Table Of Contents

Connecting an Appliance to a Terminal Server

Understanding Time on the Sensor

Correcting the Time on the Sensor

10/100Base-TX and 10/100/1000Base-TX Connectors

Introducing the Sensor

This chapter introduces the sensor and provides information you should know before you install the sensor. In this guide, the term "sensor" refers to all models unless specifically noted otherwise. For a complete list of supported sensors and their model numbers, see Supported Sensors.

This chapter contains the following sections:

How the Sensor Functions

This section describes how the sensor functions, and contains the following topics:

Capturing Network Traffic

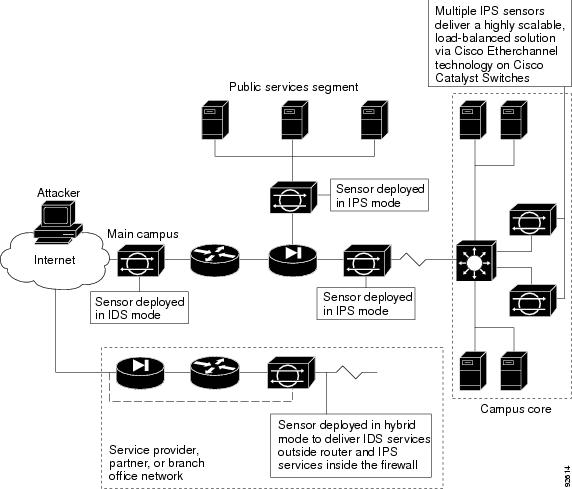

The sensor can operate in either promiscuous or inline mode. Figure 1-1 shows how you can deploy a combination of sensors operating in both inline (IPS) and promiscuous (IDS) modes to protect your network.

Figure 1-1 Comprehensive Deployment Solutions

Note

IDS-4210 and NM-CIDS do not operate in inline mode.

The command and control interface is always Ethernet. This interface has an assigned IP address, which allows it to communicate with the manager workstation or network devices (Cisco switches, routers, and firewalls). Because this interface is visible on the network, you should use encryption to maintain data privacy. SSH is used to protect the CLI and TLS/SSL is used to protect the manager workstation. Both SSH and TLS/SSL are enabled by default on the manager workstations.

When responding to attacks, the sensor can do the following:

•

Insert TCP resets via the monitoring interface.

Note

The TCP reset action is only appropriate as an action selection on those signatures that are associated with a TCP-based service. If selected as an action on non-TCP-based services, no action is taken. Additionally, TCP resets are not guaranteed to tear down an offending session because of limitations in the TCP protocol. On IDS-4250-XL, TCP resets are sent through the TCP reset interface.

•

Make ACL changes on switches, routers, and firewalls that the sensor manages.

Note

ACLs may block only future traffic, not current traffic.

•

Generate IP session logs, session replay, and trigger packets display.

IP session logs are used to gather information about unauthorized use. IP log files are written when a certain event or events occur that you have configured the appliance to look for.

•

Implement multiple packet drop actions to stop worms and viruses.

Sensor Interfaces

The command and control interface is permanently mapped to a specific physical interface, which depends on the type of sensor you have. You can let the sensing interfaces operate in promiscuous mode, or you can pair the network sensing interfaces into logical interfaces called "inline pairs." You must enable the interfaces or inline pairs before the sensor can monitor traffic.

Note

On appliances, the sensing interfaces are disabled by default. On modules, the sensing interfaces are always enabled and cannot be disabled.

The sensing interface does not have an IP address assigned to it and is therefore invisible to attackers. This lets the sensor monitor the data stream without letting attackers know they are being watched. Promiscuous mode is contrasted by inline technology where all packets entering or leaving the network must pass through the sensor. For more information, see Promiscuous Mode and Inline Mode.

The sensor monitors traffic on interfaces or inline pairs that are assigned to the default virtual sensor. For more information, refer to Assigning Interfaces to the Virtual Sensor.

To configure the sensor so that traffic continues to flow through inline pairs even when SensorApp is not running, you can enable bypass mode. Bypass mode minimizes dataflow interruptions during reconfiguration, service pack installation, or software failure.

The sensor detects the interfaces of modules that have been installed while the chassis was powered off. You can configure them the next time you start the sensor. If a module is removed, the sensor detects the absence of the interfaces the next time it is started. Your interface configuration is retained, but the sensor ignores it if the interfaces are not present.

The following interface configuration events are reported as status events:

•

Link up or down

•

Traffic started or stopped

•

Bypass mode auto activated or deactivated

•

Missed packet percentage threshold exceeded

Promiscuous Mode

In promiscuous mode, packets do not flow through the IPS. The sensor analyzes a copy of the monitored traffic rather than the actual forwarded packet. The advantage of operating in promiscuous mode is that the IPS does not affect the packet flow with the forwarded traffic. The disadvantage of operating in promiscuous mode, however, is the IPS cannot stop malicious traffic from reaching its intended target for certain types of attacks, such as atomic attacks (single-packet attacks). The response actions implemented by promiscuous IPS devices are post-event responses and often require assistance from other networking devices, for example, routers and firewalls, to respond to an attack. While such response actions can prevent some classes of attacks, for atomic attacks, however, the single packet has the chance of reaching the target system before the promiscuous-based sensor can apply an ACL modification on a managed device (such as a firewall, switch, or router).

