Protecting production integrity and intellectual property

ZEISS is an international leading technology enterprise operating in the fields of optics and optoelectronics. Known for innovation, the company has more than 7,300 R&D employees and holds more than 12,500 patents. Protecting intellectual property and production integrity are essential to the business. ZEISS also needs to comply with cybersecurity standards like ISA/IEC 62443 and the EU’s NIS2 Directive.

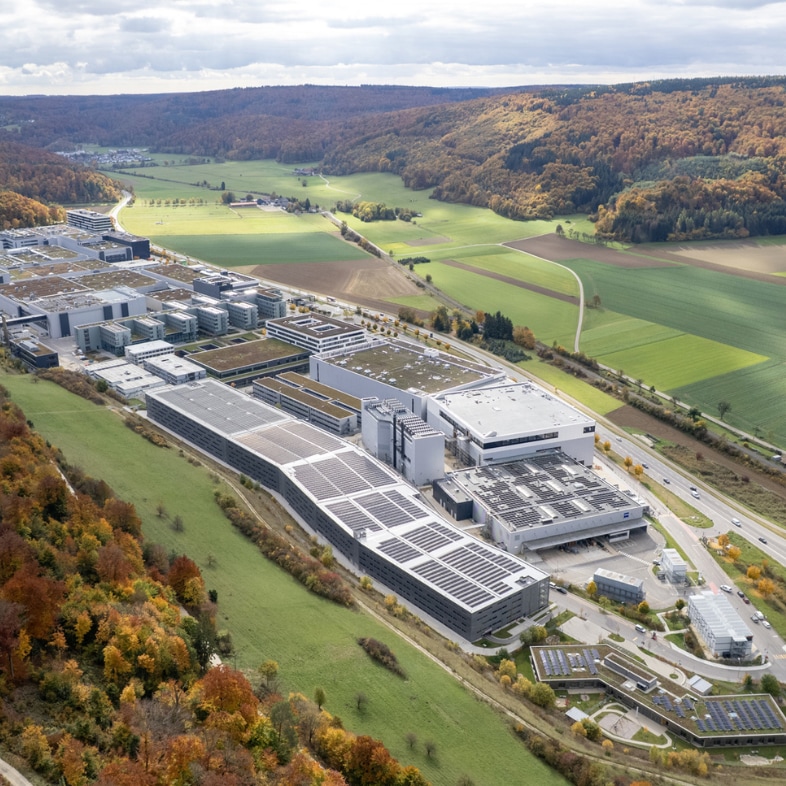

ZEISS has thousands of industrial assets in multiple sites. Protecting them from security threats that could interrupt production or result in information leakage has become more complicated over the years. The reason: many industrial devices communicate with each other, IT systems, and cloud services to streamline operations and enhance overall equipment effectiveness (OEE). Protecting the production infrastructure requires understanding each site’s security posture, identifying unauthorized traffic, and spotting anomalous industrial control behaviors.

To maintain production integrity, ZEISS wanted a centrally managed industrial security solution. Requirements included deep visibility into industrial assets, maps showing what other assets they communicated with, real-time monitoring, and advanced threat detection.