Ethernet Line Card Installation and Configuration

Available Languages

Table Of Contents

Ethernet Line Card Installation and Configuration

Ethernet Line Card Product Numbers

Cisco IOS Software Release and Hardware Revision Requirements

8-Port Fast Ethernet Line Card

1-Port Gigabit Ethernet Line Card

3-Port Gigabit Ethernet Line Card

4-Port Gigabit Ethernet ISE Line Card

10-Port 1-Gigabit Ethernet Line Card

1-Port 10-Gigabit Ethernet Line Card

Modular Gigabit Ethernet Line Card

Preventing Electrostatic Discharge

Removing and Installing a Line Card

Guidelines for Line Card Removal and Installation

Removing an EPA from the Modular Gigabit Ethernet Line Card

Inserting an EPA into a Modular Gigabit Ethernet Line Card

General GBIC Handling and Maintenance Guidelines

Removing the GBIC from an Ethernet Line Card

Inserting a GBIC into the Gigabit Ethernet Interface

Removing and Installing SFP Modules

Removing a Bale Clasp SFP Module

Installing a Bale Clasp SFP Module

Removing a Mylar Tab SFP Module

Installing a Mylar Tab SFP Module

Removing an Actuator Button SFP Module

Installing an Actuator Button SFP Module

Removing a Slide Tab SFP Module

Installing a Slide Tab SFP Module

Line Card Cable-Management Bracket

Removing a Line Card Cable-Management Bracket

Installing a Line Card Cable-Management Bracket

GBIC Laser Optical Transceiver Modules

Removing and Installing Fiber-Optic Interface Cables

Removing Fiber-Optic Interface Cables

Installing Fiber-Optic Interface Cables

Cleaning Fiber-Optic Connectors

Type RJ-45 100BASE-T Copper Cables

Removing and Installing RJ-45 100BASE-T Copper Cable

Verifying and Troubleshooting the Installation

8-Port Fast Ethernet Line Card LEDs

Troubleshooting the Installation

Configuring and Troubleshooting Line Card Interfaces

Configuring Ethernet Line Cards

Configuring 802.1Q VLAN Counters

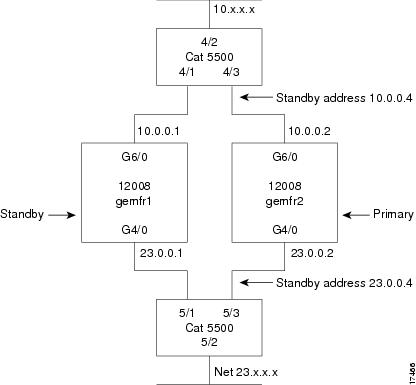

IP and VLAN Configuration for Gigabit Ethernet Example

Advanced Line Card Troubleshooting

Checking the Current Status of the Line Card

Line Card Diagnostics Using Cisco IOS Software Release 12.0(22)S and Later

Line Card Diagnostics Using Cisco IOS Software Releases Prior to 12.0(22)S

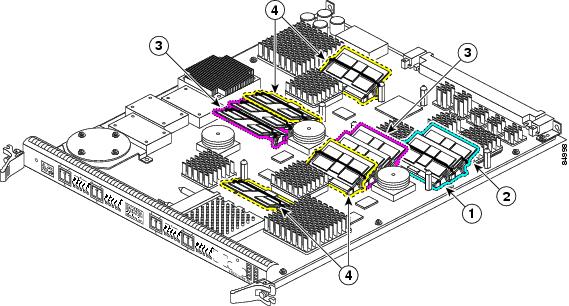

Engine 0 and Engine 1 Line Card Memory Locations

Engine 2 Line Card Memory Locations

ISE Line Card Memory Locations

Engine 4 Line Card Memory Locations

Ethernet Line Card Route Memory Options

Ethernet Line Card Packet Memory Options

Removing and Installing Line Card Memory

Checking the Installation of Line Card Memory

Regulatory, Compliance, and Safety Information

Translated Safety Warnings and Agency Approvals

Electromagnetic Compatibility Regulatory Statements

Class A Notice for Taiwan and Other Traditional Chinese Markets

Class 1 Laser Product Warning (Single-mode)

Class 1 LED Product Warning (Multimode)

Obtaining Technical Assistance

Obtaining Additional Publications and Information

Ethernet Line Card Installation and Configuration

Document Order Number: DOC-7816361=

This guide contains instructions for installing and configuring Ethernet line cards in supported Cisco 12000 Series Routers. Also included are basic troubleshooting and diagnostic techniques and tools designed to help resolve line card installations that do not successfully come online.

Contents

This installation and configuration guide includes the following sections:

•

Removing and Installing a Line Card

•

Removing and Installing GBICs

•

Removing and Installing SFP Modules

•

Line Card Cable-Management Bracket

•

Verifying and Troubleshooting the Installation

•

Configuring and Troubleshooting Line Card Interfaces

•

Regulatory, Compliance, and Safety Information

•

Obtaining Technical Assistance

•

Obtaining Additional Publications and Information

Important Information

This section contains information about the following topics:

•

Ethernet Line Card Product Numbers

•

Cisco IOS Software Release and Hardware Revision Requirements

Ethernet Line Card Product Numbers

Table 1 lists the Cisco product numbers to which this publication applies. This guide replaces the individual Ethernet line card installation and configuration documents for the Cisco 12000 Series Router.

Router Hardware Installation

For hardware installation and configuration information for Cisco 12000 Series Routers, refer to the installation and configuration guide for your router. The guide includes information on the router switch fabric and how it affects operation of the line card, as well as line card slot locations, slot width, and other requirements.

Also refer to the field-replaceable unit (FRU) publications that describe how to install, maintain, and replace router subsystems, such as cooling fans, power supplies, chassis backplanes, and so on.

Supported Platforms

Table 2 lists the supported router platforms for Ethernet line cards:

Note

The Cisco 12000 Series Routers must have a full set of switch fabric cards installed to support the requirements of the Ethernet line cards. See the appropriate Cisco 12000 Series Router installation and configuration guide for information about the switch fabric and other related requirements.

Note

Because the 10-Port 1-Gigabit Ethernet, 1-Port 10-Gigabit Ethernet, and Modular Gigabit Ethernet line cards require a card cage slot that is 1.8 inches (4.5 centimeters) wide, you can use these line cards in only the Cisco 12416 Router, Cisco 12410 Router, Cisco 12406 Router, Cisco 12404 Router, Cisco 12816 Router, and Cisco 12810 Router.

Cisco IOS Software Release and Hardware Revision Requirements

The Ethernet line cards have certain Cisco IOS software requirements. Also, to ensure compatibility with the software, your Ethernet line card should have a specific hardware revision number. The number is printed on a label affixed to the component side of the card and is displayed by the show diag command.

Table 3 lists the hardware and software requirements for Ethernet line cards.

Table 3 Ethernet Line Card and Cisco IOS Release and Hardware Version Compatibility

Part Number8-Port Fast Ethernet

8FE-FX-SC=

(fiber optic)11.2(18)GS2, or later and 12.0(6)S, or later, version of 12.0S

73-3684-03

8FE-FX-SC-B=

(fiber optic)11.2(19)GS4 or later version of release 11.2GS4; or 12.0(10)S or a later version of 12.0S

73-3684-03

8FE-TX-RJ45= (copper)

11.2(18)GS2, or later, and 12.0(6)S, or later version of 12.0S

73-3683-03

8FE-TX-RJ45-B= (copper)

11.2(19)GS4 or later version of release 11.2GS4; or 12.0(10)S or a later version of 12.0S

73-3683-03

1-Port Gigabit Ethernet

GE-SX/LH-SC=

12.0(5)S or later version of 12.0S

73-3302-03, revision A0 or later

GE-GBIC-SC-B=

12.0(10)S or later version of 12.0S

73-3302-04, revision A0 or later

3-Port Gigabit Ethernet

3GE-GBIC-SC=

The Ethernet line cards equipped with shorthaul multimode (WS-G5484=), longhaul single-mode (WS-G5486=), or extended distance (WS-G5487=) single-mode Gigabit Interface Converters (GBICs) is compatible with Cisco IOS Release 12.0(11)S3 or a later release of 12.0S.

The Ethernet line cards equipped with Coarse Wave Division Multiplexing (CWDM) GBICs in any of the eight supported wavelengths is compatible with Cisco IOS Release 12.0(23)Sn or a later release of 12.0S.

73-4775-02 revision A0 or later

4-Port Gigabit Ethernet ISE

4GE-SFP-LC=

Cisco IOS Release 12.0(25)S or later

73-8517-03, revision A0 or later

10-Port 1-Gigabit Ethernet

10X1GE-LC=

12.0(19)S or later release of 12.0S; or 12.0(19)ST or later release of 12.0ST

73-5479-06 or later

10X1GE-LC-B=

12.0(21)S or later release of 12.0S; or 12.0(21)ST or later release of 12.0ST

73-7673-02 or later

1-Port 10-Gigabit Ethernet

1X10GE-LR-SC=

(LR laser optical transceiver)12.0(23)S, or later, release of 12.0S1

73-7182-01 or later

1X10GE-ER-SC=

(ER laser optical transceiver)12.0(23)S, or later release of 12.0S

73-7182-01 or later

Modular Gigabit Ethernet

EPA-GE/FE-BBRD=

12.0(23)S, or later release of 12.0S

73-6701-02

EPA-3GE-SX/LH-LC=

12.0(23)S, or later release of 12.0S

73-6701-02

1 Cisco IOS Release 12.0(22)S does not support the 1X10GE-LR-SC Ethernet line cards.

The show diag slot_number, show version, and show hardware commands display the current hardware configuration of the router, including the system software version that is currently loaded and running, and the hardware revision number. For complete descriptions of show commands, refer to the Cisco IOS Configuration Fundamentals Configuration Guide and the Cisco IOS Configuration Fundamentals Command Reference for the installed Cisco IOS release.

If the command displays indicate that the Cisco IOS software is a version earlier than you need, check the contents of flash memory to determine if the required images are available on your system. The dir devicename command displays a list of all files stored in flash memory. If you do not have the correct software version, contact Cisco customer service.

For software configuration information, refer to the Cisco IOS software configuration and command reference publications for the installed Cisco IOS release. Also refer to the Cisco IOS software release notes for additional information.

Memory Options

Ethernet line card memory options vary by line card. See "Line Card Memory" section for more information.

Related Documentation

This publication describes the basic installation and initial configuration of Ethernet line cards. For complete configuration information, refer to the following publications:

•

Cisco 12xxx Series Internet Router Installation and Configuration Guide

•

Cisco IOS Configuration Fundamentals Configuration Guide

•

Cisco IOS Configuration Fundamentals Command Reference

•

Software Configuration Guide for the Cisco 12000 Series Internet Router

•

Cisco IOS Release 12.0S Release Notes for Cisco 12000 Series Internet Routers

•

Field Diagnostics for the Cisco 12000 Series Internet Router

•

Regulatory Compliance and Safety Information for Cisco 12000 Series Internet Routers

See the "Obtaining Documentation" section for information on how to obtain these publications.

