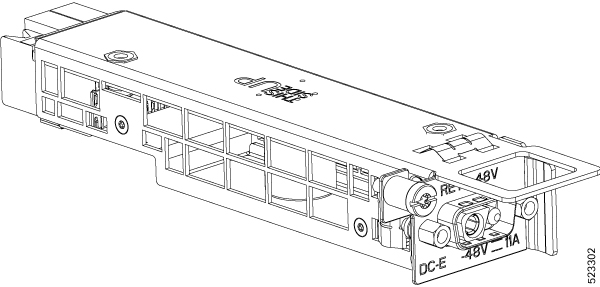

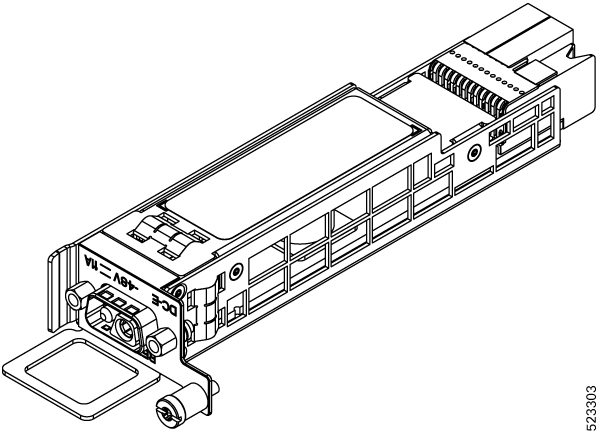

The fan-tray supported on the Cisco NCS 2002 shelf is FTA

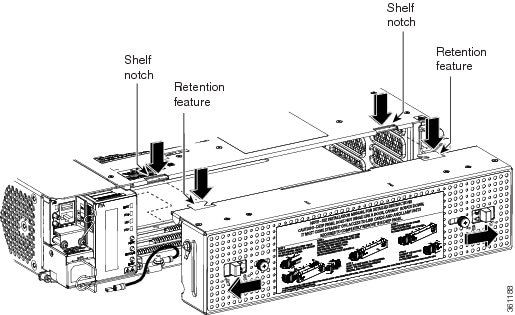

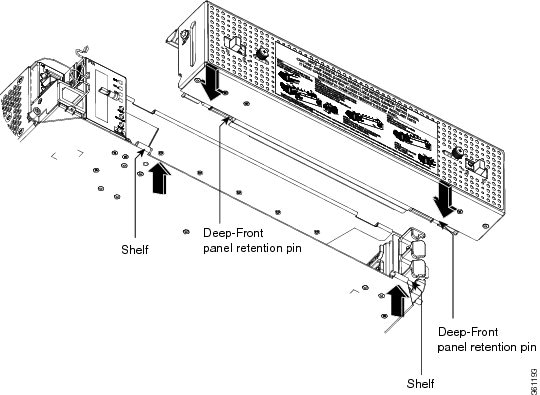

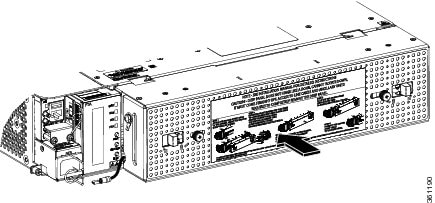

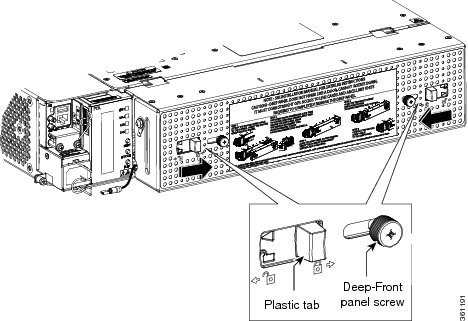

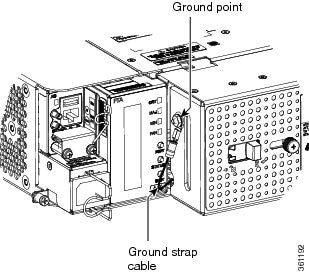

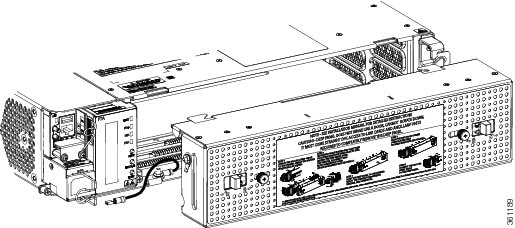

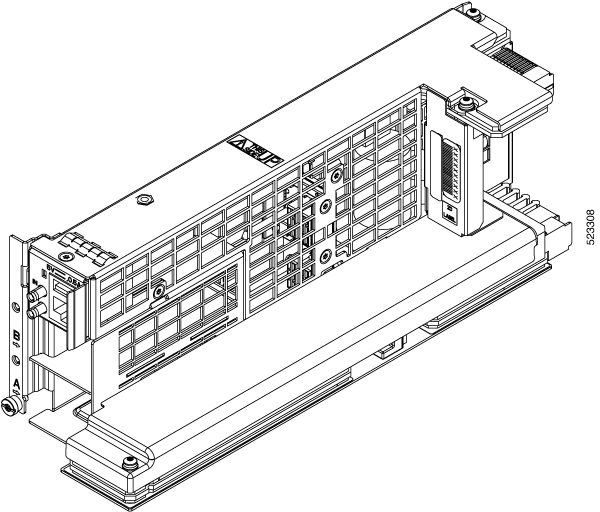

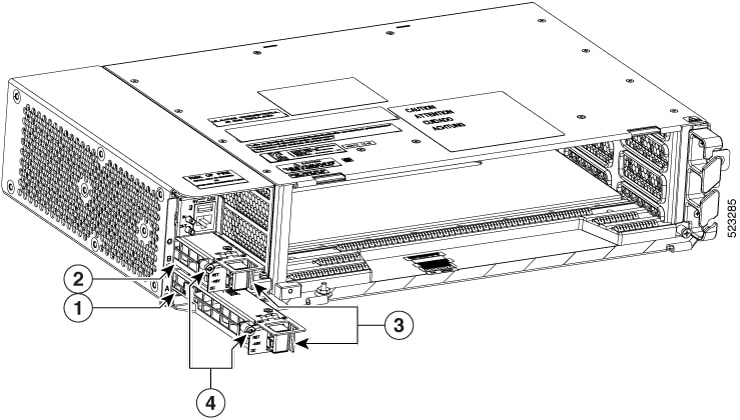

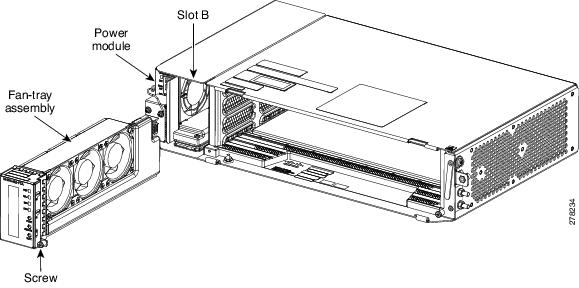

