Preinstallation Checks and Installation Guidelines

Before you mount and deploy your access point, we recommend that you perform a site survey (or use the Site Planning tool) to determine the best location to install your access point.

You should have the following information about your wireless network available:

-

Access point locations

-

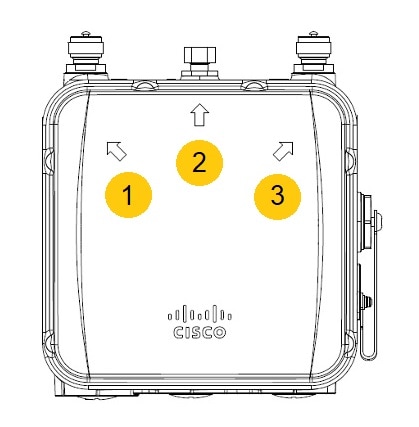

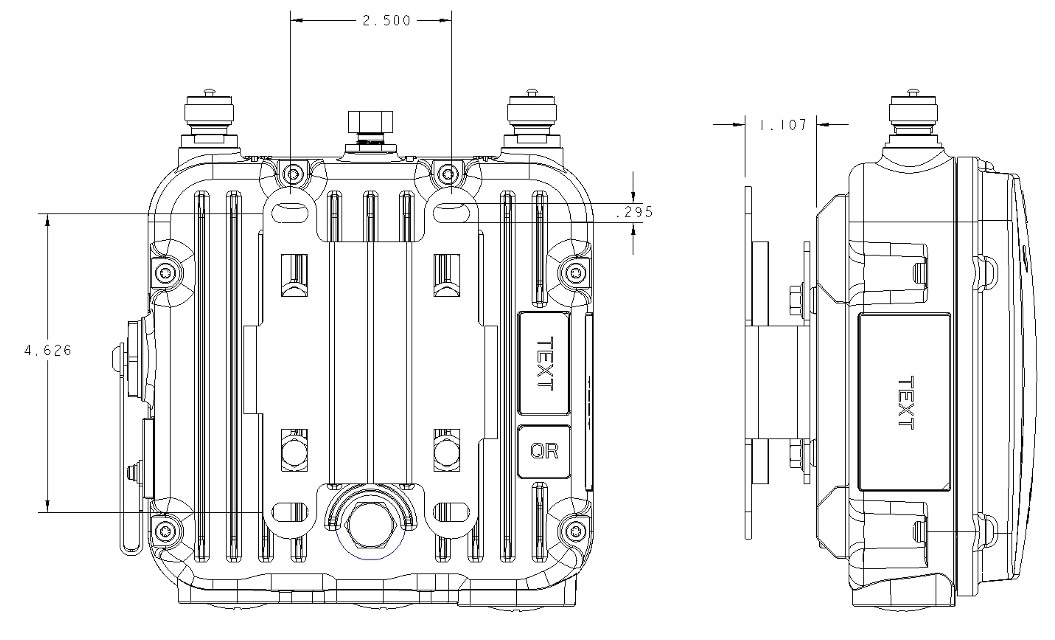

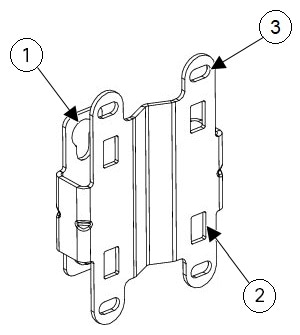

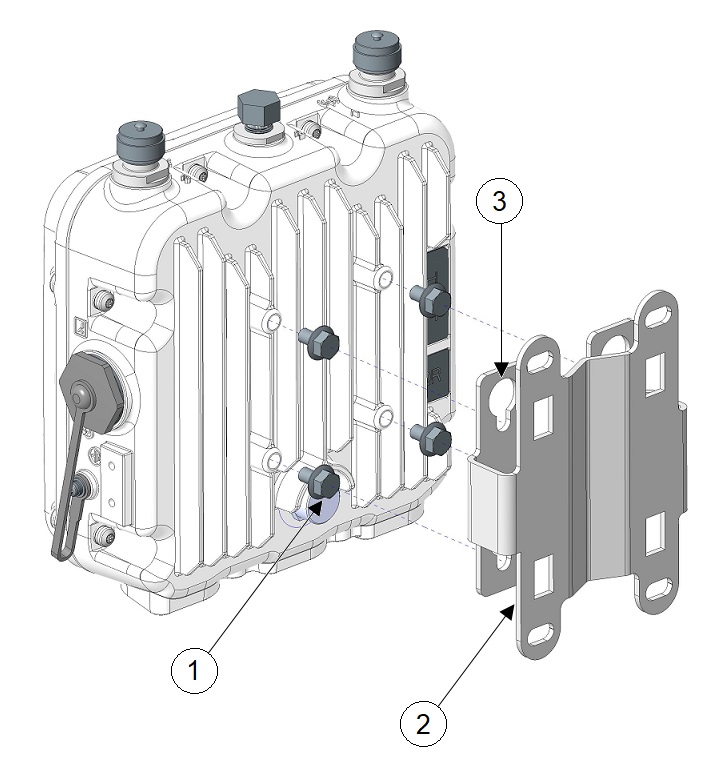

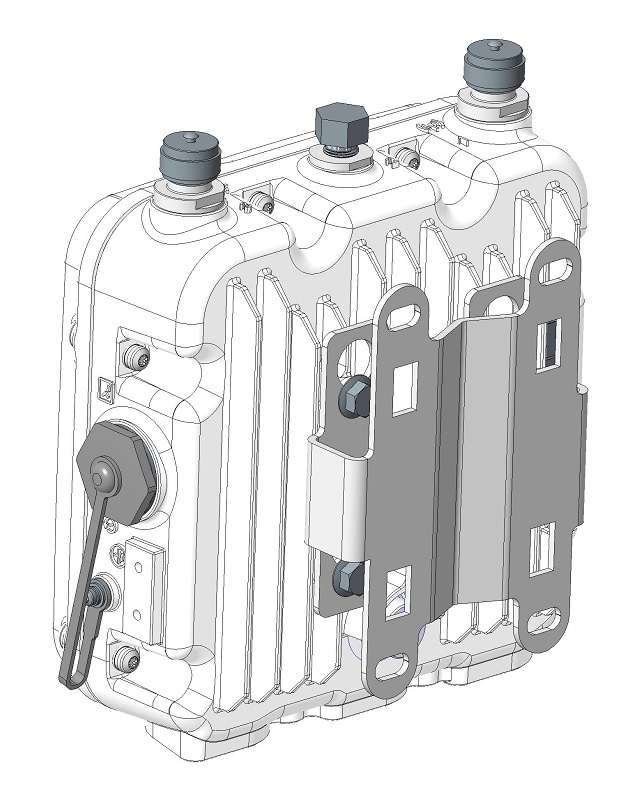

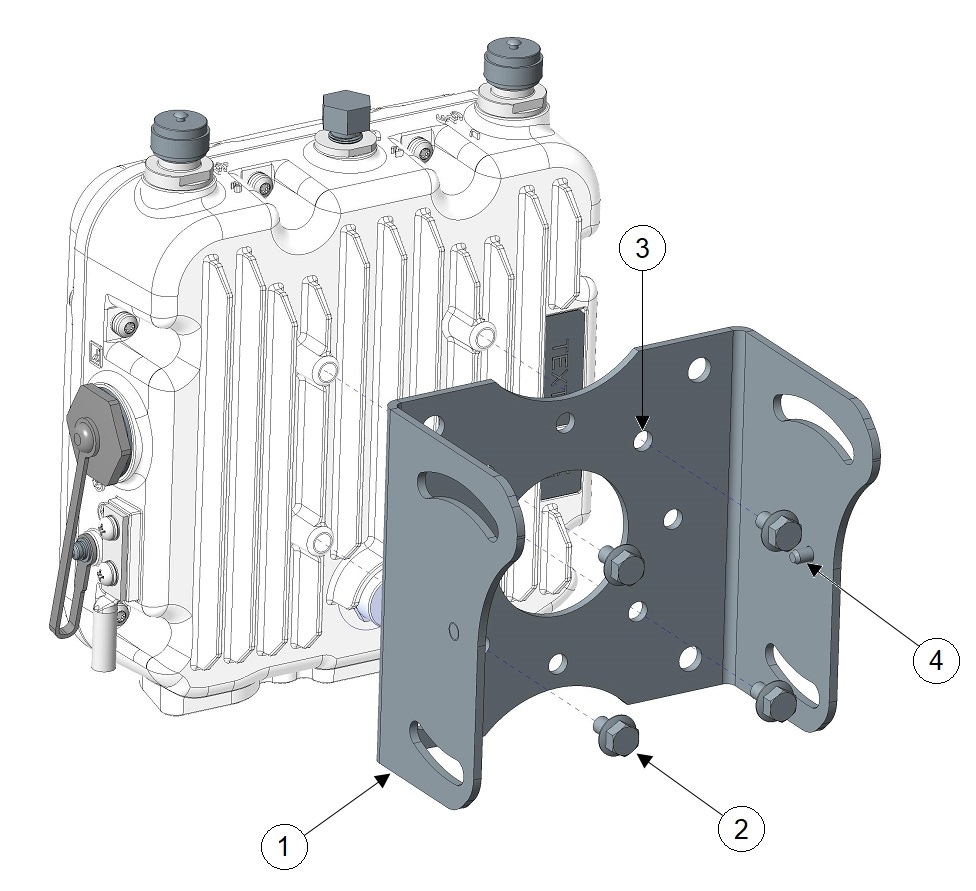

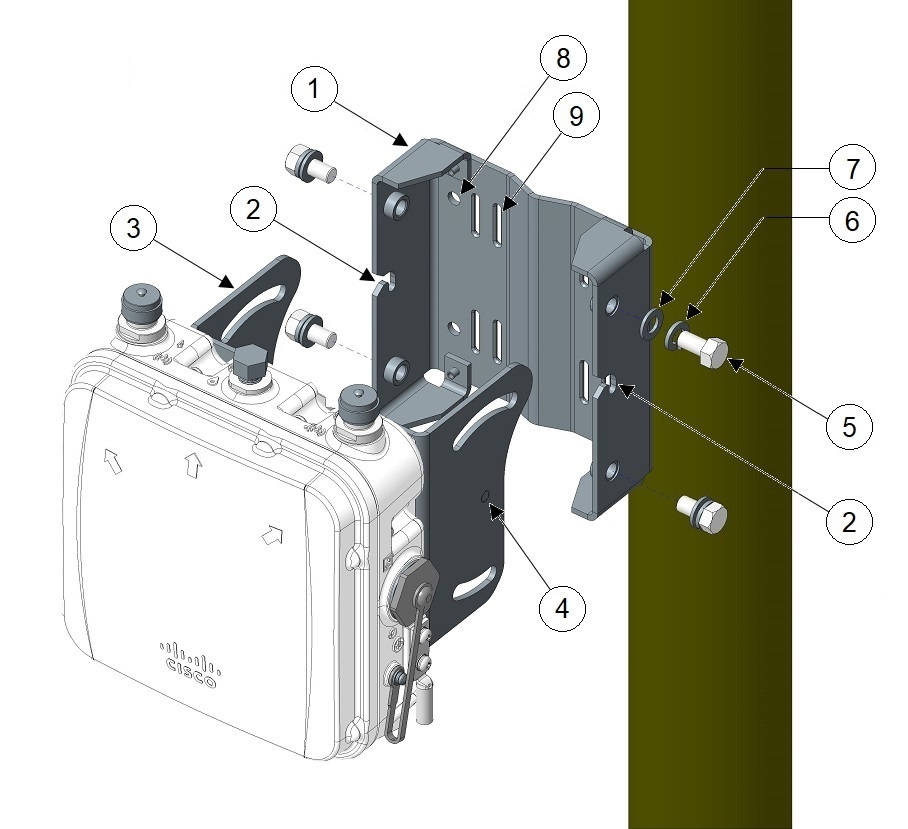

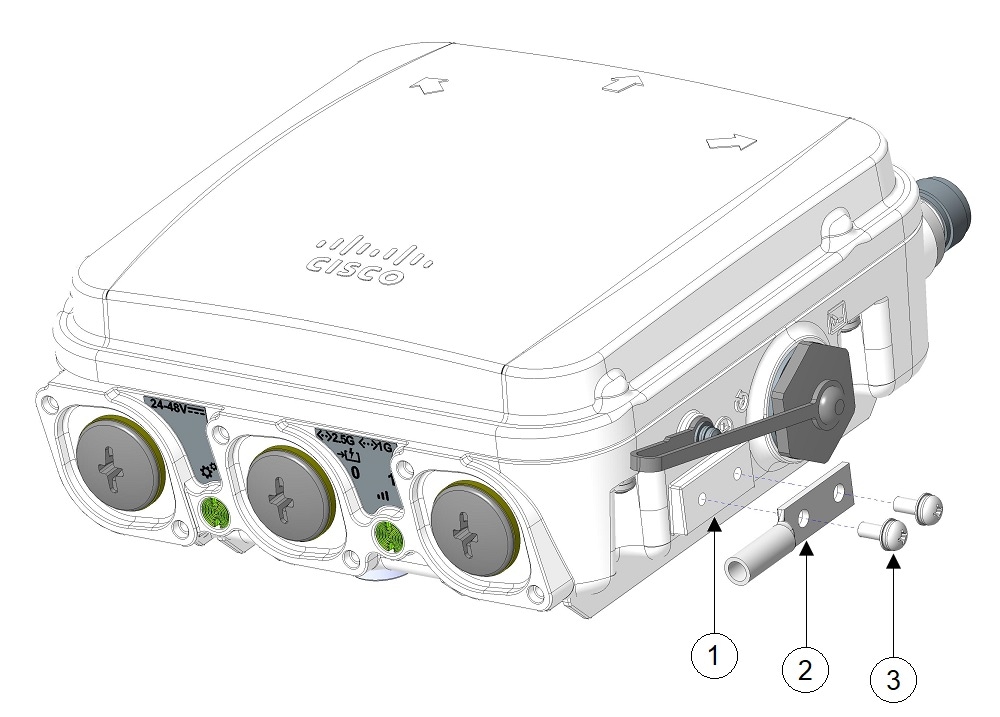

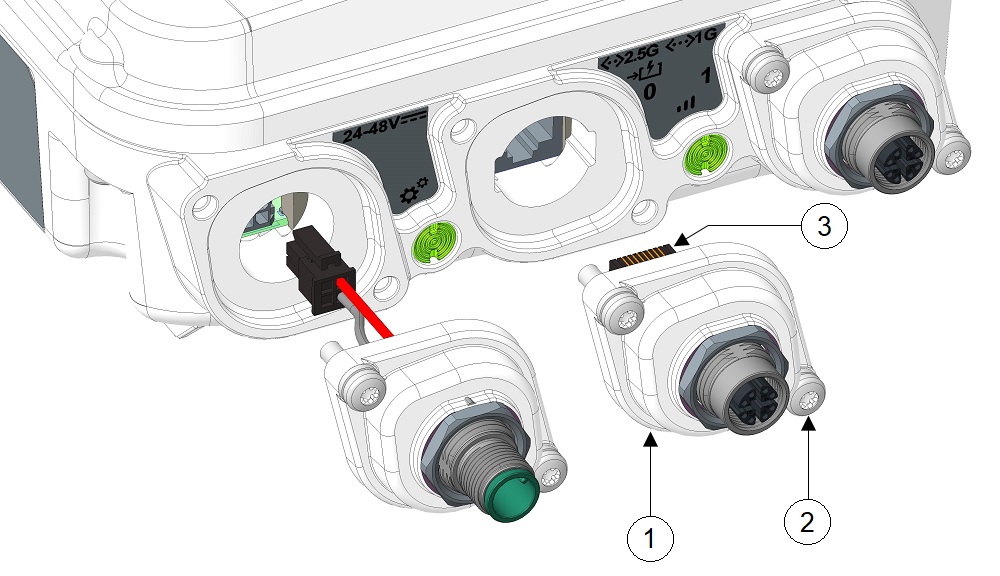

Access point mounting options: To a vertical or horizontal wall or a DIN rail

