Preinstallation

Cisco MDS 9000 Series Telco and EIA Shelf Bracket

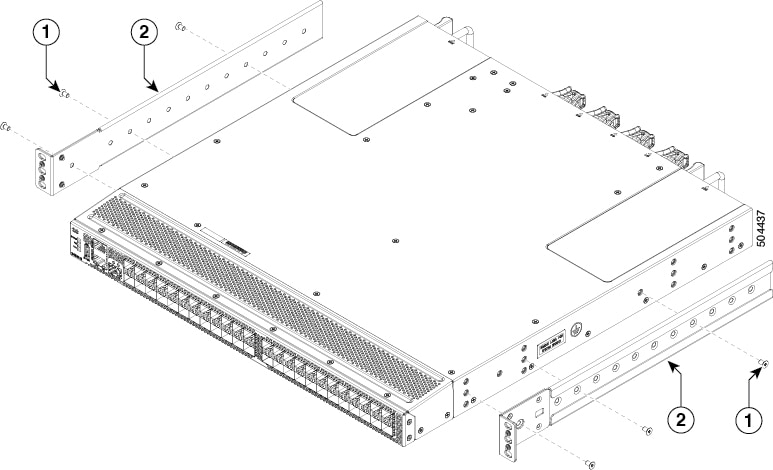

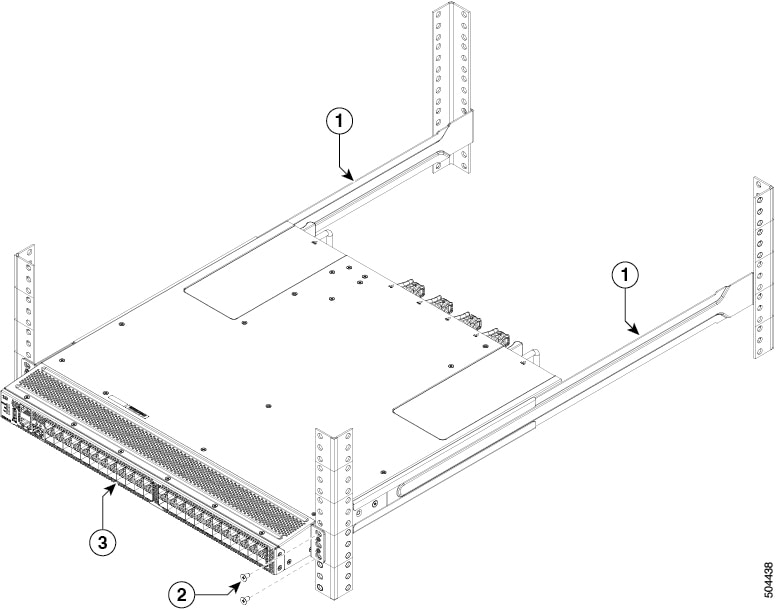

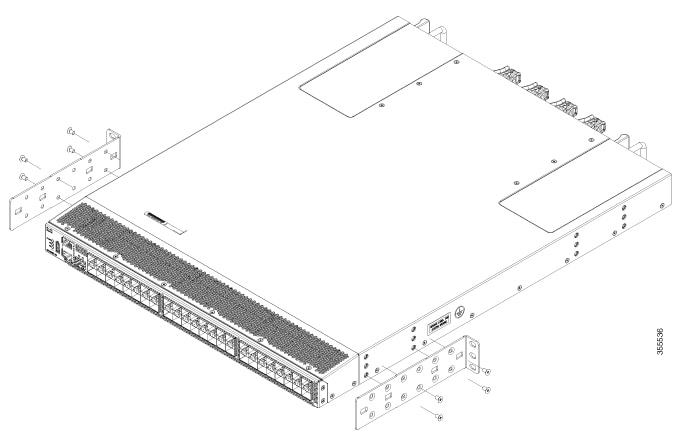

The optional Telco and EIA Shelf Bracket Kit (part number DS-SHELF=) can temporarily or permanently support the switch during installation. After the front rack-mount brackets are securely attached to the rack-mounting rails, the shelf bracket can be removed.

The Telco and EIA Shelf Bracket kit supports the following configurations:

-

A two-post Telco rack

-

A four-post EIA rack

Note |

Telco and EIA Shelf Bracket optional kit is not provided with the switch; to order the kit, contact your switch supplier. |

This section describes the procedure for installing a switch in a rack or cabinet using the optional Telco and EIA Shelf Bracket Kit.

