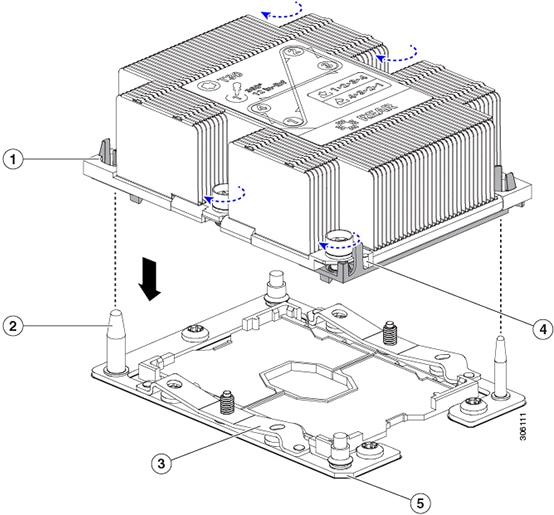

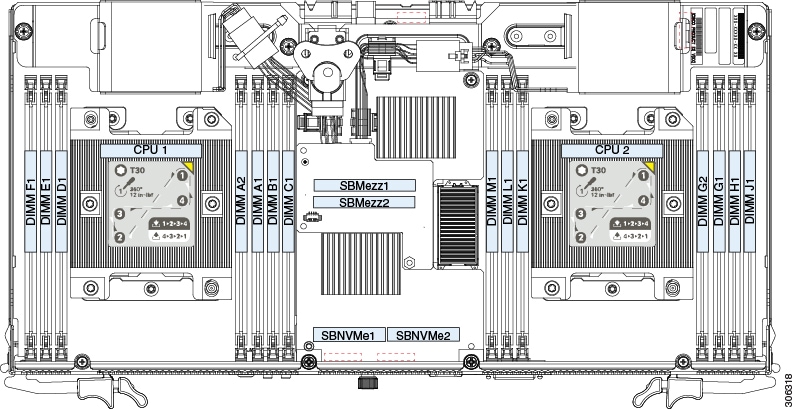

Preparing For Component Replacement

This section contains procedures that are referred to from the replacement procedures.

