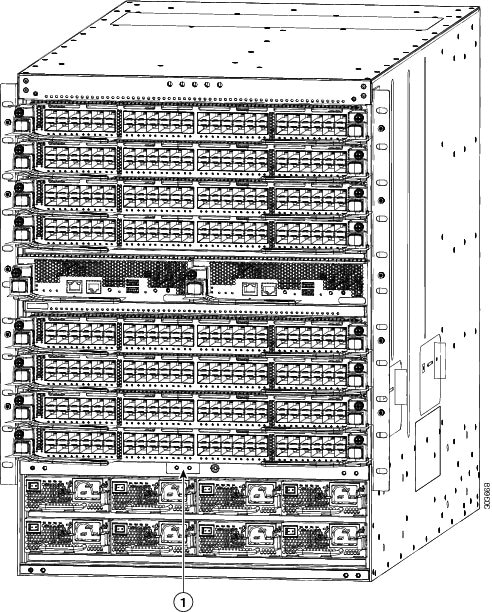

Installing a Rack or Cabinet

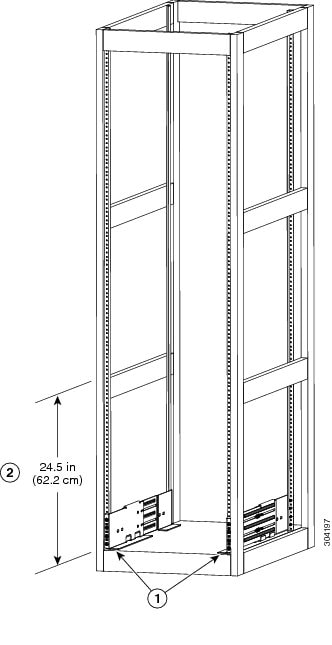

Before you install the switch, you must install a standard four-post, 19-inch EIA data center rack (or a cabinet that contains such a rack) that meets the requirements listed in Cabinet and Rack Requirements.

Procedure

| Step 1 |

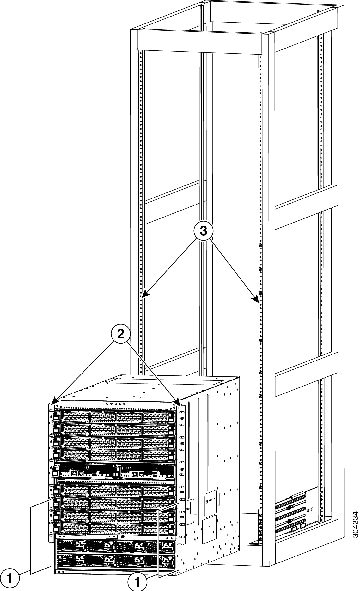

Bolt the rack to the concrete subfloor before moving the chassis onto it.

Statement 1048 |

||||

| Step 2 |

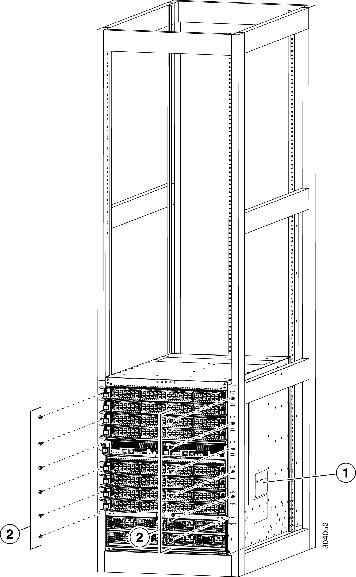

If the rack has bonded construction, connect it to the earth ground. This action enables you to easily ground the switch and its components and to ground your electrostatic discharge (ESD) wrist strap to prevent damaging discharges when you handle ungrounded components before installing them. |

||||

| Step 3 |

If you need access to the source power at the rack, include either AC power receptacles or a DC power interface unit (PIU) with the amperage required by the switch that you are installing. . If you are using DC power, be sure that the DC power supply is grounded and that there is direct access to the facility DC power or indirect access though a power interface unit (PIU). You must connect the DC power supply to the earth ground before you connect it to the facility DC power.

Statement 1018

|

Feedback

Feedback