Cisco UCS B440 High Performance Blade Server Installation and Service Note

Available Languages

Table Of Contents

Cisco UCS B440 High Performance Blade Server Installation and Service Note

Installing and Removing a Blade Server Hard Drive

Removing a Blade Server Hard Drive

Installing a Blade Server Hard Drive

Removing and Installing a UCS B440 High Performance Blade Server

Shutting Down and Powering Off A Blade Server

Removing a Cisco UCS B440 High Performance Blade Server

Installing a Cisco UCS B440 High Performance Blade Server

topicWorking Inside the Blade Server

Installing a Motherboard CMOS Battery

Installing a RAID Battery Backup Unit (BBU)

Obtaining Documentation and Submitting a Service Request

Cisco UCS B440 High Performance Blade Server Installation and Service Note

(N20-B6740-2)The Cisco UCS B440 High Performance Blade Servers (shown in Figure 1) are based on industry-standard server technologies and provide the following:

•

Up to four Intel Xeon 7500 Series processors

•

Four optional front-accessible, hot-swappable SAS hard drives

•

Support for up to two dual-port adapter card connections for up to 40 Gbps of redundant I/O throughput

•

Industry-standard double-data-rate 3 (DDR3) memory, supporting up to 32 DIMM slots and up to 256 GB of memory

•

Remote management through an integrated service processor that also executes policy established in Cisco UCS Manager software

•

Local keyboard, video, and mouse (KVM) access through a front console port on each server

•

Out-of-band access by remote KVM, Secure Shell (SSH) Protocol, and virtual media (vMedia) as well as Intelligent Platform Management Interface (IPMI)

•

LSI RoC 6G SAS 2108 RAID Controller (onboard version of LSI MegaRAID 9260), with Battery Back-up option and write back cache

M1 and M2 versions are available, supporting different processor classes.

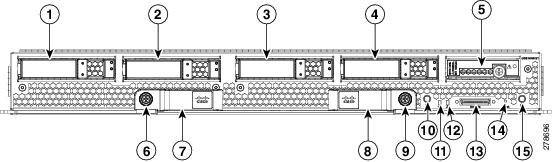

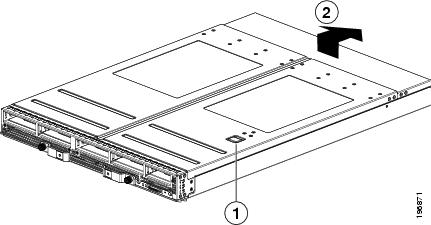

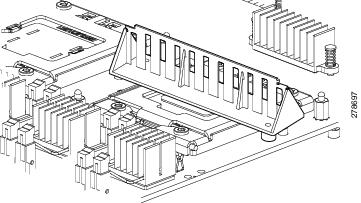

Figure 1 Cisco UCS B440 Front Panel

Note

Each server has a blank plastic tag that pulls out of the front panel, provided so you can add your own asset tracking label without interfering with the intended air flow.

LEDs

The LED indicators indicate whether the blade server is in active or standby mode, the status of the network link, the overall health of the blade server, and whether the server is set to give a flashing blue beaconing indication. The removable hard disks also have LEDs indicating hard disk access activity and hard disk health.

Buttons

The Reset button is just inside the chassis and must be pressed using the tip of a paper clip or a similar item. Hold the button down for five seconds and then release it to restart the server if other methods of restarting are not working.

The beaconing function for an individual server may be turned on or off by pressing the combination button and LED.

The Power button and LED allows you to manually take a server temporarily out of service but leave it in a state where it can be restarted quickly. If the desired power state for a service profile associated with a blade server or an integrated rack-mount server is set to "off", using the power button or Cisco UCS Manager to reset the server will cause the desired power state of the server to become out of sync with the actual power state and the server may unexpected shutdown at a later time. To safely reboot a server from a power-down state, use the Boot Server action in Cisco UCS Manager.

Connectors

A console port is provided to give a direct connection to a blade server to allow operating system installation and other management tasks to be done directly rather than remotely. The port uses the KVM dongle device included in the chassis accessory kit.

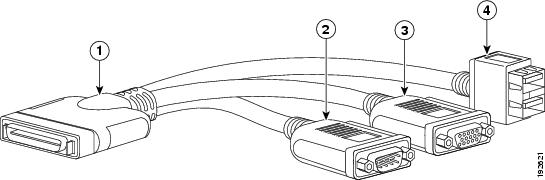

The KVM cable (N20-BKVM) shown in Figure 2 allows a KVM onnection into a Cisco UCS blade server, providing a DB9 serial connector, a VGA connector for a monitor, and dual USB ports for a keyboard and mouse. With this cable you can create a direct connection to the operating system and the BIOS running on a blade server. The pinout for the DB-9 connector is shown in Table 2.

Figure 2 KVM Cable for Blade Servers

Connector to blade server

DB9 serial connector

VGA connection for a monitor

2-port USB connector for a mouse and keyboard

Table 2 DB-9 Connector Pinout

DCD

1

RX

2

TX

3

DTR

71

GND

5

DSR

6

RTS

41

CTS

8

RI

9

1 UCS 440 only.

Conventions

This document uses the following conventions for notes, cautions, and safety warnings.

Notes and Cautions contain important information that you should know.

Note

Means reader take note. Notes contain helpful suggestions or references to material that are not covered in the publication.

CautionMeans reader be careful. You are capable of doing something that might result in equipment damage or loss of data.

Safety warnings appear throughout this publication in procedures that, if performed incorrectly, can cause physical injuries. A warning symbol precedes each warning statement.