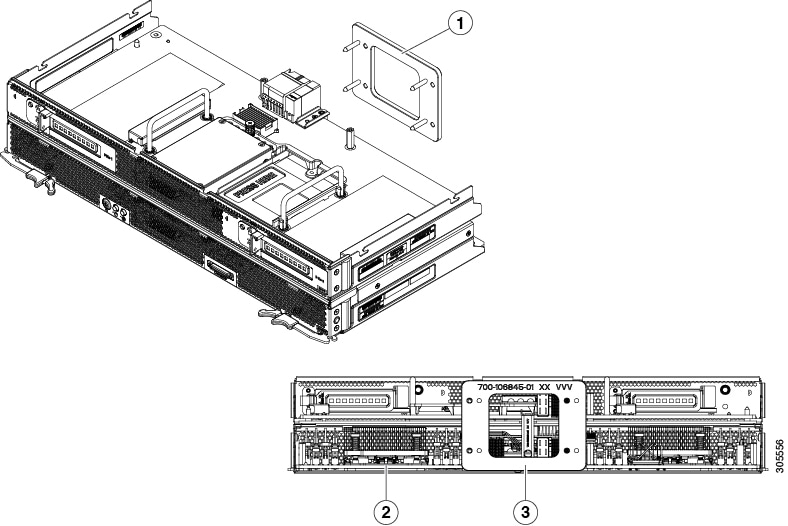

Removing an S3260 M5 Server Node or I/O Expander Top Cover

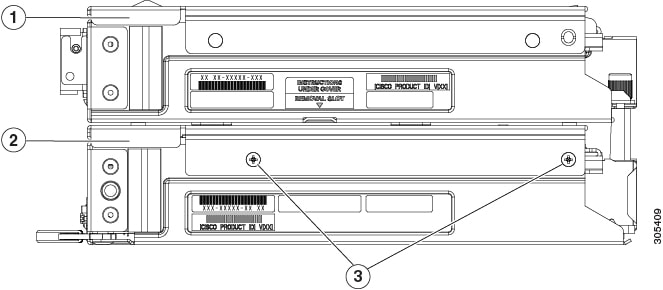

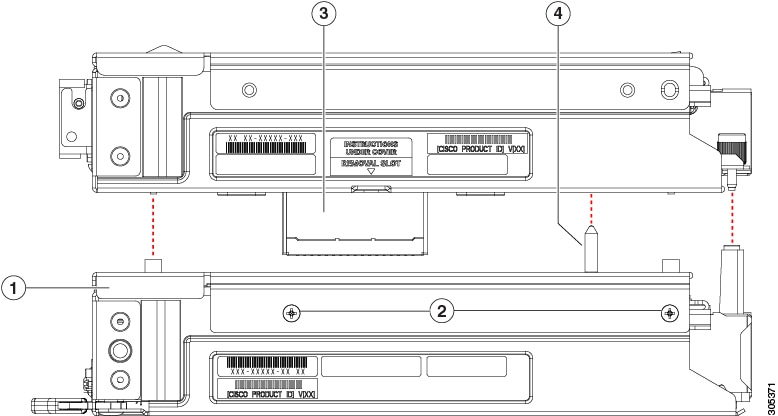

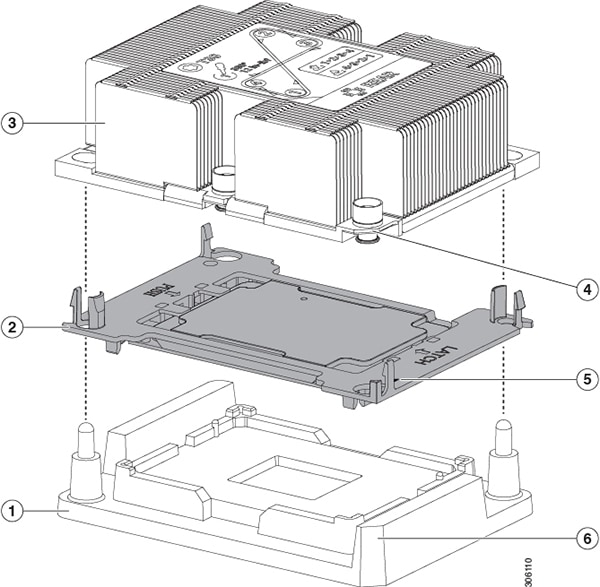

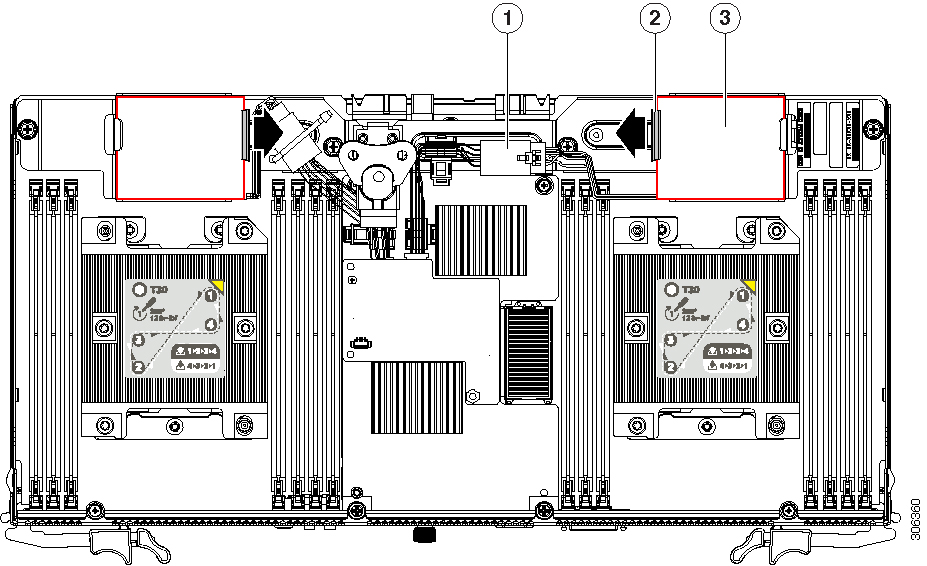

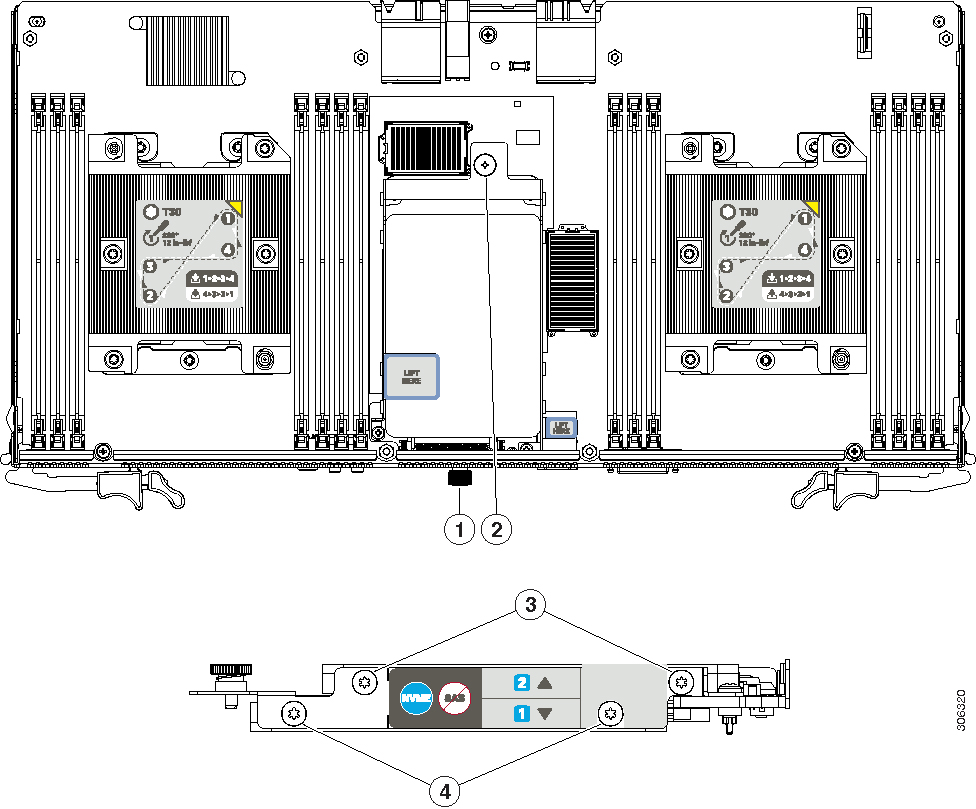

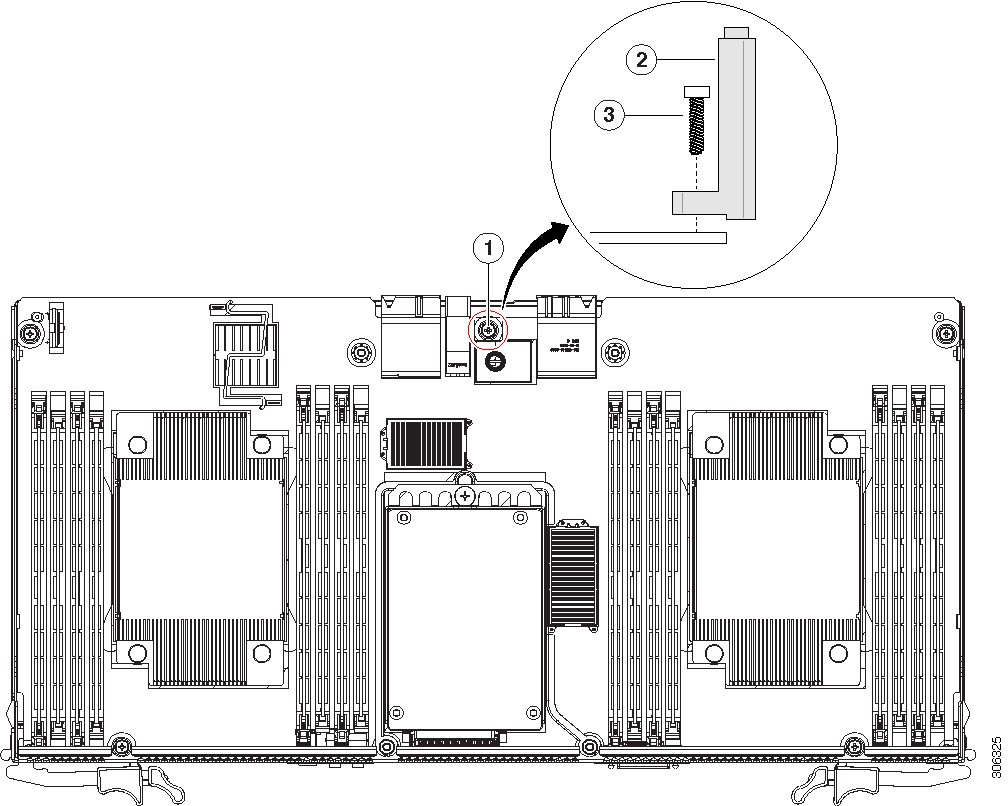

The optional I/O expander and the server node use the same top cover. If an I/O expander is attached to the top of the