Inline Mode

Operating in inline mode puts the IPS directly into the traffic flow and affects packet-forwarding rates making them slower by adding latency. An inline IPS sits in the fast-path, which allows the sensor to stop attacks by dropping malicious traffic before it reaches the intended target, thus providing a protective service. Not only is the inline device processing information on layers 3 and 4, but it is also analyzing the contents and payload of the packets for more sophisticated embedded attacks (layers 3 to 7). This deeper analysis lets the system identify and stop and/or block attacks that would normally pass through a traditional firewall device.

In inline mode, a packet comes in through the first interface of the pair on the sensor and out the second interface of the pair. The packet is sent to the second interface of the pair unless that packet is being denied or modified by a signature.

Note

You can configure AIP-SSM to operate inline even though it has only one sensing interface.

TCP Reset

You need to designate an alternate TCP reset interface in the following situations:

•

When a switch is being monitored with either SPAN or VACL capture and the switch does not accept incoming packets on the SPAN or VACL capture port.

•

When a switch is being monitored with either SPAN or VACL capture for multiple VLANs, and the switch does not accept incoming packets with 802.1q headers.

Note

The TCP resets need 802.1q headers to tell which VLAN the resets should be sent on.

•

When a network tap is used for monitoring a connection.

Note

Taps do not allow incoming traffic from the sensor.

Supported Interfaces

Table 1-1 describes the interface support for appliances and modules running Cisco IPS 5.0:

Table 1-1 Interface Support

InlineIDS-4210

—

None

N/A

All

IDS-4215

—

None

N/A

All

IDS-4215

4FE

FastEthernet0/1

4FE

FastEthernetS/01

FastEthernetS/1

FastEthernetS/2

FastEthernetS/31/0<->1/1

1/0<->1/2

1/0<->1/3

1/1<->1/2

1/1<->1/3

1/2<->1/3

0/1<->1/0

0/1<->1/1

0/1<->1/2

0/1<->1/3FastEthernet0/0

IDS-4235

—

None

N/A

All

IDS-4235

4FE

4FE

FastEthernetS/0

FastEthernetS/1

FastEthernetS/2

FastEthernetS/31/0<->1/1

1/0<->1/2

1/0<->1/3

1/1<->1/2

1/1<->1/3

1/2<->1/3GigabitEthernet0/0

GigabitEthernet0/1IDS-4250

—

None

N/A

All

IDS-4250

4FE

4FE

FastEthernetS/0

FastEthernetS/1

FastEthernetS/2

FastEthernetS/31/0<->1/1

1/0<->1/2

1/0<->1/3

1/1<->1/2

1/1<->1/3

1/2<->1/3GigabitEthernet0/0

GigabitEthernet0/1IDS-4250

SX

None

N/A

All

IDS-4250

XL

2 SX of the XL GigabitEthernet2/0

GigabitEthernet2/12/0<->2/1

GigabitEthernet0/0

GigabitEthernet0/1IDSM-2

—

port 7 and 8

GigabitEthernet0/7

GigabitEthernet0/80/7<->0/8

GigabitEthernet0/2

IPS-4240

—

4 onboard GE

GigabitEthernet0/0

GigabitEthernet0/1

GigabitEthernet0/2

GigabitEthernet0/30/0<->0/1

0/0<->0/2

0/0<->0/3

0/1<->0/2

0/1<->0/3

0/2<->0/3Management0/0

IPS-4255

—

4 onboard GE

GigabitEthernet0/0

GigabitEthernet0/1

GigabitEthernet0/2

GigabitEthernet0/30/0<->0/1

0/0<->0/2

0/0<->0/3

0/1<->0/2

0/1<->0/3

0/2<->0/3Management0/0

NM-CIDS

—

None

N/A

All

AIP-SSM-10

—

GigabitEthernet0/1

By security context

GigabitEthernet0/0

AIP-SSM-20

—

GigabitEthernet0/1

By security context

GigabitEthernet0/0

1 The 4FE card can be installed in either slot 1 or 2. S indicates the slot number, which can be either 1 or 2.

Your Network Topology

Before you deploy and configure your sensors, you should understand the following about your network:

•

The size and complexity of your network.

•

Connections between your network and other networks (and the Internet).

•

The amount and type of network traffic on your network.

This knowledge will help you determine how many sensors are required, the hardware configuration for each sensor (for example, the size and type of network interface cards), and how many managers are needed.

Supported Sensors

Table 1-2 lists the sensors (appliances and modules) that are supported by Cisco IPS 5.0.