Warning

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with standard practices for preventing accidents. Use the statement number provided at the end of each warning to locate its translation in the translated safety warnings that accompanied this device. Statement 1071

SAVE THESE INSTRUCTIONS

Waarschuwing

BELANGRIJKE VEILIGHEIDSINSTRUCTIES

Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat werken, dient u zich bewust te zijn van de bij elektrische schakelingen betrokken risico's en dient u op de hoogte te zijn van de standaard praktijken om ongelukken te voorkomen. Gebruik het nummer van de verklaring onderaan de waarschuwing als u een vertaling van de waarschuwing die bij het apparaat wordt geleverd, wilt raadplegen.

BEWAAR DEZE INSTRUCTIES

Varoitus

TÄRKEITÄ TURVALLISUUSOHJEITA

Tämä varoitusmerkki merkitsee vaaraa. Tilanne voi aiheuttaa ruumiillisia vammoja. Ennen kuin käsittelet laitteistoa, huomioi sähköpiirien käsittelemiseen liittyvät riskit ja tutustu onnettomuuksien yleisiin ehkäisytapoihin. Turvallisuusvaroitusten käännökset löytyvät laitteen mukana toimitettujen käännettyjen turvallisuusvaroitusten joukosta varoitusten lopussa näkyvien lausuntonumeroiden avulla.

SÄILYTÄ NÄMÄ OHJEET

Attention

IMPORTANTES INFORMATIONS DE SÉCURITÉ

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une situation pouvant entraîner des blessures ou des dommages corporels. Avant de travailler sur un équipement, soyez conscient des dangers liés aux circuits électriques et familiarisez-vous avec les procédures couramment utilisées pour éviter les accidents. Pour prendre connaissance des traductions des avertissements figurant dans les consignes de sécurité traduites qui accompagnent cet appareil, référez-vous au numéro de l'instruction situé à la fin de chaque avertissement.

CONSERVEZ CES INFORMATIONS

Warnung

WICHTIGE SICHERHEITSHINWEISE

Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die zu Verletzungen führen kann. Machen Sie sich vor der Arbeit mit Geräten mit den Gefahren elektrischer Schaltungen und den üblichen Verfahren zur Vorbeugung vor Unfällen vertraut. Suchen Sie mit der am Ende jeder Warnung angegebenen Anweisungsnummer nach der jeweiligen Übersetzung in den übersetzten Sicherheitshinweisen, die zusammen mit diesem Gerät ausgeliefert wurden.

BEWAHREN SIE DIESE HINWEISE GUT AUF.

Avvertenza

IMPORTANTI ISTRUZIONI SULLA SICUREZZA

Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe causare infortuni alle persone. Prima di intervenire su qualsiasi apparecchiatura, occorre essere al corrente dei pericoli relativi ai circuiti elettrici e conoscere le procedure standard per la prevenzione di incidenti. Utilizzare il numero di istruzione presente alla fine di ciascuna avvertenza per individuare le traduzioni delle avvertenze riportate in questo documento.

CONSERVARE QUESTE ISTRUZIONI

Advarsel

VIKTIGE SIKKERHETSINSTRUKSJONER

Dette advarselssymbolet betyr fare. Du er i en situasjon som kan føre til skade på person. Før du begynner å arbeide med noe av utstyret, må du være oppmerksom på farene forbundet med elektriske kretser, og kjenne til standardprosedyrer for å forhindre ulykker. Bruk nummeret i slutten av hver advarsel for å finne oversettelsen i de oversatte sikkerhetsadvarslene som fulgte med denne enheten.

TA VARE PÅ DISSE INSTRUKSJONENE

Aviso

INSTRUÇÕES IMPORTANTES DE SEGURANÇA

Este símbolo de aviso significa perigo. Você está em uma situação que poderá ser causadora de lesões corporais. Antes de iniciar a utilização de qualquer equipamento, tenha conhecimento dos perigos envolvidos no manuseio de circuitos elétricos e familiarize-se com as práticas habituais de prevenção de acidentes. Utilize o número da instrução fornecido ao final de cada aviso para localizar sua tradução nos avisos de segurança traduzidos que acompanham este dispositivo.

GUARDE ESTAS INSTRUÇÕES

¡Advertencia!

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este símbolo de aviso indica peligro. Existe riesgo para su integridad física. Antes de manipular cualquier equipo, considere los riesgos de la corriente eléctrica y familiarícese con los procedimientos estándar de prevención de accidentes. Al final de cada advertencia encontrará el número que le ayudará a encontrar el texto traducido en el apartado de traducciones que acompaña a este dispositivo.

GUARDE ESTAS INSTRUCCIONES

Varning!

VIKTIGA SÄKERHETSANVISNINGAR

Denna varningssignal signalerar fara. Du befinner dig i en situation som kan leda till personskada. Innan du utför arbete på någon utrustning måste du vara medveten om farorna med elkretsar och känna till vanliga förfaranden för att förebygga olyckor. Använd det nummer som finns i slutet av varje varning för att hitta dess översättning i de översatta säkerhetsvarningar som medföljer denna anordning.

SPARA DESSA ANVISNINGAR

Aviso

INSTRUÇÕES IMPORTANTES DE SEGURANÇA

Este símbolo de aviso significa perigo. Você se encontra em uma situação em que há risco de lesões corporais. Antes de trabalhar com qualquer equipamento, esteja ciente dos riscos que envolvem os circuitos elétricos e familiarize-se com as práticas padrão de prevenção de acidentes. Use o número da declaração fornecido ao final de cada aviso para localizar sua tradução nos avisos de segurança traduzidos que acompanham o dispositivo.