Product Overviews

The following sections provide information about the Ethernet line card products:

•

Ethernet Line Card Comparison

•

8-Port Fast Ethernet Line Card

•

1-Port Gigabit Ethernet Line Card

•

3-Port Gigabit Ethernet Line Card

•

4-Port Gigabit Ethernet ISE Line Card

•

10-Port 1-Gigabit Ethernet Line Card

•

1-Port 10-Gigabit Ethernet Line Card

•

Modular Gigabit Ethernet Line Card

Ethernet Line Card Comparison

Table 4 provides comparative information about Ethernet line cards. The first Ethernet line card has a Fast Ethernet interface and the others have a Gigabit Ethernet interface.

CautionTo prevent system problems, do not use Gigabit Interface Converters (GBICs) from third-party vendors. Use only the GBIC that shipped with your Ethernet line card. The GBIC might contain an internal EPROM that identifies it to the Cisco IOS software.

CautionOnly use small form-factor pluggable modules (SFPs) supplied by Cisco in Cisco 12000 Series Routers. Each SFP module contains an internal serial number that is security programmed by the SFP module manufacturer with information that provides a way for Cisco (through the Cisco IOS software) to identify and validate the SFP module as a module type that is qualified by Cisco to operate with Gigabit Ethernet line cards. Unapproved SFP modules (those not purchased directly from Cisco) do not work.

8-Port Fast Ethernet Line Card

The 8-Port Fast Ethernet line card provides eight Fast Ethernet (IEEE 802.3u) interfaces that operate at a full-duplex data rate of 100 Mbps each.

The 8-Port Fast Ethernet line card supports either copper or fiber-optic Fast Ethernet transceivers. The fiber-optic 100BASE-FX interface supports multimode SC duplex connectors operating in half- or full-duplex mode. The copper interface supports both half- and full-duplex 100BASE-TX standards that use an RJ-45 connector.

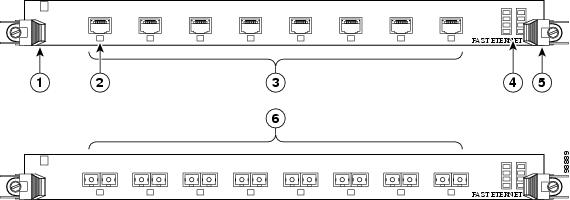

There are two models, each with updated revisions (-B), of the 8-Port Fast Ethernet line card. The two fiber-optic interface versions are functionally equivalent; the -B model contains some newer ASICs and memory chips, however, and requires a later version of Cisco IOS. The copper interface versions are also both functionally equivalent; the -B model contains some newer ASICs and memory chips and requires a later version of Cisco IOS. The front panels are shown in Figure 1.

Figure 1 8-Port Fast Ethernet Line Card

Ejector lever

Alphanumeric LEDs

Status LED (one per port)

Ejector lever

8 RJ-45 copper ports on wire version

8 SC connectors on fiber version

Table 5 summarizes the optics and connectors used by the 8-Port Fast Ethernet line card.

Figure 2 Onboard Receive and Transmit Status LEDs

Note

The Link LED is located on the line card front-panel. The receive and transmit LEDs are located on the line card and are not visible when a line card is fully installed in the GSR.

For more information on the Fast Ethernet interface, cabling, and connectors, see the "Fast Ethernet Interface" section and the "Cabling and Specifications" section.

1-Port Gigabit Ethernet Line Card

The 1-Port Gigabit Ethernet line card provides Cisco 12000 Series Routers with an optical Ethernet interface that operates at a rate of 1 Gbps. The card provides Cisco 12000 Series Routers with a single-port Gigabit Ethernet SC single-mode or multimode connection. The Ethernet optical interface is provided by the GBIC module on the 1-Port Gigabit Ethernet line card.

Figure 3 1-Port Gigabit Ethernet Line Card

Ejector lever

Alphanumeric LEDs

Gigabit Ethernet port (provided by a GBIC in one line card model)

Ejector lever

Status LEDs

Table 6 summarizes the optics and connectors used by the 1-Port Gigabit Ethernet line card.

Table 6 1-Port Gigabit Ethernet Line Card Optics and Connector Types

GE-SX/LH-SC

See Table 14.

See Table 14.

SC

GE-GBIC-SC-B

See Table 14.

See Table 14.

SC

For more information, refer to the "GBIC Laser Optical Transceiver Modules" section and the "Cabling and Specifications" section.

The default line card route memory configuration is 128 MB; one 128-MB DIMM is installed in the route memory DRAM DIMM0 socket. For more information on memory, see the "Line Card Memory" section.

3-Port Gigabit Ethernet Line Card

The 3-Port Gigabit Ethernet line card provides Cisco 12000 Series Routers with three optical Gigabit Ethernet interfaces on a single line card. These interfaces will provide high-speed connections to other network devices, such as Cisco 12000 Series Routers, other routers, or layer-2 and layer-3 switches that support Gigabit Ethernet interfaces. The 3-Port Gigabit Ethernet line card supports full line rate with two ports in service while the third port is shutdown. With three ports turned on, the 3-Port Gigabit Ethernet line card throughput is limited to the line card forwarding engine limit of 4 million packets per second (4 Mpps) at 64 bytes.

The three ports on the front panel of the line card are port number 0, 1, and 2, from the top of the card to the bottom. Each port consists of a receptacle for a field-replaceable GBIC laser optical transceiver module, which is inserted into the receptacle to provide the Gigabit Ethernet optical interface.

Next to each port on the line card are three green LEDs, aligned vertically and labeled from top to bottom as follows: Link, Active, and RX Frame.

This line card requires a narrow line card slot within the router chassis. Figure 4 shows the line card.

Figure 4 3-Port Gigabit Ethernet Line Card

Ejector lever

Port 1 GBIC

Port 2 Status LEDs

Port 0 GBIC

Port 1 status LEDs

Alphanumeric LEDs

Port 0 status LEDs

Port 2 GBIC

Ejector lever

Table 7 3-Port Gigabit Ethernet Line Card Optics and Connector Types

3GE-GBIC-SC

See Table 14.

See Table 14.

SC

Table 7 summarizes the optics and connectors used by the 1-Port Gigabit Ethernet line card.

For more information, refer to the "GBIC Laser Optical Transceiver Modules" section and "Cabling and Specifications" section.

The default line card route memory configuration is 128 MB; one 128-MB DIMM installed in the route memory DRAM DIMM0 socket. For more information on memory, see the "Line Card Memory" section.

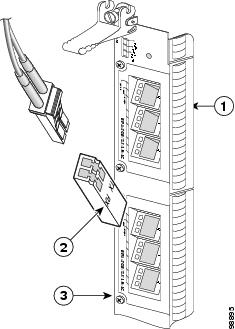

4-Port Gigabit Ethernet ISE Line Card

The 4-Port Gigabit Ethernet ISE line card provides Cisco 12000 Series Routers with four optical Gigabit Ethernet interfaces on a single line card, using field replaceable SFP modules. The line card provides high-speed connections to other network devices, such as another Cisco 12000 Series Router, other routers, or layer-2 and layer-3 switches that support Gigabit Ethernet interfaces. The 4-Port Gigabit Ethernet line card throughput is limited to 4 million packets per second (4 Mpps) at 64 bytes, so all four ports cannot run at line rate.

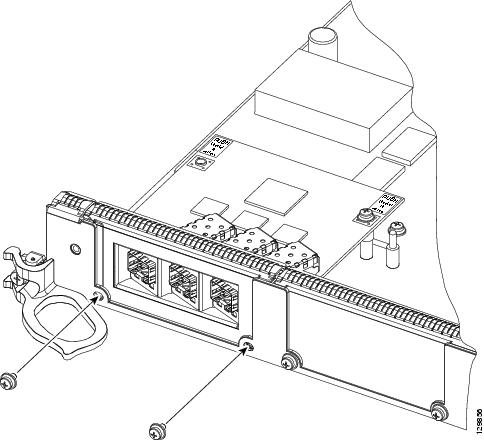

Figure 5 shows the front view of the 4-Port Gigabit Ethernet ISE line card.

Figure 5 4-Port Gigabit Ethernet ISE Line Card

Ejector lever (one at each end)

Alphanumeric LEDs

Status LEDs (one set per port)

Port (provided by SFP module)

Table 8 summarizes the optics and connectors used by the 4-Port Gigabit Ethernet ISE line card.

Table 8 4-Port Gigabit Ethernet ISE Line Card Optics and Connector Types

4GE-SFP-LC

See Table 18.

See Table 18.

LC

For more information, refer to the "Gigabit Ethernet SFP Modules" section and the "Cabling and Specifications" section.

The 4-Port Gigabit Ethernet ISE line card ships with 256 MB of route memory and 512 MB of packet memory. Route memory is field serviceable. For more information on memory, see the "Line Card Memory" section.

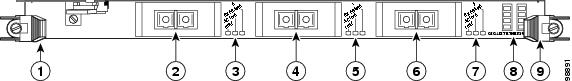

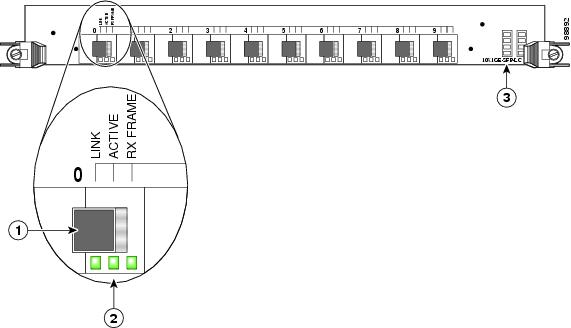

10-Port 1-Gigabit Ethernet Line Card

The 10-Port 1-Gigabit Ethernet line card, which is designed for high-density and server-aggregation applications, provides the Cisco 12400 and 12800 Routers with 10 optical 802.3 Gigabit Ethernet interfaces on a single line card. These interfaces provide high-speed connections to other network devices, such as another Cisco 12000 Series Router, other routers, or layer-2 or layer-3 switches that support Gigabit Ethernet interfaces. Figure 6 shows a front view of the line card.

The 10 ports on the front panel of the line card are numbered 0 through 9, from the top of the card to the bottom. Each port consists of a receptacle for a field-replaceable SFP laser optical transceiver module, which is inserted into the receptacle to provide the Gigabit Ethernet optical interface.

Next to each port on the line card are three green LEDs, aligned vertically and labeled from top to bottom as follows: LINK, ACTIVE, and RX FRAME.

Note

The 10X1GE-SFP-LC-B version of this card is not shown. The 10X1GE-SFP-LC-B model of the 10-Port 1-Gigabit Ethernet line card is enhanced with minor hardware features that are not available with the original design.

Figure 6 10-Port 1-Gigabit Ethernet Line Card

Table 9 summarizes the optics and connectors used by the 10-Port 1-Gigabit Ethernet line card.