Note

For instructions on how to obtain the most recent Cisco IPS software, see Obtaining Cisco IPS Software.

CautionInstalling the most recent software (version 5.0) on unsupported sensors may yield unpredictable results. We do not support software installed on unsupported platforms.

Table 1-2 Supported Sensors

IDS-4210

IDS-4210

IDS-4210-K9

IDS-4210-NFR—

—

—IDS-4215

IDS-4215-K9

IDS-4215-4FE-K91IDS-4FE-INT=

—IDS-4235

IDS-4235-K9

IDS-4FE-INT=

IDS-4250

IDS-4250-TX-K9

IDS-4250-SX-K9

IDS-4250-XL-K9IDS-4FE-INT=

IDS-4250-SX-INT=

IDS-XL-INT=

IDS-XL-INT=

—IPS-4240

IPS-4240-K9

—

IPS-4255

IPS-4255-K9

—

—

AIP-SSM-10

ASA-SSM-AIP-10-K9

—

AIP-SSM-20

ASA-SSM-AIP-20-K9

—

IDSM-2

WS-SVC-IDSM2-K9

—

NM-CIDS

NM-CIDS-K9

—

1 IDS-4215-4FE-K9 is the IDS-4215-K9 with the optional 4FE card (IDS-4FE-INT=) installed at the factory.

The following NRS and IDS appliance models are legacy models and are not supported in this document:

•

NRS-2E

•

NRS-2E-DM

•

NRS-2FE

•

NRS-2FE-DM

•

NRS-TR

•

NRS-TR-DM

•

NRS-SFDDI

•

NRS-SFDDI-DM

•

NRS-DFDDI

•

NRS-DFDDI-DM

•

IDS-4220-E

•

IDS-4220-TR

•

IDS-4230-FE

•

IDS-4230-SFDDI

•

IDS-4230-DFDDI

Note

WS-X6381, IDSM, is a legacy model and is not supported in this document.

Note

IDS-4210 requires a memory upgrade to support the most recent Cisco IPS software. For more information, see Upgrading the Memory.

Appliances

This section describes the Cisco 4200 series appliance, and contains the following topics:

•

Connecting an Appliance to a Terminal Server

Introducing the Appliance

The appliance is a high-performance, plug-and-play device. The appliance is a component of the IPS, a network-based, real-time intrusion prevention system. For a list of supported appliances see Supported Sensors.

You can use the CLI, IDM, or ASDM to configure the appliance. For the list of IPS documents and how to access them, refer to Documentation Roadmap for Cisco Intrusion Prevention System 5.0.

You can configure the appliance to respond to recognized signatures as it captures and analyzes network traffic. These responses include logging the event, forwarding the event to the manager, performing a TCP reset, generating an IP log, capturing the alert trigger packet, and reconfiguring a router. The appliance offer significant protection to your network by helping to detect, classify, and stop threats including worms, spyware and adware, network viruses, and application abuse.

After being installed at key points in the network, the appliance monitors and performs real-time analysis of network traffic by looking for anomalies and misuse based on an extensive, embedded signature library. When the system detects unauthorized activity, appliances can terminate the specific connection, permanently block the attacking host, log the incident, and send an alert to the manager. Other legitimate connections continue to operate independently without interruption.

Appliances are optimized for specific data rates and are packaged in Ethernet, Fast Ethernet, and Gigabit Ethernet configurations. In switched environments, appliances must be connected SPAN port or VACL capture port of the switch.

The Cisco IPS 4200 series appliances provide the following:

•

Protection of multiple network subnets through the use of up to eight interfaces

•

Simultaneous, dual operation in both promiscuous and inline modes

•

A wide array of performance options—from 80 Mbps to multiple gigabits

•

Embedded web-based management solutions packaged with the sensor

Appliance Restrictions

The following restrictions apply to using and operating the appliance:

•

The appliance is not a general purpose workstation.

•

Cisco Systems prohibits using the appliance for anything other than operating Cisco IPS.

•

Cisco Systems prohibits modifying or installing any hardware or software in the appliance that is not part of the normal operation of the Cisco IPS.

Connecting an Appliance to a Terminal Server

A terminal server is a router with multiple, low speed, asynchronous ports that are connected to other serial devices. You can use terminal servers to remotely manage network equipment, including appliances.

To set up a Cisco terminal server with RJ-45 or hydra cable assembly connections, follow these steps:

Step 1

Connect to a terminal server using one of the following methods:

•

For IDS-4215, IPS-4240, and IPS-4255:

–

For RJ-45 connections, connect a 180 rollover cable from the console port on the appliance to a port on the terminal server.

–

For hydra cable assemblies, connect a straight-through patch cable from the console port on the appliance to a port on the terminal server.

•

For all other appliances, connect the M.A.S.H. adapter (part number 29-4077-01) to COM1 on the appliance and:

–

For RJ-45 connections, connect a 180 rollover cable from the M.A.S.H. adapter to a port on the terminal server.