GUARDE ESTAS INSTRUÇÕES

Advarsel

VIGTIGE SIKKERHEDSANVISNINGER

Dette advarselssymbol betyder fare. Du befinder dig i en situation med risiko for legemesbeskadigelse. Før du begynder arbejde på udstyr, skal du være opmærksom på de involverede risici, der er ved elektriske kredsløb, og du skal sætte dig ind i standardprocedurer til undgåelse af ulykker. Brug erklæringsnummeret efter hver advarsel for at finde oversættelsen i de oversatte advarsler, der fulgte med denne enhed.

GEM DISSE ANVISNINGER

Installing and Removing a Blade Server Hard Drive

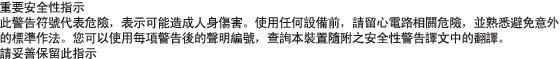

There are up to 4 front-accessible, hot-swappable, 2.5-inch SAS or SATA drives per blade. You can remove blade server hard drives without removing the blade server from the chassis. All other component replacement for a blade server requires removing the blade from the chassis. Unused hard drive bays should always be covered with cover plates (N20-BBLKD) to assure proper cooling and ventilation. The chassis is omitted from illustrations here to simplify the drawing.

CautionTo prevent ESD damage, wear grounding wrist straps during these procedures and handle modules by the carrier edges only.

Replacing an HDD or SSD with a drive of the same size, model, and manufacturer generally causes few problems with UCS Manager. If the drive being replaced was part of a RAID array we recommend using a newly ordered drive of identical size, model, and manufacturer to replace the failed drive. Cisco recommends following industry standard practice of using drives of the same capacity when creating RAID volumes. If drives of different capacities are used, the useable portion of the smallest drive will be used on all drives that make up the RAID volume. Before upgrading or adding an HDD to a running system, check the service profile in UCS Manager and make sure the new hardware configuration will be within the parameters allowed by the service profile.

Hard disk and RAID troubleshooting information is in the Troubleshooting Server Hardware chapter of the Cisco UCS Troubleshooting Guide. The B440 uses an LSI SAS 2108 RAID controller (the onboard version of the LSI MegaRAID 9260).

Table 3 shows the drives supported in this blade server.

Table 3 Supported Hard Disk Drives (HDD)

A03-D073GC2

73 GB, 6Gb SAS transfer rate, 15K RPM HDD/hot plug/drive sled mounted

A03-D146GC2

146 GB 6Gb SAS transfer rate, 15k RPM SFF HDD/hot plug/drive sled mounted

A03-D300GA2

300 GB, 6Gb SAS transfer rate, 10K RPM HDD/hot plug/drive sled mounted

A03-D100SSD

100 GB SATA SSD HDD/hot plug/drive sled mounted (no longer sold)

UCS-SSD100GI1F104

100 GB SATA SSD HDD/hot plug/drive sled mounted

A03-D600GA2

600 GB, 6Gb SAS transfer rate, 10K RPM HDD/hot plug/drive sled mounted

UCS-HDD300GI2F105

300GB 6Gb SAS 15K RPM SFF HDD/hot plug/drive sled mounted1

UCS-HDD900GI2F106

900GB 6Gb SAS 10K RPM SFF HDD/hot plug/drive sled mounted2

1 This drive requires UCS capability catalog version 1.0.50.T or 2.0.1nT or later.

2 This drive requires UCS capability catalog version 1.0.54.T or 2.0.1pT or later.

Removing a Blade Server Hard Drive

To remove a hard drive from a blade server, follow these steps:

Step 1

Push the button to release the ejector, and then pull the hard drive from its slot. (See Figure 3.)

Step 2

Place the hard drive on an antistatic mat or antistatic foam if you are not immediately reinstalling it in another blade server.

Step 3

Install a blank faceplate (N20-BBLKD) to keep dust out of the blade server if the slot will remain empty.

Figure 3 Removing and Installing a Hard Drive

Installing a Blade Server Hard Drive

To install a blade server hard drive, follow these steps:

Step 1

Place the hard drive lever into the open position by pushing the release button (see Figure 3).

Step 2

Gently slide the hard drive into the opening in the blade server until it seats into place.

Step 3

Push the hard drive lever into the closed position.

You can use UCS Manager to format and configure RAID services. refer to the UCS Manager configuration guide for your software release for details on RAID configuration.

If you need to move a RAID cluster, refer to the Moving a RAID Cluster section of the the Troubleshooting Server Hardware chapter of the Cisco UCS Troubleshooting Guide.

Removing and Installing a UCS B440 High Performance Blade Server

Before performing any internal operation on a blade server, you must turn it off and remove it from the chassis.

CautionTo prevent ESD damage, wear grounding wrist straps during these procedures and handle modules by the carrier edges only.

Shutting Down and Powering Off A Blade Server

The server can run in two power modes:

•

Main power mode—Power is supplied to all server components and any operating system on your hard drives can run.

•

Standby power mode—Power is supplied only to the service processor and the cooling fans and it is safe to power off the server from this mode.

After establishing a connection to the blade server's operating system, you can directly shut down the blade server using the operating system.

You can invoke a graceful shutdown or an emergency shutdown (hard shutdown) by using either of the following methods:

•

Use the UCS Manager . See either the Cisco UCS Manager GUI Configuration Guide or the Cisco UCS Ma nager CLI Configuration Guide.

•

Use the Power button on the server front panel. To use the Power button, follow these steps:

Step 1

Check the color of the Power Status LED.

•

Green indicates that the server is in main power mode and must be shut down before it can be safely powered off. Go to Step 2.

•

Amber indicates that the server is already in standby mode and can be safely powered off. Go to Step 3.

Step 2

Invoke either a graceful shutdown or a hard shutdown:

CautionTo avoid data loss or damage to your operating system, you should always invoke a graceful shutdown of the operating system.

