Catalyst 4500 E-Series Installation Guide

Bias-Free Language

The documentation set for this product strives to use bias-free language. For the purposes of this documentation set, bias-free is defined as language that does not imply discrimination based on age, disability, gender, racial identity, ethnic identity, sexual orientation, socioeconomic status, and intersectionality. Exceptions may be present in the documentation due to language that is hardcoded in the user interfaces of the product software, language used based on RFP documentation, or language that is used by a referenced third-party product. Learn more about how Cisco is using Inclusive Language.

- Updated:

- March 14, 2013

Chapter: Removing and Replacing FRUs

Removal and Replacement Procedures

This chapter provides removal and replacement procedures for the following Catalyst 4500-E series field-replaceable units (FRUs):

- Removing and Installing the AC-Input Power Supplies

- Removing and Installing the DC-Input Power Supplies

- Removing and Installing the Chassis Fan Tray Assembly

- Removing and Installing the Backplane Modules

- Installing the Remote Power Cycling Feature Control Wires (Optional)

Tip For additional information about the Cisco Catalyst 4500 E-series switches (including configuration examples and troubleshooting information), see the documents listed on this page:

http://www.cisco.com/en/US/products/hw/switches/ps4324/index.html

Warning Read the installation instructions before connecting the system to the power source. Statement 1004

Warning Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

Warning This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority or an electrician if you are uncertain that suitable grounding is available. Statement 1024

Warning Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces, and watches). Metal objects will heat up when connected to power and ground and can cause serious burns or weld the metal object to the terminals. Statement 43

Warning Ultimate disposal of this product should be handled according to all national laws and regulations. Statement 1040

For procedures to remove and replace switching modules, see the Catalyst 4500 Series Module Installation Guide .

For procedures to remove and replace supervisor engines see Supervisor Engine Notes .

Removing and Installing the AC-Input Power Supplies

This section describes how to remove and install the AC-input power supplies for the Catalyst 4500-E series switches. The section is contains the following topics:

Warning Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

Figure 4-1 shows a single-input AC-input power supply, Figure 4-2 shows a dual-input AC-input power supply, and Figure 4-3Figure 4-3 shows a triple-input AC-input power supply.

Note The power supplies are hot-swappable, so in redundant mode, you will not need to power down the switch to replace or upgrade most power supplies. With dual power supplies running in combined mode, some chassis slots may lose power during an upgrade or power supply replacement.

Figure 4-1 AC-Input Power Supply (Single-Input)

Figure 4-2 Dual-Input AC-Input Power Supply (4200 W and 6000 W)

Figure 4-3 Triple-Input AC-Input Power Supply (9000 W)

Removing an AC-Input Power Supply

To remove the AC-input power supply, follow these steps:

Step 1 Set the AC-input power supply power switch to the off (0) position (see Figure 4-4).

Figure 4-4 Powering Off the Power Switch (Single-Input Power Supply Shown)

Note There are two on/off switches on the 4200 W and the 6000 W AC-input power supplies and three on/off switches on the 9000 W AC-input power supply. Each switch controls one of the source AC inputs.

Step 2 Loosen the side-clamp screw on the power cord plug (see Figure 4-5).

Figure 4-5 Loosening the Side-Clamp Screw (Single-Input Power Supply Shown)

Step 3 Disconnect the power cord appliance plug from the AC-in receptacle.

Step 4 Loosen the two captive screws on the power supply (see Figure 4-6).

Figure 4-6 Loosening the Captive Screws

Step 5 Grasp the power supply handle with one hand. Place your other hand underneath to support the bottom of the power supply, as shown in Figure 4-7.

Figure 4-7 Handling an AC-Input Power Supply

Step 6 Slide the power supply out of the bay and set it aside.

Step 7 If the power supply bay is to remain empty, install a blank power supply cover (WS-C4K-PS-CVR) over the opening. Secure the blank power supply cover with the two mounting screws.

Warning Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

Installing an AC-Input Power Supply

Warning The plug-socket combination must be accessible at all times, because it serves as the main disconnecting device. Statement 1019

To install an AC-input power supply, follow these steps:

Step 1 Remove the replacement power supply from its shipping packaging.