Table 9 10-Port 1-Gigabit Ethernet Line Card Optics and Connector Types

10X1GE-SFP-LC,

10X1GE-SFP-LC-BSee Table 18.

See Table 18.

LC

For more information, refer to the "Gigabit Ethernet SFP Modules" section and "Cabling and Specifications" section.

The 10-Port 1-Gigabit Ethernet line card ships with the following memory configurations installed:

•

256 MB of route processor memory (Product Number MEM-LC4-256)

•

512 MB of packet memory (Product Number MEM-LC4-PKT-512)—256 MB in both the receive and transmit directions

Line card memory on Engine 4 line cards (packet and route memory) is not field replaceable. For more information on memory, see the "Line Card Memory" section.

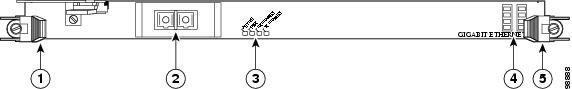

1-Port 10-Gigabit Ethernet Line Card

The 1-Port 10-Gigabit Ethernet line card provides the supported Cisco 12000 Series Routers with one optical 802.3ae 10-Gigabit Ethernet interface. This interface provides a high-speed connection to other network devices, such as Cisco 12000 Series Routers, or to other routers or layer-2 or layer-3 switches that support 10-Gigabit Ethernet interfaces. Figure 7 shows the front view of the line card.

The port on the front panel of the line card is port number 0. This port uses a hardwired laser optical transceiver to provide a 10-Gigabit Ethernet optical interface. The transceiver consists of two optical interfaces—laser transmit (TX) and laser receive (RX)—that use SC connectors.

Next to the port on the line card are three green LEDs, aligned vertically and labeled from top to bottom as follows: LINK, ACTIVE, and RX FRAME.

Figure 7 1-Port 10-Gigabit Ethernet Line Card

Table 10 summarizes the optics and connectors used by the 1-Port 10-Gigabit Ethernet line card.

For more information, refer to the "10-Gigabit Ethernet" section and the "Cabling and Specifications" section.

The 1-Port 10-Gigabit Ethernet line card ships with 256 MB of route processor memory and 512 MB of packet memory. The memory in the 1-Port 10-Gigabit Ethernet line card is not field replaceable. For more information on memory, see the "Line Card Memory" section.

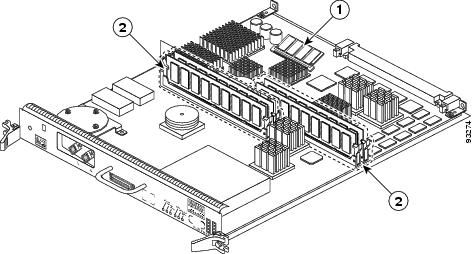

Modular Gigabit Ethernet Line Card

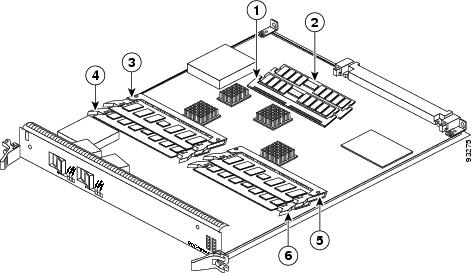

The Modular Gigabit Ethernet line card, which is designed for high-density and server-aggregation applications, provides the supported Cisco 12000 Series Routers with up to 10 optical 802.3 Gigabit Ethernet interfaces. These interfaces provide high-speed connections to other network devices, such as other Cisco 12000 Series Routers, other types of routers, or layer-2 or layer-3 switches that support Gigabit Ethernet interfaces.

In addition to one hardwired Gigabit Ethernet SFP receptacle, the Modular Gigabit Ethernet line card has three bays in which you can install Ethernet port adapters (EPAs). Each EPA has three receptacles that can be populated with Gigabit Ethernet SFPs, for a total of 10 Gigabit Ethernet ports (one hardwired, plus three on each of the three EPAs). The Ethernet line card ships with 0, 1, 2, or 3 EPAs installed and with at least one SFP module installed.

Next to the port on the line card are three green LEDs, aligned vertically and labeled from top to bottom as follows: LINK, ACTIVE, and RX FRAME.

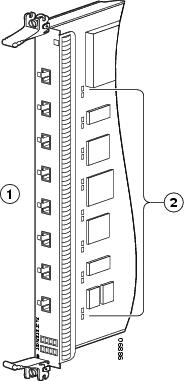

Figure 8 shows a vertical front view of the line card and the backplane connector.

Figure 8 Modular Gigabit Ethernet Line Card

Ejector lever (one on each end)

Hardwired SFP receptacle

5

Status LEDsEPA (three bays)

Alphanumeric LEDs

Table 11 summarizes the optics and connectors used by the Modular Gigabit Ethernet line card.

Table 11 Modular Gigabit Ethernet Line Card Optics and Connector Types

EPA-GE/FE-BBRD,

EPA-3GE-SX/LH-LCSee Table 18.

See Table 18.

LC

For more information, refer to the "Gigabit Ethernet SFP Modules" section and the "Cabling and Specifications" section.

The Ethernet line cards ship with the following memory configurations installed:

•

256 MB of route processor memory

•

512 MB of packet memory—256 MB in both the receive and transmit directions

Line card memory on this line card (packet and route memory) is not field replaceable. For more information on memory, see the "Line Card Memory" section.

Preparing for Installation

The following sections provide information about preparing to install line cards:

•

Preventing Electrostatic Discharge

Safety Guidelines

Before you perform any procedure in this publication, review the safety guidelines in this section to avoid injuring yourself or damaging the equipment.

The following guidelines are for your safety and to protect equipment. The guidelines do not include all hazards. Be alert.

Note

Review the safety warnings listed in the Regulatory Compliance and Safety Information for Cisco 12000 Series Internet Router publication (Document Number 78-4347-xx) that accompanied your router before installing, configuring, or maintaining a line card.

•

Keep the work area clear and dust free during and after installation. Do not allow dirt or debris to enter into any laser-based components.

•

Do not wear loose clothing, jewelry, or other items that could get caught in the router while working with line cards.

•

Cisco equipment operates safely when it is used in accordance with its specifications and product usage instructions.

Before working with laser optics, read the "Laser Safety" section.

Preventing Electrostatic Discharge

Electrostatic discharge (ESD) damage, which can occur when electronic cards or components are improperly handled, results in complete or intermittent failures. Electromagnetic interference (EMI) shielding is an integral component of the line card. Cisco recommends using an ESD-preventive strap whenever you are handling network equipment or one of its components.

The following are guidelines for preventing ESD damage:

•

Always use an ESD-preventive wrist or ankle strap and ensure that it makes good skin contact. Connect the equipment end of the connection cord to an ESD connection socket on the router or to bare metal on the chassis.

•

Handle Ethernet line cards by the captive installation screws, the provided handle, ejector levers, or the line card metal carrier only; avoid touching the board or connector pins.

•

Place removed Ethernet line cards board-side-up on an antistatic surface or in a static shielding bag. If you plan to return the component to the factory, immediately place it in a static shielding bag.

•

Avoid contact between the Ethernet line cards and clothing. The wrist strap only protects the board from ESD voltages on the body; ESD voltages on clothing can still cause damage.

Warning

For safety, periodically check the resistance value of the ESD strap. The measurement should be between 1 and 10 megohms.

Required Tools and Equipment

You need the following tools and parts to remove and install Ethernet line cards:

•

Flat-blade or Phillips screwdriver

•

ESD-preventive wrist or ankle strap and instructions

•

Interface cables to connect the Ethernet line card with another router or switch

•

Any EPAs, GBICs, SFP modules, or memory you need to install (and are not already installed)

Note

If you need additional equipment, see Cisco.com or your service representative for ordering information.

Refer to the individual line card descriptions in the "Product Overviews" section for more information. Table 4 summarized the hardware requirements for each Ethernet line card.

Removing and Installing a Line Card

The following sections provide procedures for removing or installing a line card:

•

Guidelines for Line Card Removal and Installation

Note

See the "Guidelines for Line Card Removal and Installation" section before removing a line card while power to the router is on.

Note

The procedures in the following sections use illustrations of a Cisco 12012 Internet Router to support the descriptions of removing and installing line cards. Although the card cages of the Cisco 12000 Series Routers differ in the number of card slots, the designated use of slots and the process of removing and installing a line card are basically the same. Therefore, separate procedures and illustrations for other Cisco routers are not included in this publication.

Guidelines for Line Card Removal and Installation

Guidelines for line card removal and installation include the following:

•

Online insertion and removal (OIR) is supported, enabling you to remove and install line cards while the router is operating. OIR is seamless to users on the network, maintains all routing information, and ensures session preservation.

Note

With OIR, notifying the software or resetting the power is not required. However, you have the option of using the shutdown command before removing a line card.

•

After you reinstall a line card, the router automatically downloads the necessary software from the route processor (RP). Next, the router brings online only those interfaces that match the current configuration and were previously configured as administratively up. You must configure all others with the configure command.

CautionThe router may indicate a hardware failure if you do not follow proper procedures. Remove or insert only one line card at a time. Allow at least 15 seconds for the router to complete the preceding tasks before removing or inserting another line card.

After removing and inserting a line card into the same slot, allow at least 60 seconds before removing or inserting another line card.

•

Line cards have two ejector levers to release the card from its backplane connector. Use the levers when you are removing the line card and to seat the line card firmly in its backplane connector when you are installing the line card. The ejector levers align and seat the card connectors in the backplane.

CautionWhen you remove a line card, always use the ejector levers to ensure that the connector pins disconnect from the backplane in the sequence expected by the router. Any card that is only partially connected to the backplane can halt the router.

When you install a line card, always use the ejector levers to ensure that the card is correctly aligned with the backplane connector; the connector pins should make contact with the backplane in the correct order, indicating that the card is fully seated in the backplane. If a card is only partially seated in the backplane, the router will hang and subsequently crash.

For line card configuration information, see the "Configuring and Troubleshooting Line Card Interfaces" section.