•

Graceful shutdown—Press and release the Power button. The operating system will perform a graceful shutdown and the server goes to standby mode, which is indicated by an amber Power Status LED.

•

Emergency shutdown—Press and hold the Power button for 4 seconds to force the main power off and immediately enter standby mode.

Step 3

If you are shutting down all blade servers in a chassis, you should now disconnect the power cords from the chassis to completely power off the servers. If you are only shutting down one server, you can skip unplugging the chassis and move to removing the server.

Removing a Cisco UCS B440 High Performance Blade Server

Using UCS Manager, decommission the server using UCS Manager before physically removing the server. To remove a blade server from the chassis, follow these steps:

Step 1

Turn off the blade server using either UCS Manager or the power on standby button.

Step 2

Completely loosen the captive screws on the front of the blade.

Step 3

Remove the blade from the chassis by pulling the ejector levers on the blade until it unseats the blade server.

Step 4

Slide the blade part of the way out of the chassis, and place your other hand under the blade to support its weight.

Step 5

Once removed, place the blade on an antistatic mat or antistatic foam if you are not immediately reinstalling it into another slot.

Step 6

If the slot is to remain empty, reinstall the slot divider (N20-CDIVV) and install two blank faceplates (N20-CBLKB1) to keep assure proper ventilation and cooling.

Installing a Cisco UCS B440 High Performance Blade Server

While the blades and chassis are designed for any device to operate in any slot, the following placement guidelines should be used when installing blades to distribute weight as intended and make insertion and removal easier:

1.

1. A chassis filled with half-width servers will require slot dividers be installed. A chassis filled with full-width servers will require the removal of all slot dividers.

2.

2. If a mixture of full- and half-width servers is desired, place full-width blades in slot 1 and down, and place half-width blades in slot 8 and up. Slot dividers are required between half-width servers to provide support to the bays above.

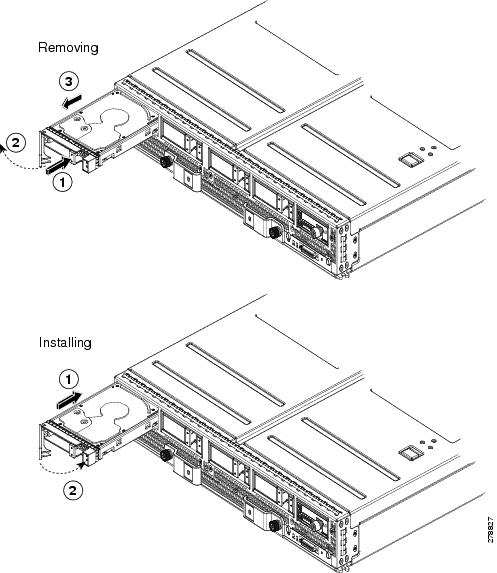

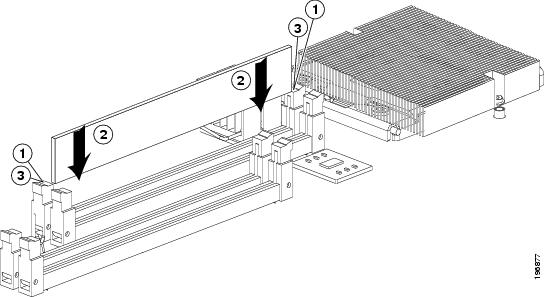

To install a blade server, follow these steps:

Step 1

If necessary, remove the slot divider (N20-CDIVV) from the chassis. To do this, follow these steps:

a.

Simultaneously pull up on the left side catch and push down on the right side catch as shown in callout 1 of Figure 4.

b.

Pull the slot divider out of the chassis as shown in callout 2 of Figure 4. Keep the slot divider in case it is needed at another time.

Tip

To reinstall the slot divider, align it with the dimples in the slot top and bottom and slide it back in until it clicks into place.

Figure 4 Removing a Chassis Partition

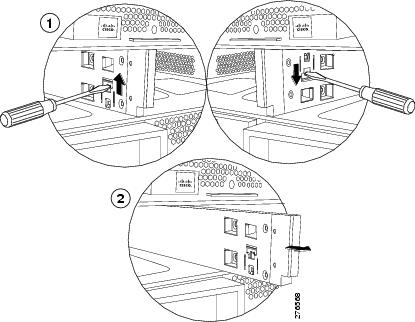

Step 2

Grasp the front of the blade server and place your other hand under the blade to support it. See Figure 5.

Figure 5 Positioning a Blade Server in the Chassis

Step 3

Open the ejector levers in the front of the blade server.

Step 4

Gently slide the blade into the opening until you cannot push it any farther.

Step 5

Press the ejector levers so that they catch the edge of the chassis and press the blade server all the way in.

Step 6

Tighten the captive screw on the front of the blade to no more than 3 in-lbs. Tightening with bare fingers only is unlikely to lead to stripped or damaged captive screws.

Removing a Blade Server Cover

To open a blade server, follow these steps:

Step 1

Press and hold the button down as shown in callout 1 of Figure 6.

Step 2

While holding the back end of the cover, pull the cover back and upas shown in callout 2 of Figure 6.

Figure 6 Opening a Blade Server

Internal Components

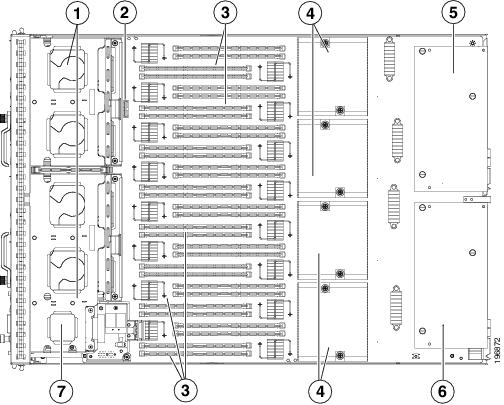

Figure 7 calls out the various components within the blade server.

