Tools and Test Equipment

The following tools and equipment are required for installation.

-

Torque wrench capable of 5 to 12 ft-lbs (6.8 to 16.3 Nm)

-

4-inch to 6-inch extension for torque wrench

-

1/2-inch socket for strand clamp bolts and cover bolts

-

1/4-inch flat-blade screwdriver

-

#2 Phillips-head screwdriver

-

Long-nose pliers

-

1/2-inch deep-well socket for seizure connector

-

True-RMS digital voltmeter (DVM)

-

EXFO FOT 22AX optical power meter with adapters

-

Optical connector cleaning supplies

-

Optical connector microscope with appropriate adapters for your optical connectors

Node Fastener Torque Specifications

Be sure to follow these torque specifications when assembling/mounting the node.

|

Fastener |

Torque Specification |

Illustration |

||||

|---|---|---|---|---|---|---|

|

Housing closure bolts |

5 to 12 ft-lbs (6.8 to 16.3 Nm) |

|

||||

|

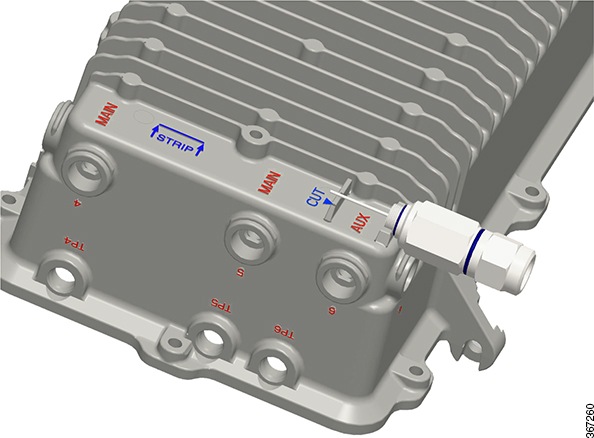

Test point port plugs Housing plugs |

5 to 8 ft-lbs (6.8 to 10.8 Nm) |

|

||||

|

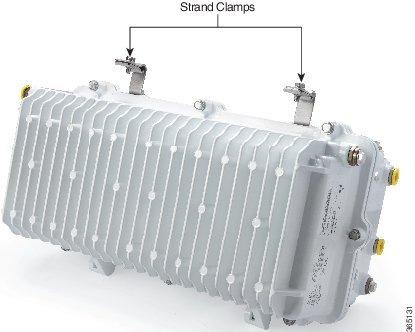

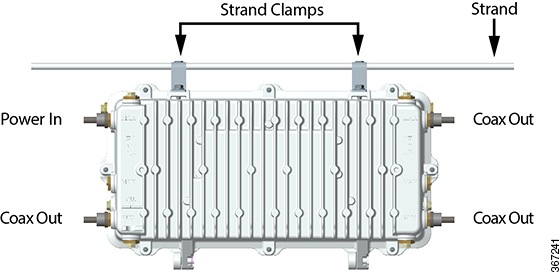

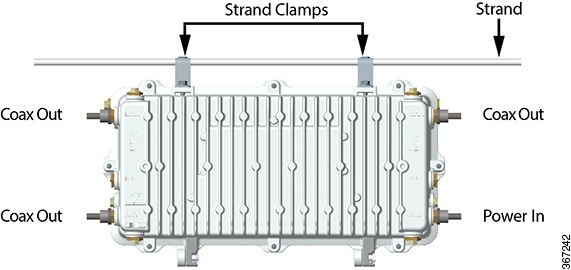

Strand clamp mounting bracket bolts |

5 to 8 ft-lbs (6.8 to 10.8 Nm) |

|

||||

|

Pedestal mounting bolts |

8 to 10 ft-lbs (10.8 to 13.6 Nm) |

|

||||

|

Module securing screws |

25 to 30 in-lbs (2.8 to 3.4 Nm) |

|

||||

|

RF Amplifier assembly shoulder screws (cross head screw) |

18 to 20 in-lbs (2.0 to 2.3 Nm) |

|

||||

|

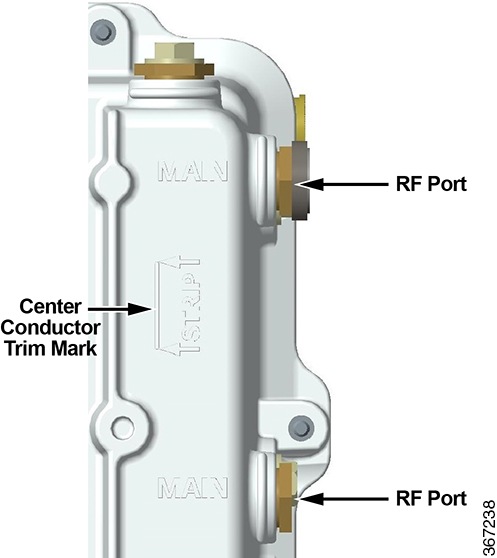

Seizure nut |

2 to 5 ft-lbs (2.7 to 6.8 Nm) |

|

||||

|

RF cable connector |

Per manufacturer instructions |

|

||||

|

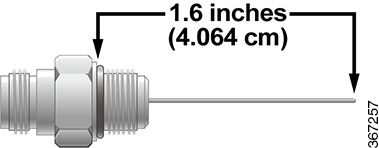

Fiber optic cable connector |

20 to 25 ft-lbs (27.1 to 33.9 Nm) |

|

||||

Feedback

Feedback