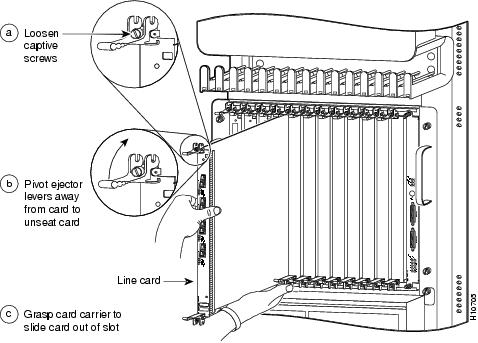

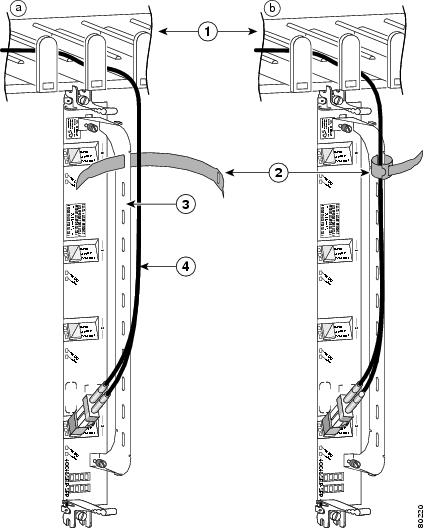

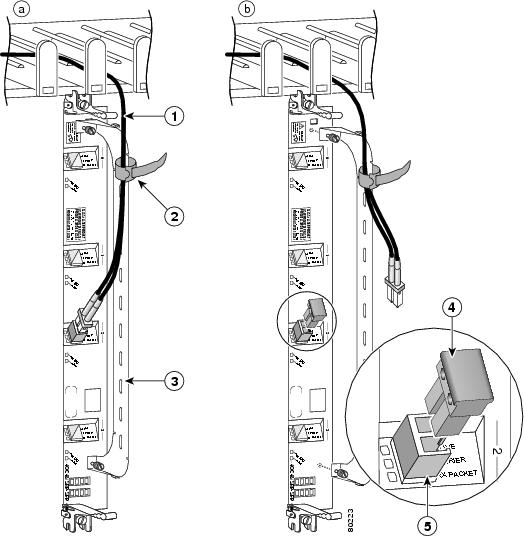

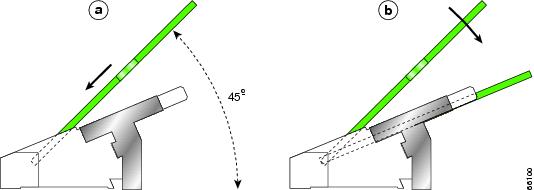

Removing a Line Card

If you are replacing a failed line card, remove the existing line card first, then install the new line card in the same slot. To remove a line card, use Figure 9 as a reference and follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

Step 3

Detach the line card cable-management bracket from the line card.

Step 4

Use a screwdriver to loosen the captive screw at each end of the line card faceplate. (See Figure 9a.)

Figure 9 Line Card Removal and Installation

CautionWhen you remove a line card, always use the ejector levers to ensure that the line card connector pins disconnect from the backplane in the logical sequence expected by the router. Any line card that is only partially connected to the backplane can halt the router.

Step 5

Simultaneously pivot the ejector levers away from each other to release the line card from the backplane connector. (See Figure 9b.)

Step 6

Grasp the ejector levers and pull the line card halfway out of the slot.

Step 7

Grasp the line card and gently pull it straight out of the slot, keeping your other hand under the line card to guide it. (See Figure 9c.) Avoid touching the line card printed circuit board, components, or any connector pins.

Step 8

Place the removed line card on an antistatic mat, or immediately place it in an antistatic bag if you plan to return it to the factory.

Step 9

If the line card slot is to remain empty, install a line card blank (Product Number MAS-GSR-BLANK) to keep dust out of the chassis and to maintain proper airflow through the line card compartment. Secure the line card blank to the chassis by tightening its captive screws.

CautionBe careful not to damage or disturb the EMI spring fingers located on the front edge of the card face plate.

Note

Always insert a dust plug in an optical port opening for each port that is not in use.

For information on disconnecting interface cables, see the "Removing and Installing Fiber-Optic Interface Cables" section.

For information on removing the cable-management bracket, see the "Removing a Line Card Cable-Management Bracket" section.

Installing a Line Card

A line card slides into almost any available line card slot and connects directly to the backplane. If you install a new line card, you must first remove the line card blank from the available slot.

Note

Refer to the installation and configuration guide for your router for information on line card slot types, slot width, and slot location.

CautionThe router may indicate a hardware failure if you do not follow proper procedures. Remove or insert only one line card at a time. Allow at least 15 seconds for the router to complete the preceding tasks before removing or inserting another line card.

To install a line card, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Choose an available line card slot for the line card, and verify that the line card interface cable is long enough for you to connect the line card with any external equipment.

CautionTo prevent ESD damage, handle line cards by the captive installation screws, the provided handle, ejector levers, or the card carrier edges only. Do not touch any of the electrical components or circuitry.

Step 3

Grasp the faceplate (or handle) of the line card with one hand and place your other hand under the card carrier to support the weight of the card; position the card for insertion into the card cage slot. Avoid touching the line card printed circuit board, components, or any connector pins.

Step 4

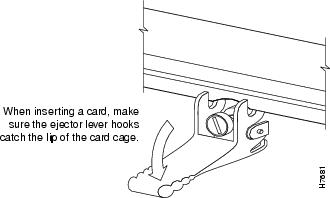

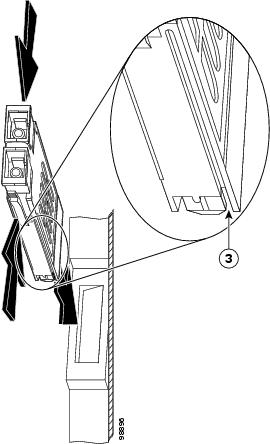

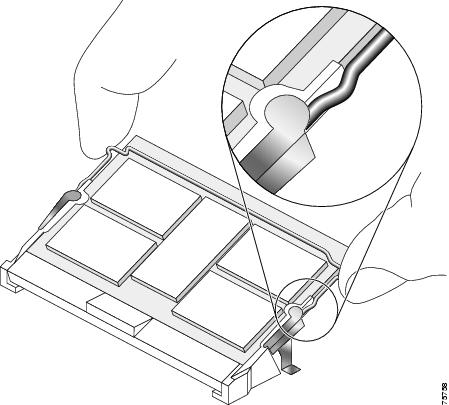

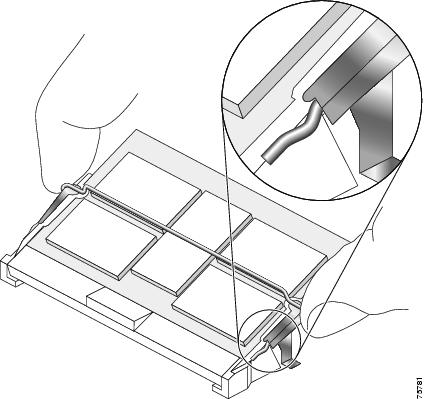

Carefully slide the line card into the slot until the ejector levers make contact with the edges of the card cage, then stop when the ejector lever hooks catch the lip of the card cage. If they do not catch, try reinserting the line card until the ejector lever hooks are fully latched. (See Figure 10.)

Figure 10 Ejector Levers

CautionWhen you install a line card, always use the ejector levers to ensure that the card is correctly aligned with the backplane connector, the card connector pins make contact with the backplane in the correct order, and the card is fully seated in the backplane. A card that is only partially seated in the backplane can cause the router to hang and subsequently crash.

Step 5

Simultaneously pivot both ejector levers toward each other until they are perpendicular to the line card faceplate. This action firmly seats the card in the backplane.

Step 6

Use a 3/16-inch flat-blade screwdriver to tighten the captive screw on each end of the line card faceplate to ensure proper EMI shielding and to prevent the line card from becoming partially dislodged from the backplane.

CautionTo ensure adequate space for additional line cards, always tighten the captive installation screws on each newly installed line card before you insert any additional line cards. These screws also prevent accidental removal and provide proper grounding and EMI shielding for the router.

Step 7

Install the cable-management bracket.

Step 8

Install GBIC or SFP modules, and EPA daughter cards, in the line cards that use them.

Step 9

Install the interface cables.

For information on installing cable-management brackets, see the "Installing a Line Card Cable-Management Bracket" section.

For information on installing EPAs, see the "Removing and Installing EPAs" section.

For information on installing GBICs, see the "Removing and Installing GBICs" section.

For information on installing SFP modules, see the "Removing and Installing SFP Modules" section.

For information on installing interface cables, see the "Removing and Installing Fiber-Optic Interface Cables" section.

For information on verifying and troubleshooting the hardware installation, see the "Verifying and Troubleshooting the Installation" section.

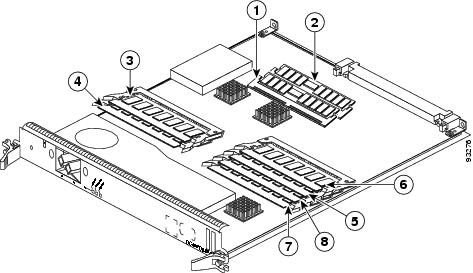

Removing and Installing EPAs

The Modular Gigabit Ethernet line card ships with 0, 1, 2, or 3 EPAs installed. If you need to add or change an EPA, follow the procedures in these sections:

•

Removing an EPA from the Modular Gigabit Ethernet Line Card

•

Inserting an EPA into a Modular Gigabit Ethernet Line Card

Figure 11 shows an exploded mechanical view of a Gigabit Ethernet EPA with three line card SFP receptacles, an SFP module, and a duplex LC-type cable.

Figure 11 Removing and Replacing EPAs

Removing an EPA from the Modular Gigabit Ethernet Line Card

You can remove an EPA from the Modular Gigabit Ethernet line card with or without the SFP modules installed.

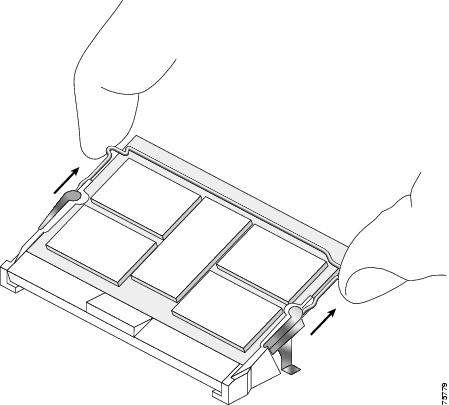

To remove an EPA from your Modular Gigabit Ethernet line card, use Figure 12 as a reference and follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its directions for use.

Step 2

Disconnect the LC-type fiber-optic cable connector from the SFP module.

Note which cable connector plug is TX and which is RX for reattachment.

Step 3

Insert a dust plug into the optical ports of the SFP module to keep the optical interfaces clean.

Step 4

Remove the Modular Gigabit Ethernet line card from the chassis, as described in the "Removing a Line Card" section, and place the line card on a clean, flat surface.

Step 5

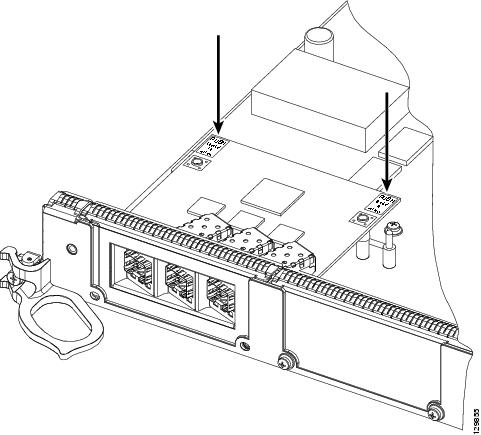

Use a Phillips screwdriver to loosen and unscrew the two screws that connect the EPA to the line card, located on the faceplate of the line card, as shown in Figure 12A.