–

For hydra cable assemblies, connect a straight-through patch cable from the M.A.S.H. adapter to a port on the terminal server.

Step 2

Configure the line and port on the terminal server as follows:

a.

In enable mode, type the following configuration, where # is the line number of the port to be configured:

config tline #logintransport input allstopbits 1flowcontrol hardwarespeed 9600exitexitwr memb.

If you are configuring a terminal server for an IDS-4215, IPS-4240, or IPS-4255, go to Step 3.

Otherwise, for all other supported appliances, to direct all output to the terminal server, log in to the CLI and type the following commands:

sensor# configure terminalsensor(config)# display-serialOutput is directed to the serial port. Use the no display-serial command to redirect output to the keyboard and monitor.

Note

You can set up a terminal server and use the display-serial command to direct all output from the appliance to the serial port. This option lets you view system messages on a console connected to the serial port, even during the boot process. When you use this option, all output is directed to the serial port and any local keyboard and monitor connection is disabled. However, BIOS and POST messages are still displayed on the local keyboard and monitor.

Note

There are no keyboard or monitor ports on an IDS-4215, IPS-4240, or IPS-4255; therefore, the display-serial and no display-serial commands do not apply to those platforms.

Step 3

Be sure to properly close a terminal session to avoid unauthorized access to the appliance.

If a terminal session is not stopped properly, that is, if it does not receive an exit(0) signal from the application that initiated the session, the terminal session can remain open. When terminal sessions are not stopped properly, authentication is not performed on the next session that is opened on the serial port.

CautionAlways exit your session and return to a login prompt before terminating the application used to establish the connection.

CautionIf a connection is dropped or terminated by accident, you should reestablish the connection and exit normally to prevent unauthorized access to the appliance.

Modules

This section describes the modules, and contains the following topics:

Introducing AIP-SSM

The Cisco ASA Advanced Inspection and Prevention Security Services Module (AIP-SSM) is the IPS plug-in module in the Cisco ASA 5500 series adaptive security appliance (ASA). ASA software combines firewall, VPN concentrator, and intrusion detection and prevention software functionality into one software image.

There are two models of AIP-SSM: ASA-SSM-AIP-K9-10 and ASA-SSM-AIP-K9-20. ASA-SSM-AIP-K9-10 supports approximately 100 Mbps throughput and ASA-SSM-AIP-K9-20 supports approximately 200 Mbps. Only one module can populate the slot in ASA at a time.

AIP-SSM runs advanced IPS software that provides further security inspection either in inline mode or promiscuous mode. ASA diverts packets to the AIP-SSM just before the packet exits the egress interface (or before VPN encryption occurs, if configured) and after other firewall policies are applied. For example, packets that are blocked by an access list are not forwarded to AIP-SSM.

In promiscuous mode, the IPS receives packets over the GigabitEthernet interface, examines them for intrusive behavior, and generates alerts based on a positive result of the examination. In inline mode, there is the additional step of sending all packets, which did not result in an intrusion, back out the GigabitEthernet interface.

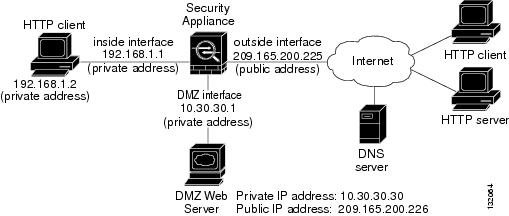

Figure 1-2 shows ASA with AIP-SSM in a typical DMZ configuration. A DMZ is a separate network located in the neutral zone between a private (inside) network and a public (outside) network. The web server is on the DMZ interface, and HTTP clients from both the inside and outside networks can access the web server securely.

In Figure 1-2 an HTTP client (10.10.10.10) on the inside network initiates HTTP communications with the DMZ web server (30.30.30.30). HTTP access to the DMZ web server is provided for all clients on the Internet; all other communications are denied. The network is configured to use an IP pool (a range of IP addresses available to the DMZ interface) of addresses between 30.30.30.50 and 30.30.30.60.

Figure 1-2 DMZ Configuration

For more information on setting up ASA, refer to the following URL:

http://www.cisco.com/en/US/products/ps6120/tsd_products_support_series_home.html

For more information on installing AIP-SSM, see Chapter 6 "Installing AIP-SSM." For more information on configuring AIP-SSM to receive IPS traffic, refer to Configuring AIP-SSM.

Introducing IDSM-2

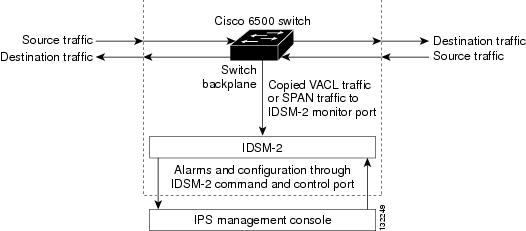

The Cisco Catalyst 6500 Series Intrusion Detection System Services Module (IDSM-2) is a switching module that performs intrusion prevention in the Catalyst 6500 series switch and 7600 series router. You can use the CLI or IDSM to configure IDSM-2. You can configure IDSM-2 for promiscuous or inline mode.