Shelf-Installation Guidelines

Caution |

|

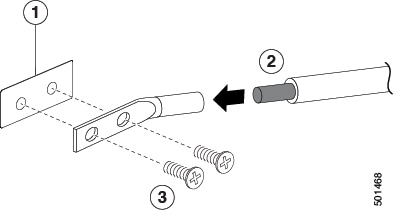

Before Installing the Shelf Brackets

Before installing the shelf brackets, inspect the contents of your kit. The following table lists the contents of the shelf bracket kit:

|

Quantity |

Part Description |

|---|---|

|

2 |

Slider brackets |

|

2 |

Shelf brackets |

|

1 |

Crossbar |

|

2 |

10-32 x 3/8-in. Phillips pan-head screws |

|

16 |

12-24 x 3/4-in. Phillips screws |

|

16 |

10-24 x 3/4-in. Phillips screws |

Required Equipment

You need the following equipment for this installation:

-

Number 2 Phillips screwdriver

-

Tape measure and level (to ensure that shelf brackets are at level with each other)

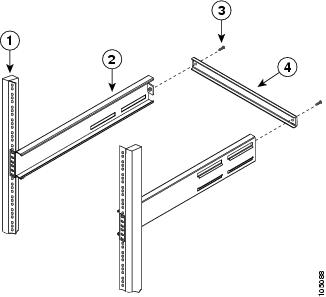

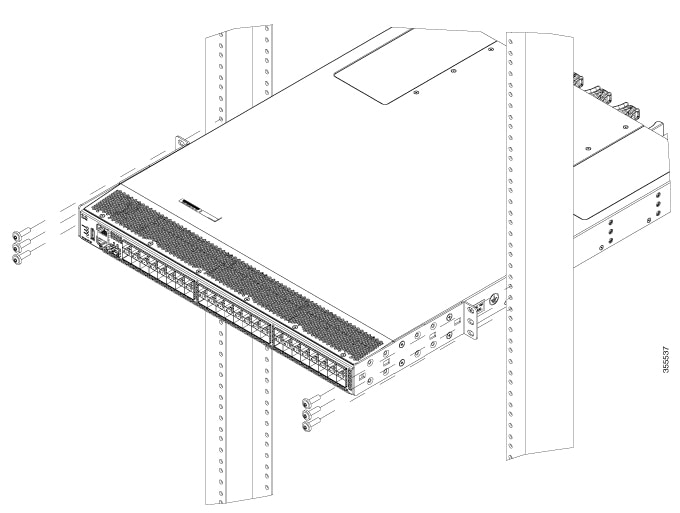

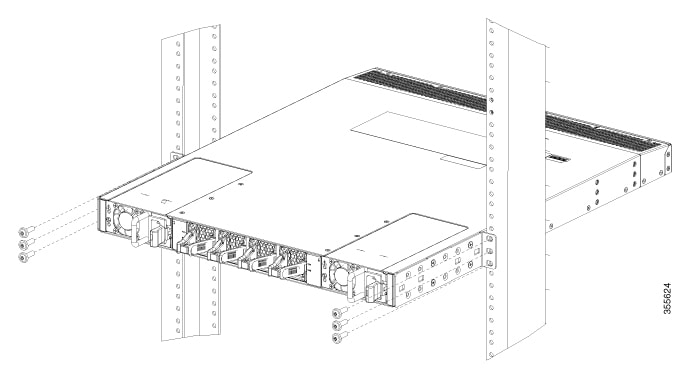

Installing the Shelf Bracket Kit into a Four-Post EIA Rack

The following figure shows the installation of the shelf bracket kit into a four-post EIA rack:

|

1 |

Rack-mounting post |

4 |

Crossbar |

|

2 |

Shelf bracket |

5 |

10-32 screws |

|

3 |

Slider post |

To install the shelf brackets in an EIA rack, follow these steps:

Procedure

|

Step 1 |

Position a shelf bracket inside the rack-mounting posts, as shown in Installing the Shelf Bracket Kit into an EIA Rack. Align the screw holes at the front of the shelf bracket with the holes in the front rack-mounting post. Then, attach the shelf bracket to the front rack-mounting post using a minimum of four 12-24 or 10-24 screws.

|

||

|

Step 2 |

Repeat Step 1 with the other shelf brackets. |

||

|

Step 3 |

Verify that the shelf brackets are at the same height (using the level or tape measure, as desired). |

||

|

Step 4 |

Attach the crossbar to the shelf brackets, as shown in Installing the Shelf Bracket Kit into an EIA Rack, using the 10-32 screws. |

||

|

Step 5 |

Insert the slider posts into the shelf brackets, as shown in Installing the Shelf Bracket Kit into an EIA Rack. Attach them to the rear rack-mounting posts, using a minimum of four 12-24 or 10-24 screws. |

Preinstallation Guidelines

Airflow Considerations

The switch comes with fan modules and power supply units that have either port-side intake or port-side exhaust airflow for cooling the switch. If you are orienting the switch with the FC ports facing a cold aisle, make sure that the switch has a port-side intake fan and power supply modules with red colorings. If you are orienting the switch with the fan and power supply modules facing a cold aisle, make sure that the switch has port-side exhaust fan and power supply units with blue colorings. All fan modules and power-supply modules must have the same direction of airflow.

Connection Guidelines for AC-Powered Systems

To connect to the switch AC power supply units to the site power source, follow these guidelines:

-

For power redundancy, each power supply should be connected to a separate power feed (at a minimum, separate branch circuits).