Figure 7 Inside View of a Blade Server

Hard drive bays

CMOS Battery

DIMM slots

CPU and heat sink

Adapter card in Slot 0

Adapter card in Slot 1

RAID BBU

Diagnostics Button and LEDs

At blade start-up, POST diagnostics test the CPUs, DIMMs, HDDs and adapter cards, and any failure notifications are sent to UCSM. You can view these notification in the System Error Log or in the output of the show tech-support command. If errors are found, an amber diagnostic LED will also light up next to the failed component. During run time, the blade BIOS, component drivers, and OS all monitor for hardware faults and will light up the amber diagnostic LED for a component if an uncorrectable error or correctable errors (such as a host ECC error) over the allowed threshold occur.

LED states are saved, and if you remove the blade from the chassis the LED values will persist for up to 10 minutes. Pressing the LED diagnostics button on the motherboard will cause the LEDs that currently show a component fault to light for up to 30 seconds for easier component identification. LED fault values are reset when the blade is reinserted into the chassis and booted, and the process begins from its start.

If DIMM insertion errors are detected, they may cause the blade discovery to fail and errors will be reported in the server POST information, viewable using the UCS Manager GUI or CLI. UCS blade servers require specific rules to be followed when populating DIMMs in a blade server, and the rules depend on the blade server model. Refer to the documentation for a specific blade server for those rules.

HDD status LEDs are on the front face of the HDD. Faults on the CPU, DIMMs, or adapter cards will also cause the server health LED to light solid Amber for minor error conditions or blinking Amber for critical error conditions.

topicWorking Inside the Blade Server

This section describes how to perform the following tasks within a blade server:

•

Installing a Motherboard CMOS Battery

•

Installing a CPU or Heat Sink

•

Installing a RAID License Key

•

Installing a RAID Battery Backup Unit (BBU)

Installing a Motherboard CMOS Battery

This server supports the following Cisco components and part numbers.

WarningThere is danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer's instructions.

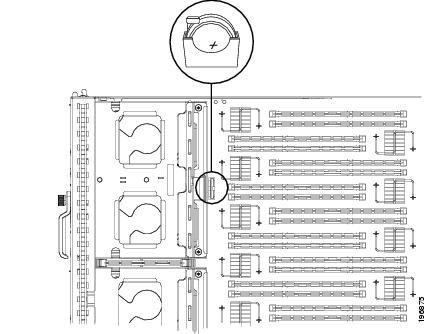

Statement 1015To install or replace a motherboard complementary metal-oxide semiconductor (CMOS) battery, follow these steps:

Step 1

Remove a motherboard CMOS battery:

a.

Set the power button to Standby (it will go from green to Amber).

b.

Remove the blade server from the chassis,

c.

Remove the top cover as described in the "Removing a Blade Server Cover" section.

d.

Press the battery socket retaining clip toward the chassis wall (see Figure 8).

e.

Lift the battery from the socket. Use needle-nose pliers to grasp the battery if there is not enough clearance for your fingers.

Step 2

Install a motherboard CMOS battery:

a.

Press the battery socket retaining clip toward the chassis wall.

b.

Insert the new battery into the socket with the battery's positive (+) marking toward the chassis wall. Ensure that the retaining clip clicks over the top of the battery.

c.

Replace the top cover.

d.

Replace the server in the chassis, and then power on the server by pressing the Power button.

Figure 8 Removing and Replacing a Motherboard CMOS Battery

Removing a CPU or Heat Sink

You can order your blade server with one CPUs, and upgrade later to up to four CPUs. All CPUs must be of the same type, and memory in slots intended for additional CPUs will not be recognized if the corresponding CPU is not present (see Memory Arrangement). You may need to use these procedures to move a CPU from one server to another, or to replace a faulty CPU.

Table 4 and Table 5 show the available CPU options:

Table 4 CPU Options, M1 Models

A01-X0200 / Xeon X7560

130 W

2.26 GHz

24 MB

A01-X0201 / Xeon X7550

130 W

2.00 GHz

18 MB

A01-X0203 / Xeon E7540

105 W

2.00GHz

18 MB

A01-X0206 / Xeon L7555

95 W

1.86 GHz

24 MB

A01-X0209 / Xeon E7520

95 W

1.86GHz

18 MB

Table 5 CPU Options, M2 Models

UCS-CPU-E74870

130 W

2.4 GHz

30 MB

UCS-CPU-E74860

130 W

2.26 GHz

24 MB

UCS-CPU-E74850

130 W

2.00 GHz

24 MB

UCS-CPU-E74830

105 W

2.13 GHz

24 MB

UCS-CPU-E74807

95 W

1.86 GHz

18 MB

UCS-CPU-E78867L

105 W

2.13 GHz

30 MB

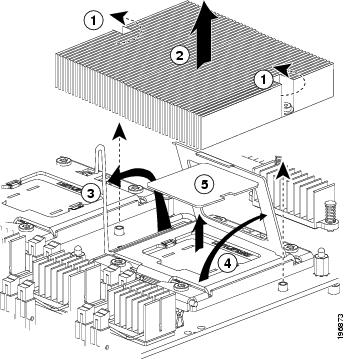

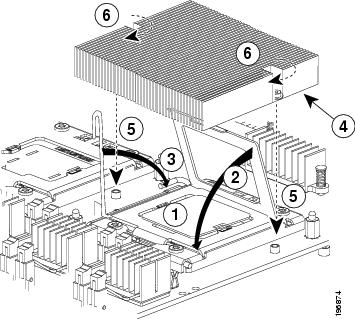

To remove a CPU, CPU filler, or heat sink, follow these steps:

Step 1

Unscrew the four captive screws securing the heat sink to the motherboard as shown in callout 1 of Figure 9.