IDSM-2 performs network sensing—real-time monitoring of network packets through packet capture and analysis. IDSM-2 captures network packets and then reassembles and compares the packet data against attack signatures indicating typical intrusion activity. Network traffic is either copied to IDSM-2 based on security VACLs in the switch or is copied to IDSM-2 through the switch's SPAN port feature. These methods route user-specified traffic to IDSM-2 based on switch ports, VLANs, or traffic type to be inspected (see Figure 1-3).

Figure 1-3 IDSM-2 Block Diagram

IDSM-2 searches for patterns of misuse by examining either the data portion and/or the header portion of network packets. Content-based attacks contain potentially malicious data in the packet payload, whereas, context-based attacks contain potentially malicious data in the packet headers.

You can configure IDSM-2 to generate an alert when it detects potential attacks. Additionally, you can configure IDSM-2 to transmit TCP resets on the source VLAN, generate an IP log, and/or initiate blocking countermeasures on a firewall or other managed device. Alerts are generated by IDSM-2 through the Catalyst 6500 series switch backplane to the IPS manager, where they are logged or displayed on a graphical user interface.

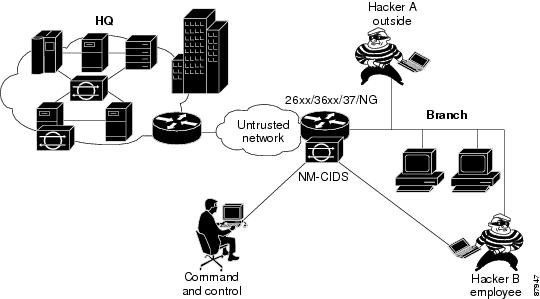

Introducing NM-CIDS

The Cisco Intrusion Detection System Network Module (NM-CIDS) integrates the Cisco IDS functionality into a branch office router. With NM-CIDS, you can implement full-featured IDS at your remote branch offices. You can install NM-CIDS in any one of the network module slots on the Cisco 2600, 3600, and 3700 series routers. NM-CIDS can monitor up to 45 Mbps of network traffic. See Software and Hardware Requirements for a list of supported routers. Only one NM-CIDS is supported per router. Figure 1-4 shows the router in a branch office environment.

Note

NM-CIDS operates in promiscuous mode (IDS mode) only.

Figure 1-4 NM-CIDS in the Branch Office Router

NM-CIDS has one internal 10/100 Ethernet port that connects to the router's backplane. There is also one external 10/100-based Ethernet port that is used for device management (management of other routers and/or PIX Firewalls to perform blocking) and command and control of NM-CIDS by IDS managers.

NM-CIDS communicates with the router to exchange control and state information for bringing up and shutting down NM-CIDS and to exchange version and status information. NM-CIDS processes packets that are forwarded from selected interfaces on the router to the IDS interface on NM-CIDS. NM-CIDS analyzes the captured packets and compares them against a rule set of typical intrusion activity called signatures. If the captured packets match a defined intrusion pattern in the signatures, NM-CIDS can take one of two actions: it can make ACL changes on the router to block the attack, or it can send a TCP reset packet to the sender to stop the TCP session that is causing the attack.

In addition to analyzing captured packets to identify malicious activity, NM-CIDS can also perform IP session logging that can be configured as a response action on a per-signature basis. When the signature fires, session logs are created over a specified time period in a tcpdump format. You can view these logs using Ethereal or replay the IP session using tools such as TCP Replay.

You can manage and retrieve events from NM-CIDS through the CLI or IDM.

The IDS requires a reliable time source. All the events (alerts) must have the correct time stamp, otherwise, you cannot correctly analyze the logs after an attack. You cannot manually set the time on NM-CIDS. NM-CIDS gets its time from the Cisco router in which it is installed. Routers do not have a battery so they cannot preserve a time setting when they are powered off. You must set the router's clock each time you power up or reset the router, or you can configure the router to use NTP time synchronization. We recommend NTP time synchronization. You can configure either NM-CIDS itself or the router it is installed in to use NTP time synchronization. For more information, see Time Sources and the Sensor.

Time Sources and the Sensor

This section explains the importance of having a reliable time source for the sensors and how to correct the time if there is an error. It contains the following topics:

•

Understanding Time on the Sensor

•

Correcting the Time on the Sensor

Understanding Time on the Sensor

The sensor requires a reliable time source. All events (alerts) must have the correct UTC and local time stamp, otherwise, you cannot correctly analyze the logs after an attack. When you initialize the sensor, you set up the time zones and summertime settings. for more information, see Initializing the Sensor.

Here is a summary of ways to set the time on sensors:

•

For appliances

–

Use the clock set command to set the time. This is the default.

