24.2.1 |

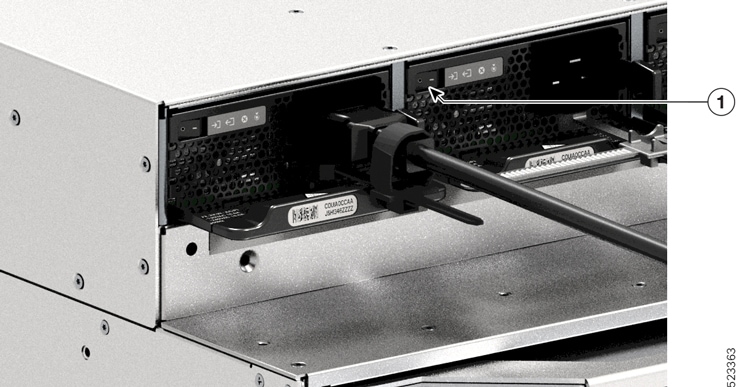

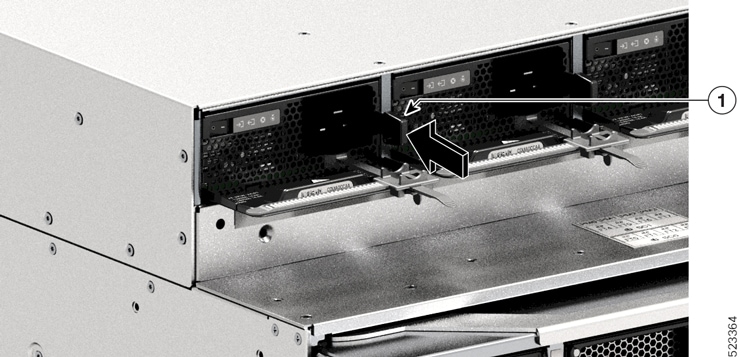

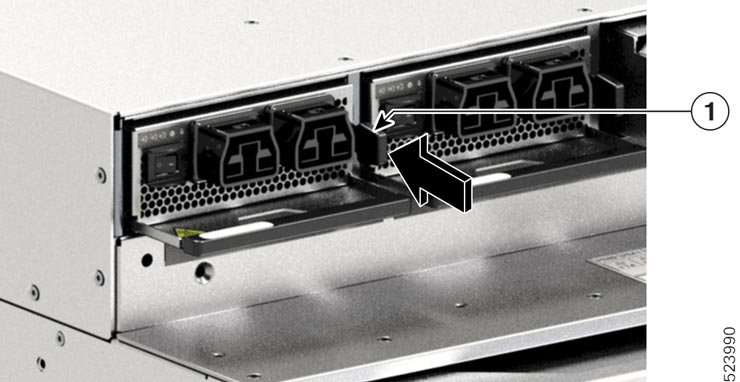

We're now introducing a high voltage power supply unit, PSU4.3KW-HVPI that accepts HVAC or HVDC input power to operate the Cisco 8608 router in the port side intake configuration. The PSU4.3KW-HVPI power supply unit has a dual input redundant power supply with 55V (main) and 3.3V (standby) outputs. The benefits of the PSU4.3KW-HVPI power supply unit are:

