Fiber-optic

connectors are used to connect two fibers together. When these connectors are

used in a communication system, proper connection becomes a critical factor.

They can be damaged by improper cleaning and connection procedures. Dirty or

damaged fiber-optic connectors can result in communication that is inaccurate

or not repeatable.

Fiber-optic

connectors differ from electrical or microwave connectors. In a fiber-optic

system, light is transmitted through an extremely small fiber core. Because

fiber cores are often 62.5 microns or less in diameter, and dust particles

range from a tenth of a micron to several microns in diameter, dust and any

other contamination at the end of the fiber core can degrade the performance of

the connector interface where the two cores meet. Therefore, the connector must

be precisely aligned and the connector interface must be absolutely free of

foreign material.

Connector loss, or

insertion loss, is a critical performance characteristic of a fiber-optic

connector. Return loss is also an important factor. Return loss specifies the

amount of reflected light: the lower the reflection, the better the connection.

The best physical contact connectors have return losses of better than –40 dB,

but –20 to –30 dB is more common.

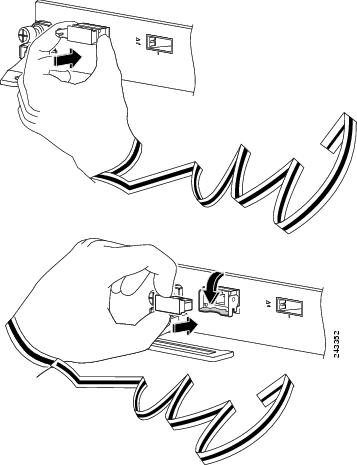

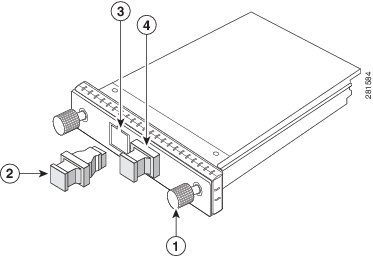

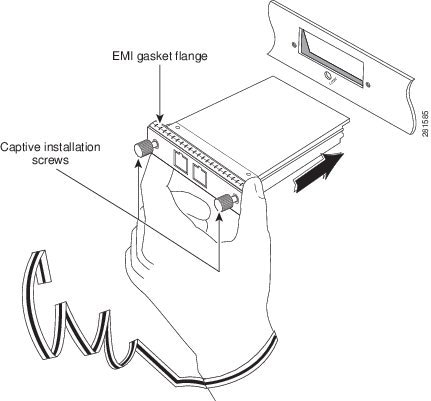

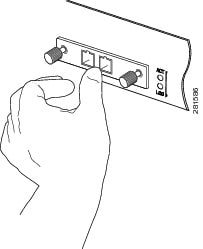

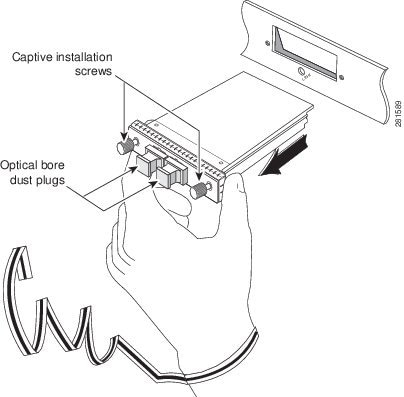

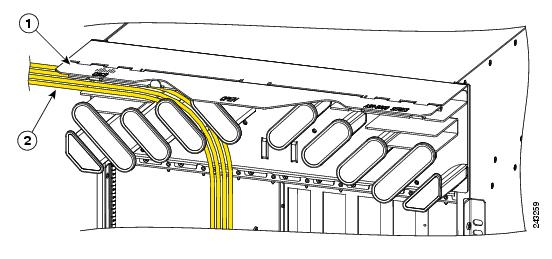

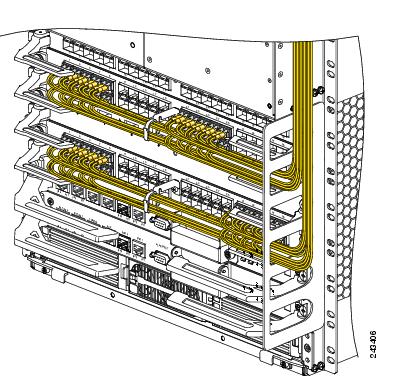

The connection

quality depends on two factors: the type of connector and the proper cleaning

and connection techniques. Dirty fiber connectors are a common source of light

loss. Keep the connectors clean at all times, and keep the dust plugs or covers

installed when the connectors are not in use.

