- Safety Recommendations

- Compliance Requirements

- NEBS Level 3 Compliance

- Cautions and Regulatory Compliance Statements for NEBS

- Standard Warning Statements

- Site Planning

- Preventing Electrostatic Discharge Damage

- Electrical Safety

- Receiving a Cisco RFGW-10 UEQAM

- Chassis-Lifting Guidelines

- Tools and Equipment

- Checking the Shipping Container Contents

- Cisco RFGW-10 UEQAM Installation Checklist

Preparing Your Site for Installation

Before you install the Cisco RFGW-10 UEQAM, consider:

- The power and cabling requirements that must be in place at your installation site

- The equipment required to install the router

- The environmental conditions your installation site must meet to maintain normal operation

This chapter contains important safety information you should know before working with the Cisco RFGW-10 UEQAM and guides you through the process of preparing your site for router installation.

Note Do not unpack the system until you are ready to install it. Keep the chassis in the shipping container to prevent accidental damage until you determine an installation site. Use the appropriate unpacking documentation included with the system.

Warning Read the installation instructions before connecting the system to the power source. Statement 1004

Warning Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

Warning Ultimate disposal of this product should be handled according to all national laws and regulations. Statement 1040

Warning Class 1 laser product. Statement 1008

This chapter contains the following sections:

- Safety Recommendations

- Compliance Requirements

- Cautions and Regulatory Compliance Statements for NEBS

- Standard Warning Statements

- Site Planning

- Preventing Electrostatic Discharge Damage

- Electrical Safety

- Receiving a Cisco RFGW-10 UEQAM

- Chassis-Lifting Guidelines

- Tools and Equipment

- Checking the Shipping Container Contents

- Cisco RFGW-10 UEQAM Installation Checklist

Safety Recommendations

The following guidelines will help to ensure your own safety and protect your Cisco equipment. This list does not cover all potentially hazardous situations, so be alert.

- Cisco safety policy is that all of its routers must conform to the requirements of IEC 60950, with appropriate national deviations, as a minimum. In addition, Cisco routers must also meet the requirements of any other normative documents (for example, standards, technical specifications, laws or regulations).

- Review the safety warnings listed in the Regulatory Compliance and Safety Information Guide that accompanied your Cisco RFGW-10 UEQAM before installing, configuring, or maintaining the router.

- Never attempt to lift an object that might be too heavy for you to lift by yourself.

- Always turn all the DC PEMs off and disconnect all power cables before opening the chassis.

- Always disconnect the power cables before installing or removing a chassis.

- Keep the chassis area clear and dust free during and after installation.

- Keep the tools and chassis components away from walk areas.

- Do not wear loose clothing, jewelry (including rings and chains), or other items that could get caught in the chassis. Fasten your tie or scarf and sleeves.

- The Cisco RFGW-10 UEQAM operate safely when it is used in accordance with its marked electrical ratings and product usage instructions.

Compliance Requirements

This section includes Safety Compliance and Network Equipment Building Systems (NEBS) standards. The Cisco RFGW-10 UEQAM is in compliance with national and international standards as described in Table 2-1.

|

|

NEBS Level 3 Compliance

The Cisco RFGW-10 UEQAM is designed to meet Network Equipment Building System (NEBS) Level 3 requirements per GR-1089-CORE and GR-63-CORE.

Cautions and Regulatory Compliance Statements for NEBS

This section lists the cautions, regulatory compliance statements, and requirements for the Network Equipment-Building System (NEBS) certification from the Telcordia Electromagnetic Compatibility and Electrical Safety – Generic Criteria for Network Telecommunications Equipment (A Module of LSSGR, FR-64; TSGR, FR-440; and NEBSFR, FR-2063) Telcordia Technologies Generic Requirements, GR-1089-CORE, Issue 4, June 2006.

- This product is designed for a common bonding network (CBN) installation.

- This product can be installed in a network telecommunication facility or location where the NEC applies.

