Table Of Contents

Distance Limitations and Interface Specifications

Maintaining Safety with Electricity

Preventing Electrostatic Discharge Damage

Preventive Site Configuration: Maintaining Normal Operation

Preparing for Installation

This chapter describes the equipment and site requirements for installing the Cisco AS5850 universal gateway. Before installing your universal gateway, you should consider the power and cabling that must be in place at your installation site, the equipment needed for installation, and the environmental conditions your installation site must meet to maintain normal operation. You must also prepare the Cisco AS5850 for rack-mounting. This chapter guides you through the installation preparation process.

Warning

Only trained and qualified personnel should be allowed to install or replace this equipment. To see translations of the warnings that appear in this publication, refer to the Cisco AS5850 Universal Gateway Regulatory Compliance and Safety Information document that accompanied this device.

This chapter contains the following sections:

Site Requirements

The Cisco AS5850 is designed with an environmental monitoring system that protects the system and components from potential damage from overvoltage and overtemperature conditions. To assure normal operation and avoid unnecessary maintenance, plan your site configuration and prepare your site before installation. After installation, make sure that the site maintains an ambient temperature of 32 to 104°F (0 to 40°C), and keep the area around the chassis as free from dust as is practical.

The following sections address the site environment requirements for the Cisco AS5850.

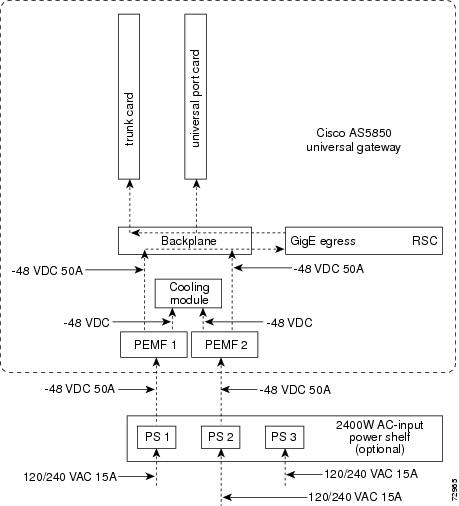

AC and DC Power

The Cisco AS5850 is designed to support either AC-input or DC-input power. Refer to Figure 2-1 to determine the number and type of power connections to provide.

Figure 2-1 AC Power Planning

If AC power is used, to provide full redundancy the Cisco AS5850 requires three 120 VAC 15A circuits.

If DC power is used, to provide full redundancy the Cisco AS5850 requires two DC power circuits providing up to 2400W.

Note

The color-coding of the DC-input power supply leads depends on the color-coding of the DC power source at your site. Typically, green or green/yellow is used for ground, black is used for -48V Return, and red or white is used for -48V. Make certain that the lead color- coding you choose for the DC-input power supply matches lead color-coding used at the DC power source. In AC systems, green cables are safety ground, red is PLUS, and black is MINUS.

Note

The PEMF will not be damaged by incorrect hookup of DC power, but the amber MISWIRE LED will come on. In this case, reverse the input connections.

For detailed system and cabling specification tables, refer to "Cisco AS5850 Specifications."

Note

Cisco recommends attaching power supplies to independent power sources for full redundancy. Cisco also recommends an uninterruptable power source to protect against power failures at your site. Each AC-input power supply operating at 120 VAC requires a minimum of 15A service.

Lifting Safety

CautionA fully configured Cisco AS5850 with server cards in all available slots, a cooling module, and both PEMFs weighs approximately 221 lb (100.2 kg). The server is not intended to be moved frequently. Before you install the Cisco AS5850, ensure that your site has the desired power sources and network connections so that you can avoid having to move the chassis. (See the "Site Specifications" section for other site requirement guidelines.)

CautionIf you install the Cisco AS5850 without using a forklift or other mechanical lifting device, you must first remove the cooling module, the cards, the DC PEMFs, and the route switch controller cards from the chassis and have two people help you with the universal gateway installation. The Cisco AS5850 weighs 55 lb. when these field replaceable units (FRUs) are removed. The instructions contained in this document are for installing the Cisco AS5850 in a rack without using a forklift. Plan on having at least two people available to help lift the unit into place to rack-mount it, and another person to attach the mounting bolts. Ensure that there is enough room for the installers to move around all four sides of the rack comfortably.