Step 2

Remove the heat sink (N20-BHTS3) as shown in callout 2 of Figure 9. Remove the old thermal compound from the bottom of the heat sink using the cleaning kit (UCSX-HSCK= ) available from Cisco. Follow the instructions on the two bottles of cleaning solvent.

Step 3

Unhook the socket latch as shown in callout 3 of Figure 9.

Step 4

Open the socket latch as shown in callout 4 of Figure 9.

Step 5

Remove the CPU or socket protective cover as shown in callout 5 of Figure 9.

Figure 9 Removing the Heat Sink and Accessing the CPU Socket

If a replacement CPU will not be used and the CPU will be left vacant, you should have an air blocker installed rather than a heat sink. The air blocker assures that air flows where it is needed, and is shown in Figure 10.

Figure 10 CPU Air Blocker

Installing a CPU or Heat Sink

Before installing a new CPU in a server, verify the following:

•

The CPU is supported for that model server.

•

A BIOS is available that supports the CPU/DIMM and server combination.

•

The service profile for this server in UCS Manager will recognize and allow the new CPU. This is especially important if you have been using a single processor and install a second processor.

To install a CPU or heat sink, follow these steps:

Step 1

Place the CPU on the base with the notches aligned to the pins on the base. See Figure 11, callout 1.

Figure 11 Inserting the CPU and Replacing the Heat Sink

Step 2

Close the socket latch. See Figure 11, callout 2.

Step 3

Lock the socket latch into place with the hook. See Figure 11, callout 3.

Step 4

Attach the thermal pad (also available as a spare A04-BTHP3=) provided with the replacement CPU or server to the bottom of the heat sink, then remove the covering film from the side that will adhere to the CPU.

Step 5

Replace the heat sink. See Figure 11, callout 5.

Step 6

Secure the heat sink to the motherboard by tightening the two captive screws hand tight. See Figure 11, callout 6.

CautionMake sure that the heat sink fins are aligned to run along the length of the blade server (see Figure 11).

Installing Memory

Check the server's service profile setting in UCS Manager before adding memory to make sure that the new memory will be recognized. To install a DIMM into the blade server, follow these steps:

Step 1

Open both DIMM connector latches, refer to callout 1 in Figure 12.

Figure 12 Installing DIMMs in the Blade Server

Step 2

Press the DIMM into its slot evenly on both ends until it clicks into place, refer to callout 2 in Figure 12. The DIMM connector latches will snap into place.

Note

DIMMs are keyed and will only insert into their slot if the notch at the bottom of the DIMM is oriented correctly. Attempting to force an incorrectly oriented DIMM will damage the slot.

Step 3

Press the DIMM connector latches inward slightly to seat them fully. Refer to callout 3 in Figure 12.

Memory and Performance

This section describes the type of memory that the blade server requires, and its effect on performance. The following topics are covered:

Modern processors are designed to support several generations of memory technology. Cisco's Extended Memory Technology allows us to replace high-density DIMMs with multiple lower-density DIMMs in a way that is transparent to the processor and to applications. In some configurations, we are emulating DIMMs that are not available, such as making four 8-GB DIMMs appear to be a single 32-GB DIMM. In other cases we can emulate high cost-per-bit DIMMs with multiple low cost-per-bit DIMMs; for example, making four 4 GB DIMMs emulate a 16 GB DIMM.

Supported DIMMs

Table 6 and Table 7 list the type of DIMMs that Cisco Systems makes available for use with this blade server:

Table 6 Cisco Systems Supported DIMMs (M1 Models)

A02-M308GB3-2

Two DIMMs, each 4 GB DDR3-1066 MHz (Low Voltage supported)

A02-M316GB3-2

Two DIMMs, each 8GB DDR3-1066 MHz (Low Voltage supported)

A02-M332GB3-2-L

Two DIMMs, each 16 GB DDR3-1066 MHz (Low Voltage supported)

UCS-MR-2X041RX-C

Two DIMMs, each 4 GB DDR3-1333 MHz (Low Voltage supported)

Table 7 Cisco Systems Supported DIMMs (M2 Models)

A02-M308GB3-2

Two DIMMs, each 4 GB DDR3-1066 MHz (Low Voltage supported)

A02-M316GB3-2

Two DIMMs, each 8 GB DDR3-1066 MHz (Low Voltage supported)

A02-M332GB3-2-L

Two DIMMs, each 16 GB DDR3-1066 MHz (Low Voltage supported)

A02-M308GD5-2

Two DIMMs, each 4 GB DDR3-1333 MHz

A02-M316GD5-2

Two DIMMs, each 8 GB DDR3-1333 MHz

UCS-MR-2X324RX-C

Two DIMMs, each 32 GB DDR3-1333 MHz (Low Voltage supported)1

1 Capability catalog 2.0(1m)T or later is required.

CautionServer memory is always sold as a matched DIMM pair intended to be installed together in a single UCS Server memory bank. Un-pairing this set and mixing with other non-matched DIMMs can potentially result in memory errors.

Cisco does not support third-party memory DIMMs, and in some cases their use may irreparably damage the server and require an RMA and down time.

