Table Of Contents

S123 Switch Fabric Card (Single-Shelf System)

S123 Switch Fabric Card Components

S123 Switch Fabric Card Physical Characteristics

Switch Fabric

This chapter describes the Cisco CRS-1 Carrier Routing System 16-Slot Line Card Chassis switch fabric. It includes the following sections:

Switch Fabric Overview

The switch fabric is the core of the Cisco CRS-1 routing system. The switch fabric is implemented through switch fabric cards installed in the chassis. The switch fabric uses a cell-switched, buffered three-stage Benes switch fabric architecture. The switch fabric receives user data from a modular services card (MSC) and performs the switching necessary to route the data to the appropriate egress MSC.

The switch fabric is divided into eight planes (plane 0 to plane 7) that are used to evenly distribute traffic across the switch fabric. Each switch fabric plane is independent and not synchronized with one another. Each cell traverses the switch fabric using a single switch fabric plane. (Cells are not bit sliced across the switch fabric.)

Depending on whether the line card chassis is operating as a single-shelf (standalone) system or as part of a multishelf system, the chassis accepts different types of switch fabric cards. S123 switch fabric cards are used when the line card chassis operates as a single-shelf (standalone) system. Each S123 fabric card implements all three stages of the switch fabric.

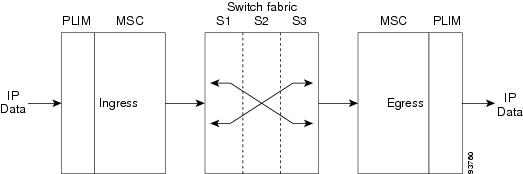

Figure 4-1 shows the basic path of IP data packets through the Cisco CRS-1 routing system switch fabric. Note that the figure shows a single-shelf system, in which all three stages of the switch fabric are provided by S123 fabric cards in the line card chassis. In a multishelf system, Stage 2 of the switch fabric is provided by S2 fabric cards in the fabric card chassis.

Figure 4-1 Basic Cisco CRS-1 Carrier Routing System Switch Fabric

Ingress data packets are received at a physical interface on a PLIM and transferred to the associated MSC, where the packets are segmented into cells for efficient switching by the switch fabric hardware. Each MSC has multiple connections to each switch fabric plane, which it uses to distribute cells to each fabric plane. On egress, cells are reassembled into data packets before being transmitted by the egress MSC.

Note

The cell structure used in the Cisco CRS-1 routing system switch fabric is a Cisco design and is not related to Asynchronous Transfer Mode (ATM) cells.

Switch Fabric Operation

Several switch element components on each switch fabric card perform the functions to implement each of the three stages (S1, S2, and S3) of the switch fabric. Each stage performs a different function:

•

Stage 1 (S1)—Distributes traffic to Stage 2 of the fabric plane. Stage 1 elements receive cells from the ingress MSC and PLIM (or RP) and distribute the cells to Stage 2 (S2) of the fabric plane. Cells are distributed to S2 elements in round-robin fashion; one cell goes to the first S2 element, the next cell goes to the next S2 element, the next cell goes to the third S2 element, and so on, and then back to the first S2 in sequence.

•

Stage 2 (S2)—Performs switching, provides 2 times (2x) speedup of cells, and performs the first stage of the multicast function. Stage 2 elements receive cells from Stage 1 and route them toward the appropriate:

–

Egress MSC and PLIM (single-shelf system)

–

Egress line card chassis (multishelf system)

•

Stage 3 (S3)—Performs switching, provides 2 times (2x) speedup of cells, and performs a second level of the multicast function. Stage 3 elements receive cells from Stage 2 and perform the switching necessary to route each cell to the appropriate egress MSC and PLIM.

Speedup Function

A line card chassis can contain up to 16 MSCs, each with 40 Gbps of bandwidth. To provide 40 Gbps of switching capacity for each MSC, the switch fabric must actually provide additional bandwidth to accommodate cell overhead, buffering, and congestion-avoidance mechanisms.

Congestion can occur in the switch fabric if multiple input data cells are being switched to the same destination egress MSC. Typically, little congestion exists between the S1 and S2 stages because there is little or no contention for individual links between the switch components. However, as multiple cells are switched from the S2 and S3 stages to the same egress MSC, cells might contend for the same output link.

To reduce the possibility of data cells being delayed during periods of congestion, the switch fabric uses 2 times (2x) speedup to reduce contention for S2 and S3 output links. The switch fabric achieves 2x speedup by providing two output links for every input link at the S2 and S3 stages.

S2 and S3 Buffering

Buffering is also used at the S2 and S3 stages of the switch fabric to alleviate any additional congestion that the switch fabric speedup does not accommodate. To ensure that this buffering does not cause cells to arrive out of sequence, the MSC resequences the cells before reassembling them into packets. To limit the amount of buffering required, a back-pressure mechanism is used for flow control (which slows the transmission of data cells to a congested destination). Back-pressure messages are carried in fabric cell headers.