Warning

Two people are required to lift the chassis. Grasp the chassis underneath the lower edge and lift with both hands. To prevent injury, keep your back straight and lift with your legs, not your back. To prevent damage to the chassis and components, never attempt to lift the chassis with the handles on the power supplies or on the interface processors, or by the plastic panels on the front of the chassis. These handles were not designed to support the weight of the chassis. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Note

You might have to lift the chassis by gripping the chassis itself (rather than by the handles), using the spaces provided by the removed DC PEMFs and cooling module.

Note

Consider the total weight of the object to be lifted and calculate at least one person for every 60 lb of weight.

Required Tools and Equipment

You need the following items to install the Cisco AS5850:

•

ESD-preventive wrist strap

•

Antistatic mat

•

No. 2 Phillips screwdriver

•

1/4-in. flat-blade screwdriver

•

3/16-in. flat-blade screwdriver (for split shelf configurations)

•

Tape measure (optional)

•

Level (optional)

•

Cisco AS5850 Universal Gateway Commissioning Guidelines

•

Cisco AS5850 Operations, Administration, Maintenance, and Provisioning Guide (online at: http://www.cisco.com/univercd/cc/td/doc/product/access/acs_serv/as5850/sw_conf/5850oamp/ index.htm)

The rack-mount kit includes the following parts:

•

Six rack-mount brackets for mounting the universal gateway in the rack

•

Two support brackets

•

A total of 12 M5 x 10-mm Phillips flathead screws to secure the brackets to the chassis

•

A total of 16 slotted 10-32 x 3/8 screws for rack installation

In addition, you might need the following external equipment, especially when installing a split backplane configuration:

•

Data service unit (DSU) to connect each serial port to an external network.

•

A serial port adapter cable for each serial port to connect the port with a remote device or network.

•

T1/E1 channel service unit/data service unit (CSU/DSU) that converts the HDLC synchronous serial data stream into an T1/E1 data stream with the correct framing and ones density to connect. Some telephone systems require a minimum number of 1 bit per time unit in a data stream, called ones density, to connect a serial port to an T1 or E1 network. Several T1/E1 CSU/DSU devices are available as additional equipment, and most provide either a V.35, EIA/TIA-449, or EIA-530 interface.

•

Ethernet transceiver.

•

Network equipment supporting a gigabit ethernet interface, such as a Cisco 7500 series router or Catalyst 5500 switch.

Plant Wiring

The following are guidelines for setting up the plant wiring and cabling at your site. When planning the location of the new system, consider the distance limitations for signaling, EMI, and connector compatibility, as described in the following sections.

Interference Considerations

When wires are run for any significant distance in an electromagnetic field, interference can occur. This fact has the following implications for the construction of plant wiring:

•

Bad wiring practice can result in radio interference emanating from the plant wiring.

•

Strong EMI, especially when caused by lightning or radio transmitters, can destroy signal drivers and receivers and can even create an electrical hazard by conducting power surges through lines and into equipment. (Review the safety warnings in the "Maintaining Safety with Electricity" section.)

Note

To predict and remedy strong EMI, you might need to consult experts in radio frequency interference (RFI).

Note

Do not add additional ground points to the (+) or (-) input wires. These are not to be tied to any building ground point. Safety ground should be connected to the chassis, and the chassis should be bolted to building ground.

If you use twisted-pair cable in your plant wiring with a good distribution of grounding conductors, the plant wiring is unlikely to emit radio interference. If you exceed the recommended distances, use a high-quality twisted-pair cable with one ground conductor for each data signal, when applicable.

If wires exceed recommended distances, or if wires pass between buildings, give special consideration to the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic devices. If such problems have occurred in the past, you might want to consult experts in electrical surge suppression and shielding.

Distance Limitations and Interface Specifications

The size of your network and the distances between connections depend on signal type and speed and on transmission media (the type of cabling used to transmit the signals). For example, standard coaxial cable has a greater channel capacity than twisted-pair cable. The distance and rate limits in the following descriptions are the IEEE recommended maximum speeds and distances for signaling. However, you can usually get good results at speeds and distances far greater than these. For example, the recommended maximum rate for V.35 is 2 Mbps, but it is commonly used at 4 Mbps without any problems. If you understand the electrical problems that might arise and can compensate for them, you should get good results with rates and distances greater than those shown here; however, you do so at your own risk.