Step 2 Verify that the replacement power supply power switch is in the off (0) position.

Step 3 If necessary, remove the blank power supply cover from the empty power supply bay by removing the two Phillips-head screws. Save the blank faceplate and the two screws for future use.

Step 4 Grasp the power supply handle with one hand and place your other hand underneath to support the bottom of the power supply, as shown in Figure 4-7, and slide the power supply all the way into the power supply bay. Make sure that the power supply is fully seated in the bay.

Step 5 Tighten the two captive installation screws (see Figure 4-1) on the front panel of the AC-input power supply.

Step 6 Before you connect the power supply to a power source, verify that all site power and grounding requirements have been met.

Step 7 Verify that you have the correct AC power cord for your location and power supply rating. See Appendix A, “Power Supply Specifications,” for a list of supported AC power cords for your particular AC-input power supply.

Step 8 Plug the power cord appliance connector into the power supply AC-in receptacle (see Figure 4-8) and tighten the screw on the power cord retention clip.

Figure 4-8 Plugging the Power Cord into the Power Supply (Single-Input Power Supply Shown)

Step 9 Plug the other end of the power cord to source AC.

Note In a chassis with dual power supplies or power supplies with multiple AC inputs, it is recommended that you connect each AC power cord to a separate source AC circuit.

Step 10 Set the power switch to the on (|) position (see Figure 4-9).

Figure 4-9 Powering On the Power Supply (Single-Input Power Supply Shown)

Step 11 Verify the power supply operation by checking the power supply’s front-panel LEDs. You should see the following:

- The LED labeled GOOD or INPUT OK is green.

- The LED labeled OUTPUT FAIL is not lit.

- The LED labeled FAN OK is green.

Step 12 Check the power supply and system status from the system console by entering show power command. For more information on this command, see the command reference publication for your switch.

Step 13 If the LEDs or show power command output indicate a power problem or other system problem, see “Troubleshooting,” for more information.

Removing and Installing the DC-Input Power Supplies

This section describes how to remove and install the DC-input power supplies and contains the following topics:

Removing a DC-Input Power Supply

Warning Before performing any of the following procedures, ensure that power is removed from the DC circuit. Statement 1003

To remove a DC-input power supply, follow these steps:

Step 1 Turn off the in-line power switch on the DC-input power supply front panel. (This step applies to the single input power supply only, PWR-C45-1400DC-P; the triple-input power supply, PWR-C45-1400DC, does not have this switch.)

Step 2 Verify that power is off to the DC circuit on the power supply that you are removing. As an added precaution, place the appropriate safety flag and lockout devices at the source power circuit breaker, or place a piece of adhesive tape over the circuit breaker handle to prevent accidental power restoration while you are working on the circuit.

Step 3 Loosen the screw on the terminal block cover, remove the cover from the terminal block, and set it aside (see Figure 4-10 or Figure 4-11).

Note The triple-input power supply has two screws securing the terminal block cover.

Figure 4-10 DC-Input Power Supply

Figure 4-11 DC Triple-Input Power Supply

Step 4 Disconnect the DC-input wires from the terminal block. Disconnect the ground wire last (see Figure 4-12 or Figure 4-13).

Warning When installing or replacing the unit, the ground connection must always be made first and disconnected last. Statement 1046

Figure 4-12 Connecting the DC-Input Wires

Figure 4-13 Connecting the DC-Input Wires (Triple-Input Power Supply)

Step 5 Loosen the two captive screws on the power supply. (See Figure 4-14, which shows the single-input power supply. The triple-input power supply has captive screws in the same location.)

Figure 4-14 Loosening the Captive Screws

Step 6 Grasp the power supply handle with one hand. Place your other hand underneath as you slowly pull the power supply out of the chassis power supply bay (see Figure 4-15).

Figure 4-15 Handling a DC-Input Power Supply

Step 7 If the chassis power supply bay is to remain empty, install a blank power supply filler plate (WS-C4KE-PS-CVR) over the opening and secure it with the mounting screws. The blank power supply filler plate protects the inner chassis from dust and prevents accidental contact with the live voltage at the rear of the bay.