Step 6

Use a Phillips screwdriver to loosen and unscrew the one screw that connects the EPA to the inside of the line card, as shown in Figure 12B.

Step 7

Gently lift up on one corner of the EPA to disconnect the EPA from the line card, as shown in Figure 12C.

CautionTo prevent ESD damage, handle EPAs by the card carrier edges only.

CautionAvoid touching the EPA printed circuit board, components, or any connector pins.

Figure 12 Removing an EPA

If the EPA bay is to remain empty, install an EPA blank (Product Number MAS-EPA-BLANK=) to keep dust out of the line card and to maintain proper airflow and EMI through the line card and chassis.

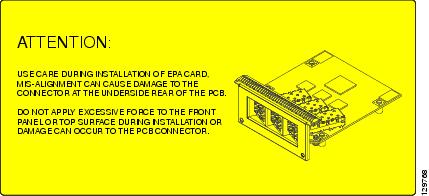

Inserting an EPA into a Modular Gigabit Ethernet Line Card

To insert an EPA into the Modular Gigabit Ethernet line card, follow these steps:

Warning

You must use an ESD-preventive wrist or ankle strap to do this procedure. Attach an ESD-preventive wrist or ankle strap and follow its directions for use, before you do this procedure.

Step 1

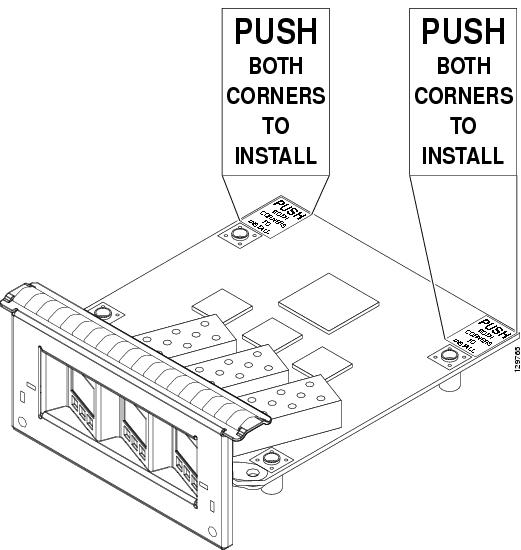

First, read the yellow caution label on the EPA. Figure 13 shows a sample of this caution label.

Figure 13 Locations of Labels and Reference Points on the EPA

CautionThe connectors must be engaged without any angular misalignment. Engaging the connectors at an angle will cause damage to the connectors.

Step 2

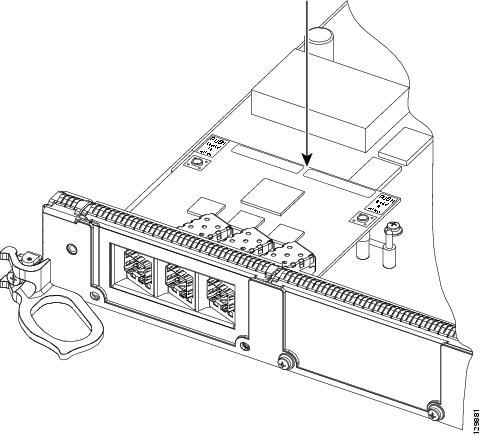

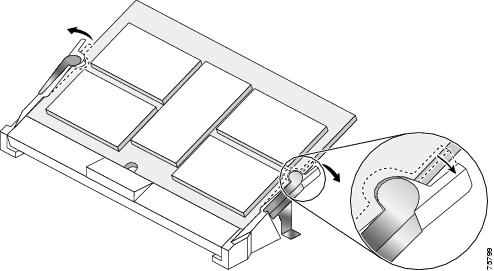

Ensure that the connector guide pins are aligned, and mate the connector of the EPA to the connector on the line card, as shown in Figure 14 and Figure 15. Figure 15 shows two side views of the EPA and line card.

Figure 14 Mating the Connector of the EPA to the Line Card

Figure 15 Side Views - Mating the Connector of the EPA to the Line Card

Step 3

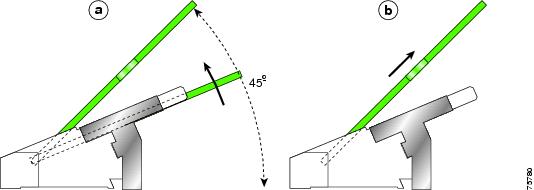

Ensure that the connector guide pins are aligned. Once the connector is engaged, apply gentle pressure with your thumbs to the two rear outer corners of the EPA, as shown in Figure 16 and Figure 17.

Figure 16 Press on the Rear Outer Corners of the EPA

Figure 17 Rear Outer Corners of the EPA (Close-up)

Step 4

Press gently on the white labels in middle of the outer edge of the EPA as shown in Figure 18 to ensure that the connector is fully seated.

Figure 18 Press on the White Labels on the EPA

Step 5

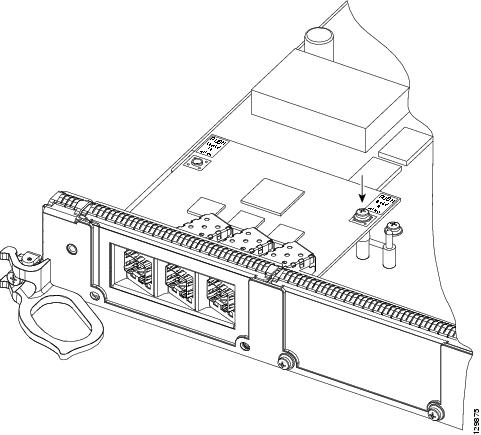

Use a Phillips screwdriver to insert and tighten the screw on the EPA, 3 to 5 in-lbs, as shown in Figure 19.

CautionApply no more than 5 in-lbs of torque when tightening the screw.

Figure 19 Inserting and Tightening the Screw on the EPA

Step 6

Use a Phillips screwdriver to insert and tighten the two screws on the faceplate of the line card, 3 to 5 in-lbs, as shown in Figure 20.

CautionApply no more than 5 in-lbs of torque when tightening the screw.

Figure 20 Inserting the 2 screws on the Faceplate of the Line Card

Removing and Installing GBICs

Your Ethernet line card may have shipped with a GBIC installed. If your line card arrived without the GBIC installed and you need to install it now, or if you need to change your GBIC for another reason, use the procedures in these sections:

•

General GBIC Handling and Maintenance Guidelines

•

Removing the GBIC from an Ethernet Line Card

•

Inserting a GBIC into the Gigabit Ethernet Interface

Before you remove or install a GBIC, read the installation information in this section and the "Laser Safety" section.

Note

Cisco strongly recommends that you disconnect all fiber-optic cables before removing or installing a GBIC.

CautionTo prevent system problems, do not use GBICs from third-party vendors. Use only the GBIC that shipped with your Gigabit Ethernet line card. These GBICs might contain an internal EPROM that identifies them to the Cisco IOS software.

CautionTo prevent problems associated with data transmission, you must attach this device only to IEEE 802.3x-compliant devices.

Note

The Ethernet line card supports online insertion and removal (OIR) of GBICs. This means that you can remove and replace GBICs while the system remains powered up. When you remove a GBIC, the interface becomes inactive because a GBIC is not detected in the GBIC receptacle.

General GBIC Handling and Maintenance Guidelines

Follow these GBIC handling and maintenance guidelines:

•

GBICs are static sensitive. To prevent ESD damage, follow the guidelines described in the "Preventing Electrostatic Discharge" section.

•

GBICs are dust sensitive. When the GBIC is stored or when a fiber-optic cable is not plugged into one of the optical ports on the GBIC, always insert an optical port dust plug.

•

Keep the optical port clean. The most common source of contamination in the optical ports is debris that collects on the ferrules of the optical cable connectors. Use an alcohol swab or Kim-Wipe to clean the ferrules of the cable connector before inserting it into the GBIC.

Removing the GBIC from an Ethernet Line Card

To remove the GBIC from an Ethernet line card, follow these steps:

Step 1

Disconnect the SC-type fiber-optic cables from the GBIC. Note which plug is TX and which plug is RX for reattachment.

Step 2

Attach an ESD wrist or ankle strap and follow its directions for use.

Step 3

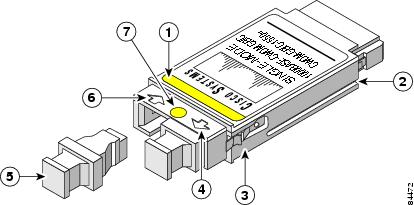

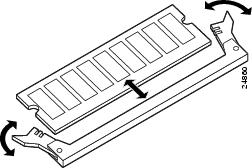

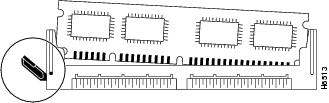

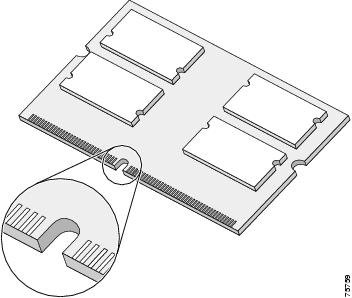

Locate the tabs on either side of the exposed portion of the GBIC and squeeze them with your thumb and forefinger, as you gently pull the GBIC out of the GBIC slot. (See arrows in Figure 21.)

Figure 21 Removing and Replacing a GBIC

Inserting a GBIC into the Gigabit Ethernet Interface

To insert a GBIC into the Gigabit Ethernet interface, follow these steps:

Step 1

Attach an ESD wrist or ankle strap and follow its directions for use.

Step 2

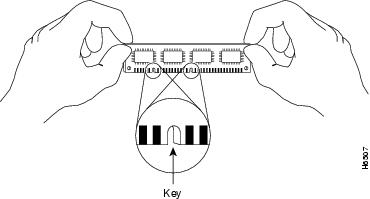

Locate the alignment groove on the GBIC. (See the enlargement in Figure 21.) Position the GBIC so that this groove is in the position shown in the enlargement to ensure that the 20-pin plug on the GBIC is in the correct position.

CautionTo prevent damage to the GBIC plug and receptacle before you insert the GBIC into the GBIC slot on the Gigabit Ethernet interface, ensure that the plug and alignment groove are matched.

Step 3

Squeeze the tabs on each side of the GBIC using your thumb and forefinger, and insert the GBIC into the GBIC slot on the Gigabit Ethernet interface. (See Figure 21.)

Step 4

Using moderate force, ensure that the GBIC is fully inserted into the 20-pin receptacle at the rear of the GBIC slot. The tabs on either side of the GBIC will snap into place when you have completely and properly inserted the GBIC.

Step 5

Reattach the SC-type fiber-optic cable to the GBIC.