Note

Cisco recommends that you do not exceed specified transmission rate and distance limits.

When preparing your site for network connections to the universal gateway, you should consider the following:

•

Type of cabling required (fiber, thick or thin coaxial, shielded twisted-pair, or unshielded twisted-pair)

•

Distance limitations

•

Cables needed for interface connections

•

Any additional interface equipment needed, such as transceivers, hubs, switches, modems, channel service units (CSUs), or data service units (DSUs)

•

Cable pinouts (if you plan to build your own cables)

Before installing the universal gateway, have on hand all additional external equipment and cables noted in the documentation that ships with each component. For ordering information, contact a customer service representative.

Safety Recommendations

This section provides safety guidelines to help you avoid injury to yourself and avoid damage to the equipment. The following safety guidelines are recommended when working with any equipment that connects to electrical power or telephone wiring:

•

Locate the emergency power-off switch for the room in which you are working before beginning any procedures requiring access to the chassis interior.

•

Disconnect all power and external cables before moving a chassis.

•

Never work alone if potentially hazardous conditions exist.

•

Never assume that power has been disconnected from a circuit; always check.

•

Never perform any action that creates a potential hazard to people or makes the equipment unsafe.

•

Carefully examine your work area for possible hazards such as moist floors, ungrounded power extension cables, and missing safety grounds.

•

A 60A DC circuit breaker is recommended for the DC-input power source. This circuit breaker should protect against short-circuit and overcurrent faults in accordance with United States National Electrical Code NFPA 70 (United States), Canadian Electrical Code, part I, C22.1 (Canada), and IEC 364 (other countries).

•

Only a DC power source that complies with the safety extra-low voltage (SELV) requirements in UL1950, CSA 950, EN 60950, and IEC950 can be connected to the DC-input power supply.

•

A readily accessible disconnect device must be incorporated in the fixed wiring.

•

This unit is to be installed in a restricted access area in accordance with articles 110-16, 110-17, and 110-18 of the National Electric Code, ANSI/NFPA 70.

Warning

Before opening the chassis, disconnect the telephone-network cables to avoid contact with telephone-network voltages. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Maintaining Safety with Electricity

The Cisco AS5850 cards, cooling module, and power supplies are designed to be removed and replaced while the system is operating, without causing damage to the system.

Warning

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces, and watches). Metal objects will heat up when connected to power and ground and can cause serious burns or weld the metal object to the terminals. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Follow these basic guidelines when working with any electrical equipment:

•

Never perform any action that creates a potential hazard to people or makes the equipment unsafe.

Warning

Read the installation instructions before you connect the system to its power source. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

•

Never install equipment that appears damaged.

In addition, use the following guidelines when working with any equipment that is disconnected from a power source, but still connected to telephone wiring or other network cabling.

•

Never install telephone wiring during a lightning storm.

•

Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations.

•

Never touch uninsulated telephone wires or terminals unless the telephone line has been disconnected at the network interface.

•

Always use caution when installing or modifying telephone lines.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage, which occurs when electronic cards or components are improperly handled, can result in complete or intermittent system failures. The Cisco AS5850 components include printed circuit boards that are fixed in metal carriers. These metal carriers provide electromagnetic interference (EMI) shielding, connectors, ejector levers, or handles to protect against ESD. Although each carrier is designed to protect the boards, an antistatic strap should be used. Remember to handle the carriers by the ejector levers, handles, and carrier edges only; never touch the circuitry or connector pins.

CautionAlways tighten the panel fasteners on the Cisco AS5850 cards. These screws prevent accidental removal, provide proper system grounding, and help ensure that the bus connectors are properly seated.

Use the following guidelines to prevent ESD damage:

•

Always use an ESD wrist strap or ankle strap and ensure that it makes good skin contact.

