Package Contents

Each AP package contains the following items:

-

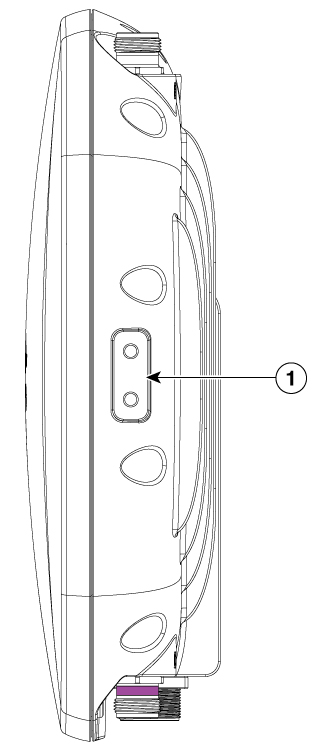

One CW9163E Outdoor AP

-

Ground lug and screws with lock washers

-

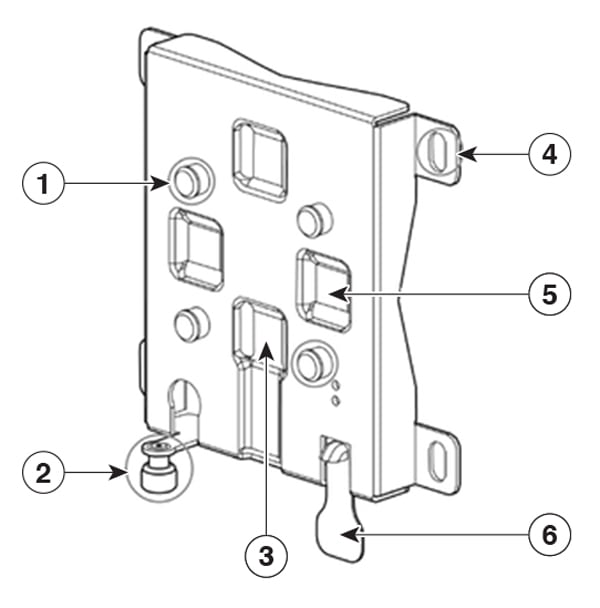

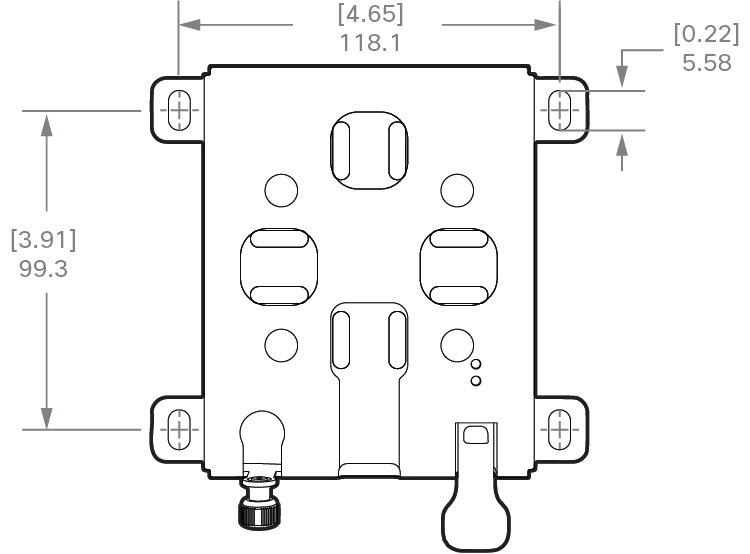

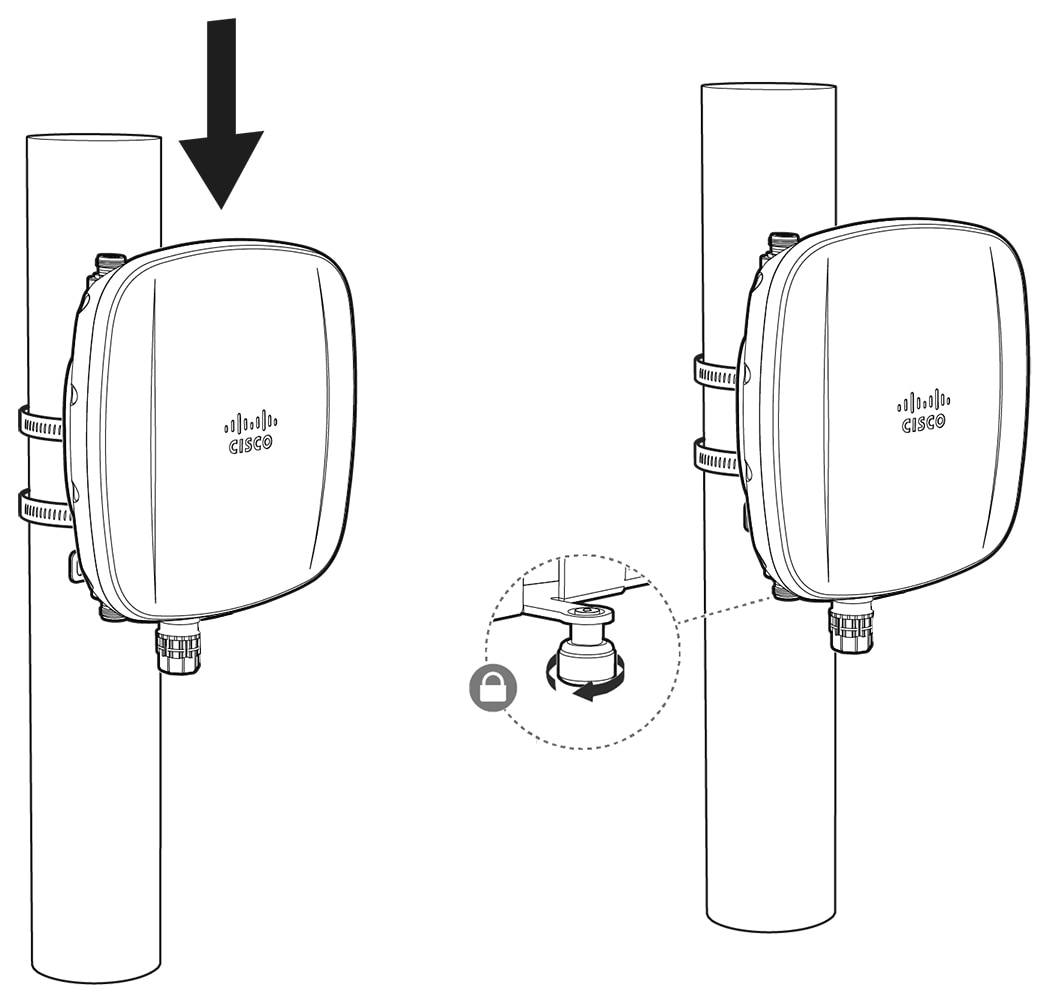

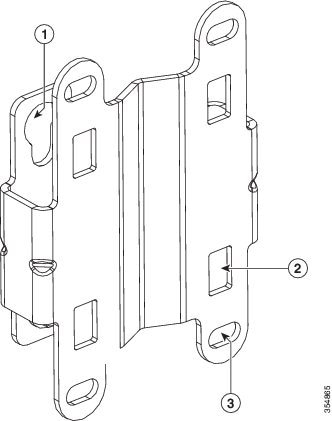