Removing and Installing SFP Modules

Before you remove or install an SFP module, read the installation information in this section and the "Laser Safety" section.

CautionProtect the SFP modules by inserting clean dust covers into them after the cables are removed. Be sure to clean the optic surfaces of the fiber cables before you plug them back into the optical ports of another SFP module. Avoid getting dust and other contaminants into the optical ports of your SFP modules, because the optics will not work correctly when obstructed with dust.

CautionIt is strongly recommended that you do not install or remove the SFP module with fiber-optic cables attached to it because of the potential of damaging the cable, the cable connector, or the optical interfaces in the SFP module. Disconnect all cables before removing or installing an SFP module.

Removing and inserting an SFP module can shorten its useful life, so you should not remove and insert SFP modules any more often than is absolutely necessary.

SFP modules use one of four different latching devices to install and remove the module from a port. The four types of SFP module latching devices are described in the following sections:

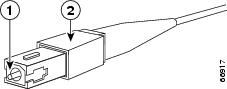

Bale Clasp SFP Module

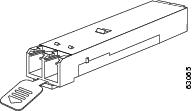

The bale clasp SFP module has a clasp that you use to remove or install the SFP module. (See Figure 22.)

Figure 22 Bale Clasp SFP Module

Removing a Bale Clasp SFP Module

To remove this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

Step 3

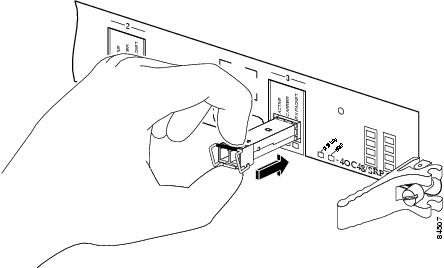

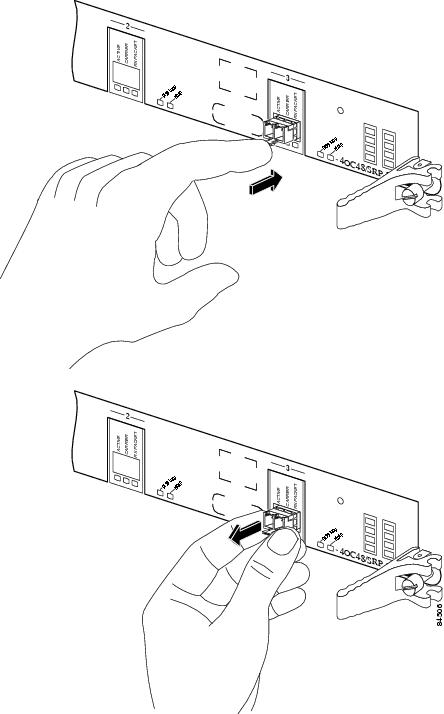

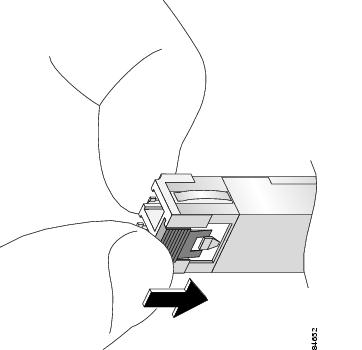

Open the bale clasp on the SFP module with your index finger in a downward direction, as shown in Figure 23. If the bale clasp is obstructed and you cannot use your index finger to open it, use a small flat-blade screwdriver or other long, narrow instrument to open the bale clasp.

Step 4

Grasp the SFP module between your thumb and index finger and carefully remove it from the port, as shown in Figure 23.

Figure 23 Removing a Bale Clasp SFP Module

Step 5

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

Step 6

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

Installing a Bale Clasp SFP Module

To install this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Close the bale clasp before inserting the SFP module.

Step 3

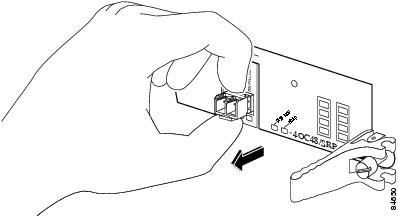

Line up the SFP module with the port and slide it into the port. (See Figure 24.)

Figure 24 Installing a Bale Clasp SFP Module into a Port

Note

Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. If the SFP module was not completely seated and secured in the receptacle, you will hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle.

Mylar Tab SFP Module

The mylar tab SFP module has a tab that you pull to remove the module from a port. (See Figure 25.)

Figure 25 Mylar Tab SFP Module

Removing a Mylar Tab SFP Module

To remove this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

Step 3

Pull the tab gently in a slightly downward direction until it disengages from the port, then pull the SFP module out. (See Figure 26.)

Figure 26 Removing a Mylar Tab SFP Module

Step 4

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

Step 5

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

CautionWhen pulling the tab to remove the SFP module, be sure to pull in a straight outward motion so you remove the SFP module from the port in a parallel direction. Do not twist or pull the tab, because you might disconnect it from the SFP module.

Installing a Mylar Tab SFP Module

To install this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

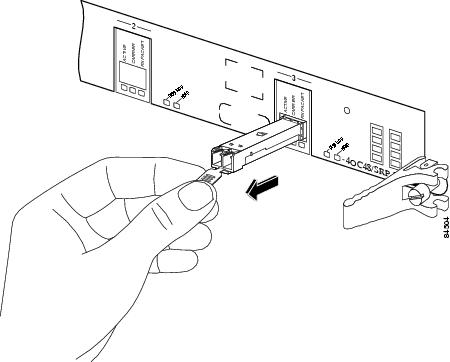

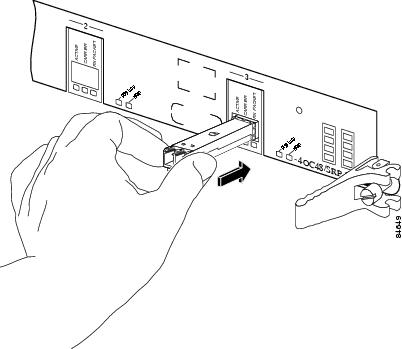

Line up the SFP module with the port, and slide it into place. (See Figure 27.)

Figure 27 Installing a Mylar Tab SFP Module

Note

Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. If the SFP module was not completely seated and secured in the receptacle, you will hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle.

Actuator Button SFP Module

The actuator button SFP module includes a button that you push in order to remove the SFP module from a port. (See Figure 28.)

Figure 28 Actuator Button SFP Module

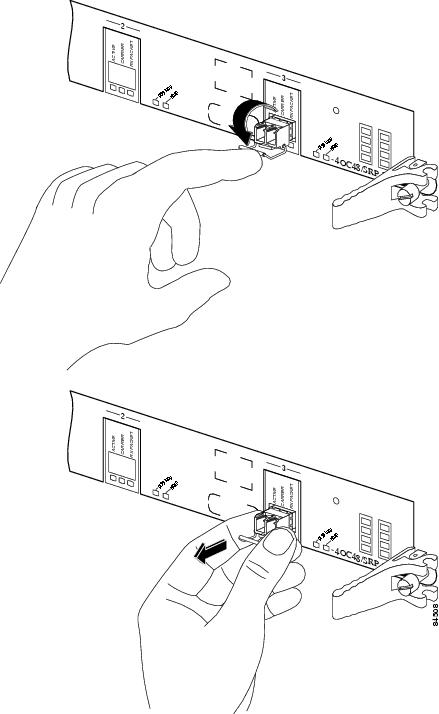

Removing an Actuator Button SFP Module

To remove this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

Step 3

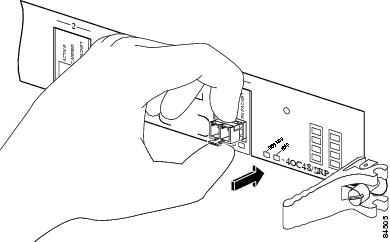

Gently press the actuator button on the front of the SFP module until it clicks and the latch mechanism activates, releasing the SFP module from the port. (See Figure 29.)

Figure 29 Removing an Actuator Button SFP Module from a Port

Step 4

Grasp the actuator button between your thumb and index finger and carefully pull the SFP module from the port.

Step 5

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

Step 6

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

Installing an Actuator Button SFP Module

To install this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

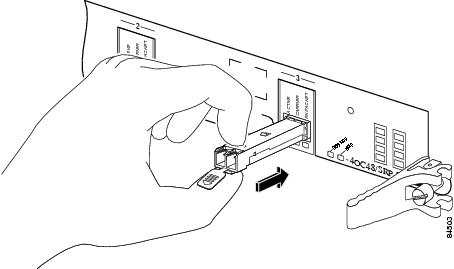

Line up the SFP module with the port and slide it in until the actuator button clicks into place. (See Figure 30.) Be sure not to press the actuator button as you insert the SFP module because you might inadvertently disengage the SFP module from the port.

Figure 30 Installing an Actuator Button SFP Module

Note

Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. If the SFP module was not completely seated and secured in the receptacle, you will hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle.

Slide Tab SFP Module

The slide tab SFP module has a tab underneath the front of the SFP module that you use to disengage the module from a port. (See Figure 31.)

Figure 31 Slide Tab SFP Module

Removing a Slide Tab SFP Module

To remove this type of SFP module, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Disconnect and remove all interface cables from the ports; note the current connections of the cables to the ports on the line card.

Step 3

Grasp the SFP module between your thumb and index finger.

Step 4

With your thumb, push the slide tab on the bottom front of the SFP module in the direction of the line card to disengage the module from the line card port. (See Figure 32.)

Figure 32 Disengaging the Slide Tab

Step 5

With the tab still pushed, carefully pull the SFP module from the port as shown in Figure 33.

CautionYou must disengage the SFP module by pushing on the slide tab before you can pull out the SFP module. If you pull on the SFP module without disengaging the tab, you can damage the SFP module.

Figure 33 Removing a Slide Tab SFP Module

Step 6

Place the removed SFP module on an antistatic mat, or immediately place it in a static shielding bag if you plan to return it to the factory.

Step 7

Protect your line card by inserting clean SFP module cage covers into the optical module cage when there is no SFP module installed.

Installing a Slide Tab SFP Module

To install this type of SFP module into a line card, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Hold the SFP module with the hardware label facing up.

CautionThe SFP module must be inserted with the hardware label facing up to avoiding damaging the module or the line card.

Step 3

Insert the SFP module into the appropriate slot and gently push on it until it snaps into the slot tightly. (See Figure 34.)

Figure 34 Installing a Slide Tab SFP Module

Note

Verify that the SFP modules are completely seated and secured in their assigned receptacles on the line card by firmly pushing on each SFP module. If the SFP module was not completely seated and secured in the receptacle, you will hear a click as the triangular pin on the bottom of the SFP module snaps into the hole in the receptacle.

Line Card Cable-Management Bracket

Note

The illustrations in this section show various line cards, but the line card cable-management bracket installation procedure is the same regardless of the specific line card.