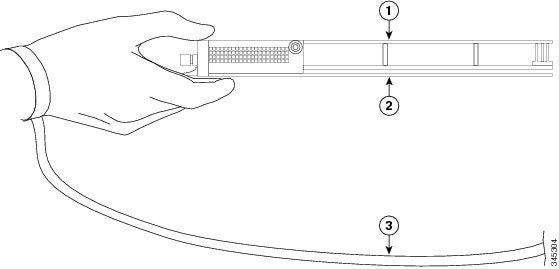

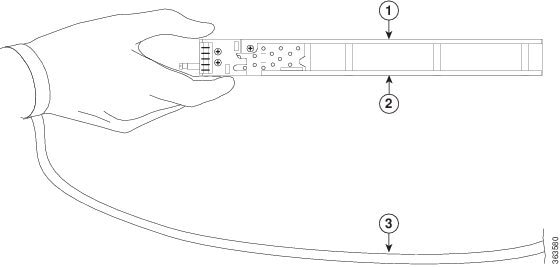

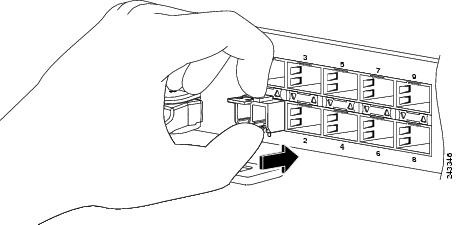

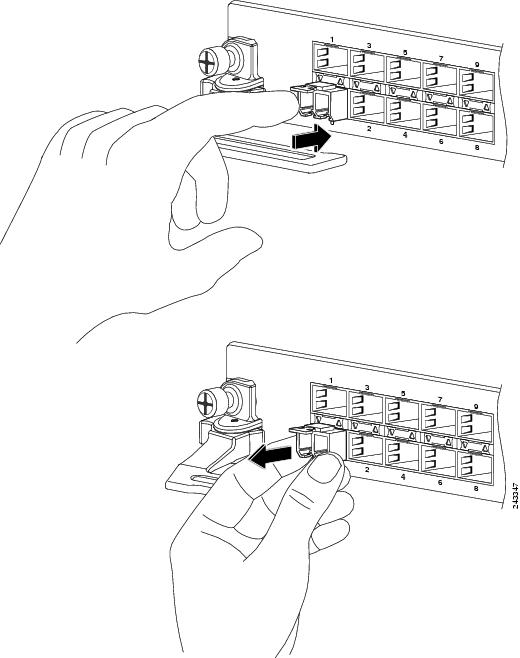

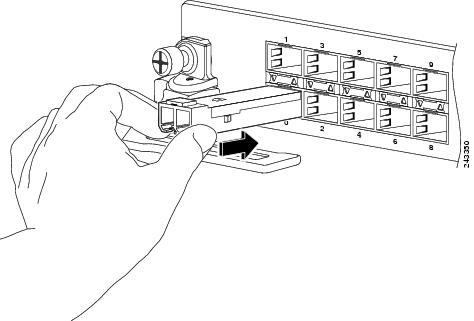

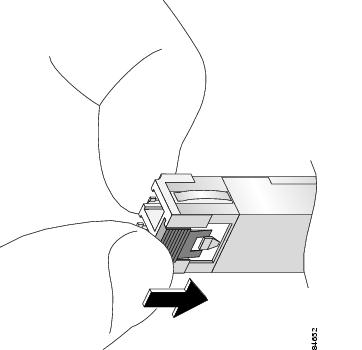

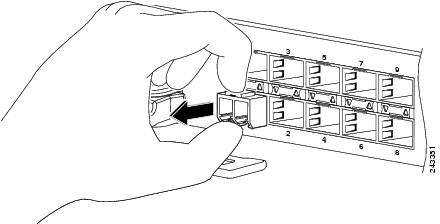

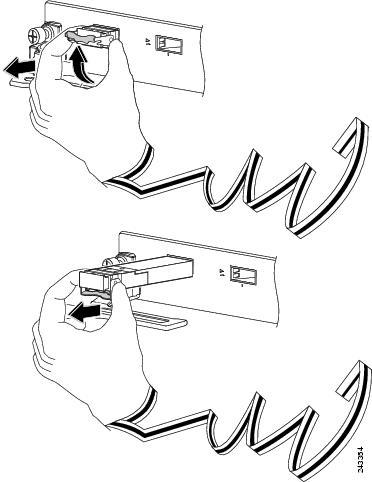

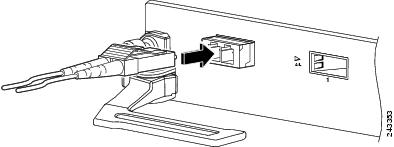

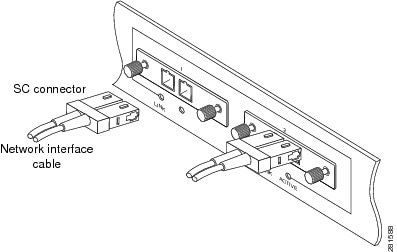

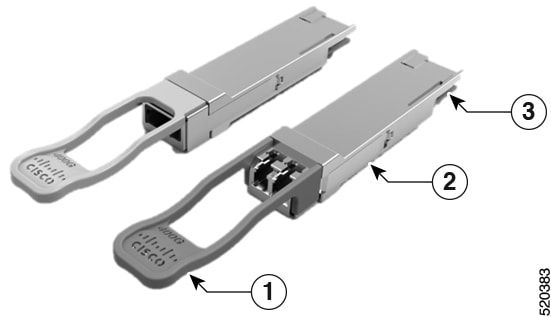

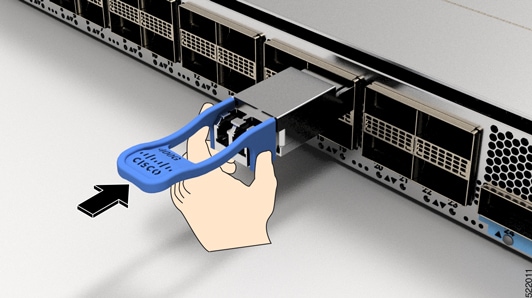

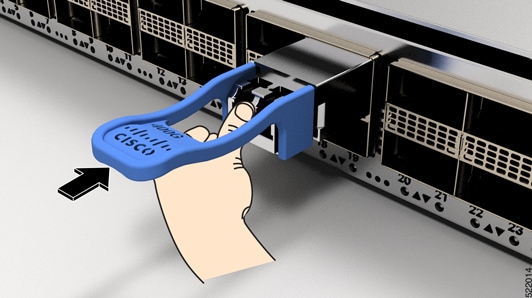

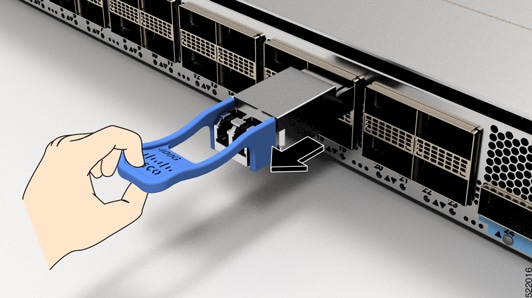

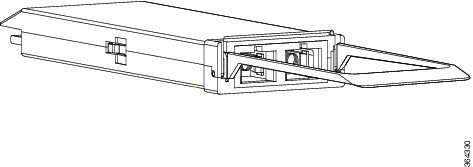

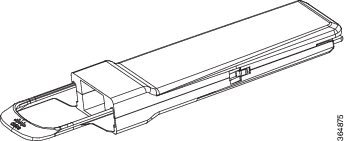

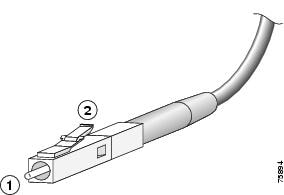