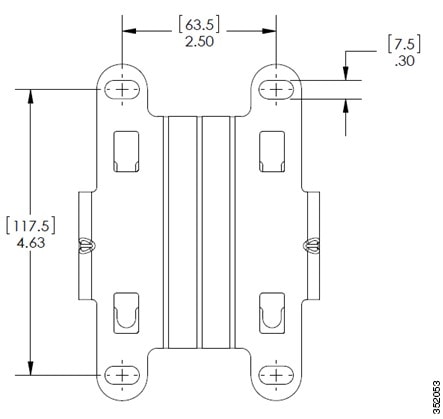

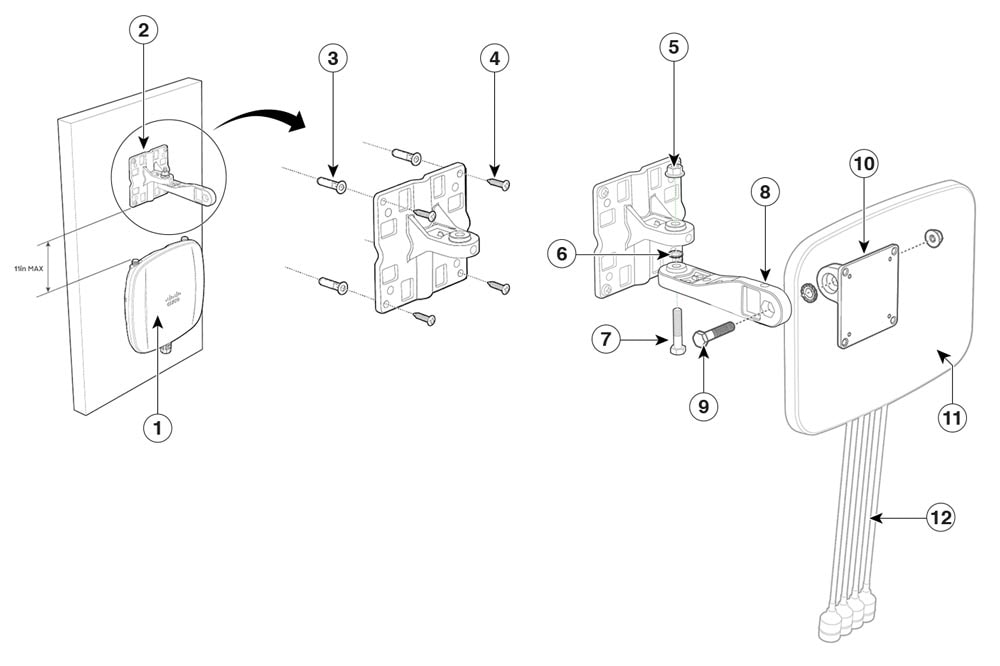

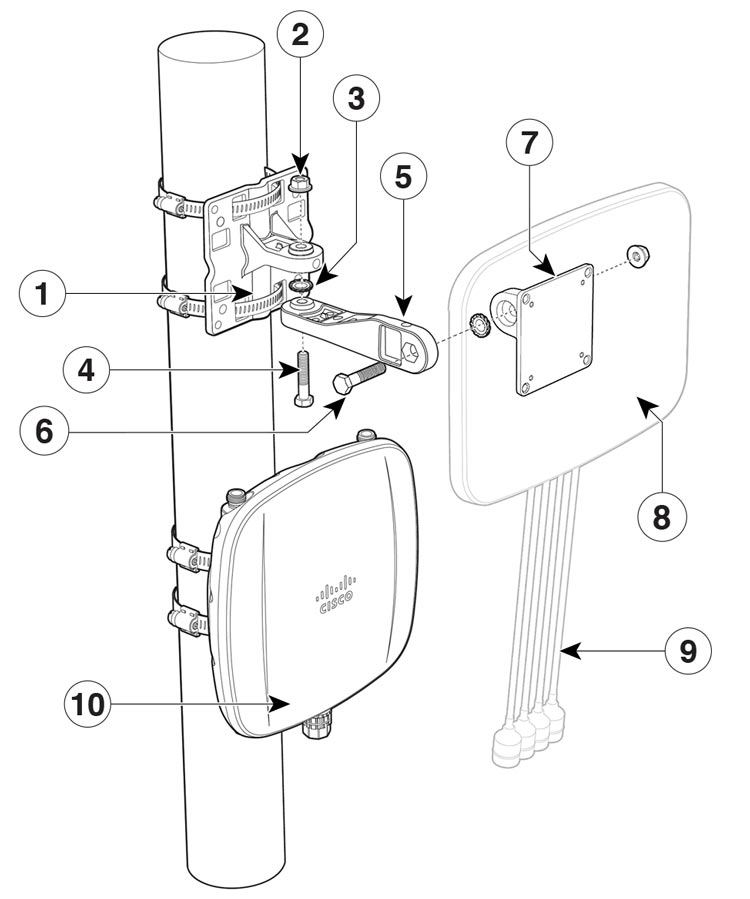

MA-MNT-MR-16 mounting plate

-