- An electrical conducting path shall exist between the product chassis and the metal surface of the enclosure or rack in which it is mounted or to a grounding conductor. Electrical continuity shall be provided by using thread-forming type mounting screws that remove any paint or nonconducting coatings and establish a metal-to-metal contact. Any paint or other nonconducting coatings shall be removed on the surfaces between the mounting hardware and the enclosure or rack. The surfaces shall be cleaned and an antioxidant applied before installation.

- The grounding architecture of this product is DC-isolated (DC-I).

- DC-powered products have a nominal operating DC voltage of 48 VDC. Minimal steady state DC operating voltage is 40 VDC. Reference Table 1, American National Standards Institute (ANSI) T1.315.

Note The English warnings in this document are followed by a statement number. To see the translations of a warning into other languages, look up its statement number in the Regulatory Compliance and Safety Information for the Cisco RF Gateway 10 document.

Standard Warning Statements

This section describes the warning definition and then lists core safety warnings grouped by topic.

Warning This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard practices for preventing accidents. Use the statement number provided at the end of each warning to locate its translation in the translated safety warnings that accompanied this device.

Note: SAVE THESE INSTRUCTIONS

Statement 1071

General Safety Warnings

Warning Read the installation instructions before you connect the system to its power source. Statement 1004

Warning Ultimate disposal of this product should be handled according to all national laws and regulations. Statement 1040

Warning Installation of the equipment must comply with local and national electrical codes. Statement 1074

Warning To comply with FCC Part 15 regulations- special UTP cables with ferrite have to be used to connect Ethernet and Console ports on Supervisor card.

Warning Power cable and AC adapter - When installing the product, please use the provided or designated connection cables/power cables/AC adaptors. Using any other cables or adapters could cause a malfunction or a fire. Electrical Appliance and Material Safety Law prohibits the use of certified cables (that have the ‘UL’ shown on the code) for any other electrical devices than products designated by Cisco. The use of cables that are certified by Electrical Appliance and Material Safety Law (that have ‘PSE’ shown on the code) is not limited to Cisco-designated products. Statement 371

Warning Only trained and qualified personnel should be allowed to install or replace this equipment

Statement 1030

Warning This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the protective device is rated not greater than: DC PEM for RFGW-10 : 60A U.S. maximum. Statement 1005

Warning This product requires short-circuit (overcurrent) protection to be provided as part of the building installation. Install only in accordance with national and local wiring regulations. Statement 1045

Warning This unit may have more than one power supply connection. All connections must be removed to de-energize the unit. Statement 1028

Warning Hazardous voltage or energy may be present on the DC power terminals. Always replace cover when terminals are not in service. Be sure un-insulated conductors are not accessible when cover is in place. Statement 1075

Warning Use copper conductors only. Statement 1025

Warning This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. Statement 1024

Warning Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

Warning Class 1 laser product. Statement 1008

Warning Class 1 LED product. Statement 1027

Warning Laser radiation is present when the system is open. Statement 1009

Warning Do not stare into the laser beam. Statement 1010

Warning Class I(CDRH) and Class 1M (IEC) laser products. Statement 1055

Warning Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not view directly with optical instruments. Viewing the laser output with certain optical instruments (for example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard. Statement 1056

Warning To prevent personal injury or damage to the chassis, never attempt to lift or tilt the chassis using the handles on modules (such as power supplies, fans, or cards); these types of handles are not designed to support the weight of the unit. Statement 1032

Warning To prevent the system from overheating, do not operate it in an area that exceeds the maximum recommended ambient temperature of: 40 degrees C. Statement 1047

Warning This equipment must be externally grounded using a customer-supplied ground wire before power is applied. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. Statement 366

Warning Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

Site Planning

This section contains site planning information, and will help you plan for the installation of the Cisco RF Gateway 10 UEQAM. It contains the following sections:

- General Precautions

- Site Selection Guidelines

- Floor Loading Considerations

- Site Power Guidelines

- Site Cabling Guidelines

- Rack-Mounting and Location Guidelines

- Site Planning Checklist

General Precautions

Observe the following general precautions when using and working with your Cisco RFGW-10 UEQAM system.