|

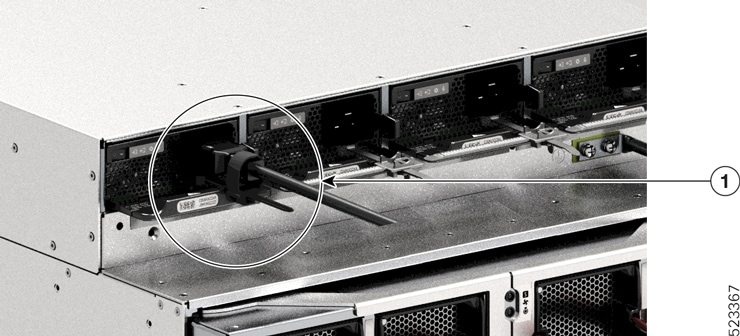

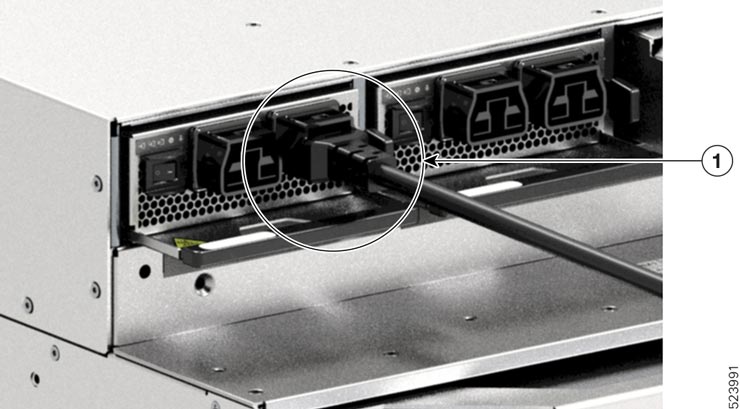

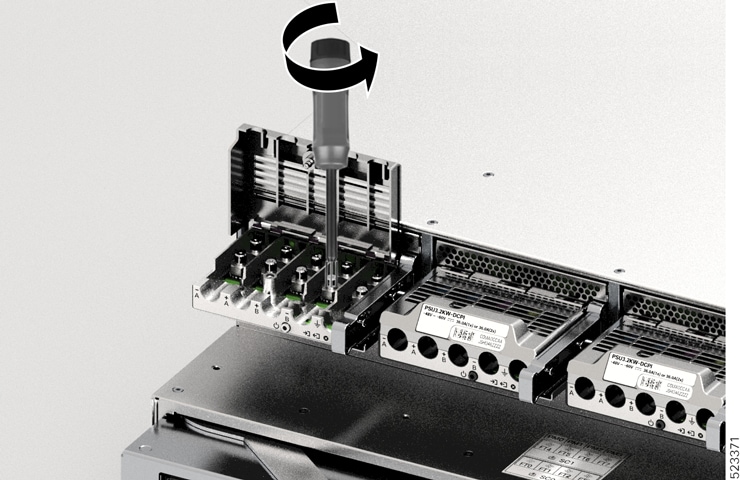

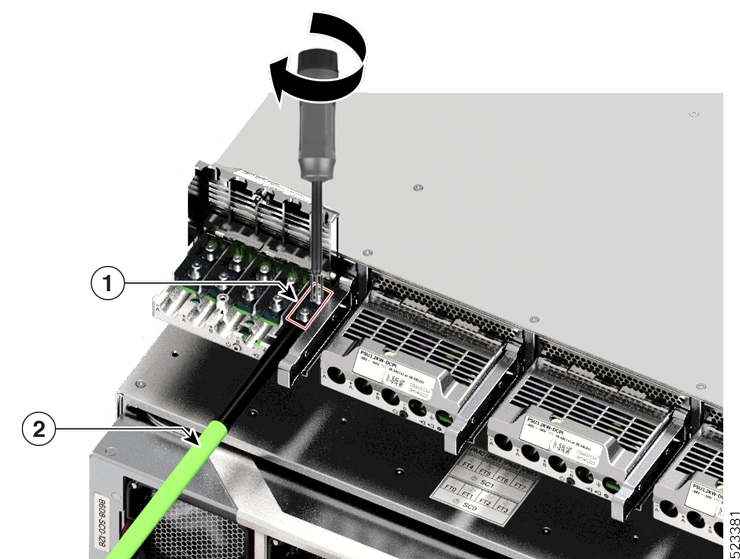

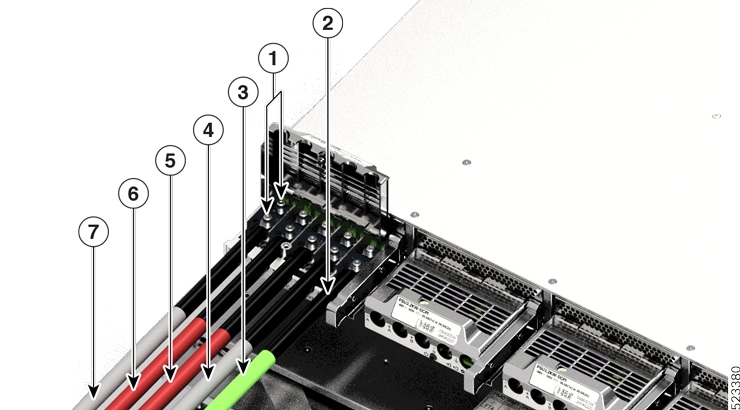

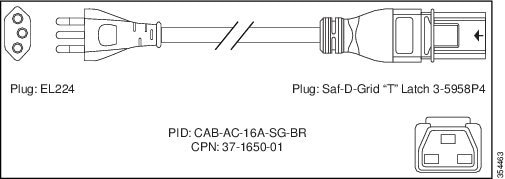

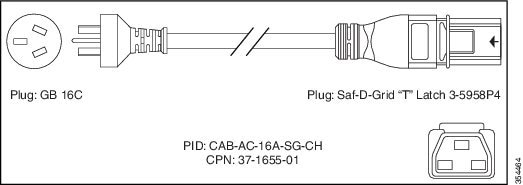

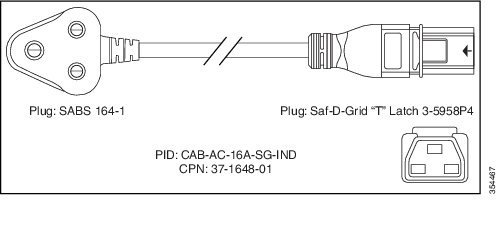

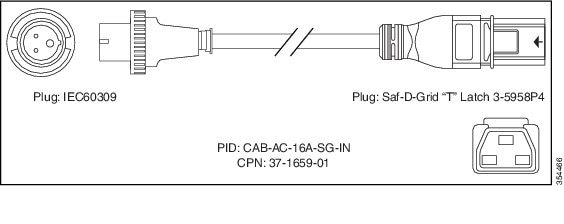

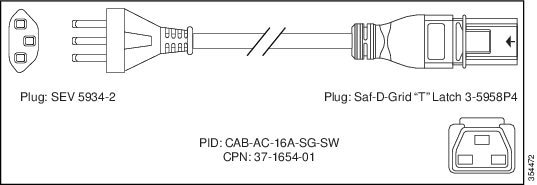

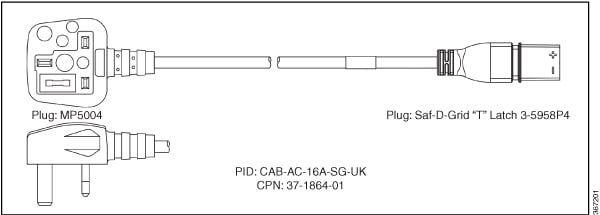