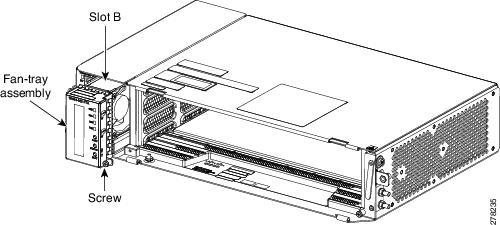

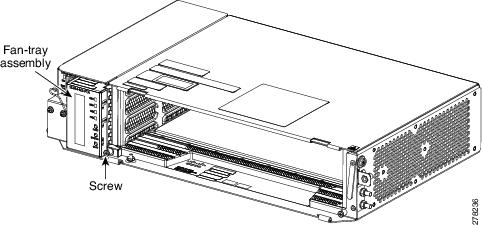

The fan-tray assembly is installed on the left side of the NCS 2002 shelf. The fan-tray assembly is removable and holds the

fan-control circuitry and the fans for the NCS 2002 shelf.

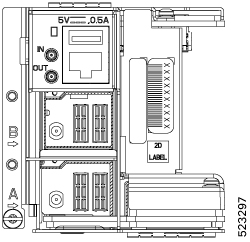

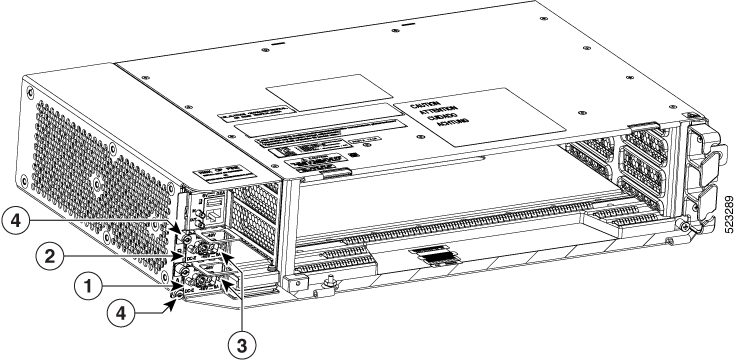

There are four LEDs on the fan-tray assembly:

-

Three alarm LEDs (CRIT, MAJ, and MIN) that indicate whether a critical, major, or minor alarm is present anywhere on the NCS

2002 shelf.