Warning Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

Installing a DC-Input Power Supply

Warning Before performing any of the following procedures, ensure that power is removed from the DC circuit. Statement 1003

Warning A readily accessible two-poled disconnect device must be incorporated in the fixed wiring. Statement 1022

Warning This product requires short-circuit (overcurrent) protection, to be provided as part of the building installation. Install only in accordance with national and local wiring regulations. Statement 1045

Warning Use copper conductors only. Statement 1025

Warning When stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type with upturned lugs. These terminations should be the appropriate size for the wires and should clamp both the insulation and conductor. Statement 1002

To install a DC-input power supply, follow these steps:

Step 1 Verify that power is off to the DC circuit on the power supply that you are removing. As an added precaution, place the appropriate safety flag and lockout devices at the source power circuit breaker, or place a piece of adhesive tape over the circuit breaker handle to prevent accidental power restoration while you are working on the circuit.

Step 2 Grasp the power supply handle with one hand. Place your other hand underneath it as you slowly insert the power supply into the bay (see Figure 4-15). Make sure that the power supply is fully seated in the bay.

Step 3 Tighten the captive screws on the power supply (see Figure 4-14).

Step 4 Before you connect the power supply to a power source, ensure that all site power and grounding requirements have been met.

Step 5 Remove the terminal block cover from the terminal block.

Step 6 Connect the source DC cables to the power supply terminal block. The proper wiring sequence is ground to ground, positive to positive, and negative to negative (see Figure 4-12 or Figure 4-13 depending on your installation).

The 1400W triple-input power supply has two grounding posts; use the one that is most convenient for your installation.

Warning When installing or replacing the unit, the ground connection must always be made first and disconnected last. Statement 1046

Step 7 After ensuring that all wire connections are secure, reinstall the terminal block cover.

Step 8 Remove any safety flag and lockout devices or any tape from the source DC circuit breaker switch handle and restore power by moving the circuit breaker switch handle to the on (|) position.

Step 9 Turn the power supply power switch to the on (|) position.

Step 10 Verify power supply operation by checking the power supply’s front-panel LEDs. You should see the following:

Step 11 Check the power supply and system status from the system console by entering the show power command. For more information on the commands, see the command reference publication for your switch and software.

Step 12 If the LEDs or the show power command (Cisco IOS) output indicate a power problem or other system problem, see “Troubleshooting,” for more information.

Removing and Installing the Chassis Fan Tray Assembly

This section describes how to remove and install the chassis fan tray assembly for the Catalyst 4500 E-series switches and is contains the following topics:

Figure 4-16 illustrates the Catalyst 4506-E system fan tray assembly. The fan tray assemblies for the other chassis attach in a very similar way.

Removing the Fan Tray Assembly

Warning When removing the fan tray, keep your hands and fingers away from the spinning fan blades. Let the fan blades completely stop before you remove the fan tray. Statement 258

To remove the existing fan tray assembly, follow these steps:

Step 1 Loosen the two captive installation screws on the fan tray assembly.

Figure 4-16 Catalyst 4506-E System Fan Tray Assembly

Step 2 Grasp the fan tray assembly handle and slide the fan tray assembly out of the chassis; gently move it side to side if necessary to unseat it from the backplane. Remove the fan tray assembly from the chassis and set it aside.

Installing the Fan Tray Assembly

To install the replacement fan tray assembly, follow these steps:

Step 1 Remove the replacement fan tray assembly from the shipping packaging.

Step 2 Hold the fan tray assembly with the fans facing to the right.

Step 3 Place the fan tray assembly into the fan tray assembly bay so it rests on the chassis, and then lift the fan tray assembly up slightly, aligning the top and bottom guides.

Step 4 Slide the fan tray assembly into the chassis until the two captive installation screws make contact with the chassis.

Step 5 Tighten the two captive installation screws to secure the fan tray assembly in the chassis.

Verifying the Installation

Note To check the operation of the fans, you need to power up the chassis.

To verify that the new fan tray assembly is installed correctly and is operating properly, follow these steps:

Step 1 Listen for the fans; you should immediately hear them operating. If you do not hear them, ensure that the fan tray assembly is inserted completely in the chassis and that the faceplate is flush with the switch back panel.

Step 2 The fan tray assembly LED should light and be green.