server node, the top cover is on the I/O expander, as shown in the side view in the following figure. In this case, there is also an intermediate cover between the server node and the I/O expander.

|

1 |

Top Cover In this view, the top cover is on the attached I/O expander. |

3 |

Intermediate cover securing screws (two on each side) |

|

2 |

Intermediate cover In this view, the intermediate cover is attached to the server node. |

- |

Note |

You do not have to power off the chassis in the next step. Replacement with the chassis powered on is supported if you shut down the server node before removal. |

Procedure

| Step 1 |

Shut down the server node by using the software interface or by pressing the node power button, as described in Shutting Down an S3260 M5 Server Node. |

||||

| Step 2 |

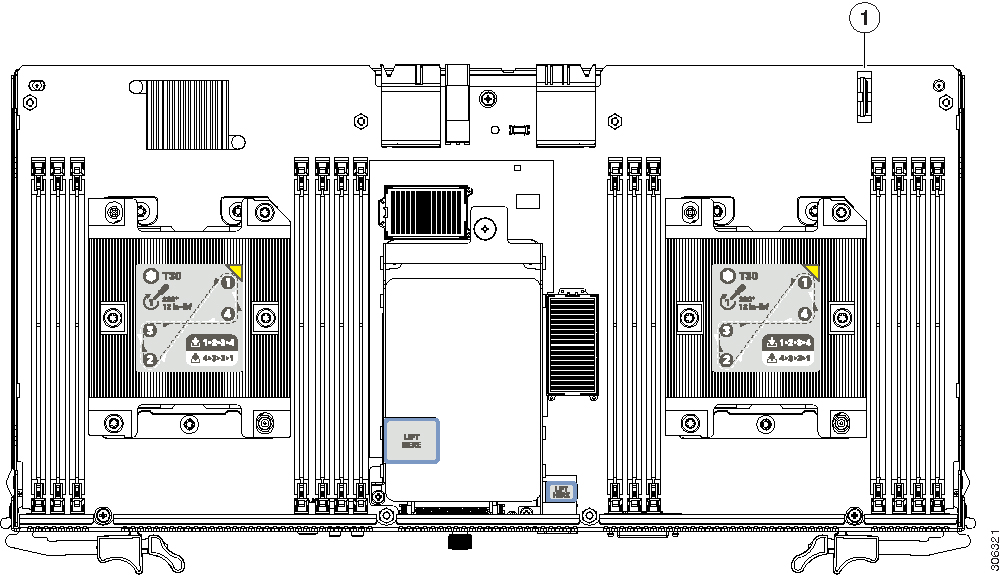

Remove the server node from the system (or server node with attached I/O expander, if present):