Before installing any

type of cable or connector, use a lint-free alcohol pad from a cleaning kit to

clean the ferrule, the protective tube or cone that surrounds the fiber core,

and the end-face surface of the fiber core.

As a general rule,

any time you detect a significant, unexplained loss of light, clean the

connectors. To clean the optical connectors, use a CLETOP fiber optic cleaning

cassette and follow the manufacturer’s usage instructions.

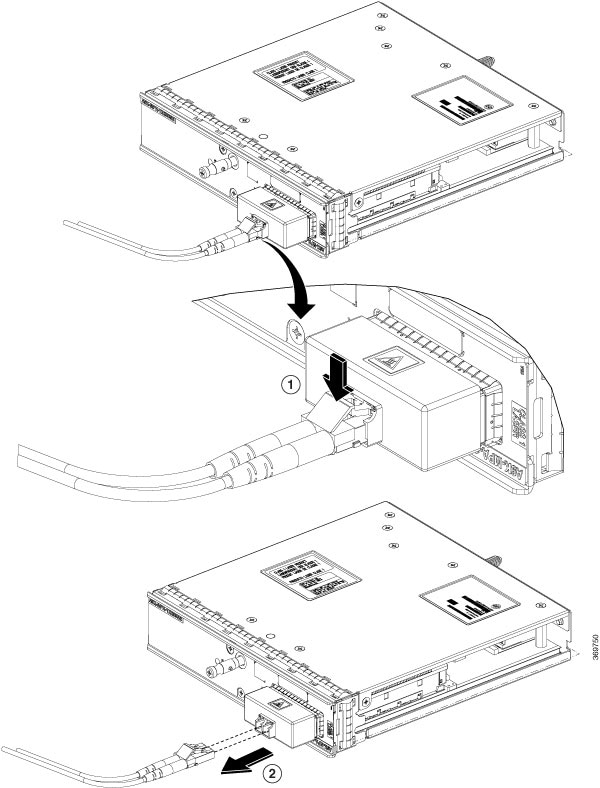

If a CLETOP cleaning

cassette is not available, follow these steps:

Warning

|

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do

not stare into beams or view directly with optical instruments.

|

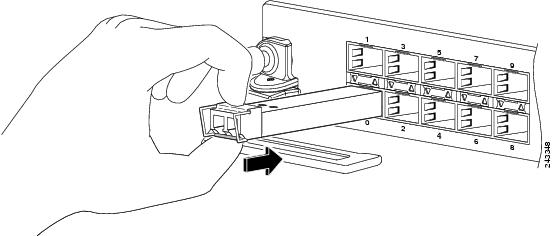

-

Use a lint-free tissue soaked in 99 percent pure isopropyl alcohol and gently wipe the end-face of the fiber core. Wait for

five seconds for the surfaces to dry and wipe the surfaces a second time.

-

Use clean, dry, oil-free compressed air to remove any residual dust from the connector.

-

Use a magnifying glass or inspection microscope to inspect the ferrule at angle. Do not look directly into the aperture. If

you detect any contamination, repeat the Step 1 and Step 2 indicated above.

For more information about cleaning fiber-optic connectors, as well as SFP/XFP transceivers, see Inspection and Cleaning Procedures for Fiber-Optic Connections.

Feedback

Feedback