- Keep your system components away from radiators and heat sources and do not block cooling vents.

- Do not spill food or liquids on your system components and never operate the product in a wet environment.

- Do not push any objects into the openings of your system components. Doing so can cause fire or electric shock by shorting out interior components.

- Position system cables and power supply cables carefully. Route system cables and the power supply cable and plug so that they cannot be stepped on or tripped over. Be sure that nothing else rests on your system component cables or power cable.

- Do not modify power cables or plugs. Consult a licensed electrician or your power company for site modifications. Always follow your local and national wiring rules.

Site Selection Guidelines

The Cisco RFGW-10 UEQAM require specific environmental operating conditions. Temperature, humidity, altitude, and vibration can affect the performance and reliability of the router. The following sections provide specific information to help you plan for the proper operating environment.

The Cisco RFGW-10 UEQAM are designed to meet the industry EMC, safety, and environmental standards described in the Regulatory Safety and Compliance Information for the Cisco RF Gateway 10 document.

Site Environmental Requirements

Environmental monitoring in the Cisco RFGW-10 UEQAM protects the system and components from damage caused by excessive voltage and temperature conditions. To ensure normal operation and avoid unnecessary maintenance, plan and prepare your site configuration before installation. After installation, make sure the site maintains the environmental characteristics as shown in Table 2-2 .

Physical Characteristics

Be familiar with the physical characteristics of the Cisco RFGW-10 UEQAM to assist you in placing the system in the proper location.

Table 2-3 shows the weight and dimensions of the Cisco RFGW-10 UEQAM.

Table 2-3 Physical Characteristics of Cisco RFGW-10 UEQAM

The following list describes additional Cisco RFGW-10 chassis characteristics:

- Chassis height meets EIA-310 rack spacing 13RU, universal rack-mount

- Chassis width meets EIA-310 19-inch wide with rack brackets

- Rear RF cable-management bracket for Cisco RFGW-10 UEQAM can hold 24 five coaxial conductor bundled cables routed to the side of the chassis.

- Optionally the chassis can be racked mid-mounted.

Floor Loading Considerations

Ensure that the floor under the rack supporting the Cisco RFGW-10 UEQAM is capable of supporting the combined weight of the rack and all other installed equipment.

To assess the weight of the fully configured Cisco RFGW-10 UEQAM respectively, refer to Table 2-3 .

For additional information about floor loading requirements, consult the document GR-63-CORE, Network Equipment Building System (NEBS) Requirements: Physical Protection .

Site Power Guidelines

The Cisco RFGW-10 UEQAM has specific power and electrical wiring requirements. Adhering to these requirements ensures reliable operation of the system. Follow these precautions and recommendations when planning your site the Cisco RFGW-10 UEQAM:

- The redundant power option provides a second, identical power supply to ensure that power to the chassis continues uninterrupted if one power supply fails or input power on one line fails.

- In systems configured with the redundant power option, connect each of the two DC PEMs to a separate input power source. If you fail to do this, your system might be susceptible to total power failure due to a fault in the external wiring or a tripped circuit breaker.

- To prevent a loss of input power, be sure the total maximum load on each circuit supplying the DC PEM is within the current ratings of the wiring and breakers.

- Check the power at your site before installation and periodically after installation to ensure that you are receiving clean power. Install a power conditioner if necessary.

- Provide proper grounding to avoid personal injury and damage to the equipment due to lightning striking power lines or due to power surges. The chassis ground must be attached to a central office or other interior ground system.

- The Cisco RFGW-10 should be connected to the DC main supplies, which are earthed within the same building.