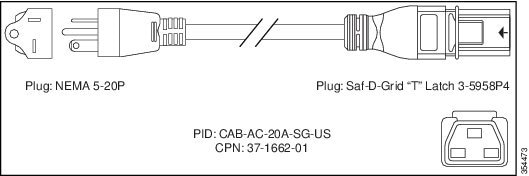

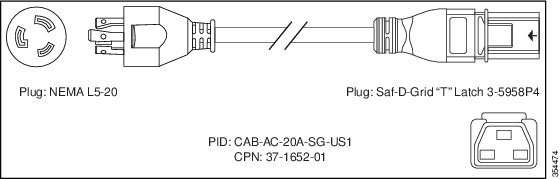

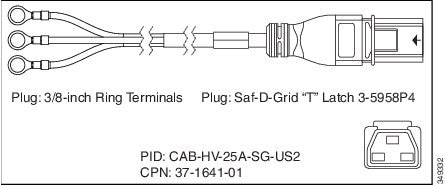

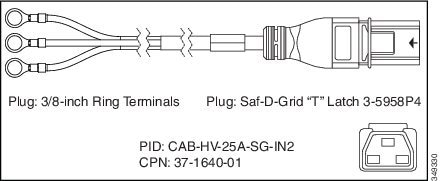

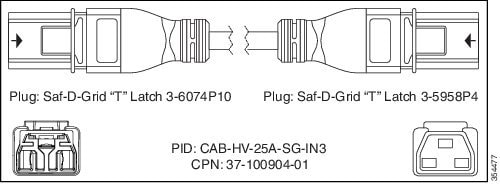

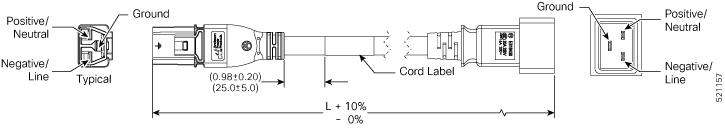

You can install up to four 3.2KW or 4.3KW HVAC/HVDC power supplies in the chassis. Ensure that all power connection wiring conforms to the rules and regulations in the National Electrical Code (NEC) and in local codes.