-

One fan fail LED that indicates fan failure.

When the fan-tray assembly is not functioning and the power line is not connected, the LED is OFF. A red LED indicates an

alarm in the fan-tray assembly. A green LED indicates that the fan-tray assembly is functioning, the power line is connected,

and the power module is functioning properly, the LED is green. When the power line is connected and if there is no TNC, TNCE,

TSC, or TSCE card installed in the NCS 2002 shelf, then the LED is OFF.

The shelf controller card controls the conditions that result in triggering the LEDs. The LED can be overwritten by the shelf

controller card (TNC, TNCE, TSC, or TSCE) in all the three states (OFF/red/green). The fan-tray assembly supports the lamp

test procedure.

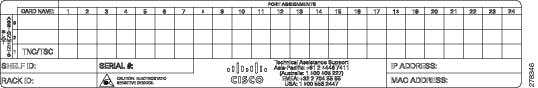

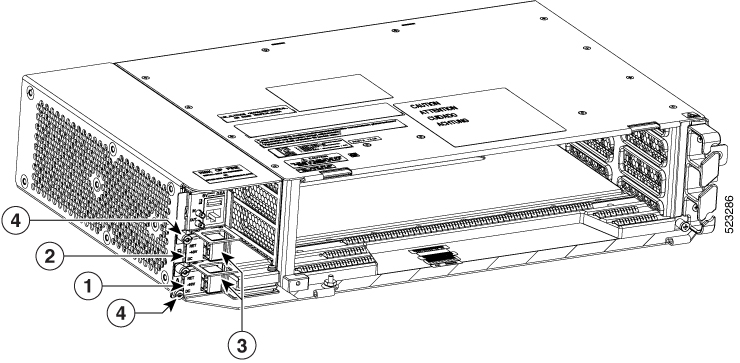

The fan-tray assembly has an LCD screen that provides slot and port-level information for all card slots, and the number of

critical, major, and minor alarms. The shelf controller card (TSC, TSCE, TNC, or TNCE) drives the 16 X 2 character LCD screen.

The LCD screen displays the shelf name, IP address, and software version that is currently used. The display contrast is automatically

adjusted for clear view. The three accessible push buttons (SLOT, STATUS, and PORT) on the fan-tray assembly are used to set

the slot and port level parameters.