Note The Cisco RFGW-10 UEQAM installation must comply with all applicable codes and is approved for use with copper conductors only. The ground bond fastening hardware should be of compatible material and preclude loosening, deterioration, and electrochemical corrosion of hardware and joined material. Attachment of the chassis ground to a central office or other interior ground system must be made with an AWG #6 gauge wire, copper ground conductor at a minimum.

Electrical Circuit Requirements

Each Cisco RFGW-10 UEQAM requires a dedicated electrical circuit. If you equip it with dual power feeds, provide a separate circuit for each DC PEM to avoid compromising the power redundancy feature.

The Cisco RFGW-10 UEQAM can be powered by a DC source. Ensure that the equipment grounding is present and observe power strip ratings. Make sure that the total ampere rating of all products plugged into the power strip does not exceed 80% of the rating.

Table 2-4 contains specifications for DC powered systems for all Cisco RFGW-10 UEQAM.

Table 2-5 lists the DC PEM rating requirements for Cisco RFGW-10 UEQAM.

Site Cabling Guidelines

This section contains guidelines for wiring and cabling at your site. When preparing your site for network connections to the Cisco RFGW-10 UEQAM, consider the type of cable required for each component, and the cable limitations. Consider the distance limitations for signaling, EMI, and connector compatibility. Possible cable types are fiber, thick or thin coaxial, foil twisted-pair, or unshielded twisted-pair cabling.

Also consider any additional interface equipment you need, such as transceivers, hubs, switches, modems, channel service units (CSU), or data service units (DSU).

Before you install the Cisco RFGW-10 UEQAM, have all additional external equipment and cables on hand. For ordering information, contact a customer service representative.

The extent of your network and the distances between network interface connections depend in part on the following factors:

The distance and rate limits referenced in the following sections are the IEEE-recommended maximum speeds and distances for signaling purposes. Use this information as a guideline in planning your network connections prior to installing the Cisco RFGW-10 UEQAM.

If wires exceed recommended distances, or if wires pass between buildings, give special consideration to the effect of a lightning strike in your vicinity. The electromagnetic pulse caused by lightning or other high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic devices. If you have had problems of this sort in the past, you may want to consult experts in electrical surge suppression and shielding.

Asynchronous Terminal Connections

The Supervisor provides a console port to connect a terminal or computer for local console access. The Supervisor also provides an auxiliary port to connect to a modem for remote dial-in console access.

Both ports have RJ-45 connectors, support RS-232 asynchronous data, and have distance recommendations specified in the IEEE RS-232 standard.

Interference Considerations

When wires are run for any significant distance, there is a risk that stray signals will be induced on the wires as interference. If interference signals are strong, they can cause data errors or damage to the equipment.

The following sections describe sources of interference and how to minimize its effects on the Cisco RFGW-10 UEQAM system.

Electromagnetic Interference

All equipment powered by AC current can propagate electrical energy that can cause electromagnetic interference (EMI) and possibly affect the operation of other equipment. The typical sources of EMI are equipment power cords and power service cables from electric utility companies.

Strong EMI can destroy the signal drivers and receivers in the Cisco RFGW-10 UEQAM and even create an electrical hazard by causing power surges through power lines into installed equipment. These problems are rare, but could be catastrophic.

To resolve these problems, you need specialized knowledge and equipment, which could consume substantial time and money. However, you should ensure that you have a properly grounded and shielded electrical environment, paying special attention to the need for electrical surge suppression.

Table 2-6 lists electrode magnetic compliance standards for the Cisco RFGW-10 UEQAM.

Radio Frequency Interference

When electromagnetic fields act over a long distance, radio frequency interference (RFI) can be propagated. Building wiring can often act as an antenna, receiving the RFI signals and creating more EMI on the wiring.

If you use twisted-pair cable in your plant wiring with a good distribution of grounding conductors, the plant wiring is unlikely to emit radio interference. If you exceed the recommended distances, use a high-quality twisted-pair cable with one ground conductor for each data signal.