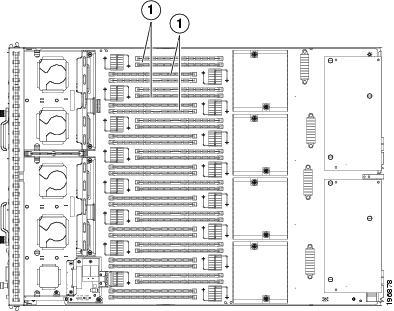

Memory Arrangement

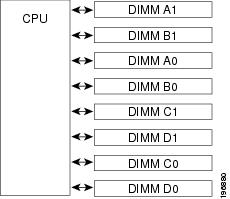

The Cisco UCS B440 high-performance blade server contains 32 slots for installing DIMMs—8 for each CPU. Each CPU has 8 DIMM slots and DDR channels, with 4 pairs of DIMMs operating in lockstep (see Figure 13) so you must install additional DIMMs in pairs, as laid out in Table 8. This blade server needs at least one matched pair of DIMMs attached to CPU 1 or CPU 2. All four CPUs can boot and run from a single DIMM pair. DIMM pairs must be identical, but one DIMM pair on a CPU can be different from other pairs. DIMMs installed in slots for an absent CPU will not be recognized. For optimal performance, distribute DIMMs evenly across all CPUs. DIMM connector latches are color coded blue, yellow, black, and white, and Cisco recommends installing memory in that order. It is also recommended to install memory evenly across the installed CPUs.

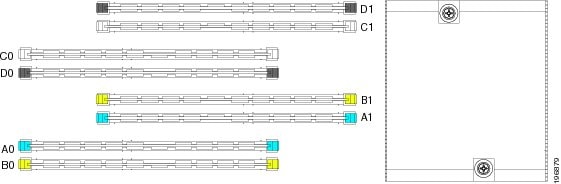

Figure 13 Memory Slots Within the Blade Server

Channels

Each CPU has 8 channels, consisting of 4 matched pairs. Each channel pair is identified by a letter: A, B, C, or D for each CPU. Each channel pair member is identified by numbers, either 1 or 0.

Figure 14 shows how channels are physically laid out on the blade server. The DIMM slots are to the left of their associated CPU. When installing DIMMs, you must add them in pairs in the configurations shown in Table 8:

Table 8 Adding DIMMs to a CPU

2 (blue)

(A0, A1)

4 (blue, white )

(A0, A1)-(C0, C1)

8 (blue, white, yellow, and black)

(A0, A1)-(C0, C1)-(B0, B1)-( D0, D1)

Note

This server does not support odd numbers of DIMMs in a channel, or a configuration of 6 DIMMs per CPU. These are the only three supported DIMM configurations. The DIMMs are sold in matched pairs which must be installed in the pairs shown in Table 8. Mixing pairs , even otherwise identical sets, within a CPU will lead to memory errors.

Figure 14 Physical Representation of DIMMs for a CPU

Figure 15 shows a logical view of the channels.

Figure 15 Logical Representation of Channels

DIMMs can be used in the High-performance blade server using the slot pairs described in Table 8.

Memory Performance

When configuring your server, consider the following.

•

DIMMs within the blade server can be of a different size, but mixing speeds will cause the faster DIMMs to run at the speed of the slower DIMMs.

•

Your selected CPU(s) can have some affect on performance. If two CPUs are used, both must be of the same type.

Bandwidth and Performance

You can achieve maximum bandwidth, performance, and system memory using the following configuration:

•

DDR3, 1066 millions of transfers per second (MT/s) across three Channels

•

8 DIMM per CPU (32 DIMMs)

•

Maximum capacity of 256 GB (using 8 GB DIMMs)

Note

The memory available for this server can only run at 1066 MHz.

Performance Loss

Performance is less than optimal if the following memory configurations are used:

•

Mixing DIMM sizes and densities within a pair

•

Unevenly populating DIMMs between CPUs

Depending on the application needed, performance loss might or might not be noticeable or measurable. Partially populating a pair is unsupported, and will not work at all.

Installing an Adapter Card

The network adapters and interface cards all have a shared installation process. The following options are available:

Table 9 Adapter Card Options

N20-AQ0002 or

N20-AE0002Cisco UCS M71KR-E/Q Converged Network Adapter

N20-AC0002

Cisco UCS M81KR Virtual Interface Card

N20-AB0002

Cisco UCS NIC M51KR-B Broadcom BCM57711 Network Adapter

N20-AI0102

Cisco UCS CNA M61KR-I Intel Converged Network Adapter1

N20-AQ0102

Cisco UCS CNA M72KR-Q QLogic Converged Network Adapter

N20-AE0102

Cisco UCS CNA M72KR-E Emulex Converged Network Adapter

UCS-VIC-M82-8P

Cisco UCS Virtual Interface Card 12802

2 Requires UCS Manager 2.0(2) or later.

If you are switching from one type of card to another, before you physically perform the switch make sure you have downloaded the latest device drivers and loaded them into the server's OS. For the most recent details, refer to the firmware management chapter of one of the UCS Manager software configuration guides.

Adapter cards can be installed in either slot 1 or slot 0; they can be of the same type or as of UCS Manager 1.3(1), the following mixed configurations are supported:

•

M81KR with M71KR-E/Q

•

M81KR with M72KR-E/Q

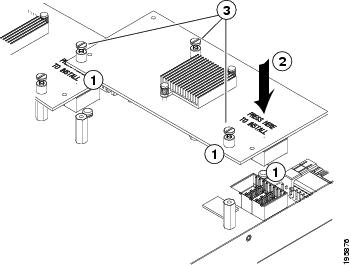

To install an adapter card on the blade server, follow these steps:

Step 1

Position the adapter board connector above either mother board connector and align the three adapter captive screws to the posts on the motherboard as shown in callout 1 of Figure 16.

