Installation Tasks

After you prepare your site for installation, follow these tasks to install the switch:

|

Task |

Description |

||

|---|---|---|---|

|

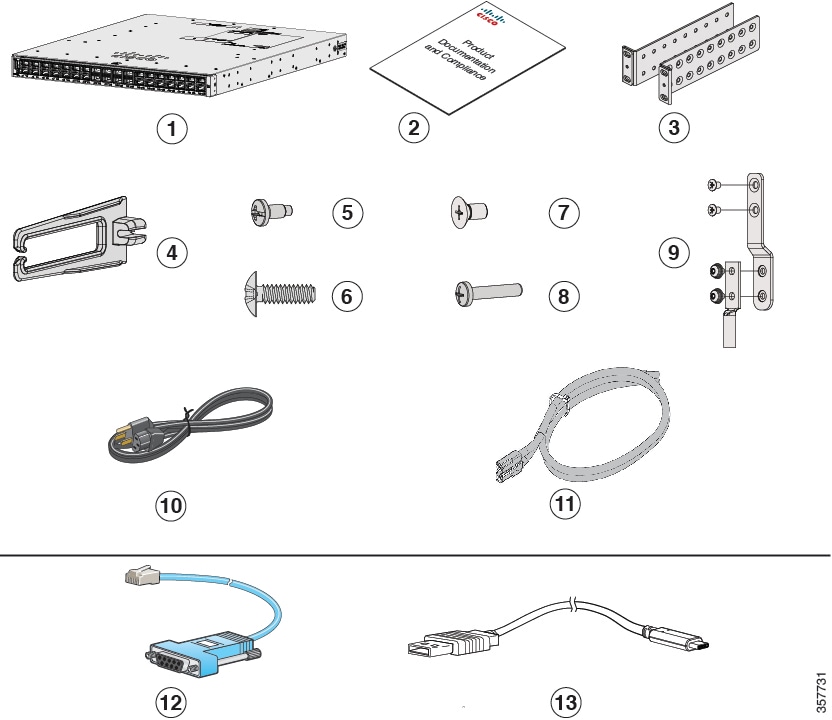

Remove the switch from the packaging material.