For the procedure, refer to Manually Setting the Clock.

–

Use NTP

You can configure the appliance to get its time from an NTP time synchronization source. For the procedure, refer to Configuring a Cisco Router to be an NTP Server. You will need the NTP server IP address, the NTP key ID, and the NTP key value. You can set up NTP on the appliance during initialization or you can configure NTP through the CLI, IDM, or ASDM.

Note

We recommend that you use an NTP time synchronization source.

•

For IDSM-2

–

IDSM-2 can automatically synchronize its clock with the switch time. This is the default.

Note

The UTC time is synchronized between the switch and IDSM-2. The time zone and summertime settings are not synchronized between the switch and IDSM-2.

CautionBe sure to set the time zone and summertime settings on both the switch and IDSM-2 to ensure that the UTC time settings are correct. The local time of IDSM-2 could be incorrect if the time zone and/or summertime settings do not match between IDSM-2 and the switch.

–

Use NTP

You can configure IDSM-2 to get its time from an NTP time synchronization source. For the procedure, refer to Configuring a Cisco Router to be an NTP Server. You will need the NTP server IP address, the NTP key ID, and the NTP key value. You can configure IDSM-2 to use NTP during initialization or you can set up NTP through the CLI, IDM, or ASDM.

Note

We recommend that you use an NTP time synchronization source.

•

For NM-CIDS

–

NM-CIDS can automatically synchronize its clock with the clock in the router chassis in which it is installed (parent router). This is the default.

Note

The UTC time is synchronized between the parent router and NM-CIDS. The time zone and summertime settings are not synchronized between the parent router and NM-CIDS.

CautionBe sure to set the time zone and summertime settings on both the parent router and NM-CIDS to ensure that the UTC time settings are correct. The local time of NM-CIDS could be incorrect if the time zone and/or summertime settings do not match between NM-CIDS and the router.

–

Use NTP

You can configure NM-CIDS to get its time from an NTP time synchronization source, such as a Cisco router other than the parent router. For the procedure, refer to Configuring a Cisco Router to be an NTP Server. You will need the NTP server IP address, the NTP key ID, and the NTP key value. You can configure NM-CIDS to use NTP during initialization or you can set up NTP through the CLI, IDM, or ASDM.

Note

We recommend that you use an NTP time synchronization source.

•

For AIP-SSM:

–

AIP-SSM can automatically synchronize its clock with the clock in the ASA in which it is installed. This is the default.

Note

The UTC time is synchronized between ASA and AIP-SSM. The time zone and summertime settings are not synchronized between ASA and AIP-SSM.

CautionBe sure to set the time zone and summertime settings on both ASA and AIP-SSM to ensure that the UTC time settings are correct. The local time of AIP-SSM could be incorrect if the time zone and/or summertime settings do not match between AIP-SSM and ASA.

–

Use NTP

You can configure AIP-SSM to get its time from an NTP time synchronization source, such as a Cisco router other than the parent router. For the procedure, refer to Configuring a Cisco Router to be an NTP Server. You will need the NTP server IP address, the NTP key ID, and the NTP key value. You can configure AIP-SSM to use NTP during initialization or you can set up NTP through the CLI, IDM, or ASDM.

Note

We recommend that you use an NTP time synchronization source.

Correcting the Time on the Sensor

If you set the time incorrectly, your stored events will have the incorrect time because they are stamped with the time the event was created.

The Event Store time stamp is always based on UTC time. If during the original sensor setup, you set the time incorrectly by specifying 8:00 p.m. rather than 8:00 a.m., when you do correct the error, the corrected time will be set backwards. New events might have times older than old events.

For example, if during the initial setup, you configure the sensor as central time with daylight saving time enabled and the local time is 8:04 p.m., the time is displayed as 20:04:37 CDT and has an offset from UTC of -5 hours (01:04:37 UTC, the next day). A week later at 9:00 a.m., you discover the error: the clock shows 21:00:23 CDT. You then change the time to 9:00 a.m. and now the clock shows 09:01:33 CDT. Because the offset from UTC has not changed, it requires that the UTC time now be 14:01:33 UTC, which creates the time stamp problem.

To ensure the integrity of the time stamp on the event records, you must clear the event archive of the older events by using the clear events command. For more information on the clear events command, refer to Clearing Events from the Event Store.

CautionYou cannot remove individual events.

Installation Preparation

To prepare for installing sensors, follow these steps:

Step 1

Review the safety precautions outlined in Regulatory Compliance and Safety Information for the Cisco Intrusion Prevention System 4200 Series Appliance Sensor.

Step 2

To familiarize yourself with the IPS and related documentation and where to find it on Cisco.com, read Documentation Roadmap for Cisco Intrusion Prevention System 5.0.

Step 3

Obtain the Release Notes for Cisco Intrusion Prevention System 5.0 from Cisco.com and completely read them before proceeding with the installation.