Step 2

Firmly press the adapter connector into the motherboard connector as shown in callout 2 of Figure 16. If the seating is bad, it may cause the network connection LED to stay amber when the server is restarted.

Step 3

Tighten the three captive screws identified in callout 3 of Figure 16.

Figure 16 Installing an Adapter Card

Installing a RAID License Key

Depending on the RAID license key that is installed, the onboard RAID controller supports the following RAID levels:

•

RAID 0 (data striping): Data is striped across all disks in the array, providing fast throughput. There is no data redundancy, and all data is lost if any disk fails.

•

RAID 1 (disk mirroring): Data is written to two disks, providing complete data redundancy if one disk fails. The maximum array size is equal to the available space on the smaller of the two drives.

•

RAID 5 (disk striping with distributed parity): Data is striped across all disks in the array. Part of the capacity of each disk stores parity information that can be used to reconstruct data if a disk fails. RAID 5 provides good data throughput for applications with high read request rates.

•

RAID 6 (disk striping with distributed parity across two disks): Data is striped across all disks in the array and two parity disks are used to provide protection against the failure of up to two physical disks. In each row of data blocks, two sets of parity data are stored.

•

RAID 10 (RAID 1 and RAID 0 in spanned arrays): RAID 10 uses mirrored pairs of disks to provide complete data redundancy and high throughput rates.

•

RAID 50 (RAID 5 and RAID 0 in spanned arrays): RAID 50 uses both parity and disk striping across multiple disks to provide complete data redundancy and high throughput rates.

•

RAID 60 (RAID 6 and RAID 0 in spanned arrays): RAID 60 uses both distributed parity across two parity disks and disk striping across multiple disks to provide complete data redundancy and high fault tolerance.

The Cisco RAID key is OEM version of LSI MegaRAID SAS 8880EM2 SGL. If a replacement is needed, the stock LSI version will not work as a replacement as the physical connector is different, you must order replacements from Cisco.

User information for RAID controllers is in the Cisco UCS Servers RAID Guide.

To install a RAID license key, follow these steps:

Step 1

With the cover removed, locate the RAID controller daughter card. It is directly behind the BBU.

Step 2

Align the key as shown, and slide it onto the connector. This should be very much like installing a jumper.

Figure 17 Installing a RAID License Key

When fully installed, the "RAID KEY" label on the daughter card will be covered by the key.

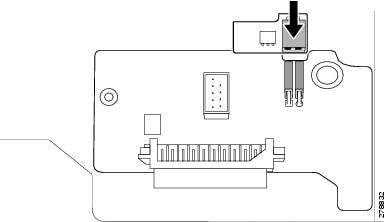

Installing a RAID Battery Backup Unit (BBU)

The BBU is an intelligent battery backup unit that protects disk write cache data during a power loss on the RAID controller for up to 72 hours. We recommend that you replace the BBU once per year or after 1,000 recharge cycles, whichever comes first. Verify whether BBU replacement is required by using the show raid-battery detail command in the CLI.

To remove the RAID license key, perform the following procedure in reverse order.

To install a RAID BBU, follow these steps:

Step 1

Using UCS Manager, perform a graceful shutdown of the server. Without a graceful shutdown, data may be permanently lost.

Step 2

Remove the blanking plate, if present, from the BBU bay at the right of the server.

Step 3

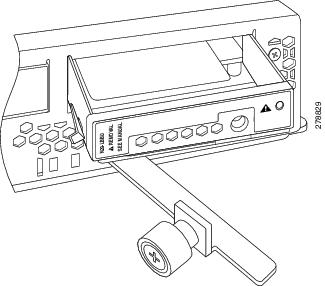

Slide the BBU unit in partially, and align the ejector lever as shown in Figure 18.

Figure 18 Slide in the BBU

.

Step 4

Continue pressing the BBU in until the ejector lever folds below the carrier tray. The BBU rear connector should automatically seat with the RAID controller at its rear.

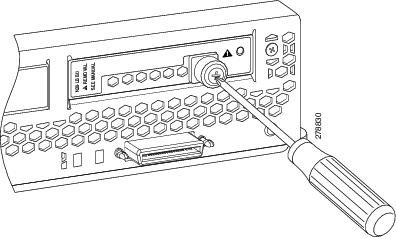

Step 5

Secure the BBU in place by tightening the captive screw with a #2 Phillips screwdriver.

Figure 19 Tighten the Captive Screw

Server Troubleshooting

For general server troubleshooting information, refer to the Troubleshooting Server Hardware chapter of the Cisco UCS Troubleshooting Guide.

Server Configuration

UCS servers are intended to be configured and managed using UCS Manager. Refer to the UCS Manager Configuration Guide appropriate for your UCS Manager version.

Server Specifications

Table 10 Physical Specifications for the Cisco UCS B440 Blade Server

Height

1.95 inches (50 mm)

Width

16.50 inches (419.1 mm)

Depth

24.4 inches (620 mm)

Weight

34.5 lbs (15.65 kg) 1

1 The system weight listed here is an estimate for a fully configured system and will vary depending on peripheral devices installed.

Related Documentation

The documentation set for the Cisco Unified Computing System environment is described in full at:

http://www.cisco.com/go/unifiedcomputing/b-series-doc

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information, see What's New in Cisco Product Documentation at: http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html.

Subscribe to What's New in Cisco Product Documentation, which lists all new and revised Cisco technical documentation, as an RSS feed and deliver content directly to your desktop using a reader application. The RSS feeds are a free service.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any other company. (1110R)

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional and coincidental.

© 2010 Cisco Systems, Inc. All rights reserved.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback