Table Of Contents

Configuration Rules for Populating Cards in the MGX 8230

Changing a Single-Height Card Slot to a Double-Height Card Slot

AC Power Cords Available for Different Regions

Power Consumption of the Different MGX 8230 Modules

MGX 8230 System Current Requirement

Heat Dissipation for a Fully Loaded MGX 8230

Card Cage and Midplane Architecture

Midplane Functional Description

Mechanical

This section describes the mechanical design of the MGX 8230, including chassis, power options, midplane, cabling, and EMI.

Chassis

The MGX 8230 is a 14-slot chassis with horizontally mounted processor modules, service modules, and back cards:

•

Two double-height slots are dedicated for the PXM1 modules.

•

Eight single-height slots (or four double-height slots) are used for service modules.

•

Two single-height slots are used for Service Resource modules.

Slots are numbered 1 to 7 on the left half of the chassis, and 8 to 14 on the right side of the chassis.

Note

Although the card slots in an MGX 8230 are horizontal, this manual refers to the card slots and modules as single-height and double-height. The PXM and service module cards are a subset of the MGX 8250 cards that are installed vertically in an MGX 8250 chassis.

Since front slots 1 and 2 are always double-height for PXM1 processor modules, slots 8 and 9 refer only to the back card slots that correspond to the two lower single-height slots on the left side of the chassis as seen from the rear.

When a double-height front card is installed, the left slot number is used. The back cards are numbered according to the front card numbering scheme, with the exception of slots 8 and 9 as noted above.

•

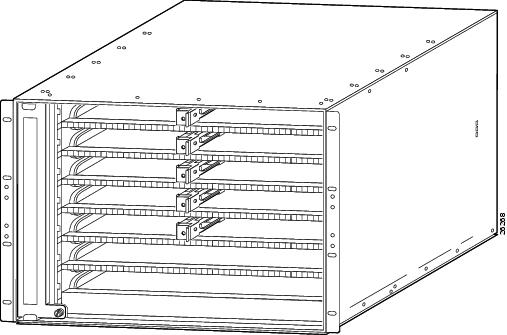

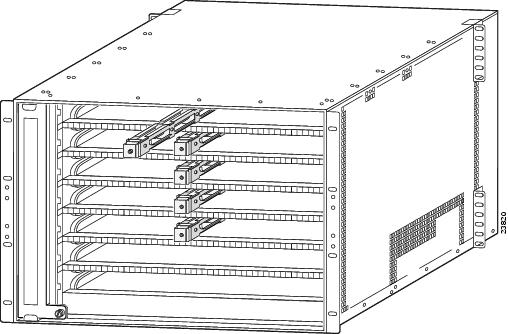

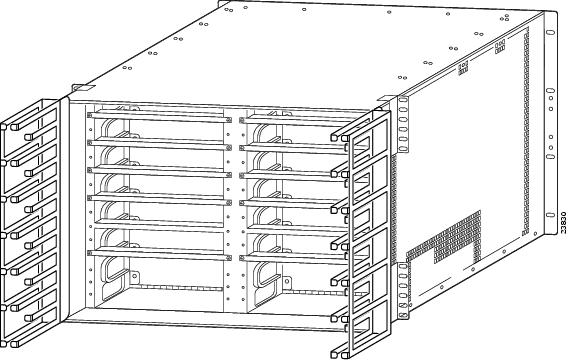

Figure 2-1 is a front view of an empty MGX 8230 chassis.

•

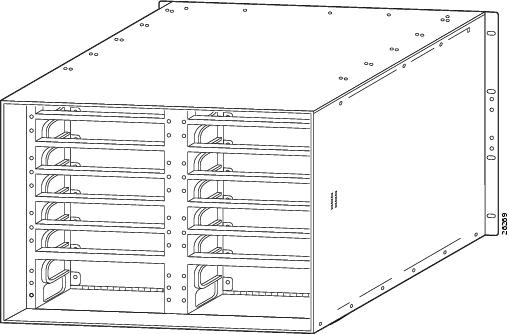

Figure 2-2 is a rear view of an empty MGX 8230 chassis.