|

|||

|

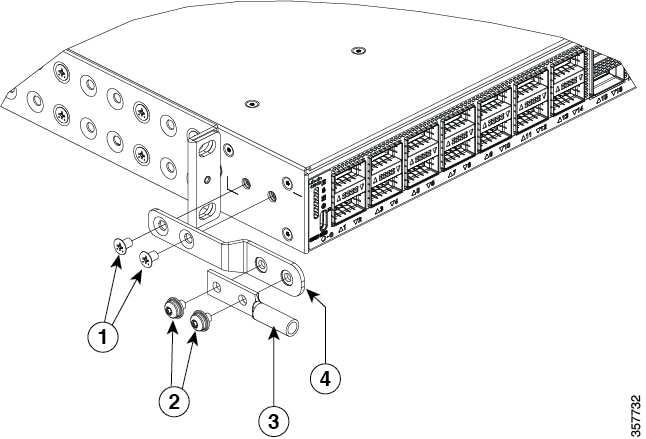

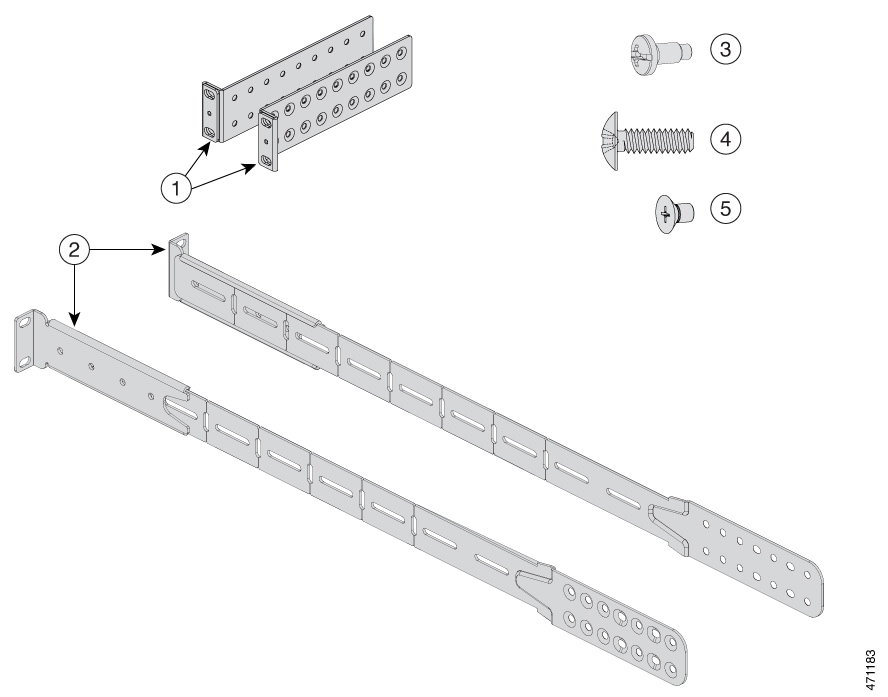

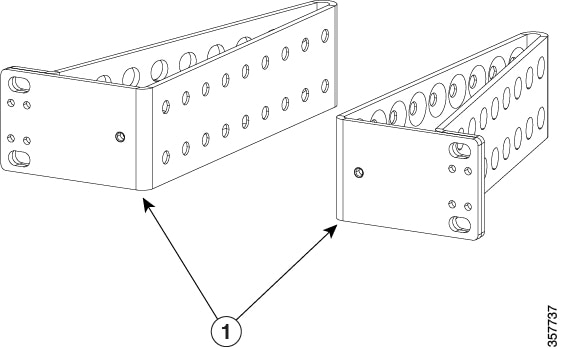

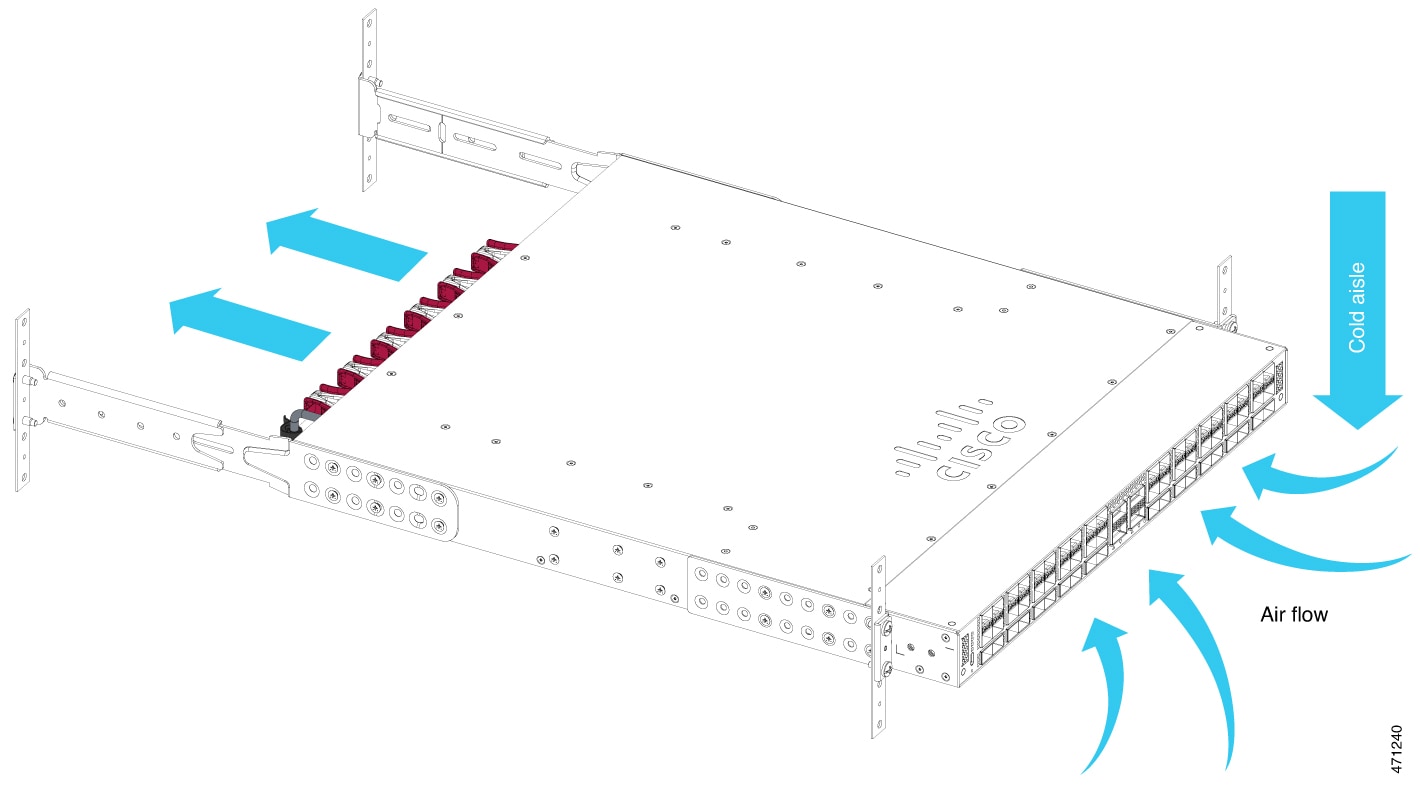

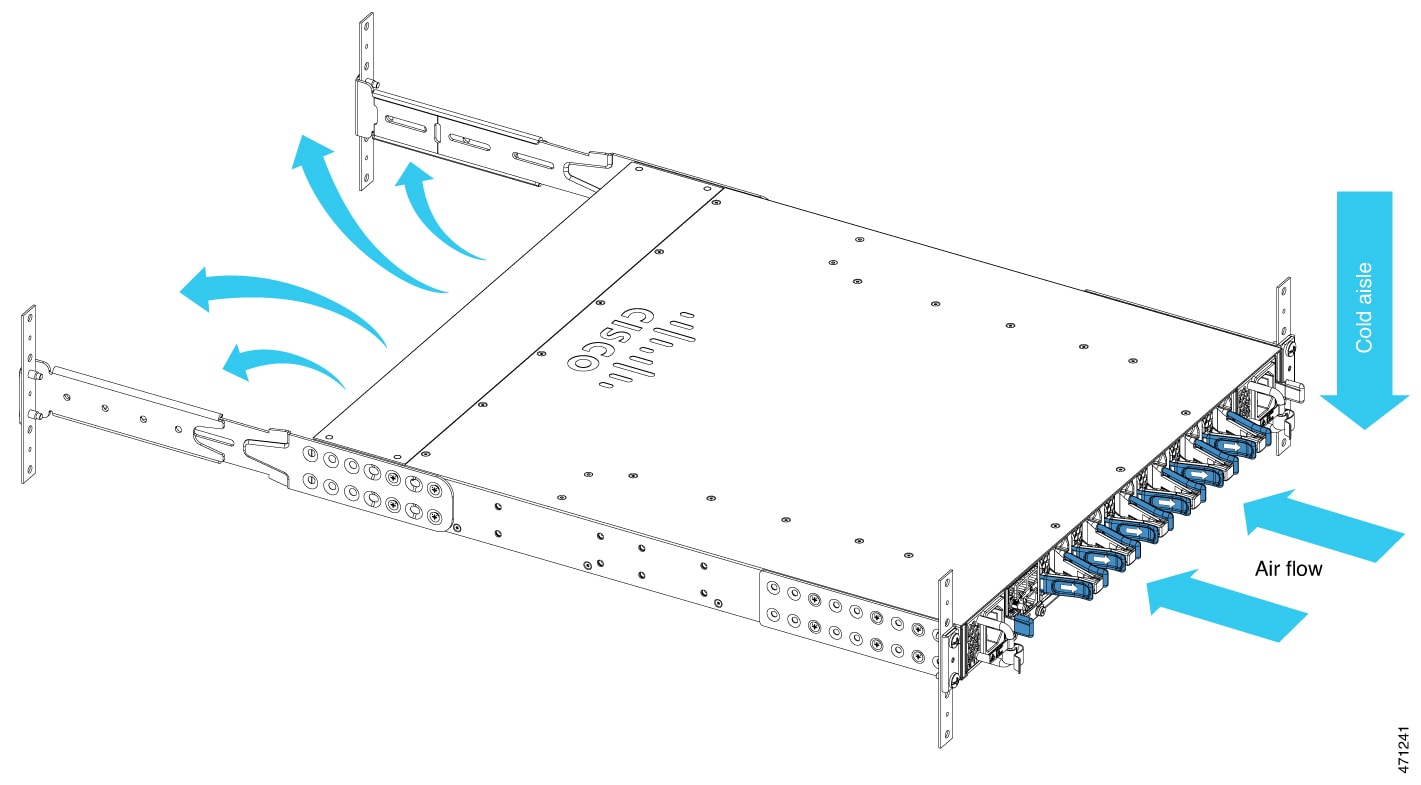