Cisco 12000 Series Routers include a cable-management system that organizes the interface cables entering and exiting the router, keeping them out of the way and free of sharp bends.

CautionExcessive bending of interface cables can damage the cables.

The cable-management system consists of two separate components:

1.

A cable-management tray that is mounted on the chassis. Refer to the appropriate Cisco 12000 Series Router installation and configuration guide for more information on the cable-management tray.

2.

A cable-management bracket that attaches to a line card.

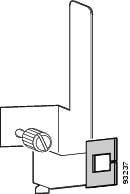

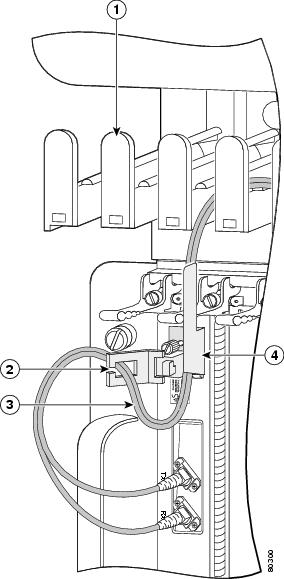

This section describes the line card cable-management bracket. Figure 35 shows the single-port line card cable-management bracket; Figure 36 shows the multiport line card cable-management bracket.

Figure 35 Single-Port Line Card Cable-Management Bracket

Figure 36 Multiport Line Card Cable-Management Bracket

Note

When shipped with spare line card orders, the cable-management bracket is not attached to the line card. You must attach the cable-management bracket to the line card before you insert the line card into the router.

CautionDo not use the cable-management bracket as a handle to pull out or push in the line card. The cable-management bracket is designed to hold the interface cables and may break if you use the bracket to push, pull, or carry the line card after it is removed from the router.

Removing and installing the line card cable-management bracket is described in the following procedures:

•

Removing a Line Card Cable-Management Bracket

•

Installing a Line Card Cable-Management Bracket

Removing a Line Card Cable-Management Bracket

To remove a line card cable-management bracket, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Note the current interface cable connections to the ports on each line card.

Step 3

Starting with the interface cable for the bottom port on the line card, disconnect the cable from the line card interface.

Note

It is not necessary to remove the interface cables from the line card cable-management bracket. The bracket (with attached cables) can be hooked to the cable-management tray or a bracket on the chassis until a new line card is installed.

Step 4

For multiport line card cable-management brackets, proceed upward and remove the interface from the Velcro strap on the end of the cable standoff. (See Figure 37.)

For single-port line card cable-management brackets, carefully remove the interface cable from the cable clip. (See Figure 38.) Avoid any kinks or sharp bends in the cable.

Step 5

Repeat Step 3 and Step 4 for all remaining interface cables, then proceed to Step 6.

Step 6

For multiport line card cable-management brackets, loosen the captive installation screw at each end of the cable-management bracket and remove the bracket from the line card.

For single-port line card cable-management brackets, loosen the captive installation screw on the cable-management bracket and remove the bracket from the line card.

Figure 37 Multiport Line Card Cable-Management Installation and Removal

(4-Port OC-48c/STM-16c DPT Line Card Shown)

Figure 38 Single-Port Line Card Cable-Management Bracket Installation and Removal (1-Port OC-192c/STM-64c DPT Line Card Shown)

Installing a Line Card Cable-Management Bracket

To install a line card cable-management bracket, follow these steps:

Step 1

Attach an ESD-preventive wrist or ankle strap and follow its instructions for use.

Step 2

Attach the line card cable-management bracket to the line card as follows:

a.

Position the cable-management bracket over the front of the line card faceplate.

b.

Insert and tighten the captive screw(s) to secure the bracket to the line card.

c.

Starting with the bottom port on the line card, connect each interface cable to the intended port.

Step 3

For multiport line card cable-management brackets, carefully wrap the cables with the supplied Velcro strap. (See Figure 37.)

For single-port line card cable-management brackets, carefully press the interface cable onto the cable clip. (See Figure 38.) Avoid any kinks or sharp bends in the cable.

For information on disconnecting and connecting interface cables, see the "Removing and Installing Fiber-Optic Interface Cables" section.

Cabling and Specifications

The following sections provide information about specifications and cabling for Ethernet line cards:

•

Removing and Installing Fiber-Optic Interface Cables

•

Cleaning Fiber-Optic Connectors

•

Type RJ-45 100BASE-T Copper Cables

•

Removing and Installing RJ-45 100BASE-T Copper Cable

Fast Ethernet Interface

The term Ethernet is commonly used for all carrier sense, multiple access/collision detection (CSMA/CD) local-area networks (LANs) that conform to Ethernet specifications, including Fast Ethernet defined by IEEE 802.3u.

IEEE 802.3u specifies the following different physical layers for 100BASE-T:

•

100BASE-TX—100BASE-T, half- and full-duplex over Category 5 unshielded twisted-pair (UTP), Electronics Industry Association/Telecommunications Industry Association [EIA/TIA]-568-compliant cable.

Note

The 8-Port Fast Ethernet line card provides an RJ-45 connector that follows the Media-Dependent Interface (MDI) port wiring standard, as opposed to the Media-Dependent Interface-crossed (MDI-X) wiring scheme found on many hubs and repeaters.

•

100BASE-FX—100BASE-T, half- and full-duplex over fiber-optic cable.

Note

100BASE-TX and 100BASE-FX are commonly called 100BASE-X rather than 100BASE-T.

•

100BASE-T4—100BASE-T, half- and full-duplex over Category 3, 4, or 5 UTP or shielded twisted-pair (STP) cabling with four pairs, also called 4T+. Two-pair UTP over Category 3 cable is called T2.

Note

The 8-Port Fast Ethernet line card supports 100BASE-TX and 100BASE-FX. 100BASE-T4 is not supported.

Table 12 lists the cabling specifications for 100 Mbps Fast Ethernet transmission over UTP, STP, and fiber-optic cables. Table 13 summarizes IEEE 802.3u 100BASE-T physical characteristics for 100BASE-TX and 100BASE-FX.

Table 12 Specification and Connection Limits for 100-Mbps Transmission

Cable specification

Category 3, 4, or 5, 150-ohm UTP or STP, or multimode fiber-optic

62.5/125 multimode fiber-optic

Maximum cable length

-

1.64 ft (0.5 m) (MII-to-MII cable4 )

-

Maximum segment length

328 ft (100 m) for 100BASE-TX

3.28 ft (1 m)5 or 1,312 ft (400 m) for 100BASE-FX

2 km

Maximum network length

656 ft (200 m)5 (with 1 repeater)

-

4 km5 (with 1 repeater)

1 EIA/TIA-568 or EIA-TIA-568 TSB-36 compliant.

2 Cisco Systems does not supply Category 5 UTP RJ-45 or 150-ohm STP MII cables. Both are available commercially.

3 AWG = American Wire Gauge. This gauge is specified by the EIA/TIA-568 standard.

4 This is the cable between the MII port on the FE interface and the appropriate transceiver.

5 This length is specifically between any two stations on a repeated segment.

Table 13 IEEE 802.3u Physical Characteristics

Data rate (Mbps)

100

100

Signaling method

Baseband

Baseband

Maximum segment length (meters)

2 km between repeaters

100 m between DTE1 and repeaters

Media

SC-type: dual simplex or single duplex for receive (RX) and transmit (TX)

RJ-45MII

Topology

Star or hub

Star or hub

1 DTE = data terminal equipment.

Gigabit Ethernet Interface

This section describes the Gigabit Ethernet interface:

•

GBIC Laser Optical Transceiver Modules

GBIC Laser Optical Transceiver Modules

The Gigabit Interface Converters (GBICs) are field-replaceable modules that plug into receptacles on the line card and provide the Gigabit Ethernet optical interface. The GBICs have two optical interfaces—laser transmit (TX) and laser receive (RX)—and an electrical interface (to the line card). All GBIC module types have dual SC connectors. Different GBICs can be ordered for each port on the line card. The 1-Port Gigabit Ethernet and 3-Port Gigabit Ethernet line cards use GBICs to provide the Gigabit Ethernet optical interface.

The following sections provide information on the GBIC and Coarse Wave Division Multiplexing (CWDM) GBIC in Ethernet line cards:

•

Using CWDM GBICs with the 3-Port Gigabit Ethernet Line Card

•

General CWDM GBIC Installation and Usage Guidelines

•

General Connection Rules for CWDM GBICs

GBIC Modules

Fiber-optic transmission specifications identify two types of fiber: single-mode and multimode. Signals can travel farther through single-mode fiber than through multimode fiber.

The 1-Port Gigabit Ethernet and 3-Port Gigabit Ethernet line cards support multimode fiber through the WS-G5484= GBIC laser optical transceiver module and single-mode fiber through the WS-G5486=, WS-G5487=. The 3-Port Gigabit Ethernet line card also supports CWDM-GBIC-xxxx= GBIC laser optical transceiver modules.

Table 14 describes the operating parameters for available GBIC laser optics.

Table 14 Ethernet GBIC Laser Optic Parameters

ConnectorWS-G5484=

SC connectorShortwave (multimode shorthaul)

Defined by 1000BASE-SX standard, IEEE 802.3

850 nm

62.5 micron MMF

902 feet (275 m)

50 micron MMF

1804 feet (550 m)

WS-G5486=

SC connectorLongwave (single-mode longhaul)

Compliant with 1000BASE-LX standard, IEEE 802.3

1310 nm

10/9 micron SMF

6.2 miles (10 km)

WS-G5487=

SC connectorExtended distance (single-mode)

1550 nm

10/9 micron SMF

43.5 miles (70 km)

8 micron SMF2

62 miles (100 km)

CWDM-GBIC-xxxx=3

Longwave (single-mode)

1470-1610 nm4

SMF 10/9 micron

62 miles (100 km)

1 These distances represent best case conditions, depending on fiber quality, dispersion, and losses due to connectors, nodes, or splices. In the case of the CWDM GBICs, CWDM OADM modules or mux/demux modules are needed for these GBICs to work in any topology other than a point-to-point topology within one building, so the maximum distance is determined by an optical power budget calculation that takes into consideration all sources of loss, including the insertion loss due to the CWDM OADM and mux/demux modules, and might be different from the distance shown in the table. For optical parameter information associated with the CWDM OADM and mux/demux modules, see the "Related CWDM Documentation" section.

2 Dispersion-shifted single-mode fiber-optic cable required for 100,000-meter distance.

3 Supported by 3-Port Gigabit Ethernet modules

4 The wavelengths of the CWDM GBICs are based on a 20-nanometer (nm) wavelength grid and are available in eight wavelengths: 1470, 1490, 1510, 1530, 1550, 1570, 1590, and 1610 nm.

Note

1000BASE-SX and 1000BASE-LX (LH) were originally part of the IEEE 802.3z standard, which has been incorporated into the IEEE 802.3 standard.