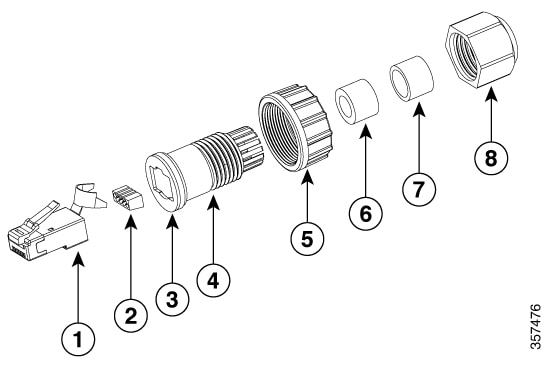

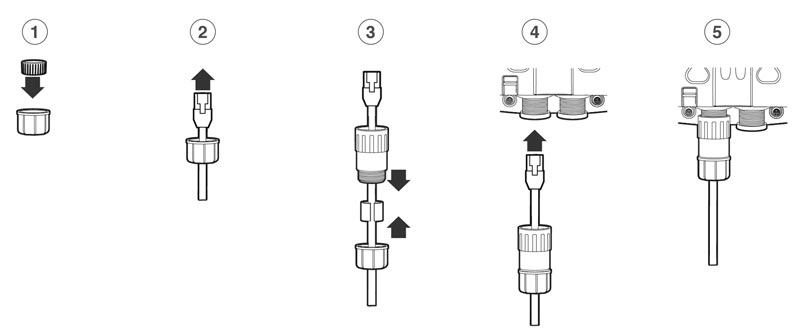

CAT 6/6A RJ45 Ethernet port termination plug

-

Anticorrosion sealant

-

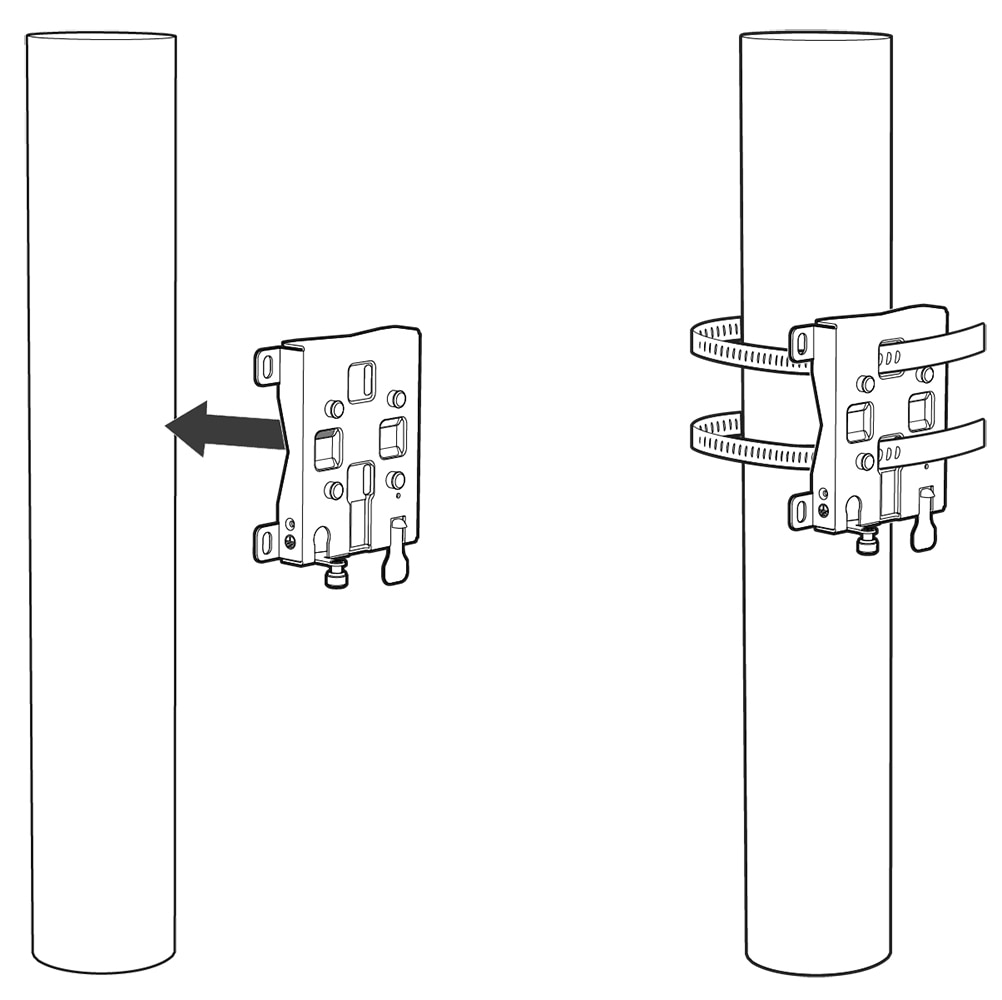