Note |

|

Power Module Specifications

|

Power Module |

Single/Dual Input |

Nominal Input Voltage Range |

Full Range |

|---|---|---|---|

|

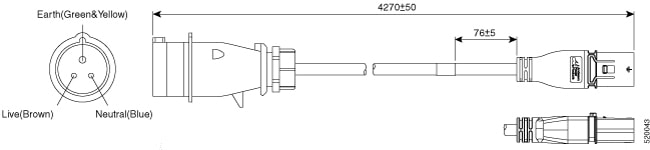

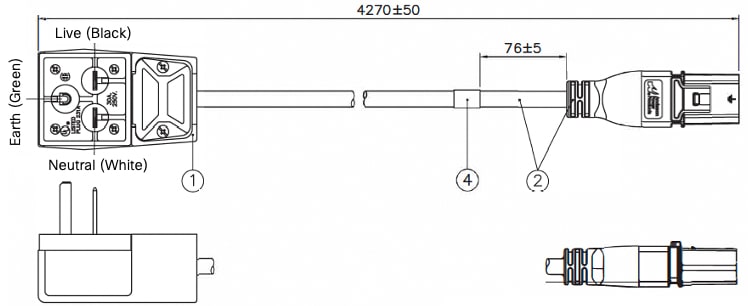

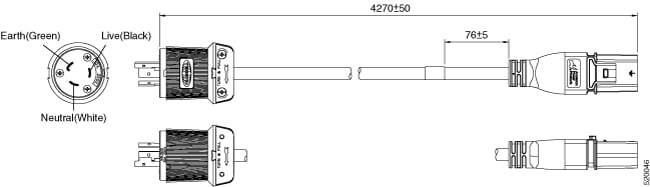

PSU3.2KW-ACPI |

The AC power modules are single feed input with 3.2KW capacity at 220V. They also support operation at 110V with half the capacity of 1570W. AC power modules are rated at 3.2KW maximum at 230V AC high line input, and 1570W maximum at 115V AC low line input. |

100—120V AC 200—240V AC |

85—300V AC |

|

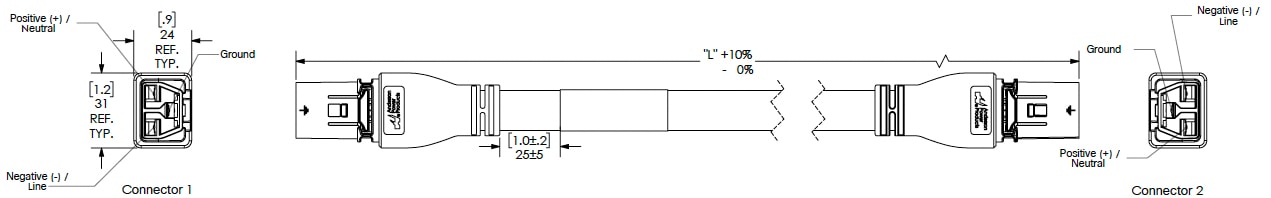

PSU3.2KW-DCPI |

The DC power modules are dual feed input with 3.2KW capacity at any specified input voltage. DC power modules with single feed at any specified input voltage provide up to 1.6KW maximum capacity. |

-48 to -60V DC |

-40 to -75V DC |

|

PSU4.3KW-HVPI |

The AC power modules supply 4310W capacity with dual 220V feeds and 3200W capacity with a single 220V feed. The AC power modules supply 3130W capacity with dual 110V feeds and 1570W capacity with a single 110V feed. The 4.3KW-HVPI PSUs shall operate within specification from 85V—305VAC or 192—400V DC continuously. |

100—120V AC 200—240V AC 265—305V AC 192—219V DC 220—289V DC 290—400 V DC |

85—305V AC 192—400V DC |

Feedback

Feedback