-

Circuits should be sized according to local and national codes.

-

The AC power receptacles that are used to power the chassis must be the grounding type. The grounding conductors that connect to the receptacles should connect to protective earth ground in the service equipment.

Installation Guidelines

Follow these guidelines when installing the switch:

-

Each new switch requires a license. See the Cisco MDS 9000 Family NX-OS Licensing Guide for instructions on installing a license.

-

Plan your site configuration and prepare the site before installing the switch.

-

Ensure that there is adequate space around the switch to allow for servicing the switch and for adequate airflow. The airflow requirements are listed the Technical Specifications section.

-

Ensure that you are positioning the switch in a rack so that it takes in cold air from the cold aisle and exhausts air to the hot aisle. For more information, see the Airflow Considerations section.

-

Ensure that the air-conditioning meets the heat dissipation requirements listed in the Technical Specifications section.

-

Ensure that the cabinet or rack meets the requirements listed in the Cabinet and Rack Installation section.

-

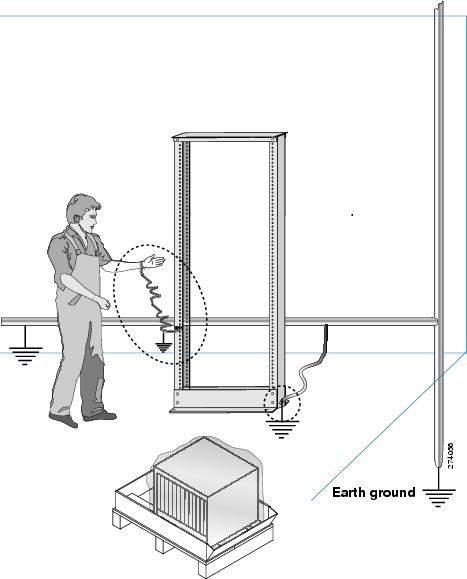

Ensure that the chassis is adequately grounded. If the switch is not mounted in a grounded rack, we recommend that you connect both the system ground on the chassis and the site power ground to an earth ground.

-

Ensure that the site power meets the power requirements listed in the Technical Specifications section. If available, you can use an uninterruptible power supply (UPS) to protect against power failures.

Caution

Avoid UPS types that use ferro-resonant technology. These UPS types can become unstable with systems such as the Cisco MDS 9000 Series, triggered by substantial current draw fluctuations due to fluctuating data traffic patterns.

-

Ensure that electrical circuits are sized according to local and national codes.

If you are using a 200 or 240 VAC power source in North America, the circuit must be protected by a two-pole circuit breaker.

Caution

To prevent loss of input power, ensure that the total maximum loads on the circuits supplying power to the switch are within the electrical current ratings for circuit for wiring and breakers.

Unpacking and Inspecting the Switch

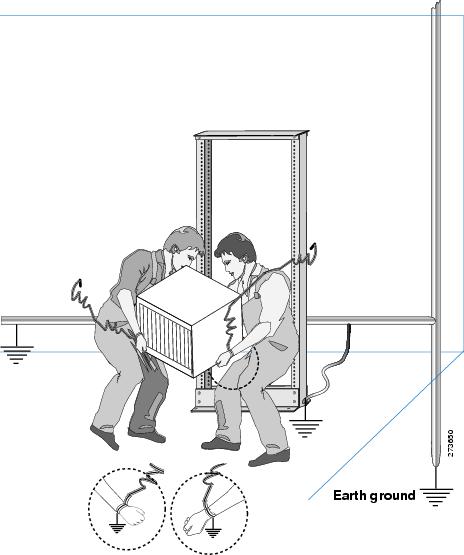

Caution |

When handling switch components, wear an ESD strap and handle modules using only the carrier edges. |

Tip |

Retain the shipping container in case the chassis has to be shipped in the future. |

Note |

The switch is thoroughly inspected before shipment. If any damage occurs during transportation, or if any item is missing, contact your customer representative immediately. If you purchased Cisco support through a Cisco reseller, contact the reseller directly. If you purchased support directly from Cisco, contact Cisco Technical Support. |

To inspect the shipment, follow these steps:

-

Compare the shipment to the equipment list provided by your customer service representative and verify that you have received all items, including the following:

-

Grounding lug kit

-

Rack-mount kit

-

ESD wrist strap

-

Cables and connectors

-

Optional items, if any, ordered

-

-

Check for damage and report any discrepancies or damage, to your customer service representative. Have the following information ready:

-

Invoice number of shipper (see packing slip)

-

Model and serial number of the damaged unit

-

Description of damage

-

Effect of damage on the installation

-

-

Check if all the power supplies and the fan trays have the expected direction of airflow. Port-side intake airflow modules have a red coloring, and port-side exhaust airflow modules have blue coloring. For more information, see the Power Supplies and Fan Modules sections.

Feedback

Feedback