Step 3 If after several attempts the fans do not operate, or if you experience trouble with the installation (for instance, if the captive installation screws do not align with the chassis holes), contact the Cisco TAC for assistance.

Removing and Installing the Backplane Modules

There are five redundancy modules (also called mux buffers) and one clock module on the Catalyst 4507R-E and the Catalyst 4507R+E switch chassis backplane. The Catalyst 4510R-E and the Catalyst 4510R+E have eight redundancy modules on their backplane. They are accessible from the front of the chassis by removing all of the supervisor engines, switching modules, and blank slot covers. There are two types of redundancy modules, and they are interchangeable.

The clock module replacement procedure is identical to the redundancy module replacement procedure. Both the redundancy modules and the clock modules are not hot-swappable; the switch must be shut down to replace them.

To replace the backplane modules, follow these steps:

Step 1 Make sure that you are grounded with an ESD strap.

Step 2 Turn off the power to the chassis.

Step 3 Make a record of all network interface cable connections to the switch. Also, make a record of the switching modules and their slot assignments. This step will aid you when you return the system to operation after the removal and replacement procedure is completed.

Step 4 Disconnect all of the network interface cables to the switch and carefully set them aside.

Step 5 Remove all supervisor engines and switching modules from the chassis and carefully place each one in a separate antistatic bag or on an individual antistatic mat.

Note Generic switching module replacement procedures are documented at

http://www.cisco.com/en/US/docs/switches/lan/catalyst4500/hardware/configuration/notes/gMdCf_nt.html

Step 6 Locate the backplane modules that you need to replace. Figure 4-17 shows a front view of the backplane with the supervisor engines and switching modules removed.

Figure 4-17 Catalyst 4507R-E Backplane

Step 7 If you are removing a clock module, remove the two screws that secure the clock module to the backplane.

Step 8 Locate the seating levers on both sides of the connector for the module that you want to replace. (See Figure 4-18.)

Figure 4-18 Finding the Seating Levers

Step 9 To release the module from its connector, pull the levers outward with your fingernails. The module will pop out slightly. (See Figure 4-19.)

Figure 4-19 Releasing the Module

Step 10 Pull the module out of the connector by grasping the top left and right corners. (See Figure 4-20.) Place the old module in an antistatic bag or on an antistatic foam pad.

Note When handling the modules, do not touch the chips or the gold edge contacts on the module.

Figure 4-20 Removing the Module

Step 11 Remove the replacement module from its packaging. Be careful not to touch the chips or the gold edge contacts on the module.

Step 12 Carefully position the replacement module in the socket, and gently push the module down to seat it in the socket. Make sure that you apply force evenly on both the left and right side of the module. (See Figure 4-21.)

Figure 4-21 Seating the Replacement Module

Step 13 Make sure that the module is fully seated and that it is clipped in by the levers on both sides. (See Figure 4-22.)

Figure 4-22 Correct Module Seating

Step 14 Repeat Step 6 through Step 13 for any other modules that you need to replace.

Step 15 If you are installing a clock module, secure the module to the backplane using the two screws from the earlier removal.

Step 16 Reinstall the supervisor engines and the switching modules in their previous slots.

Step 17 Reconnect all of the network interface cables to the switching modules.

Step 18 Restore power to the switch.

Verifying the New Modules

After the switch is reassembled and power is restored, connect a terminal to the supervisor engine and monitor the boot process. Look for the following messages (or any others), which may indicate a problem with the replaced modules:

The above messages (either at startup or output from a show logging command) indicate that the mux-buffer is not present in slots 3, 4 and 7. You need to reinsert and reseat the modules in those slots.

If the switch has already started up, you may also verify the correct function of the new modules with the show logging command.

Installing the Remote Power Cycling Feature Control Wires (Optional)

The remote power cycling feature allows you to power down and power up a switch chassis through the network rather than being physically present to turn the power supply power switch off and on. The remote power cycling feature is only available on the 6000 W and the 9000 W AC-input power supplies.

