|

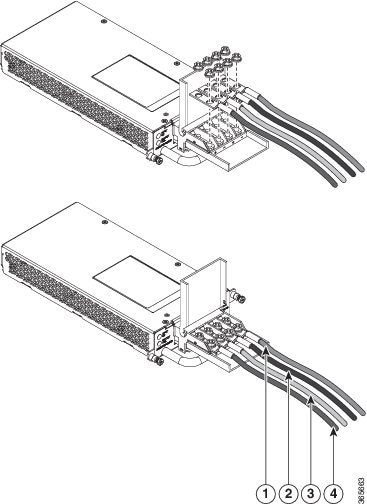

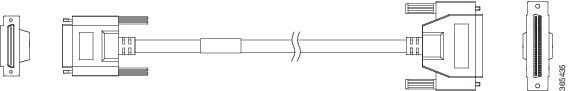

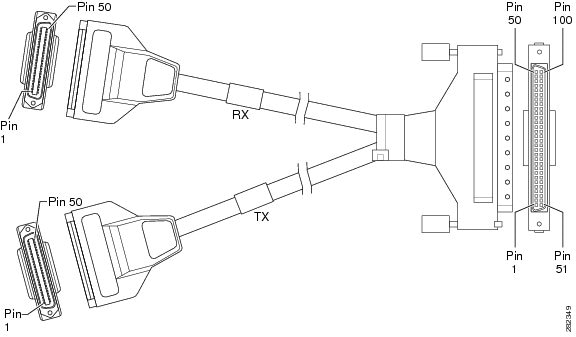

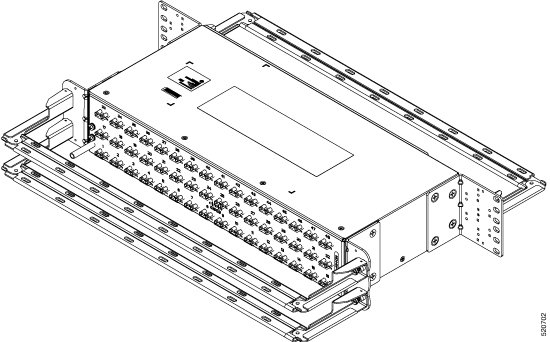

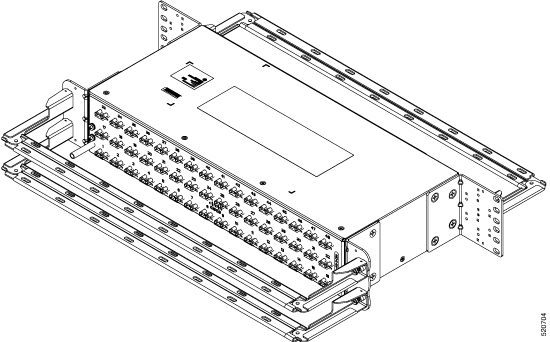

CABLE-16TDM-R1EL1

|

T1/E1-Cable S-3

|

16-port cable for TDM CEM Interface Module, 42 inches cable length and 10 inches stub length, even slot

|

|

T1/E1 Cable S-2

|

16-port cable for TDM CEM Interface Module, 42 inches cable length and 7.5 inches stub length, even slot

|

|

T1/E1 Cable S-1

|

16-port cable for TDM CEM Interface Module, 42 inches cable length and 6.5 inches stub length, even slot

|

|

CABLE-16TDM-R1EL2

|

T1/E1-Cable M-3

|

16-port cable for TDM CEM Interface Module, 62 inches cable length

and 10 inches stub length, even slot

|

|

T1/E1-Cable M-2

|

16-port cable for TDM CEM Interface Module, 62 inches cable length

and 7.5 inches stub length, even slot

|

|

T1/E1-Cable M-1

|

16-port cable for TDM CEM Interface Module, 62 inches cable length

and 6.5 inches stub length, even slot

|

|

CABLE-16TDM-R1EL3

|

T1/E1-Cable L-3

|

16-port cable for TDM CEM Interface Module, 78 inches cable length

and 10 inches stub length, even slot

|

|

T1/E1-Cable L-2

|

16-port cable for TDM CEM Interface Module, 78 inches cable length

and 7.5 inches stub length, even slot

|

|

T1/E1-Cable L-1

|

16-port cable for TDM CEM Interface Module, 78 inches cable length

and 6.5 inches stub length, even slot

|

|

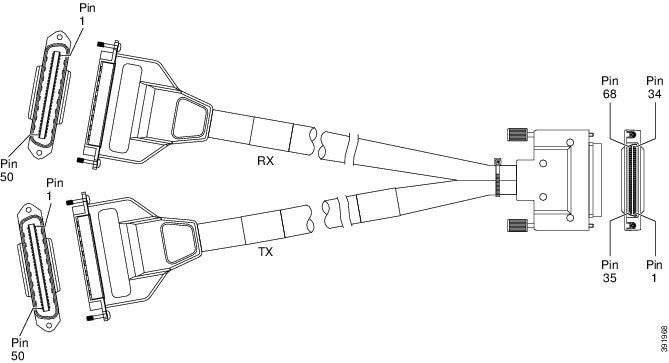

CABLE-16TDM-R3EL1

|

T3/E3-Cable S-3

|

16-port cable for TDM CEM Interface Module, 42 inches cable length and 10 inches stub length, even slot