•

Verify that the equipment end of your ESD strap is attached to an unfinished chassis surface when handling a card, module, or port adapter. Do not touch the printed circuit board, and avoid contact between the printed circuit board and your clothing. When working with a card, module, or port adapter, always place it "component side up" on an antistatic surface or in a static shielding bag. If returning an item to the factory, immediately place it in a static shielding bag.

•

Ensure that all server cards within the Cisco AS5850 are fully inserted in their respective chassis slots. Ensure that all ejector levers are in their locked positions and that all captive screws are properly tightened. The captive installation screws prevent accidental removal, provide proper grounding for the system, and help ensure that the bus connectors are properly seated.

CautionFor safety, periodically check the resistance value of the antistatic strap. The measurement should be between 1 and 10 Mohm.

Rack-Mounting Considerations

If you are using AC-input power, mount the AC-input power shelf below the universal gateway. There is no clearance requirement for mounting the chassis directly above the power supply. However, the power supply chassis is not intended to support the weight of the Cisco AS5850 chassis, so Cisco recommends that you mount the support brackets between the power supply and gateway chassis. In a DC installation, you can stack three universal gateways in a single 42 RU rack.

Some equipment racks provide a power strip along the length of one of the mounting strips. If your rack has a power strip, consider the position of the strip when planning fastener points to ensure that you can slide cards straight out of their respective slots. If the power strip does impair a rack-mount installation, remove the power strip before installing the chassis in the rack, and then replace it after the chassis is installed.

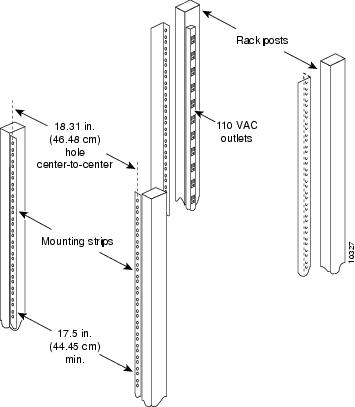

Figure 2-2 shows a typical 19-inch, 4-post equipment rack with a power strip along one of the back posts.

Figure 2-2 Typical 19-Inch Equipment Rack Posts and Mounting Strips

Note

Do not attempt to plug all three AC power cords into a single power strip. A single power strip cannot support the requirements for the AC shelf. Each AC input should be on a separate fuse or breaker circuit.

To use the rack-mounting hardware provided with your Cisco AS5850 universal gateway, consider the following guidelines:

•

To mount the chassis between two 19-inch posts or rails, the inner clearance (the width between the inner sides of the two posts or rails) must be at least 17.5 in. (44.45 cm).

•

The height of the chassis is 24.5 in. (62.23 cm).

•

When mounting the chassis in 4-post or telco racks, be sure to use all the screws and brackets provided to secure the chassis to the rack posts.

When planning your rack installation, consider the following guidelines:

•

Install the forward rack-mount brackets before you install the chassis in the rack; and then install the rear brackets.

•

Install the chassis in an open rack whenever possible. If installation in a cabinet is unavoidable, ensure that the cabinet has adequate ventilation.

CautionTo prevent the universal gateway from overheating, never install your Cisco AS5850 in a cabinet or room that is not properly ventilated or air conditioned.

•

Allow sufficient clearance around the rack for maintenance. You need 24 in. (61 cm) of clearance to remove and replace system components.

•

Always install heavier equipment in the lower half of a rack to maintain a low center of gravity and prevent the rack from falling over.

–

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

–

When mounting this unit in a partially filled rack, load the rack from the bottom to the top, with the heaviest component at the bottom of the rack.

–

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

Warning

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

•

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack.

•

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the unit in the rack.

•

To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

Warning

Care must be given to connecting units to the supply circuit so that wiring is not overloaded. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

•

Ensure that the universal gateway is connected to earth ground during normal use.

Warning

This equipment is intended to be grounded. Ensure that the host is connected to earth ground during normal use. To see translations of the warnings that appear in this publication, refer to the Regulatory Compliance and Safety Information document that accompanied this device.