Note

|

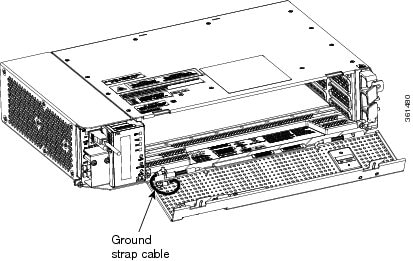

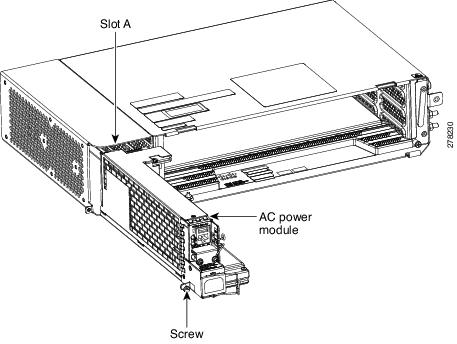

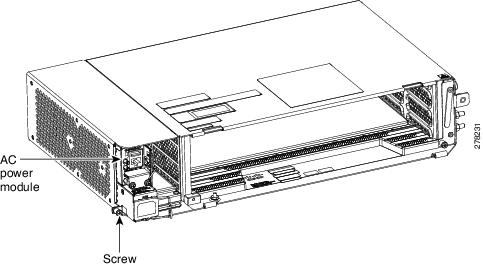

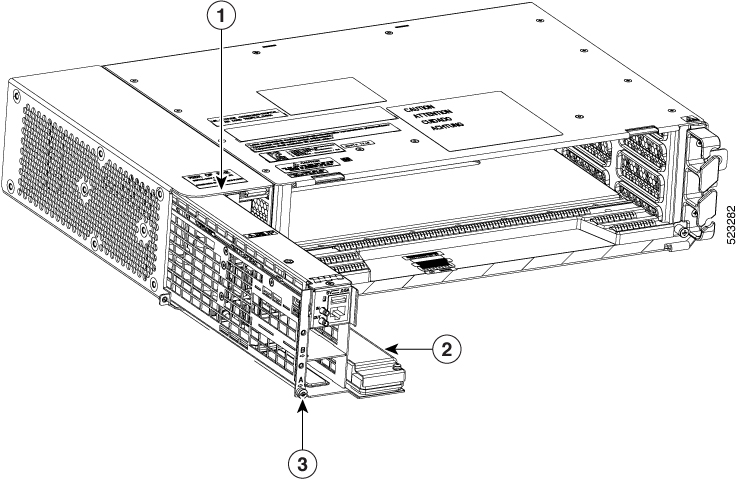

The fan-tray assembly should be installed only after installing the power module. During the system startup or fan-tray replacement,

the inventory data of the fan-tray assembly and the power module is displayed in the Inventory tab of CTC after a delay of approximately 6 minutes.

|

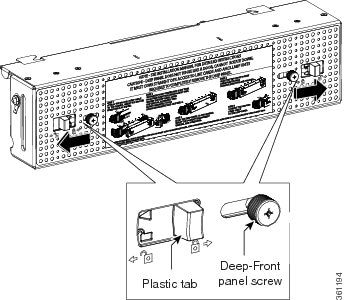

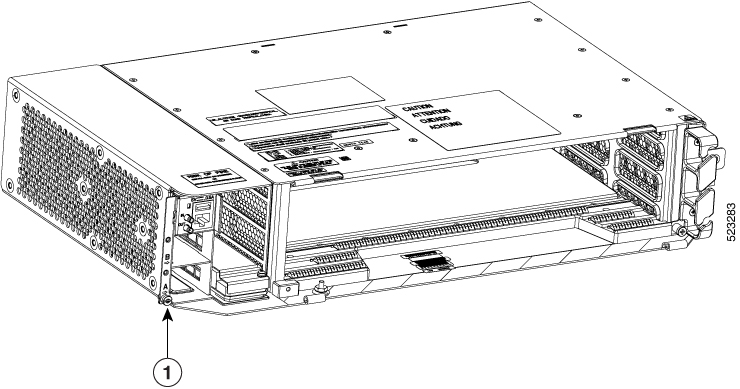

After you install the fan-tray, you should only access it if a fan failure occurs. To clean and replace the fan-tray assembly,

see the “Maintain the Node” chapter in the Cisco NCS 2000 Series Network Configuration Guide

.

Note

|

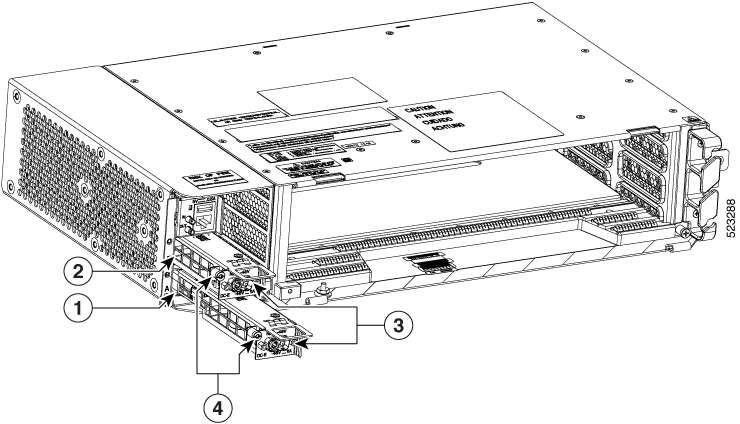

If the fan-tray assembly is removed from the shelf, wait for at least 5 seconds before plugging it back into the shelf. In

the event the LCD display on the fan-tray assembly appears blank, remove the unit from the shelf, wait for at least 5 seconds

and reinsert the unit into the shelf.

|

A back-up flash memory is fitted into the fan-tray assembly to support the database (DB) and image back-up in the single mode

operation of the NCS 2002.

The AC power supply has Double Pole/Neutral Fusing.

The AC power supply has Double Pole/Neutral Fusing.

Hazardous moving parts. Keep away from moving fan blades during fan tray replacement.

Hazardous moving parts. Keep away from moving fan blades during fan tray replacement.

Feedback

Feedback