Step 4

Unpack the sensor.

Step 5

Place the sensor in an ESD-controlled environment.

For more information, see Site and Safety Guidelines.

Step 6

Place the sensor on a stable work surface.

Step 7

Refer to the chapter that pertains to your sensor model.

Site and Safety Guidelines

This section describes site guidelines and safety precautions to take when working with electricity, with power supplies, and in an ESD environment. It contains the following topics:

•

Rack Configuration Guidelines

•

Working in an ESD Environment

Site Guidelines

Place the appliance on a desktop or mount it in a rack. The location of the appliance and the layout of the equipment rack or wiring room are extremely important for proper system operation. Equipment placed too close together, inadequate ventilation, and inaccessible panels can cause system malfunctions and shutdowns, and can make appliance maintenance difficult.

When planning the site layout and equipment locations, keep in mind the following precautions to help avoid equipment failures and reduce the possibility of environmentally-caused shutdowns. If you are experiencing shutdowns or unusually high errors with your existing equipment, these precautions may help you isolate the cause of failures and prevent future problems.

•

Electrical equipment generates heat. Ambient air temperature might not be adequate to cool equipment to acceptable operating temperatures without adequate circulation. Make sure that the room in which you operate your system has adequate air circulation.

•

Always follow the ESD-prevention procedures to avoid damage to equipment. Damage from static discharge can cause immediate or intermittent equipment failure.

•

Make sure that the chassis top panel is secure. The chassis is designed to allow cooling air to flow effectively within it. An open chassis allows air leaks, which can interrupt and redirect the flow of cooling air from the internal components.

Rack Configuration Guidelines

Follow these guidelines to plan your equipment rack configuration:

•

Enclosed racks must have adequate ventilation. Make sure the rack is not overly congested because each chassis generates heat. An enclosed rack should have louvered sides and a fan to provide cooling air.

•

When mounting a chassis in an open rack, make sure the rack frame does not block the intake or exhaust ports. If the chassis is installed on slides, check the position of the chassis when it is seated all the way into the rack.

•

In an enclosed rack with a ventilation fan in the top, excessive heat generated by equipment near the bottom of the rack can be drawn upward and into the intake ports of the equipment above it in the rack. Make sure you provide adequate ventilation for equipment at the bottom of the rack.

•

Baffles can help to isolate exhaust air from intake air, which also helps to draw cooling air through the chassis. The best placement of the baffles depends on the airflow patterns in the rack. Experiment with different arrangements to position the baffles effectively.

Electrical Safety Guidelines

WarningBefore working on a chassis or working near power supplies, unplug the power cord on AC units.

Follow these guidelines when working on equipment powered by electricity:

•

Before beginning procedures that require access to the interior of the chassis, locate the emergency power-off switch for the room in which you are working. Then, if an electrical accident occurs, you can act quickly to turn off the power.

•

Do not work alone if potentially hazardous conditions exist anywhere in your work space.

•

Never assume that power is disconnected from a circuit; always check the circuit.

•

Look carefully for possible hazards in your work area, such as moist floors, ungrounded power extension cables, frayed power cords, and missing safety grounds.

•

If an electrical accident occurs, proceed as follows:

–

Use caution; do not become a victim yourself.

–

Disconnect power from the system.

–

If possible, send another person to get medical aid. Otherwise, assess the condition of the victim and then call for help.

–

Determine if the person needs rescue breathing or external cardiac compressions; then take appropriate action.

•

Use the chassis within its marked electrical ratings and product usage instructions.

•

Install the sensor in compliance with local and national electrical codes as listed in Regulatory Compliance and Safety Information for the Cisco Intrusion Prevention System 4200 Series Appliance Sensor.

•

The sensor models equipped with AC-input power supplies are shipped with a 3-wire electrical cord with a grounding-type plug that fits only a grounding-type power outlet. This is a safety feature that you should not circumvent. Equipment grounding should comply with local and national electrical codes.

Power Supply Guidelines

Follow these guidelines for power supplies:

•

Check the power at the site before installing the chassis to ensure that the power is free of spikes and noise. Install a power conditioner if necessary, to ensure proper voltages and power levels in the source voltage.

•

Install proper grounding for the site to avoid damage from lightning and power surges.

•

The following applies to a chassis equipped with an AC-input power supply:

–

The chassis does not have a user-selectable operating range. Refer to the label on the chassis for the correct AC-input power requirement.

–

Several types of AC-input power supply cords are available; make sure you have the correct type for your site.

–

Install a UPS for your site.

–

Install proper site-grounding facilities to guard against damage from lightning or power surges.

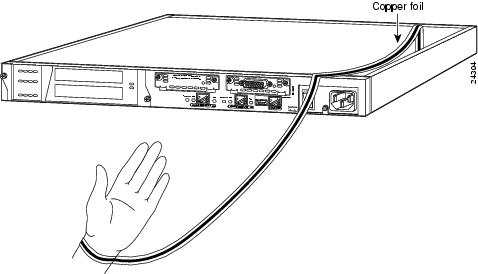

Working in an ESD Environment

Work on ESD-sensitive parts only at an approved static-safe station on a grounded static dissipative work surface, for example, an ESD workbench or static dissipative mat.

To remove and replace components in a sensor, follow these steps:

Step 1

Remove all static-generating items from your work area.

Step 2

Use a static dissipative work surface and wrist strap.

Note

Disposable wrist straps, typically those included with an upgrade part, are designed for one time use.

Step 3

Attach the wrist strap to your wrist and to the terminal on the work surface. If you are using a disposable wrist strap, connect the wrist strap directly to an unpainted metal surface of the chassis.

Step 4

Connect the work surface to the chassis using a grounding cable and alligator clip.

CautionAlways follow ESD-prevention procedures when removing, replacing, or repairing components.

Note

If you are upgrading a component, do not remove the component from the ESD packaging until you are ready to install it.

Cable Pinouts

This section describes pinout information for 10/100/1000BaseT, console, and RJ 45 to DB 9 ports, and the MGMT 10/100 Ethernet port. This section contains the following topics:

•

10/100Base-TX and 10/100/1000Base-TX Connectors

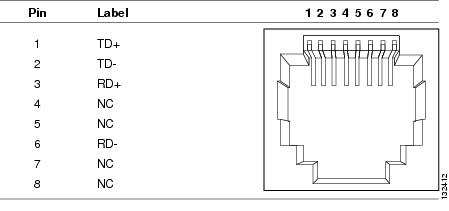

10/100Base-TX and 10/100/1000Base-TX Connectors

Sensors support 10/100/1000Base-TX ports. You must use at least a Category 5 cable for 100/1000Base-TX operations. You can use a Category 3 cable for 10Base-TX operations.

Note

Some sensors support 10/100Base-TX (IDS-4210, IDS-4215, and the optional 4FE card) while others support 10/100/1000Base-TX (IDS-4235, IDS-4250-TX, IPS-4240, and IPS-4255). This only applies to the copper appliances. The fiber appliances support 1000Base-SX only.

The 10/100/1000Base-TX ports use standard RJ-45 connectors and support MDI and MDI-X connectors. Ethernet ports normally use MDI connectors and Ethernet ports on a hub normally use MDI-X connectors.

An Ethernet straight-through cable is used to connect an MDI to an MDI-X port. A cross-over cable is used to connect an MDI to an MDI port, or an MDI-X to an MDI-X port.

Figure 1-5 shows the 10/100Base-TX (RJ-45) port pinouts.

Figure 1-5 10/100 Port Pinouts

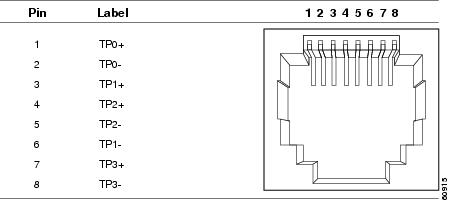

Figure 1-6 shows the 10/100/1000BASE-TX (RJ-45) port pinouts.

Figure 1-6 10/100/1000 Port Pinouts

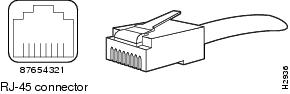

Console Port (RJ-45)

Cisco products use the following types of RJ-45 cables:

•

Straight-through

•

Cross-over

•

Rolled (console)

Note

Cisco typically provides a rolled RJ-45 cable with hardware for console use. The IPS appliances are shipped with the rolled (console) cable and one or more straight-through cables for sensing ports.

Figure 1-7 shows the RJ 45 cable.

Figure 1-7 RJ-45 Cable

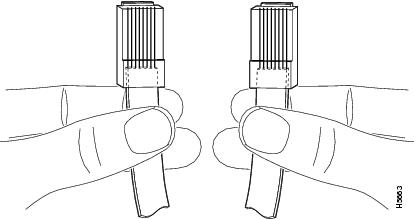

To identify the RJ-45 cable type, hold the two ends of the cable next to each other so that you can see the colored wires inside the ends, as shown in Figure 1-8.

Figure 1-8 RJ-45 Cable Identification

Examine the sequence of colored wires to determine the type of RJ-45 cable, as follows:

•

Straight-through—The colored wires are in the same sequence at both ends of the cable.

•

Cross-over—The first (far left) colored wire at one end of the cable is the third colored wire at the other end of the cable.

•

Rolled—The colored wires are in the opposite sequence at either end of the cable.

RJ-45 to DB-9 or DB-25

Table 1-3 lists the cable pinouts for RJ-45 to DB-9 or DB-25.

Table 1-3 Cable Pinouts for RJ-45 to DB-9 or DB-25

RTS

8

8

DTR

7

6

TxD

6

2

GND

5

5

GND

4

5

RxD

3

3

DSR

2

4

CTS

1

7

Feedback

Feedback