•

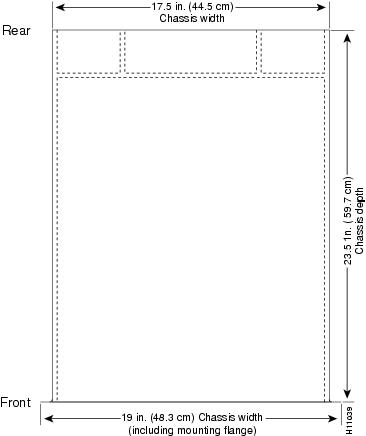

If you plan to use an equipment shelf, ensure that the shelf is constructed to support the weight and dimensions of the universal gateway. Figure 2-3 shows the universal gateway footprint, which you will need if you are designing a customized shelf mount. Cisco recommends that you use the rack-mount kit designed for your Cisco AS5850.

Figure 2-3 Cisco AS5850 Footprint and Outer Dimensions

CautionTo prevent the rack from tipping when installing the router in telco racks, ensure that the rack is bolted to the floor and, if necessary, anchored with appropriate fixtures.

Note

Frame ground should be tied to the single building point ground, or the closest return point to building ground.

CautionTo maintain a low center of gravity, ensure that heavier equipment is installed near the bottom of the rack.

Site Specifications

Table 2-1 lists the operating and nonoperating environmental site requirements. The following ranges are those within which the universal gateway continues to operate; however, a measurement that is approaching the minimum or maximum of a range indicates a potential problem. You can maintain normal operation by anticipating and correcting environmental anomalies before they approach the maximum operating range.

Airflow to cool the chassis is from front to back in the chassis, and from right to left in the router shelf chassis (when viewing the router from the front). Adhere to all spacing requirements for proper airflow maintenance.

Preventive Site Configuration: Maintaining Normal Operation

Planning a proper location for the universal gateway and the layout of your equipment rack or wiring closet is essential for successful system operation. Equipment placed too close together or ventilated inadequately can cause system overtemperature conditions. In addition, chassis panels made inaccessible by poor equipment placement impair system maintenance.

Follow these precautions and recommendations when planning power connections to the Cisco AS5850:

•

Check the power at your site before installation and periodically after installation to ensure that you are receiving clean power. Install a power conditioner if necessary.

•

Install proper grounding to avoid damage from lightning and power surges.

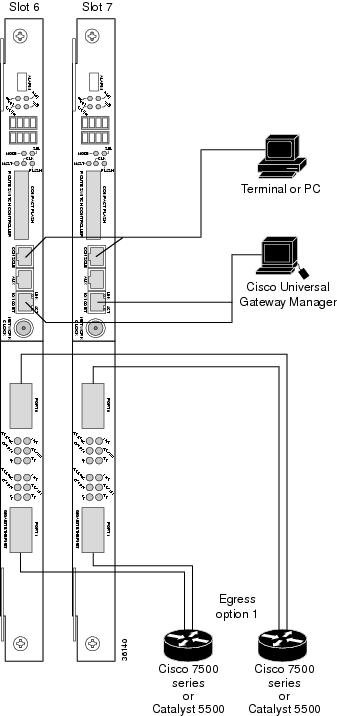

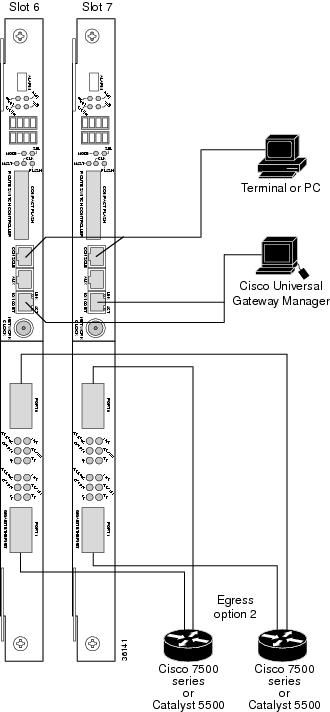

Egress Plan

The RSC provides two gigabit Ethernet interfaces for redundancy on the server egress. Only one gigabit ethernet connection is needed for the connections that can be handled by a single RSC, but two are provided to help assure uninterrupted service.

A maximum of four gigabit ethernet interfaces are available to connect to your backbone network. They can be configured as in Figure 2-4 and Figure 2-5, as you feel would provide the best service for your situation.

Figure 2-4 Egress Option (1 of 2)

Figure 2-5 Egress Option (2 of 2)

Feedback

Feedback