Several vendors make remote power cycling relay controller boxes that can be used to power cycle the Catalyst 4500 E-series switch chassis. Most of these relay controller boxes have the capability of controlling multiple power supplies. The relay controller boxes have a network interface that allows the user to remotely access the relay controller box and toggle a built-in relay. The built-in relay can be either a normally open (NO) type or an RS-232 type of relay. We strongly recommend that you purchase a relay controller box that uses a NO relay. The relay controller box is installed near the switch chassis and is attached to the network. Two control wires extend from the relay controller box to a four-position terminal block located on the front panel of the 6000 W and 9000 W power supplies. A signal from the relay controller box travels through the control wires to toggle the power supply on or off.

This section only describes how to install the remote power cycling feature control wires; relay controller box installation instructions should be provided by the maker of the relay controller box.

Required Tools and Components

The following tools and components are required to perform this procedure:

We strongly recommend that you purchase a relay controller box that uses a NO (normally open) relay to control the remote power cycling.

Installing the Remote Power-Cycling Control Wires

To install the two control wires from the relay controller box to the 6000 W or the 9000 W power supply, follow these steps:

Step 1 Remove the relay controller box from its shipping packaging.

Step 2 Install the relay controller box following the installation documentation supplied with the product.

Step 3 Measure and cut two pieces of 18 AWG control wire long enough to run between the relay controller box terminals and the terminal block on the power supply.

Step 4 Strip approximately 1/4-inch of insulation from each end of both control wires.

Step 5 Connect the two control wires to the relay controller box terminals following the instruction documentation supplied with the relay controller box.

Step 6 Identify which pair of terminals on the power supply terminal block (either terminals +V and IN for a NO relay (recommended) or terminals IN and GND for an RS-232 relay) where you need to connect the control wires. Using a small flat-blade screwdriver, depress the wire release mechanism for one of the terminals on the power supply terminal block and insert the bare wire into the terminal. (See Figure 4-23.) Remove the screwdriver to secure the wire. Gently tug on the wire to verify that it is secure in the terminal block.

Step 7 Repeat Step 6 for the second control wire.

Figure 4-23 Installing the Relay Control Wires (6000 W Power Supply Shown)

You are now ready to install the ferrite bead on the control wires. Follow the installation instructions supplied in the package containing the ferrite bead or the installation procedure in the next section.

Installing the Ferrite Bead

The ferrite bead is a passive device that limits high-frequency interference on interface and control cables, and it is only required when you install the remote power-cycling feature. The ferrite bead is installed on the two control wires that link the external relay controller box with the remote power-cycling terminal block on the 6000 W or the 9000 W power supply.

To install the ferrite bead on the remote power-cycling control wires, follow these steps:

Step 1 Remove the ferrite bead and the two plastic ties from the plastic bag.

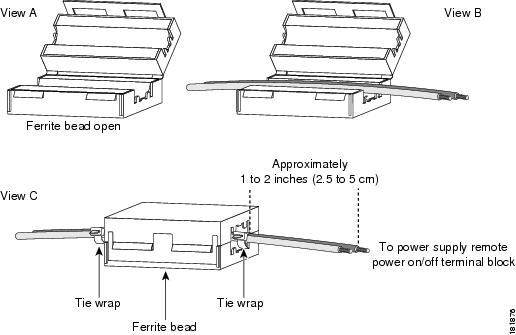

Step 2 Open the ferrite bead as shown in Figure 4-24, View A.

Step 3 Place the two remote power-cycling control wires (18 AWG maximum) in the ferrite bead as shown in Figure 4-24, View B. Close the ferrite bead making sure that the two halves have completely snapped together and are secure.

Step 4 Locate a point on the remote power-cycling control wires that leaves approximately 1 to 2 inches (2.5 to 5 cm) of exposed wire from the remote power cycling terminal block located on the front of the power supply. Wrap one of the 4-inch plastic ties around the remote power-cycling control wires at that point. Tighten the plastic tie so that it is snug against the control wires and cannot slide. See Figure 4-24, View C.

Step 5 Slide the ferrite bead so that it is positioned just behind the first plastic tie wrap. Take the second plastic tie and wrap it around the control wires directly behind the ferrite bead and tighten it so that the ferrite bead cannot slide up or down the control wires. See Figure 4-24, View C.

Step 6 To finish the procedure, trim the excess plastic strap from the two plastic tie wraps.

Figure 4-24 Installing the Ferrite Bead

Feedback

Feedback