|

|

T3/E3-Cable S-2

|

16-port cable for TDM CEM Interface Module, 42 inches cable length and 7.5 inches stub length, even slot

|

|

T3/E3-Cable S-1

|

16-port cable for TDM CEM Interface Module, 42 inches cable length and 6.5 inches stub length, even slot

|

|

CABLE-16TDM-R3EL2

|

T3/E3-Cable M-3

|

16-port cable for TDM CEM Interface Module, 62 inches cable length

and 10 inches stub length, even slot

|

|

T3/E3-Cable M-2

|

16-port cable for TDM CEM Interface Module, 62 inches cable length

and 7.5 inches stub length, even slot

|

|

T3/E3-Cable M-1

|

16-port cable for TDM CEM Interface Module, 62 inches cable length

and 6.5 inches stub length, even slot

|

|

CABLE-16TDM-R3EL3

|

T3/E3-Cable L-3

|

16-port cable for TDM CEM Interface Module, 78 inches cable length

and 10 inches stub length, even slot

|

|

T3/E3-Cable L-2

|

16-port cable for TDM CEM Interface Module, 78 inches cable length

and 7.5 inches stub length, even slot

|

|

T3/E3-Cable L-1

|

16-port cable for TDM CEM Interface Module, 78 inches cable length

and 6.5 inches stub length, even slot

|

|

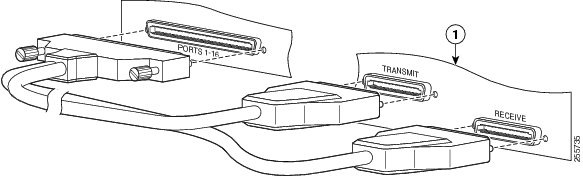

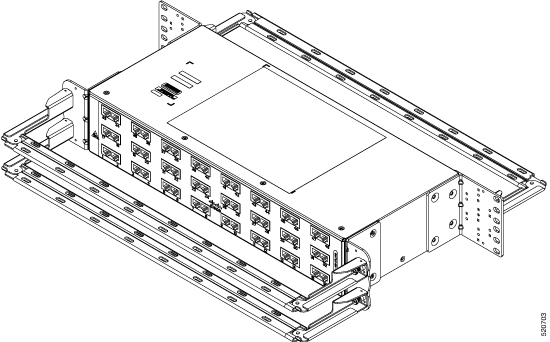

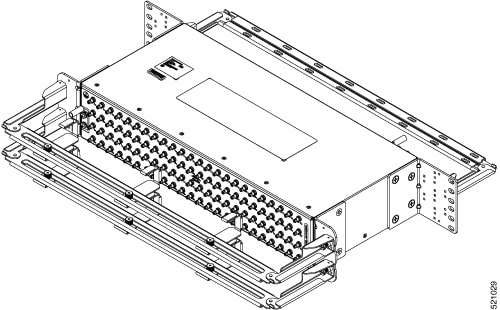

CABLE-16TDM-R1OL1

|

T1/E1-Cable S-3

|

3 x 16-port cables for TDM CEM Interface Module, 42 inches cable length and 10 inches stub length, odd slot

|

|

CABLE-16TDM-R1OL2

|

T1/E1-Cable M-3

|

3 x 16-port cables for TDM CEM Interface Module, 62 inches cable length and 10 inches stub length, odd slot

|

|

CABLE-16TDM-R1OL3

|

T1/E1-Cable L-3

|

3 x 16-port cables for TDM CEM Interface Module, 78 inches cable length and 10 inches stub length, odd slot

|

|

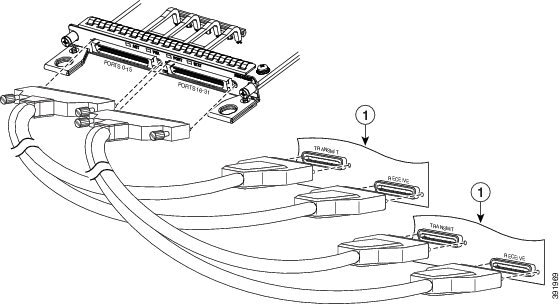

CABLE-16TDM-R3OL1

|

T3/E3-Cable S-3

|

3 x 16-port cables for TDM CEM Interface Module, 42 inches cable length and 10 inches stub length, odd slot

|

|

CABLE-16TDM-R3OL2

|

T3/E3-Cable M-3

|

3 x 16-port cables for TDM CEM Interface Module, 62 inches cable length and 10 inches stub length, odd slot

|

|

CABLE-16TDM-R3OL3

|

T3/E3-Cable L-3

|

3 x 16-port cables for TDM CEM Interface Module, 78 inches cable length and 10 inches stub length, odd slot

|

Feedback

Feedback