Failure Operation

The routing system can withstand the loss of a single plane of the switch fabric with no impact on the system. The loss of multiple planes results in linear and graceful degradation of performance, but does not cause the routing system to fail.

Note

At least two planes of the switch fabric (an even plane and an odd plane) must be active at all times for the Cisco CRS-1 routing system to operate. Otherwise, the switch fabric fails, causing a system failure.

Switch Fabric Upgrade

You can upgrade the switch fabric to accommodate system growth or support for a newer version of the switch fabric. To avoid traffic loss, you must upgrade the switch fabric one plane at a time, which allows the system to continue operating with seven fabric planes. During the upgrade, some fabric planes may run in one configuration while others run in a different configuration.

To upgrade a fabric plane, first shut down the fabric plane and then remove the fabric card that implements that plane. Then, replace the original fabric card with the new fabric card and restore service to that fabric plane before upgrading the next plane.

For information about how to perform online insertion and removal (OIR) of switch fabric cards in a single-shelf system, see Cisco CRS-1 Carrier Routing System Getting Started Guide. For information about how to upgrade from a single-shelf system to a multishelf system, see Cisco CRS-1 Carrier Routing System Single-Shelf to Multishelf Upgrade Guide.

Switch Fabric Cards

The Cisco CRS-1 16-slot line card chassis (single-shelf) supports the S123 switch fabric card.

S123 Switch Fabric Card (Single-Shelf System)

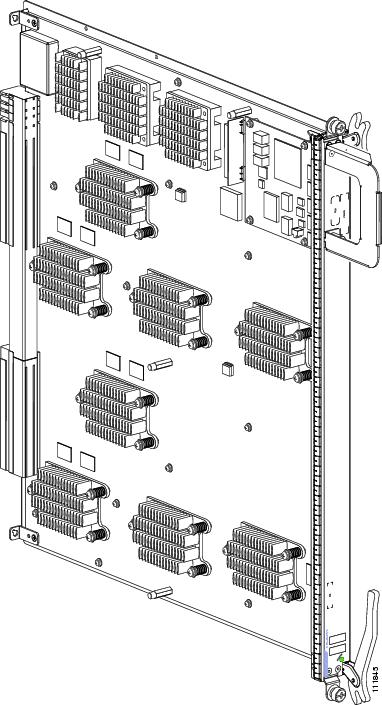

In a single-shelf (standalone) Cisco CRS-1 16-slot system, the S123 switch fabric card (CRS-16-FC/S) implements all three stages of the three-stage Benes switch fabric. Each card also implements one plane of the eight-plane switch fabric. Figure 4-2 shows the S123 switch fabric card.

Figure 4-2 S123 Switch Fabric Card

S123 Switch Fabric Card Components

The S123 switch fabric card contains the following major components:

•

S1 switch element—Implements Stage 1 of the switch fabric. Receives cells from the MSC (or RP) and distributes them to Stage 2. Each S1 switch element is connected to every S2 switch element.

•

S2 switch element—Implements Stage 2 of the switch fabric. Receives cells from Stage 1, performs 2x speedup, and routes the cells toward the appropriate egress S3 element. Each S2 switch element is connected to every S3 switch element.

•

S3 switch element—Implements Stage 3 of the switch fabric. Receives data cells from Stage 2 and performs switching and 2x speedup. The S2 and S3 switch elements are pure output-buffered switch elements with a central memory to buffer cells and queuing capabilities to distinguish between high-priority and low-priority traffic.

•

Service processor—Controls the operation of the fabric card and provides the interface to the system control plane. The service processor performs card power up and power down, performs link-up and link-down processing, configures switch element components, updates the fabric group ID (FGID) for multicast traffic, and maintains cell configuration.

•

Power modules—Take -48 VDC input power from the midplane and convert it to the voltages required by the components on the switch fabric card.

Figure 4-3 shows the major components of the S123 switch fabric card.

Figure 4-3 Block Diagram of the S123 Switch Fabric Card

Note

Each stage of the three-stage Benes switch fabric is implemented with the same switch element components. However, during system startup the components are programmed by Cisco IOS XR software to operate in S1, S2, or S3 mode, depending on their functions in the switch fabric. Each S123 switch fabric card contains two S1, two S2, and four S3 components.

S123 Switch Fabric Card Physical Characteristics

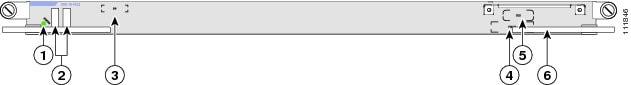

Figure 4-4 shows the front panel of the S123 switch fabric card.

Figure 4-4 S123 Switch Fabric Card Front Panel

The S123 switch fabric card front panel contains:

•

Status LED—Indicates the status of the fabric card.

•

Alphanumeric display—Displays switch fabric card messages.

The S123 switch fabric card physical characteristics are:

•

Height—20.6 in. (52.3 cm)

•

Depth—11.2 in. (28.5 cm)

•

Width—1.4 in. (3.6 cm)

•

Weight—11.9 lb (5.4 kg)

•

Power consumption—up to 206 W