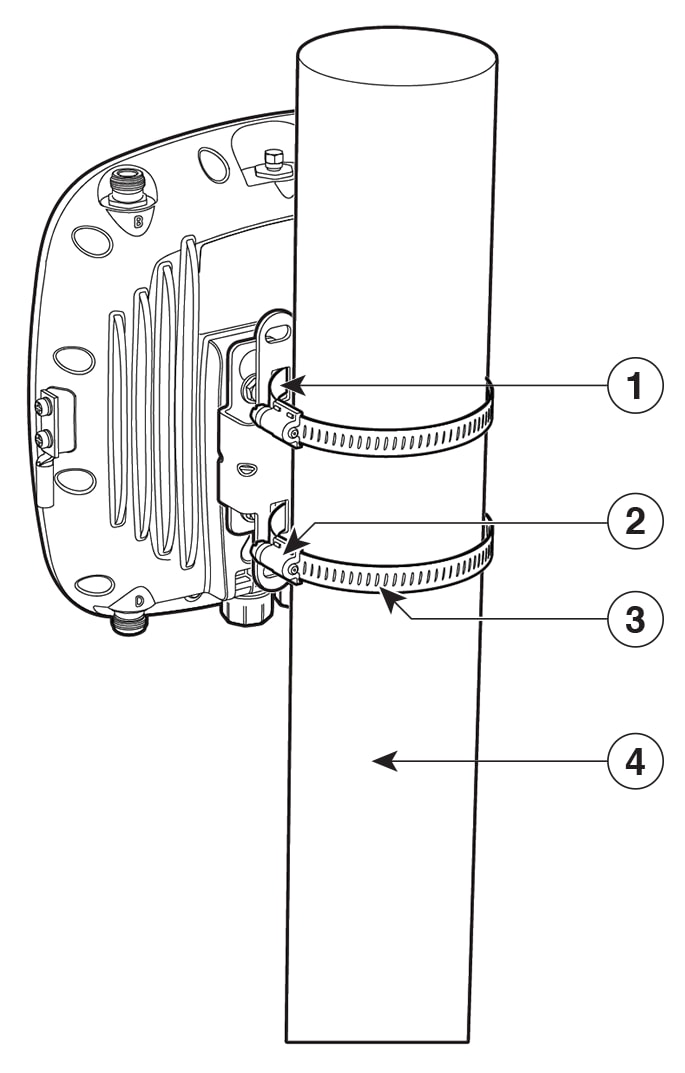

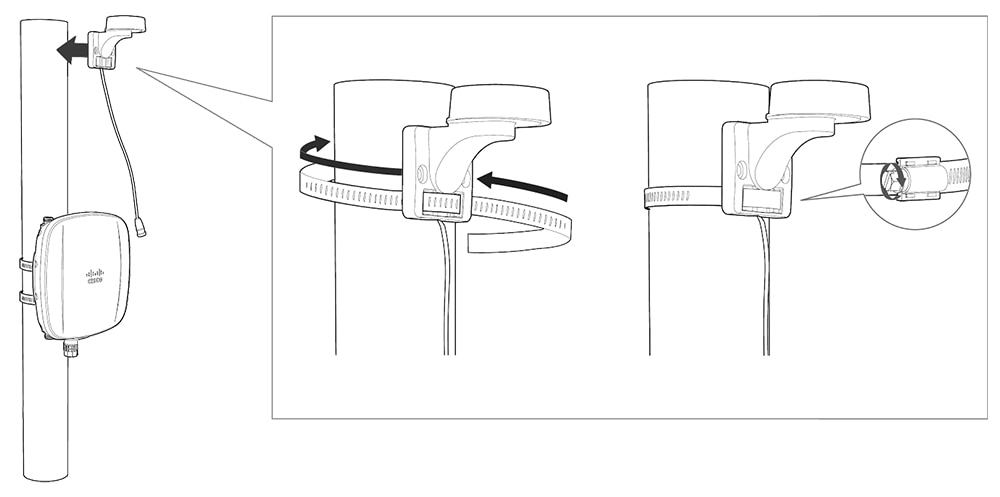

Mounting straps

-

Cisco product documentation and pointer card

Feedback

Feedback