Lightning and AC Power Fault Interference

If signal wires exceed recommended cabling distances, or if signal wires pass between buildings, you should consider the effect that a lightning strike in your vicinity might have on the Cisco RFGW-10 UEQAM.

The electromagnetic pulse (EMP) generated by lightning or other high-energy phenomena can couple enough energy into unshielded conductors to damage or destroy electronic equipment. If you have previously experienced such problems, you should consult with RFI/EMI experts to ensure that you have adequate electrical surge suppression and shielding of signal cables in your Cisco RFGW-10 UEQAM operating environment.

Rack-Mounting and Location Guidelines

The Cisco RFGW-10 UEQAM is designed for standalone, two-post 19-inch rack-mount, four-post 19-inch rack-mount and closed cabinet systems with front and rear doors.

The sections that follow describe criteria for selecting a rack to mount the Cisco RFGW-10 UEQAM, guidelines for placing the rack for reliable operation, and safety precautions to take to prevent bodily injury when mounting a Cisco RFGW-10 UEQAM system in a rack.

Precautions for Rack-Mounting

The following rack-mount guidelines are provided to ensure your safety:

- Do not move large racks by yourself. Due to the height and weight of a rack, a minimum of two people are required to accomplish this task.

- Ensure that the rack is level and stable before extending a component from the rack.

- Ensure that proper airflow is provided to components in the rack.

- Do not step or stand on any component or system when servicing other systems or components in a rack.

- When mounting the Cisco RFGW-10 UEQAM in a partially filled rack, load the rack from the bottom to the top with the heaviest component at the bottom of the rack.

- If the rack is provided with stabilizing devices, then install the stabilizers before mounting or servicing the unit in the rack.

Rack Selection Guidelines

The Cisco RFGW-10 UEQAM can be mounted in most two-post or four-post, 19-inch equipment racks that comply with the Electronics Industries Association (EIA) standard for equipment racks (EIA-310-D 19-inch). The rack must have at least two posts with mounting flanges to mount the chassis.

The distance between the center lines of the mounting holes on the two mounting posts must be 18.31 inches ± 0.06 inch (46.50 cm ± 0.15 cm). The rack-mounting hardware included with the chassis is suitable for most 19-inch equipment racks.

We recommend that you mount the Cisco RFGW-10 UEQAM in an equipment rack that includes the necessary rack-mounting hardware, which is suitable for most 19-inch equipment racks.

Consider installing the Cisco RFGW-10 UEQAM in a rack with the following features:

- NEBS-compliant, 19-inch (48.3 cm) wide rack.

- EIA or ETSI hole patterns in the mounting rails. Required mounting hardware is shipped with the Cisco RFGW-10 UEQAM. If the rack that you plan to install the system in has metric-threaded rails, you must provide your own metric mounting hardware.

- Perforated top and open bottom for ventilation to prevent overheating.

- Leveling feet for stability.

Equipment Rack Guidelines

The placement of the rack can affect personnel safety, system maintenance, and the system ability to operate within the environmental characteristics described in Table 2-2 . Choose a proper location for the Cisco RFGW-10 UEQAM by following the guidelines below.

Locating for Safety

If the Cisco RFGW-10 UEQAM is the heaviest or the only piece of equipment in the rack, consider installing it at or near the bottom to ensure that the rack center of gravity is as low as possible.

For additional information about the proper placement of electronic equipment, consult the document GR-63-CORE, Network Equipment Building System (NEBS) Requirements: Physical Protection.

Locating for Easy Maintenance

Keep at least 3 feet of clear space in front and behind the rack. This space ensures that you can remove the Cisco RFGW-10 UEQAM components and perform routine maintenance and upgrades easily.

Avoid installing the Cisco RFGW-10 UEQAM in a congested rack and consider how the routing of cables from other pieces of equipment in the same rack could affect access to the routers cards.

The front and back of the chassis must remain unobstructed to ensure adequate airflow and prevent overheating inside the chassis.

Allow the following clearances for normal system maintenance:

- At the back of the chassis for maintenance—To 4 ft (91.44 cm to 121.92 cm)

- At the back of the chassis for airflow obstructions—At least 4 inches (7.6 cm)

- In the front of the chassis for maintenance—3 to 4 ft (91.44 cm to 121.92 cm)

- In the front of the chassis for airflow obstructions—At least 4 inches (7.6 cm)

To avoid problems during installation and ongoing operation, follow these general precautions when you plan the equipment locations and connections:

- Use the show environment all command regularly to check the internal system status. The environmental monitor continually checks the interior chassis environment; it provides warnings for high temperature and creates reports on any occurrences. If warning messages are displayed, take immediate action to identify the cause and correct the problem.

- Keep the Cisco RFGW-10 UEQAM off of the floor and out of areas that collect dust.

- Follow ESD prevention procedures to avoid damage to equipment. Damage from static discharge can cause immediate or intermittent equipment failure.

Locating for Proper Airflow

Ensure the location of the Cisco RFGW-10 UEQAM has enough airflow to keep the system operating within the environmental characteristics and the air temperature is sufficient to compensate for the heat dissipated by the system.

Avoid locating the Cisco RFGW-10 UEQAM in a location in which the chassis air intake vents could draw in the exhaust air from adjacent equipment. Consider how the air flows through the Cisco RFGW-10 UEQAM. The Cisco RFGW-10 UEQAM airflow direction is front to back with ambient air drawn in from the venting located on the chassis front sides.

Site Planning Checklist

Table 2-7 is provided to help you perform and account for all the site planning tasks.

Table 2-7 Site Planning Checklist

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage, occurs when electronic cards or components are improperly handled and can result in complete or intermittent failures. The Supervisors, and all line cards consist of a printed circuit card that is fixed in a metal carrier. Electromagnetic interference (EMI) shielding and connectors are integral components of the carrier. Although the metal carrier helps to protect the cards from ESD, use an antistatic strap each time you handle the modules. Handle the carriers by the edges only; never touch the cards or connector pins.

Static electricity can harm delicate components inside your system. To prevent static damage, discharge static electricity from your body before you touch any of your system components, such as an microprocessor. As you continue to work on your system, periodically touch an unpainted metal surface on the computer chassis.

Following are guidelines for preventing ESD damage:

- Always use an ESD-preventive wrist or ankle strap and ensure that it makes good skin contact. Before removing a card from the chassis, connect the equipment end of the strap to the ESD plug at the bottom of the chassis below the power entry modules (see Figure 3-13, and Figure 3-14).

- Handle line cards by the faceplates and carrier edges only; avoid touching the card components or any connector pins.

- When removing a card, place the removed module component-side-up on an antistatic surface or in a static-shielding bag. If the module will be returned to the factory, immediately place it in a static-shielding bag.

- Avoid contact between the modules and clothing. The wrist-strap protects the card from ESD voltages on the body only; ESD voltages on clothing can still cause damage.

- When transporting a sensitive component, first place it an antistatic container or packaging.

- Handle all sensitive components in a static-safe area. If possible, use antistatic floor pads and workbench pads.

Electrical Safety

All system components are hot-swappable. They are designed to be removed and replaced while the system is operating without presenting an electrical hazard or damage to the system.

Follow these basic guidelines when you are working with any electrical equipment:

- Before beginning any procedures requiring access to the chassis interior, locate the emergency power-off switch for the room in which you are working.

- Disconnect all power and external cables before installing or removing a chassis.

- Do not work alone when potentially hazardous conditions exist.

- Never assume that power has been disconnected from a circuit; always check.

- Do not perform any action that creates a potential hazard to people or makes the equipment unsafe. Never install equipment that appears damaged.

- Carefully examine your work area for possible hazards such as moist floors, ungrounded power extension cables, and missing safety grounds.

In addition, use the guidelines that follow when working with any equipment that is disconnected from a power source but is still connected to telephone wiring or other network cabling.

- Never install telephone wiring during a lightning storm.

- Never install telephone jacks in wet locations unless the jack is specifically designed for wet locations.

- Never touch un-insulated telephone wires or terminals unless the telephone line has been disconnected at the network interface.

- Use caution when installing or modifying telephone lines.

Warning Do not work on the system or connect or disconnect cables during periods of lightning activity. Statement 1001

Receiving a Cisco RFGW-10 UEQAM

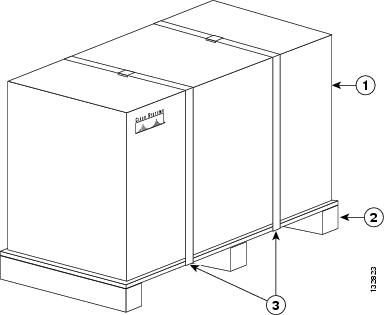

Each Cisco RFGW-10 UEQAM chassis is shipped in a container that is strapped to a pallet as illustrated in Figure 2-1.

Figure 2-1 Cisco RFGW-10 UEQAM Packaged for Shipping

Note We recommend that you have at least two people available to help with the installation and ensure safe lifting.

Chassis-Lifting Guidelines

The fully configured system weighs approximately 275 pounds. The chassis is not intended to be moved frequently. Before you install the system, ensure that your site is properly prepared so you can avoid moving the chassis later to accommodate power sources and network connections.

Two or more people are required to lift the chassis. Each time you lift the chassis or any heavy object, follow these guidelines:

- Do not remove installed components from the chassis until you are ready to install it into a rack.

- When ready to install the Cisco RFGW-10 UEQAM into a rack it is recommended to remove all components except the fan tray, two TCC cards, and the 12 RF Switch cards. In this configuration the chassis weighs 139 lbs (63.2 kg).

- Always disconnect all external cables before lifting or moving the chassis.

- Never attempt to lift the chassis by yourself. Because of the size and weight of the chassis, use at least two people to safely lift and move it without causing injury or damaging the equipment.

- Ensure that your footing is solid, and balance the weight of the chassis between your feet.

- Lift the chassis slowly; never move suddenly or twist your body as you lift.

- Keep your back straight and lift with your legs, not your back. If you must bend down to lift the chassis, bend at the knees, not at the waist, to reduce the strain on your back muscles.

Note To unpack the Cisco RFGW-10 UEQAM, it is recommended that the chassis installation handles be installed to help facilitate lifting of the chassis off the palette.

Note When moving a fully loaded Cisco RFGW-10 UEQAM chassis, it is recommended that a hand lift and a hydraulic lift or forklift be used.

Note To install a Cisco RFGW-10 UEQAM in a rack, see the “Installing the Cisco RFGW-10 UEQAM in a Rack” section for rack installation guidelines.

Step 1 Each person should stand on either side of the chassis and place one hand under the air intake at the bottom front of the chassis.

Step 2 With the other hand, grasp the top rear of the chassis under the air exhaust and carefully lift the chassis.

Tools and Equipment

The tools and equipment listed below are recommended as the minimum necessary to install the Cisco RFGW-10 UEQAM. You may need additional tools and equipment to install associated equipment and cables. You may also require test equipment to check electronic and optical signal levels, power levels, and communications links.