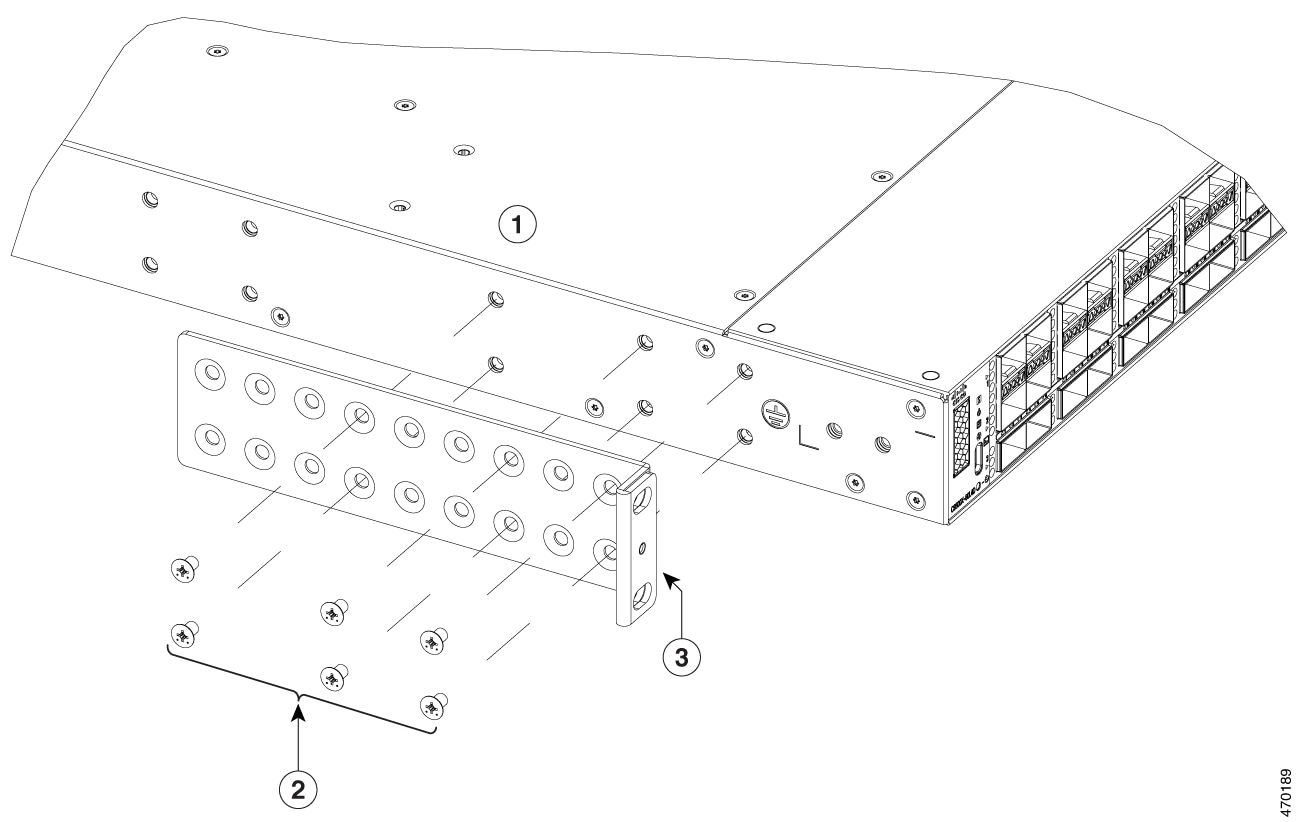

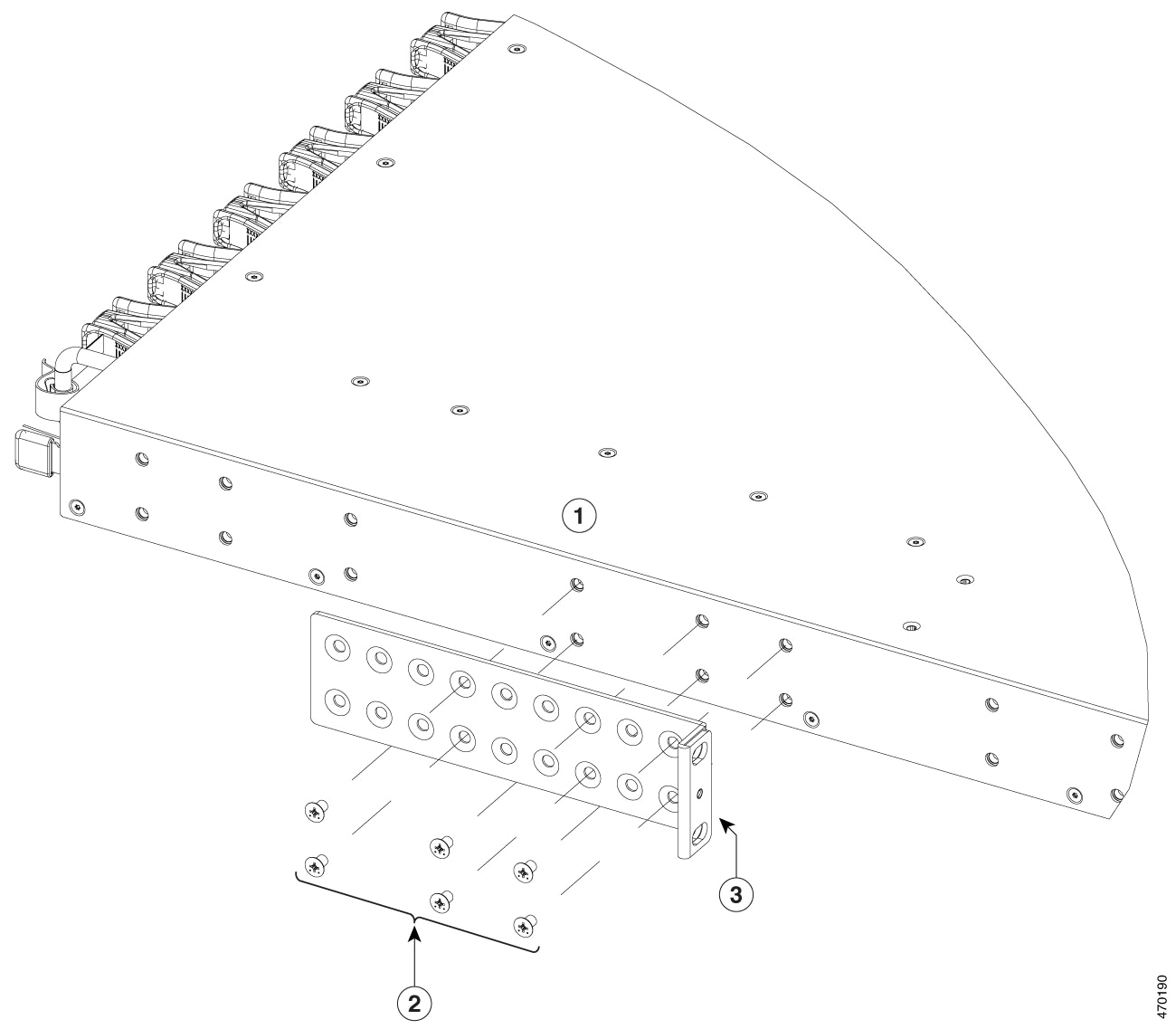

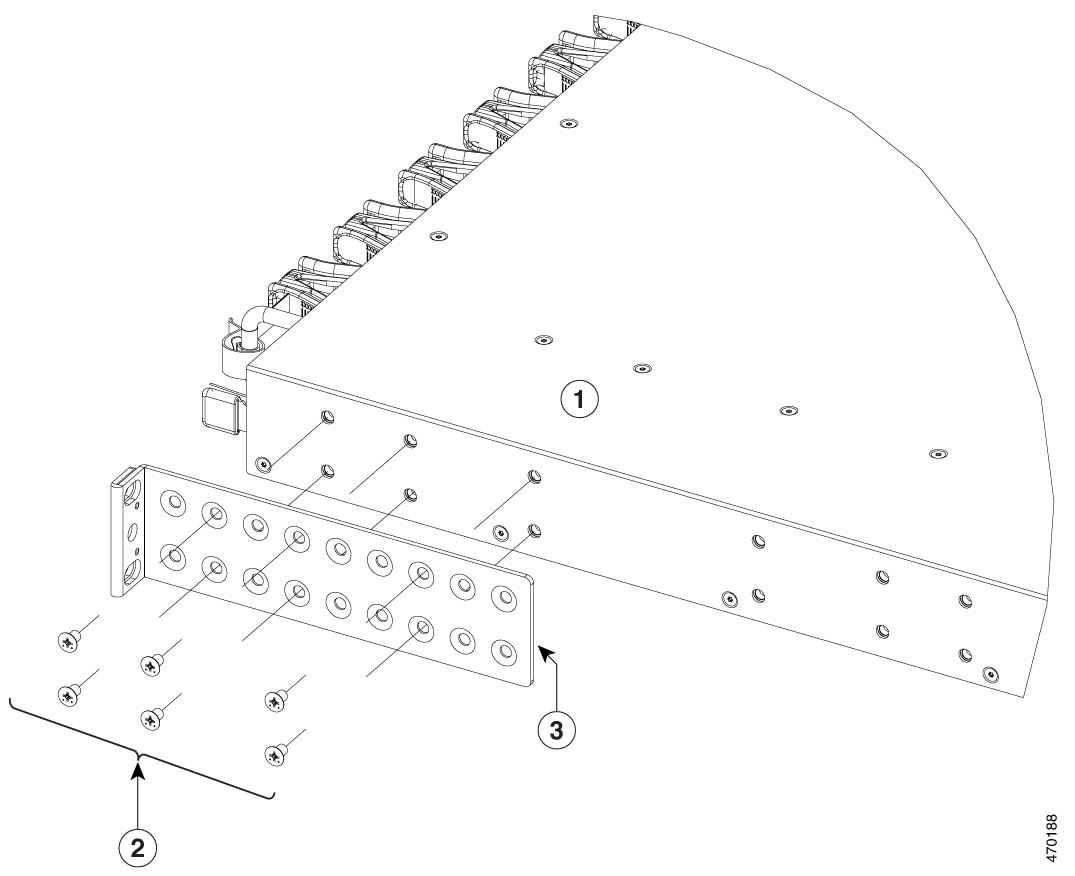

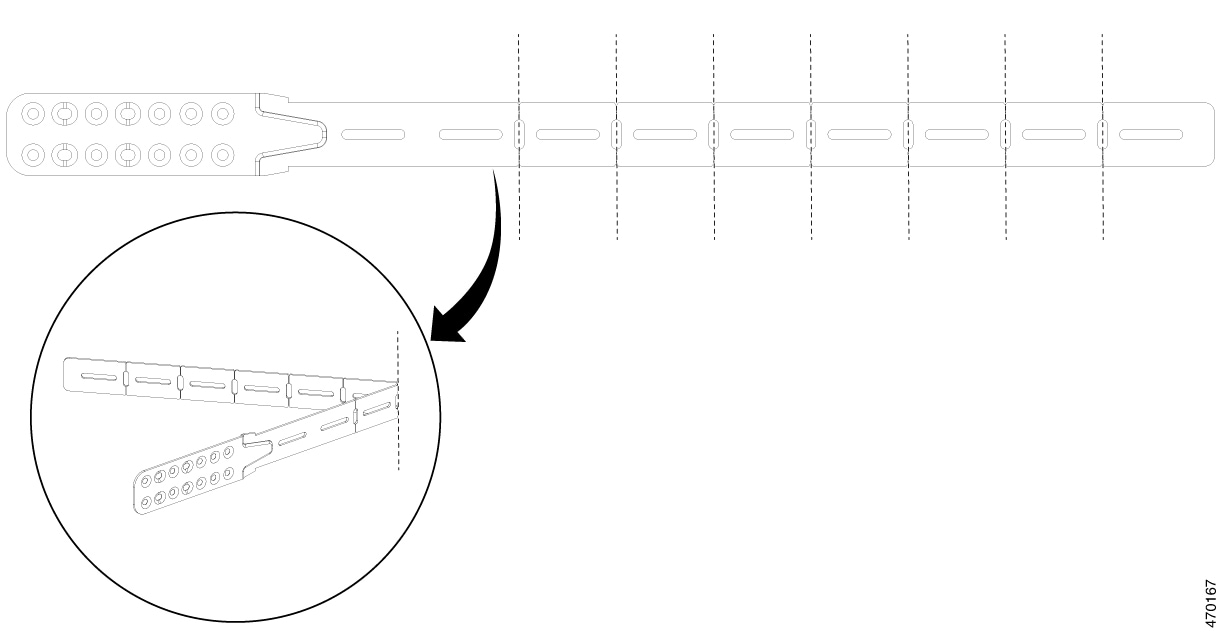

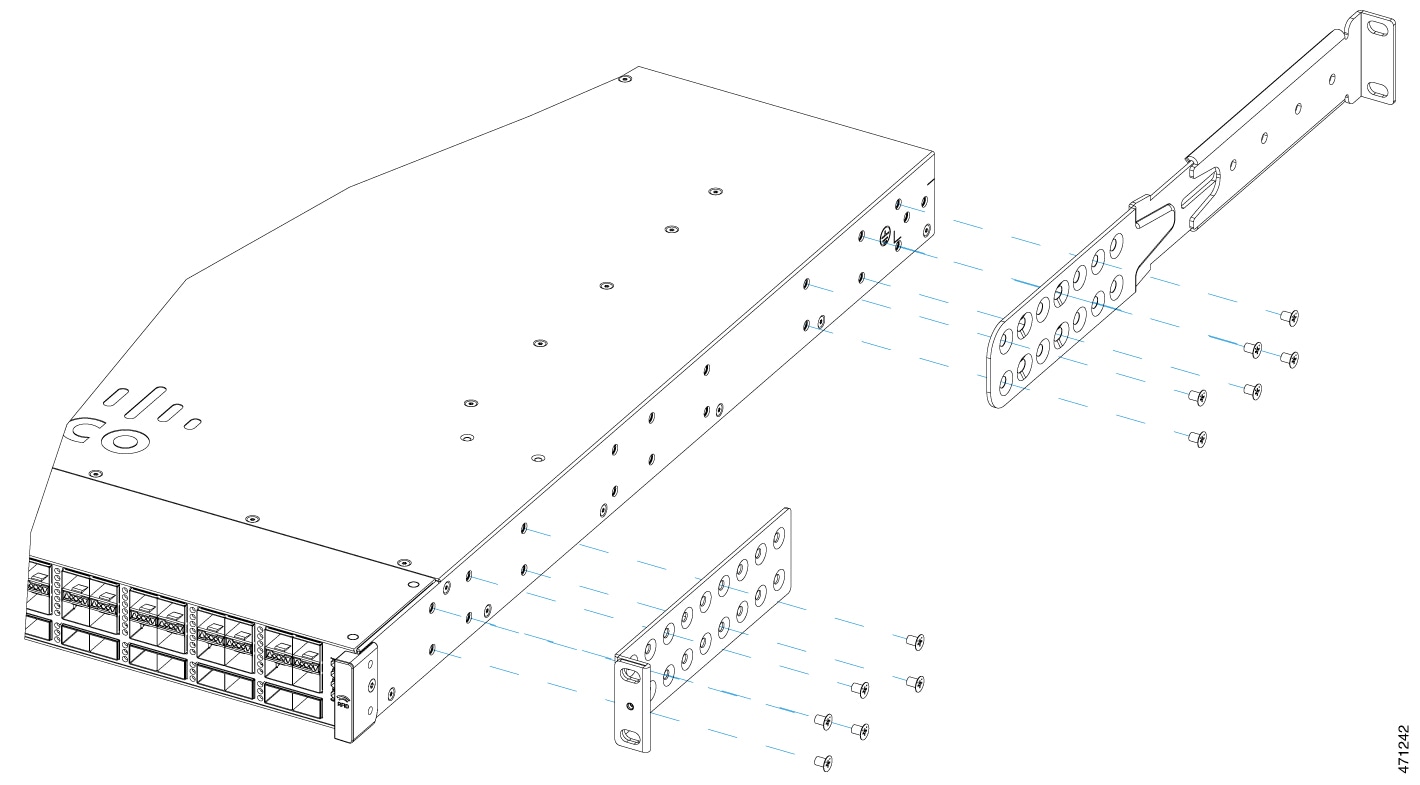