|

||||

| Step 3 |

Remove the top cover from the server node or the I/O expander (if present):

|

||||

| Step 4 |

Reinstall the top cover:

|

||||

| Step 5 |

Reinstall the server node to the chassis:

|

||||

| Step 6 |

Power on the server node. |

Removing an I/O Expander From a Server Node

This topics in this section describe how to remove and then reinstall an I/O expander and intermediate cover from a server node so that you can access the components inside the server node.

Note |

You do not have to power off the chassis in the next step. Replacement with the chassis powered on is supported if you shut down the server node before removal. |

Disassembling the I/O Expander Assembly

Procedure

| Step 1 |

Shut down the server node by using the software interface or by pressing the node power button, as described in Shutting Down an S3260 M5 Server Node. |

||||

| Step 2 |

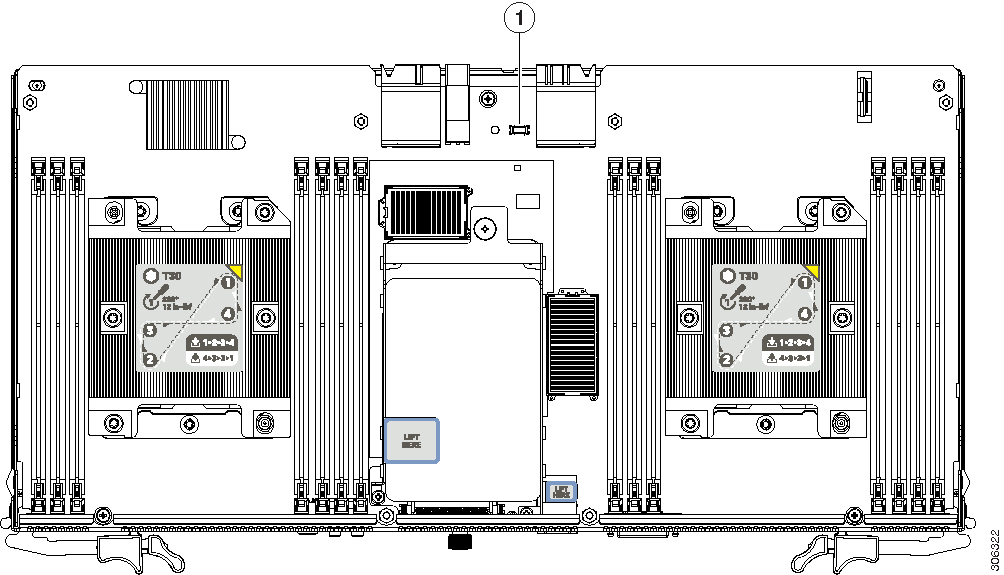

Remove the server node with attached I/O expander from the system:

|

||||

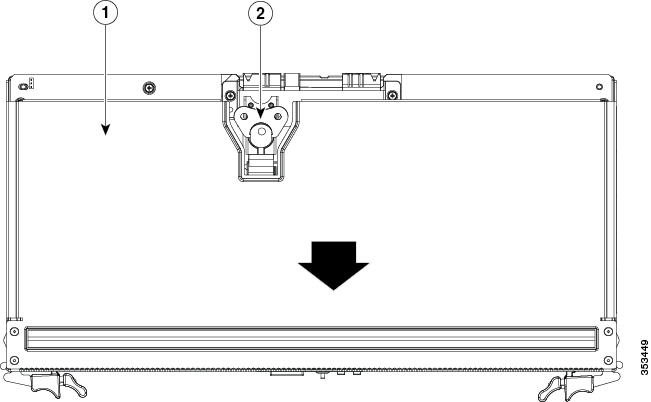

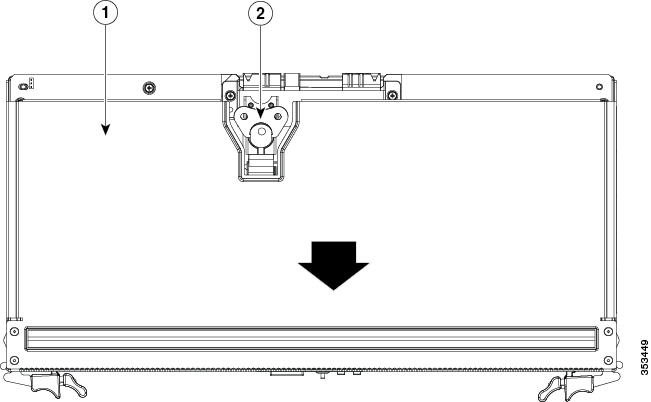

| Step 3 |

Remove the top cover from the I/O expander:

|

||||

| Step 4 |

Remove the I/O expander from the server node:

|

||||

| Step 5 |

Remove the intermediate cover from the server node:

|

||||

| Step 6 |

Install the server node (with attached I/O expander, if present) to the chassis:

|

||||

| Step 7 |

Power on the server node. |

Reassembling the I/O Expander Assembly

Before you begin

This procedure assumes that you have already taken apart the I/O expander/server node assembly.

Procedure

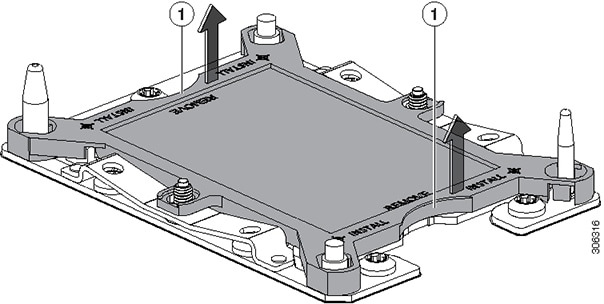

| Step 1 |

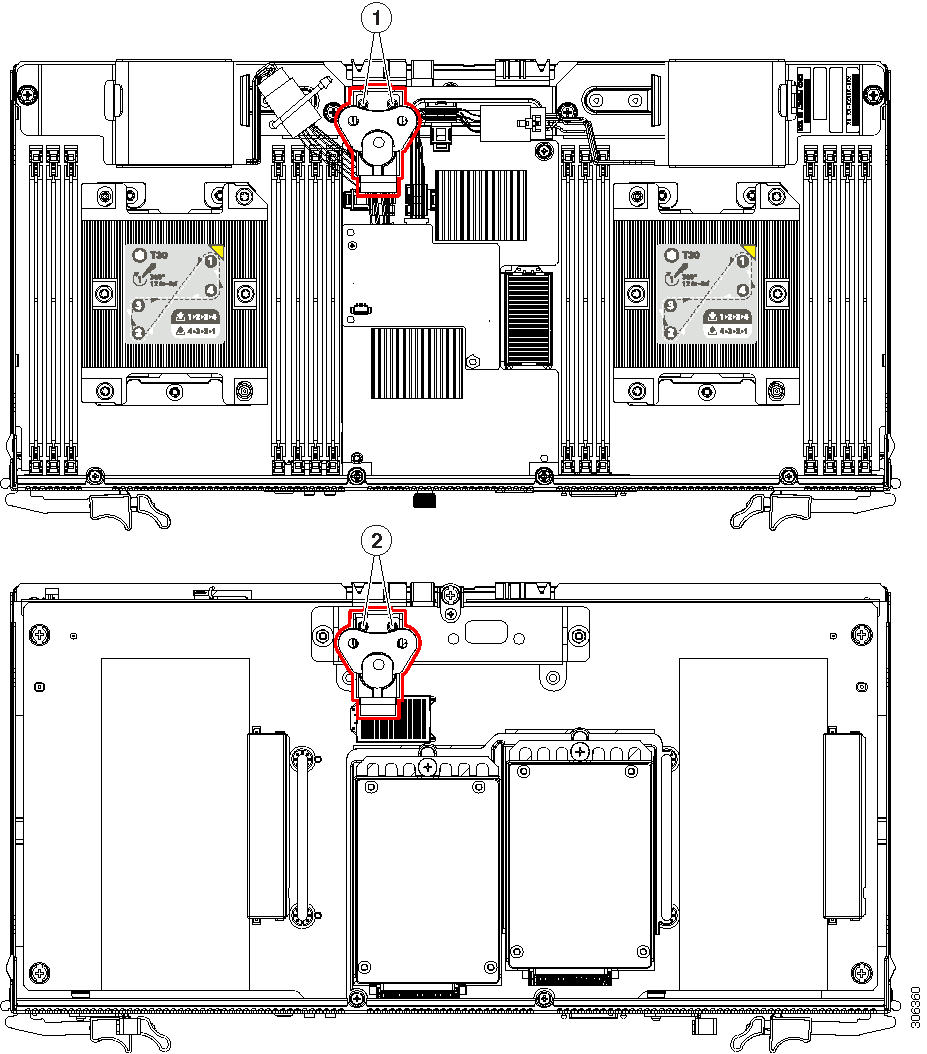

Reinstall the intermediate cover to the server node:

|

||||||||

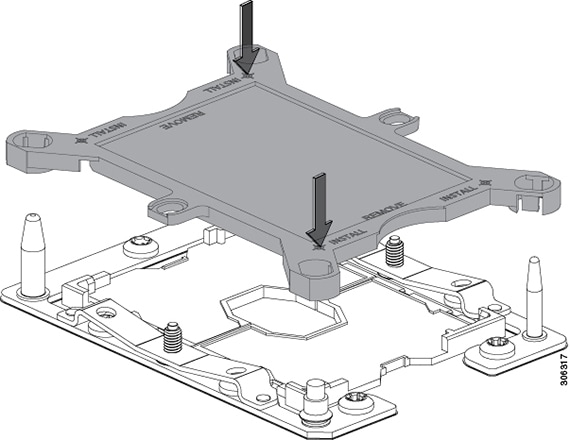

| Step 2 |

Reinstall the I/O expander to the server node:

|

||||||||

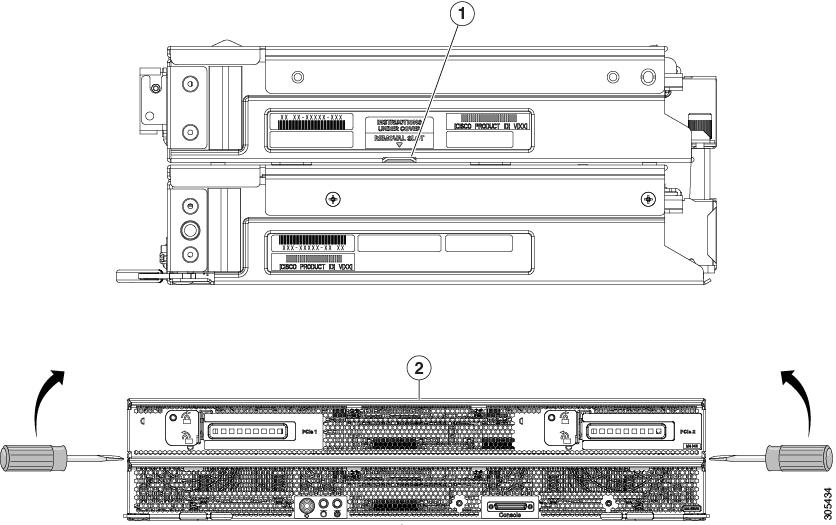

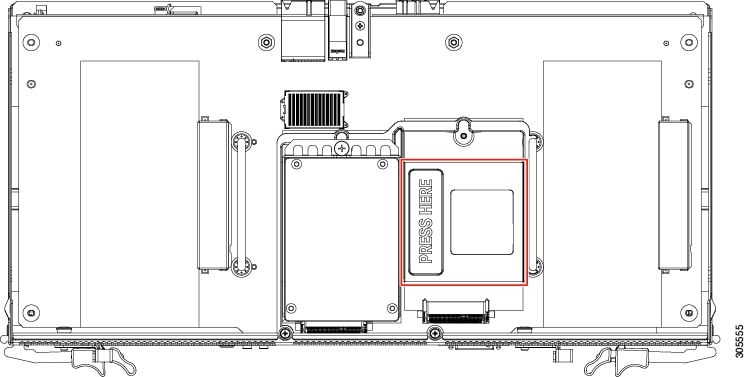

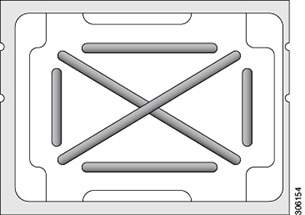

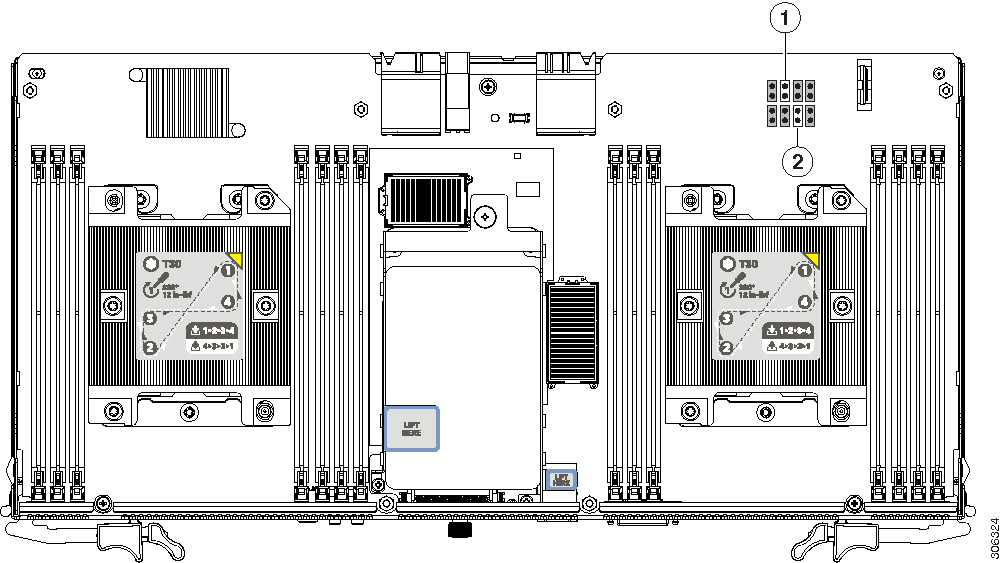

| Step 3 |

Insert the four pegs of the alignment tool into the holes that are built into the connector side of the server node and I/O expander. Ensure that the alignment tool fits into all four holes and lies flat. The alignment tool is shipped with systems that are ordered with an I/O expander. It is also shipped with I/O expander replacement spares. You can order the tool using Cisco PID UCSC-C3K-M4IOTOOL.

|

||||||||

| Step 4 |

Reinstall and tighten the five screws that secure the I/O expander to the top of the server node. |

||||||||

| Step 5 |

Remove the alignment tool. |

||||||||

| Step 6 |

Reinstall the top cover to the I/O expander:

|

||||||||

| Step 7 |

Reinstall the server node to the chassis:

|

||||||||

| Step 8 |

Power on the server node. |

Feedback

Feedback