-

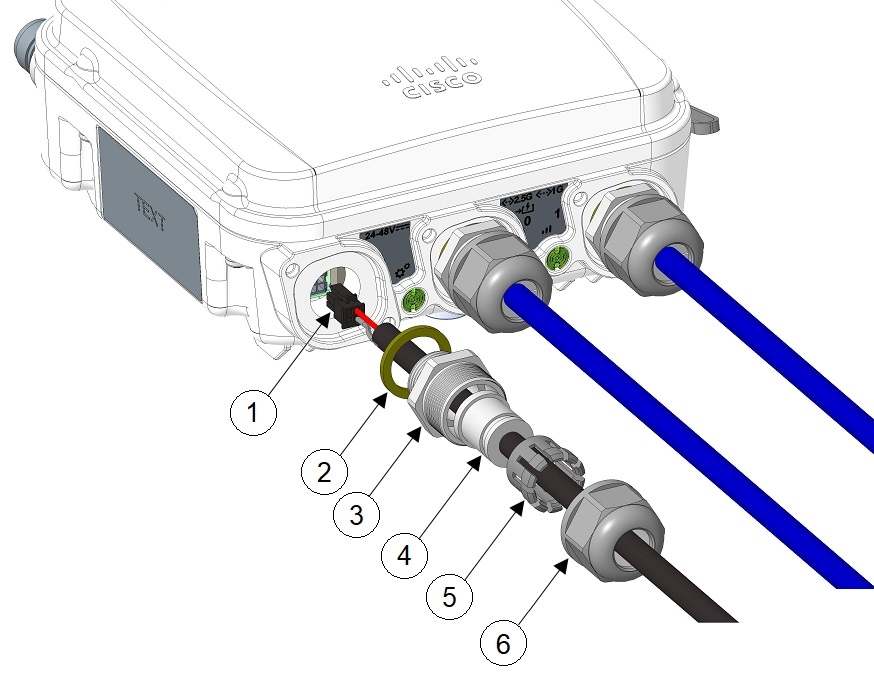

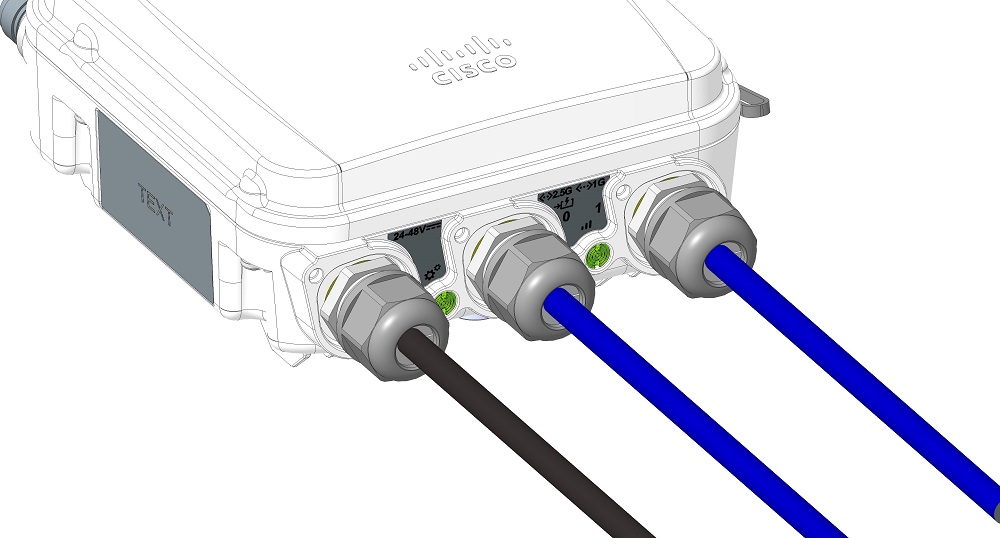

Access point power options: Use either of the following options to power the AP:

-

DC power input

-

Cisco-approved power injector

-

802.3at (PoE+), 802.3bt, and Cisco Universal PoE (Cisco UPOE)

-

-

Operating temperature : -40° to +140°F (-40° to +60°C) with solar load and still air.

-

Extended operating temperature (DC powered): -58° to +167°F (-50° to +75°C) without solar loading, still air, and cold start limited to -40°C (-40°F).

-

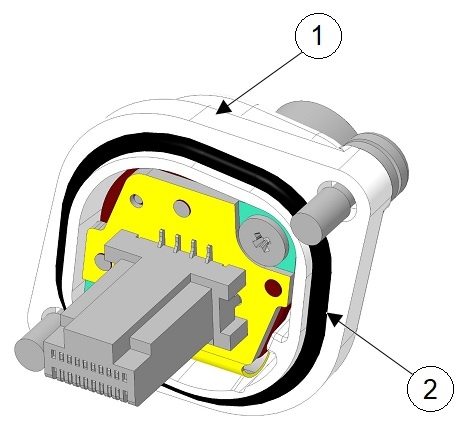

Console access using the console port

We recommend that you use a console cable that is one meter or less in length.

Note

The AP may face issues while booting if you use an unterminated console cable (not plugged into any device or terminal) or a console cable that is more than one meter in length.

We recommend that you make a site map showing access point locations so that you can record the device MAC addresses from each location and return them to the person who is planning or managing your wireless network.

Feedback

Feedback