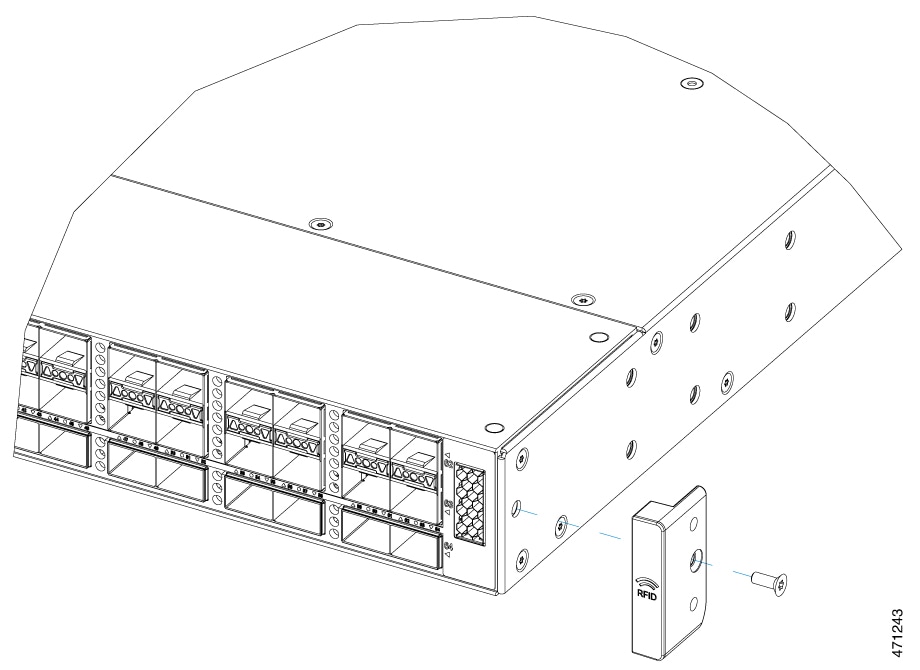

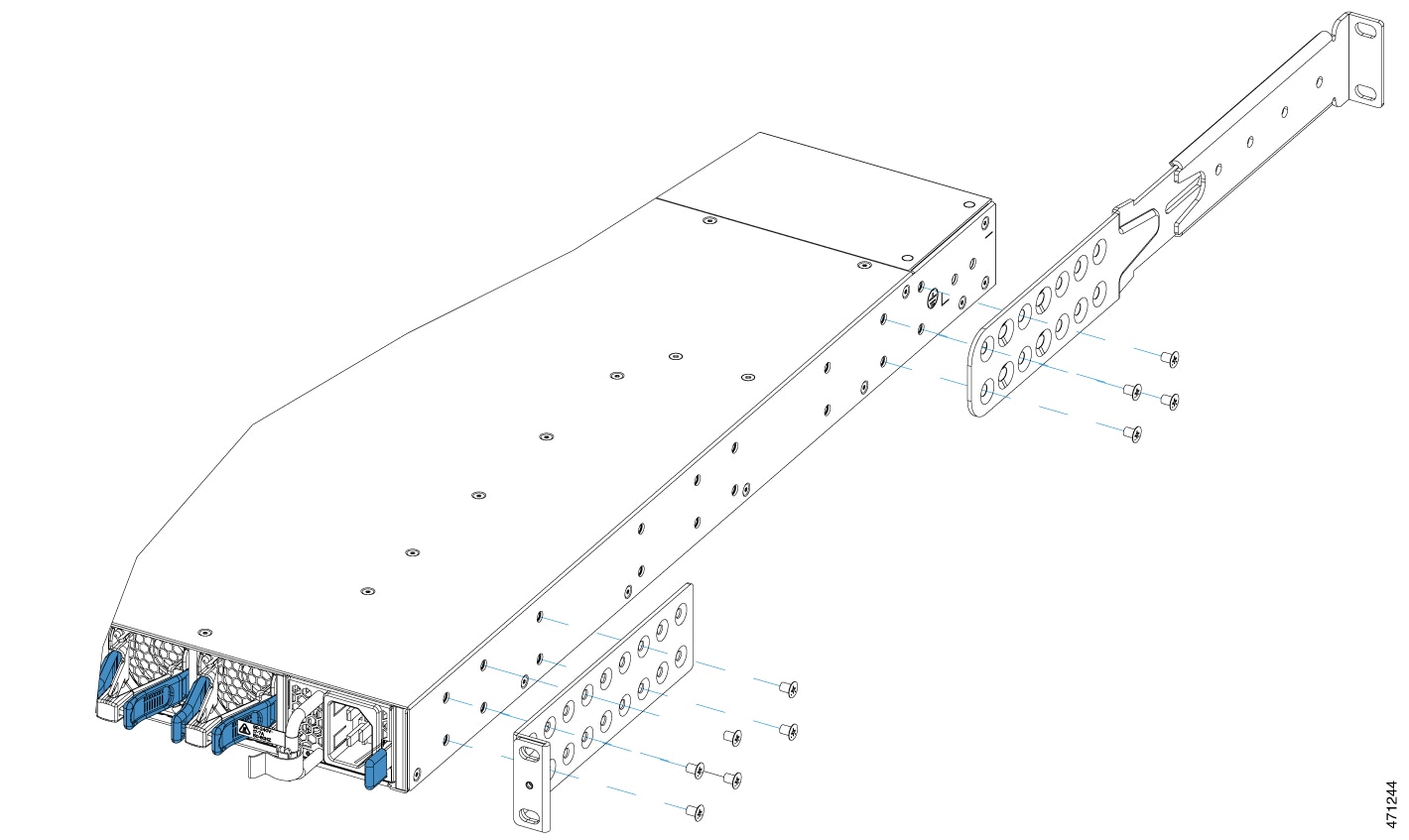

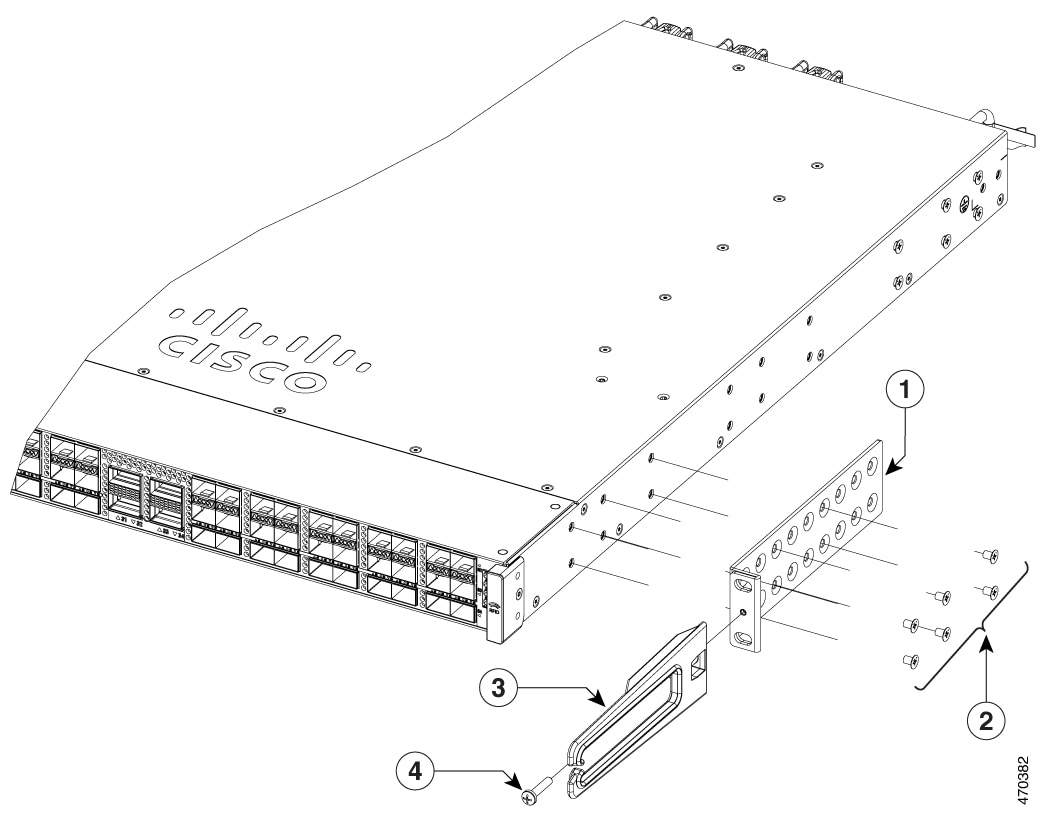

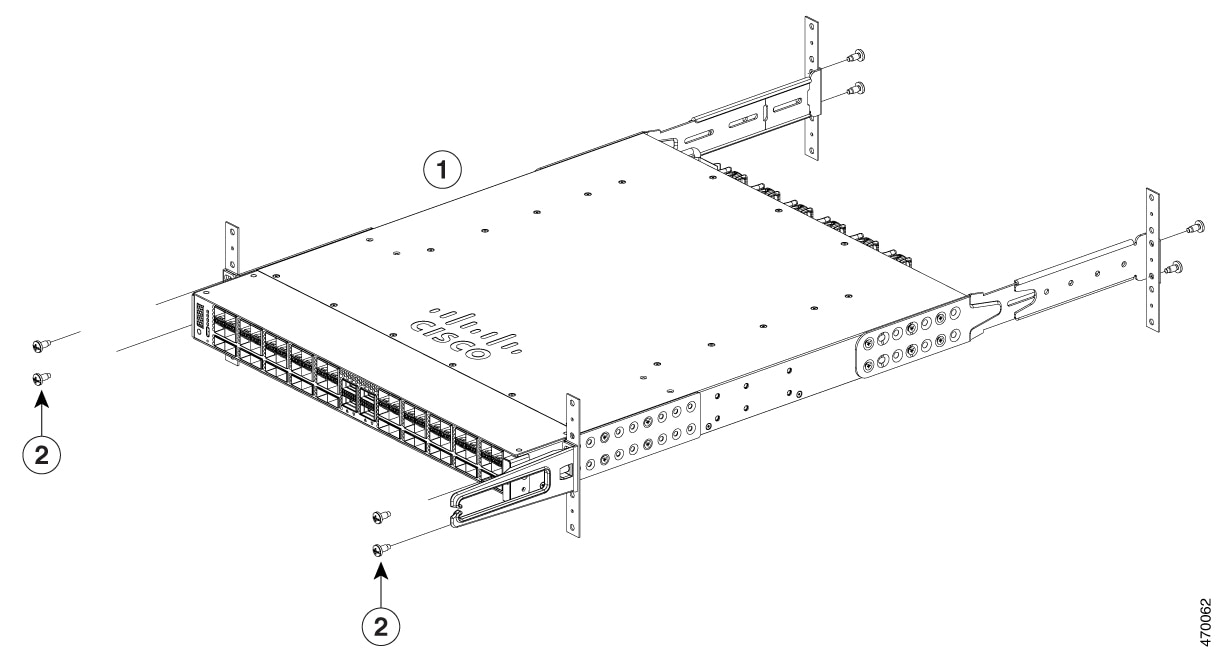

Install the switch. |

|||

|

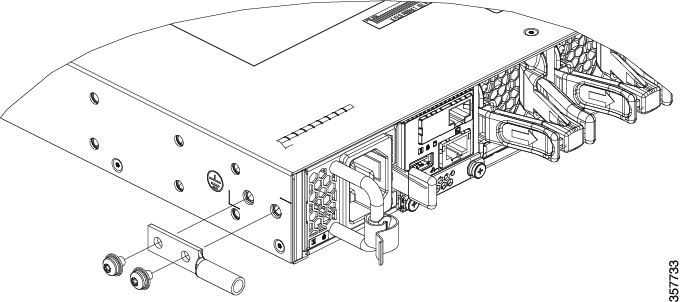

Construct and attach a system ground wire from the building (earth) ground to the system ground point on the chassis. |

|||

|

Power supplies that are ordered with the switch are preinstalled in the switch. If ordered separately, install the power supplies. |

|||

|

Install the fan modules in the fan module slots. |

|||

|

The various ports on the chassis must be connected to the network. This process can involve only attaching a network interface cable to the port or it can include the installation of a transceiver of some type in port and then attaching the network interface cable to the transceiver. |

|||

|

Powering up the chassis |

After completing the network cabling and making sure that system ground is connected, the power supplies can be turned on. The system powers up and runs through a set of built-in diagnostics. |

Feedback

Feedback