Note

Use only GBIC modules supplied by Cisco with your Ethernet line card. They have been tested by Cisco Engineering and, in some cases, a Cisco-supplied GBIC might contain an internal erasable programmable read-only memory (EPROM) that identifies the GBIC to the Cisco IOS software. To verify the version of the installed GBIC module, refer to "Verifying the GBIC Version" section.

The maximum distance for any fiber span in an optical network is determined by the fiber type and quality, as well as the span length, number of splices, and number of optical nodes in the path. If your network design requires the signal to travel close to the theoretical maximum distance (as listed in Table 15), you must calculate the optical power budget and receive (RX) sensitivity for the entire network topology to ensure it is within the specifications of the GBIC option in use.

Note

Actual power budget calculations involve a number of variables specific to network topology and design, and are therefore outside the scope of this publication.

Table 15 Optical Parameter Values for Calculating Link Power Budget

Power

Power

Sensitivity

BudgetWS-G5484=

-9.5dBm to 0 dBm2

-17 to 0 dBm

-17 dBm

7.5 dB

1,804 feet (550 m)

WS-G5486=

-11 to -3 dBm

-19 to -3 dBm

-19 dBm

8 dB

6.2 miles (10 km)

WS-G5487=

0 to +5 dBm

-23 to 0 dBm

-23 dBm

23 dB

43.5 to 62 miles (70 to 100 km3 )

CWDM-GBIC-xxxx=

+1 to +5 dBm

-31 to -7 dBm

-31 dBm

32 dB

62 miles (100 km)4

1 These distances represent best case conditions, depending on fiber quality, dispersion, and losses due to connectors, nodes, or splices.

2 dBm = decibels referenced to 1 milliwatt.

3 Dispersion-shifted single-mode fiber-optic cable required for 100-km distance.

4 This distance represents best case conditions, depending on fiber quality, dispersion, and losses due to connectors, nodes, or splices. In the case of the CWDM GBICs, CWDM OADM modules or mux/demux modules are needed for these GBICs to work in any topology other than a point-to-point topology within one building, so the maximum distance is determined by an optical power budget calculation that takes into consideration all sources of loss, including the insertion loss due to the CWDM OADM and mux/demux modules, and might be different from the distance shown in the table. For optical parameter information associated with the CWDM OADM and mux/demux modules, see the "Related CWDM Documentation" section.

Using CWDM GBICs with the 3-Port Gigabit Ethernet Line Card

The 3-Port Gigabit Ethernet line card supports CWDM GBICs. The eight CWDM GBICs available for use with an Ethernet line card are active components that plug into standard GBIC receptacles in the line card. They convert Gigabit Ethernet electrical signals into an optical single-mode fiber (SMF) interface that feeds into a CWDM network through a Cisco optical add/drop multiplexing (OADM) plug-in module or multiplexing/demultiplexing (mux/demux) plug-in module. Figure 39 shows the physical appearance of a CWDM GBIC with one optical port dust plug removed.

Figure 39 CWDM GBIC (Yellow-Coded CWDM-GBIC-1550= Shown)

Color band on label

Transmit optical bore

Receive optical bore

Alignment groove

Optical bore dust plug

Color dot

Spring clip

The eight CWDM GBICs available for use with a Gigabit Ethernet line card come in eight wavelengths in a range from 1470 nm to 1610 nm. The color dot between the receive and transmit ports and the color band on the label of the Cisco CWDM GBIC identify the wavelength of the GBIC. Table 16 lists the CWDM GBICs and their associated color codes.

General CWDM GBIC Installation and Usage Guidelines

The Cisco CWDM GBIC solution has two main components: the Cisco CWDM GBICs and the Cisco OADM plug-in modules or mux/demux plug-in modules, which are rack mounted in a Cisco CWDM OADM chassis external to the Cisco 12000 Series Router that contains the Ethernet line card.

The CWDM OADM plug-in modules and mux/demux plug-in modules are passive optical components that multiplex together multiple wavelengths from multiple SMF fiber pairs into one SMF fiber pair. Up to two CWDM plug-in modules can be rack-mounted by using the single-rack-unit CWDM chassis.

The CWDM GBICs plug into the standard GBIC receptacles on the faceplate of the Ethernet line card and are connected to the CWDM OADM or mux/demux plug-in modules in the external CWDM chassis using SMF jumper cables with SC-type connectors.

A Cisco 12000 Series Router equipped with an Ethernet line card and CWDM GBICs can be connected into a CWDM network through external CWDM plug-in modules in the following deployment scenarios:

•

Point-to-point—Two endpoints are directly connected via a fiber link. You can add or drop up to eight Gigabit Ethernet channels into a pair of single-mode fibers.

•

Hub-and-spoke (ring)—Multiple nodes (spokes) are connected with a hub location through a ring of single-mode fiber. Each hub/node connection can consist of one or more wavelengths, each carrying a full Gigabit Ethernet channel.

•

Mesh (ring)—Combines the hub-and-spoke and point-to-point (or even multiple point-to-point) connections in parallel on the same CWDM optic link. The maximum of eight GBIC wavelengths allows different combinations of these scenarios.

Related CWDM Documentation

For more information about CWDM GBIC solution deployment, including the optical parameters (insertion loss and isolation values) for the CWDM OADM and mux/demux plug-in modules, see the following related documentation:

•

Cisco CWDM GBIC Solution, Data Sheet

•

Cisco CWDM GBIC Solution, Q & A

•

Installation Note for the CWDM Passive Optical System

General Connection Rules for CWDM GBICs

Observe the following connection rules for CWDM GBICs:

•

Always match the CWDM GBIC color with the equipment port of the same color on the CWDM passive optical system plug-in module.

Use the CWDM passive optical system connector color codes shown in Table 16 to help you connect your router to the CWDM passive optical system.

•

Always connect from transmit (TX) to receive (RX) when connecting GBICs to other equipment:

–

Connect GBIC TX to equipment RX

–

Connect GBIC RX to equipment TX

•

Optical transceivers—such as the Cisco CWDM GBICs—have a maximum optical receive power, above which damage might occur to the receive diode. The incoming power level might be too high if the fiber lacks sufficient attenuation, which might occur in a short run of fiber (less than approximately 25 km). Attenuators are used to lower the incoming optical signal below the maximum optical receive power of the Cisco CWDM GBIC (-7 dB).

•

When the length of the fiber-optic link is less than 15.5 miles (25 km), you must insert a 10-dB inline optical attenuator (Cisco product number AT-10DB-SC=) between the fiber-optic network and the receiving port on the Cisco CWDM GBIC at each end of the link to ensure that the maximum receive power is always less than -7 dBm.

Gigabit Ethernet SFP Modules

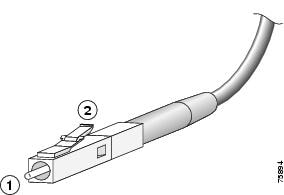

The Gigabit Ethernet laser optical transceiver module is a field-replaceable small form-factor pluggable (SFP) module that plugs into the receptacle on the Ethernet port adapter (EPA) located on the Modular Ethernet line card and provides the Gigabit Ethernet optical interface. (See Figure 40.) The module has two optical interfaces—laser transmit (TX) and laser receive (RX)—and an electrical interface (to the line card). The 4-Port Gigabit Ethernet ISE, 10-Port 1-Gigabit Ethernet, and Modular Gigabit Ethernet line cards use SFP modules.

Figure 40 SFP Module and Fiber-Optic Cable

The following SFP module options are available for a Gigabit Ethernet line card:

•

GLC-SX-MM—Short wavelength SFP module (850 nm nominal), for use in 1000BASE-SX links.

•

GLC-LH-SM—Long-haul or long-wavelength SFP module (1310 nm nominal), for use in 1000BASE-LX links.

•

GLC-LX-SM—Single-mode, long-reach

•

GLC-ZX-SM=—Single-mode, extended-reach (supported by 4-Port Gigabit Ethernet ISE line card only)

The SFP modules have LC connectors. Different SFP module options allow you to customize the physical interfaces on the line card by using both types of modules on the same line card. The only restriction is that each port must match the specifications on the other end of the cable (short or long wavelength), and must not exceed the recommended cable length for reliable communication.

Fiber-optic transmission specifications identify two types of fiber: single-mode and multimode. The maximum distance for single-mode installations is determined by the amount of light loss in the fiber path. If your environment requires the light to travel close to the typical maximum distance, you should use an optical time domain reflectometer (OTDR) to measure the power loss.

Table 17 describes the operating parameters for the supported SFP modules.

Table 17 Gigabit Ethernet SFP Module Power Budget and Signal Requirements

Power

PowerGLC-SX-MM

Short wavelength

Multimode,

short haul7.5 dB

-17 to 0 dBm

-17 dBm

984 feet (300 meters)

GLC-LH-SM3

Long wavelength

Single-mode,

long haul8.0 dB

-9.5 to -3 dBm

at 1310 nm-19 to -3 dBm

32,808 feet (10,000 meters)

GLC-LX-SM4

Single-mode,

long-reach8 dB

-11 to -3 dBm

at 1310 nm-19 to -3 dBm

-19 dBm

GLC-ZX-SM5

Single-mode,

extended-reach23 dB

0 to +5 dBm

at 1550 nm-23 to 0 dBm

-23 dBm

1 dBm = decibels referenced to 1 milliwatt

2 nm = nanometer

3 Not valid for 4-Port Gigabit Ethernet ISE line card

4 4-Port Gigabit Ethernet ISE line card only

5 4-Port Gigabit Ethernet ISE line card only

Note

Use only the SFP modules supplied by Cisco with your Gigabit Ethernet line card. Each SFP module contains an internal serial EEPROM that is security-programmed by the SFP manufacturer with information that provides a way for Cisco (through the Cisco IOS software) to identify and validate the SFP module as a module type that was tested and qualified by Cisco to operate properly with Cisco Gigabit Ethernet line cards. Unapproved SFP modules (those not purchased directly from Cisco) will not work on the Gigabit Ethernet line card. To verify the version of the installed SFP module, refer to "Verifying the SFP Version" section.

10-Gigabit Ethernet

The 1-Port 10-Gigabit Ethernet line card uses single-mode fiber-optic cable. The maximum distance for single-mode installations is determined by the amount of light loss in the fiber path. If your environment requires the light to travel close to the typical maximum distance (as listed in Table 20), you should use an optical time domain reflectometer (OTDR) to measure the power loss.

The Ethernet line card is offered in two transceiver options:

•

Long haul or long wavelength, 1310 nanometers (nm) nominal, used for 1000BASE-LR links.

•

Long haul or long wavelength, 1550 nm nominal, used for 1000BASE-ER links.

Table 19 describes the operating parameters for the transceiver options.

Table 20 lists the power ratings and maximum distances of both models of the Ethernet line cards. The actual distance in any given case depends on the quality of the fiber connected to the transceiver.

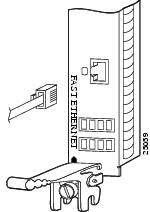

Fiber-Optic Interface Cables