•

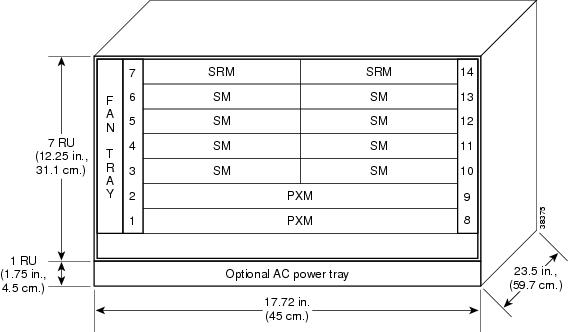

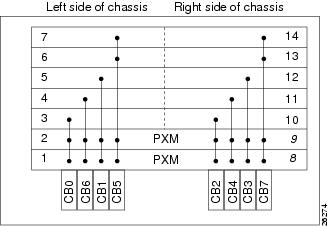

Figure 2-3 shows the slot configuration of an MGX 8230 chassis.

For information on converting single-height slots, see the "Changing a Single-Height Card Slot to a Double-Height Card Slot" section.

The MGX 8230 chassis is 17.72 inches wide, 12.25 inches high (14.00 inches high with optional AC Power Tray), and 23.5 inches deep. The chassis can be mounted in either a 19-inch or a 23-inch EIA/RETMA and ETSI racks. Figure 2-3 illustrates the different sections of the MGX 8230 chassis.

Figure 2-1 MGX 8230 Card Cage—Front View

Figure 2-2 MGX 8230 Card Cage—Rear View

Configuration Rules for Populating Cards in the MGX 8230

The following rules and guidelines are to assist the user in installing single-height and double-height service modules in an MGX 8230 chassis. Rules must be followed while guidelines are instituted for better performance.

Changing a Single-Height Card Slot to a Double-Height Card Slot

The MGX 8230 is typically configured at the factory as you ordered it. Unused card slots are configured for single-height modules and covered with blank faceplates.

Single-height service module slots 3-7 and 10-14 can be converted into double-height slots by removing the center divider module.

Note

When converting single-height slots into double-height slots, the conversion must start from the bottom and be contiguous. For example, slot 3 must be converted to a double-height slot before slot 4 can be converted.

Figure 2-3 illustrates the slot numbering of an MGX 8230 with slot 3 configured for a double-height module.

Figure 2-3 MGX 8230 Slot Configuration

Note

After conversion, the left slot, which identifies both single-height and double-height slots, is numbered from the left side. Thus, slot 4 could refer to either a single-height slot or a double-height slot. The right slots are numbered on the right side, as shown in Figure 2-3, and refer only to single-height slots.

•

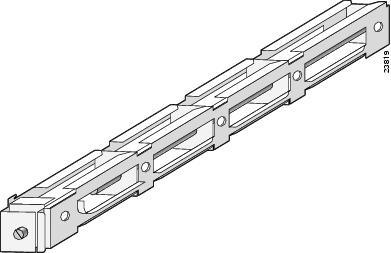

Figure 2-4 illustrates a the center guide module.

•

Figure 2-5 shows the location of center guide modules in the MGX 8230 chassis.

Figure 2-4 Center Guide Module—Slot Divider

Figure 2-5 Front View of an MGX 8230 Card Cage

Card Dimensions

Table 2-1 shows the physical characteristics for modules supported on the MGX 8230.

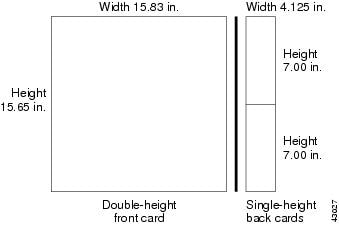

Figure 2-6 is an illustration of the Double-Height Card Dimensions.

Figure 2-6 Double-Height Card Dimensions

Figure 2-7 is an illustration of the Single-Height Card Dimensions.

Figure 2-7 Single-Height Card Dimensions

Optical Specifications

Table 2-2 provides the optical specifications for the different interfaces.

As the optical transceivers in the PXM1 interfaces are compliant with ITU-T G.957, the dispersion tolerance according to G.957 are:

•

STM-1 Intermediate Reach (S-1.1)—Maximum dispersion in the optical path is 96 ps/nm

•

STM-1 Long Reach (L-1.1)—Maximum dispersion in the optical path is 185 ps/nm

•

STM-4 Intermediate Reach (S-4.1)—Maximum dispersion in the optical path is 74 ps/nm

•

STM-4 Long Reach (L-4.1)—Maximum dispersion in the optical path is 109 ps/nm

The modulation used in all PXM1 optics is direct build-in electroabsortion modulator in standard temperature range (0 - 70°C).

The type of laser sources for the different PXM1 interfaces are

•

OC-3 IR: Fabry-Perot

•

OC-3 LR: Fabry-Perot

•

OC-12 IR: Fabry-Perot

•

OC-12 LR: DFB

All MGX single mode optical interfaces (OC-3, OC-12, and OC-48) are terminated with the UPC (Ultra Physical Contact) polish type. Note that this does not apply to multimode fiber. The UPC polish includes an extended polishing cycle at the end-face surface for a better surface finish, resulting in back reflection as low as -55 dB.

Interface Ranges

The supported cable distance ranges are shown in the following list.

1.

DS1 per ANSI T1.102 states distance of 655 feet. This refers to a compliant pulse (per pulse mask template) to the DSX-1 (cross-connect).

2.

Ethernet (10BaseT) is a distance of 100 meters to the first repeater.

3.

DS3 per ANSI T1.102 is a distance of 450 feet to the DSX-3 cross-connect.

4.

HSSI per ITU-T V.12 (ANSI/EIA/TIA-612) is a distance of 50 feet (15 meters) between load and generator.

MGX 8230 Power

The MGX 8230 power system is designed with distributed power architecture centered around a -48 VDC bus on the system backplane. The -48 VDC bus accepts redundant DC power from either a -42 to -56 VDC source via optional DC power entry modules (PEMs) or from a 100 to 120, or a 200 to 240, VAC source via the optional AC Power Supply Tray. The MGX 8230 backplane distributes power via connectors on the -48 VDC bus to each hot-pluggable processor or service module. Each card incorporates on-board DC-DC converters to convert the -48 VDC from the distribution bus voltage to the voltages required on the card.

Optional AC Power Supply

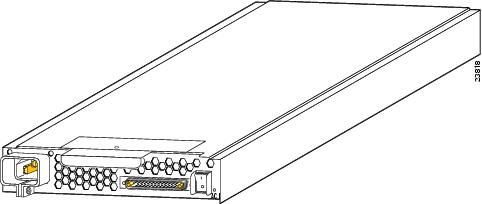

For an AC-powered MGX 8230, an optional AC power supply tray is attached to the bottom of the 8230 card cage at the factory. The AC power supply tray is 1 rack-unit high, and can hold up to two AC Power Supply modules. Each AC Power Supply module can provide up to 1200W at 48VDC and has its own AC power cord and power switch. Figure 9 shows the rear view of an optional AC Power Supply module. The power supplies can be configured as 1+1 redundant. If no redundancy is desired, an AC tray with one AC power supply and one AC power cord can also be ordered.

Figure 2-8 AC Power Supply Module—Rear View

Each AC Power Supply Module incorporates the following features:

•

One rack unit high

•

Output capacity of 1200 Watts at -48 VDC

•

O-ring diode

•

EMI filtering

•

Cooling fan

•

Power switch

•

DC and AC status LEDs

DC-Power

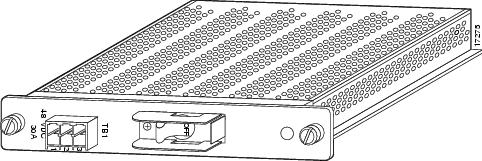

For DC systems, a DC Power Entry Module (PEM) is required for each DC source of central office power -42 to -56 VDC. The MGX 8230 can support two DC power sources and has rear panel slots for two DC PEMS. Figure 2-9 illustrates a DC PEM.

The DC PEMs incorporate the following features:

•

Hot swappable

•

O-ring diode

•

EMI filtering

Figure 2-9 MGX 8230 DC Power Entry Module

AC Power Cords Available for Different Regions

The following chart details the AC power cords available by regions.

Power Consumption of the Different MGX 8230 Modules

The power consumption of the different modules is defined in Table 2-4.

MGX 8230 System Current Requirement

The current requirements are configuration-dependent. For general planning purposes use

48VDC, Current rating: 25 AMP

Note

The total power consumption is dependent on the configuration of the MGX 8230.

Heat Dissipation for a Fully Loaded MGX 8230

A fully loaded, AC powered MGX 8230 dissipates up to 4800 Btus. A DC powered MGX 8230 dissipates up to 4100 Btus.

Safety Switches

The MGX 8230 does not use circuit breakers instead of switches or magnetic conductors. These circuit breakers are compliant with VDE and IEC 950 specifications.

Circuit Breakers

For an AC-powered MGX 8230, verify that the shelf's power comes from dedicated AC branch circuits. The circuits must be protected by a dedicated, 15 amp circuit breaker. Cisco Systems recommends that the site has a 15 amp AC circuit breaker with a long trip-delay at each branch circuit.

For a DC-powered MGX 8230, verify that its power comes from a dedicated DC branch circuit. This branch circuit must be protected by a dedicated circuit breaker. Cisco Systems recommends that the site has a dedicated 30 amp circuit breaker with a medium trip delay at each branch circuit. A DC-powered MGX 8230 uses a 30 amp circuit breaker with a short trip delay on each -48V input.

Cooling

The MGX 8230 incorporates a fan tray assembly (with eight fans) located on the left side of the card cage to pull ambient cooling air into the system through openings between front card faceplates, over the boards in the card cage, and out through air exhaust openings on the left side of unit.

Figure 2-10 is an illustration of the MGX 8230 fan tray assembly.

The cooling system incorporates the following design features:

•

-48 VDC fans with rotation sensing

•

N+1 fan redundancy

•

Hot pluggable (if done quickly) Fan Tray Assembly

•

Noise level < 65 dBA

The PXMs provide a variety of system environmental monitoring and logging functions. The PXM is capable of reading the speed of these fans to determine if they are operating below the configured threshold. Upon failure of any of the fans, an alarm is generated. The temperature monitor circuit monitors the MGX 8230 shelf air-intake temperature in units of one degree Celsius.

Figure 2-10 MGX 8230 Fan Tray Assembly

Environmental

MGX 8230 environmental specifications are listed as follows.

•

Ambient Temperature Range

–

In operation +41 to +104°F (+5 to +40°C)

–

In short-term operation +35 to +122°F (+1.7 to +50°C) (up to or less than 72 consecutive hours and 15 days in one year)

–

In storage -40 to +140°F (-40 to +60°C)

•

Relative Humidity Range

–

In operation: up to 85%

•

Altitude Range

–

200 feet below the mean sea level to 10,000 feet above the mean sea level taking into account the function of temperature and humidity.

•

Shock

–

Withstands 10 G, 10 ms. at 1/2 sine wave.

•

Vibration:

–

Withstands 1/4 G, 20 to 500 Hz.

•

Maximum Heat Gain

–

5 kw or 17,070 Bus/hour (50% to 75% of this value in typical configurations).

•

Minimum Floor Void

–

The minimum clearance requirements are 30 inches front and rear; nominal 12-inch side clearance.

Electromagnetic Interference

To maintain correct airflow and to reduce Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI), all unused back card slots must be covered with the blank faceplates provided by Cisco Systems. If a front door option is ordered, there is no need to order or install blank front faceplates.

Front side EMI is obtained by either installing Cisco provided blank cards or by installing an EMI-tight front door, which can be ordered as an option. There will be different faceplates to accommodate double-height and single-height slots.

Card Cage and Midplane Architecture

The MGX 8230 chassis has two dedicated slots for the PXM1, eight single-height slots (four double-height slots) for service modules, and two single-height slots for SRMs.

Midplane Functional Description

The MGX 8230 has a midplane design that increases flexibility and minimizes service disruptions by allowing front cards to be replaced without disrupting cabling at the rear of the chassis. In backplane architectures, the design reduces the flexibility to change interfaces and increases the risk of causing accidental operational outages due to cables coming loose when cards are being swapped.

Midplane Key Benefits

The benefits of the midplane design are as follows.

•

Operational IssuesæAll MGX cards have a modular architecture that includes a front card inserted from the front of the switch and a matching back card inserted from the rear of the switch. Front cards contain all of the intelligence, processor, and switching functions. Back cards contain the physical interfaces and adaptation functions. All cards (both front and back) are hot swappable. In the event of a failure, typically only front cards need to be replaced. All of the cables and card connections can remain intact.

•

Interface FlexibilityæInterface types can be changed by simply replacing the back card. With Cisco the MGX 8230, the customer can easily and cost-effectively migrate the physical interface type for a particular interface by replacing the back card.

Backplane Components

Components of the backplane include:

•

Cell Bus—Eight master cell buses and one slave cell bus connected from each PXM to the midplane.

•

Local Bus—To communicate between the PXMs and the SRMs.

•

T1/E1 Redundancy Bus—To route the T1/E1 signals from a selected service module's line module to the standby module.

•

BERT Bus—To generate and test using a variety of BERT on any specific T1/E1 line or ports.

•

Distribution Bus—To distribute T1 or T3 signals to the service modules. It is a poin-to-point connection between the SRM and service module slots. Up to 4 DS3s are routed to the single-height service modules.

Cell Buse Artchitecture

The MGX 8230 architecture is built around the switching fabric on the processor switching module, the backplane, and the service modules.

The main function of the MGX 8230 backplane is to connect cards together, terminate critical signals properly, provide -48 VDC power to all cards, and set ID numbers for each slot. In addition, the

MGX 8230 backplane interconnects both front cards and back cards together via pass-through connectors.The cell bus provides high-speed interface between the switch fabric and the service modules. Figure 2-11 shows the overall cell bus distribution of the backplane.

Each PXM supports eight master cell buses and one slave cell bus connected to the backplane. The service modules have two slave cell bus ports, one from each PXM.

A cell bus is comprised of a group of signals used to transfer data between the PXM and a service module. CB 0, 6, 1, 2, 4, and 3 are dedicated to physical slots 3, 4, 5, and 10, 11, and 12 respectively, which support high-speed service modules. CB5 supports physical slots 6 and 7, and CB7 supports physical slots 13 and 14, as well as the alternate PXM's slave port.

There is a connection on cell bus 7 to the alternate PXM. A PXM is able to communicate with the other PXM using the slave cell bus port on that card. Slots 8 and 9 only refer to back card slots.

Figure 2-11 shows the interconnection of the cell bus lanes on the midplane.

Figure 2-11 MGX 8230 Cell Bus Lane Interconnection

Distribution Bus

The MGX 8230 backplane supports the same distribution bus employed in the MGX 8220. This is used in conjunction with the SRM-3T3 to provide M13 circuit breakout and distribution capability as well as T1/E1 1:N service module redundancy (in bulk mode the service modules have 1:N redundancy without using the separate T1 redundancy bus). The distribution system is also augmented with a T3 distribution mechanism, so that a future SRM could break out an OC-12 into DS3 streams, which in turn could be routed to individual DS3 speed service modules. The TDM distribution buses for the upper and lower service bays are independent. In the future, the SRM may also be required to break out traffic to the DS0 level in order to provide more advanced grooming/pooling capabilities.

Service Redundancy Bus

A redundancy bus supports T1/E1 service module redundancy. The service modules have access to the redundant bus, and the service redundant logic on the SRM is responsible for sending control signals to each service modules to use the redundant bus. This redundancy bus carries traffic from the back card of a failed service module to the front card of an active secondary card module.

Local Bus

The local bus is the core card bus that connects the PXM and SRM cards.

BERT Bus

The BERT bus is used by the SRM-3T3/C to distribute T1 signals to the service modules. The SRM can support BERT on only one line or port at a time. BERT is capable of generating a variety of test patterns, including all ones, all zeros, alternate one zero, double alternate one zero, 223-1, 220-1, 215-1, 211-1, 29-1, 1 in 8, 1 in 24, DDS1, DDS2, DDS3, DDS4, and DDS5.

The BERT bus is used to provide the BERT operation to the individual service modules. This bus is also used to drive special codes such as fractional T1 loopback codes, and so on, onto the T1 line. The BERT function is initiated on ONLY one logical T1/E1 Nx64K port per MGX 8230 at any given time and this is controlled by the PXM. The SRM-3T3 ensures that the BERT patterns are generated and monitored (if applicable) at the appropriate time slots.

The data path then for that particular port (n x 64K) is from the service module to the SRM-3T3/C (via the BERT bus) and back to the service module (via the BERT bus). On the service module, the data that is transmitted is switched between the regular data and the BERT data at the appropriate timeslots as needed. Similarly in the receive direction, the received data is diverted to the BERT logic for comparison during appropriate time slots.

The BERT logic is self synchronizing to the expected data. It also reports the number of errors for bit error rate calculation purposes.

CautionBERT is a disruptive test. Activation of this test will stop the data flow on all the channels configured on the port under test. BERT testing requires the presence of an SRM-3T3/C card in the service bay where the card under test is located.

Cable Management

The following cables are required for minimum configuration of one MGX 8230 shelf:

•

Fan Cable—This cable connects the fan tray to the midplane, supplies power to the fans, and provides status signals to the PXM.

•

AC Cable—On an AC system, power cable connects the AC power supply tray to the midplane to supply redundant 48VDC. AC power-supply status can be monitored by the PXM through these cables.

For systems sold in the United States, the AC power is supplied through standard IEC power cord. Power cords for different countries can be ordered through Cisco.

Additionally, the system also requires the following cables under different configurations.

•

DC Cable—For DC systems, the wiring is connected from a 48 VDC power source to one or two DC Power Entry Modules. All wires must be six AWG in size.

•

SM Cable—Table 2-5 summarizes the type of interfaces provided by the different service modules.

MGX 8230 Cable Management

A fully loaded MGX 8230 may have many cables attached to the rack's modules. Cable management kits are available for installation on the rear of rack modules. These kits provide the means to route the power and data cables in a neat and orderly fashion to and from the modules in the shelf. The cable-management system is shipped with attaching hardware along with your MGX 8230. Install the cable-management brackets after a rack-mounted unit has been installed in a rack, or a standalone MGX 8230 has been positioned.

Figure 2-12 illustrates an installed cable management system. When installing the cable-management system on a rack-mount MGX 8230, the screws securing cable guides to the shelf chassis are inserted from the outside into the captive nuts in the chassis. When installing the cable-management system in a standalone MGX 8230, the screws securing cable guides to the shelf chassis are inserted from the outside to the captive nuts in the chassis.

Figure 2-12 Cable Management Assembly at Back Enclosure

The cable-management system provides the following features:

•

Cards can be inserted or removed without disturbing cables attached to cards in adjacent slots.

•

Cables can be routed from both above and below the chassis.

•

Fiber cables are prevented from bending tighter than allowable radius.

Feedback

Feedback