- ¼-inch flat-head screwdriver (for UCH2 cable holder installation onto the RF Switch Cards)

- 3/16-inch flat blade screwdriver

- Number 2 Phillips screwdrivers to tighten the captive installation screws on most systems

- Antistatic mat, bags, or antistatic foam for you to remove modules

- 10-mm socket wrench for tightening DC power and ground connection nuts

- 4 AWG (21mm^2) wire for DC power and ground connections (customer provided)

- 6 AWG (13mm^2) wire for NEBS Chassis ground connection (customer provided)

- Wire stripper and crimping tool for preparing the DC power and ground connections (the accessory kit comes with specific 4 AWG and 6 AWG 90-degree ground lugs)

- Heat shrink tubing or electrical insulation for exposed DC power and ground crimp joints

- 12 universal cable holders UCH2 (supplied in the accessory kit) <does this require a change?>

- T-10 TORX driver tool

- Tape measure (optional)

- Level (optional)

- MCX terminated cable bundle (optional)

- Rack-mount kit (provided in the accessory kit)

- Ten #4 AWG wire, 90 degree, dual ring lugs, 0.63 spacing for M6 studs (reference Panduit LCD4-14AF-L, provided in the accessory kit for DC PEM power and ground connections)

- One #6 AWG wire, 90 degree, dual ring lugs, 0.63 spacing for M5 studs (reference Panduit LCD6-10AF-L, provided in the accessory kit for NEBS chassis ground connection)

- Two M5 pan-head Phillips screws (provided in the accessory kit for NEBS chassis ground connection)

- Eight rack-mounting screws (customer provided)

- Connectors and wire for the DC circuit or circuits

- Cables—75-ohm quad-shielded precision miniature video cable, bonded foil 1855 type (reference YR50386 and YR52310)

- Wrist-strap or other grounding device

Unpacking and Verifying Shipping Contents

When you receive your chassis, perform the following steps and use the shipping contents checklist from the next section:

Step 1 Inspect the box for any shipping damage. (If there is damage contact your service representative).

Step 2 Unpack the Cisco RFGW-10 UEQAM.

Step 3 Perform a visual inspection of the chassis.

Step 4 After you have unpacked the system verify that you have received all of the required components. Using the packing list as a guide, take the following steps to check the contents of the Cisco RFGW-10 UEQAM shipping container:

Step 5 Check the contents of the boxes containing accessory items. Verify that you have received all equipment listed in your order.

Step 6 Check that all Cisco RFGW-10 UEQAM components and DC PEM you ordered are installed in the chassis. Ensure that the configuration matches the packing list.

Checking the Shipping Container Contents

Use the components list to check the contents of the Cisco RFGW-10 UEQAM shipping container. (See Table 2-8 .) Do not discard the shipping container. You need the container if you move or ship the Cisco RFGW-10 UEQAM in the future.

Table 2-8 Cisco RFGW-10 UEQAM Shipping Container Contents List

Cisco RFGW-10 UEQAM chassis configured with fan tray, 12 RFGW-10-RFSW1 cards, two RFGW-TCC1 cards, dual DC PEM. |

||

Check that the proper number and type of cards are installed for the Supervisor Slots, and Universal RF slots. All other empty slots should be filled with blank panels. |

||

2 Front chassis rack-mount brackets that you will attach to the chassis with the respective screws |

||

12 UCH2 cable holders for coaxial termination fixing to the RF switch cards |

||

4 Ferrite clips for the Supervisor console and management cables for EMI suppression |

||

Regulatory Safety and Compliance Information for the Cisco RF Gateway 10 |

Note Most Cisco documentation is online or on the Cisco Documentation DVD. Documentation that ships with your Cisco RFGW-10 UEQAM includes the Cisco RF Gateway 10 Documentation Flyer, Cisco RF Gateway 10 Quick Start Guide and the Regulatory Compliance and Safety Information for the Cisco RF Gateway 10. See also the “Related Documentation” section.

Cisco RFGW-10 UEQAM Installation Checklist

To assist you with your installation and to provide a historical record of what was done by whom, photocopy the Cisco RFGW-10 UEQAM Installation Checklist (see Table 2-9 ). Use this to indicate when each procedure or verification is completed. When the checklist is completed, place it in your site log along with the other records for your new router.

Table 2-9 Cisco RFGW-10 UEQAM Installation Checklist

Feedback

Feedback