Catalyst 6500 and Cisco 7600 Supervisor Engine 720 SP and RP Memory Install Note

Available Languages

Table Of Contents

Statement 1071—Warning Definition

Removing the Supervisor Engine 720

Removing and Installing the DRAM DIMMs

Installing the Supervisor Engine 720

Preventing Electrostatic Discharge Damage

Obtaining Documentation and Submitting a Service Request

Catalyst 6500 Series and Cisco 7600 Series Supervisor Engine 720 Switch Processor and Route Processor Memory Installation Note

Product Numbers: MEM-S2-512MB=, MEM-MSFC2-512MB=, MEM-SUP720-SP-1GB=, MEM-MSFC3-1GB=, MEM-RSP720-4G=, MEM-RSP720-2G=, MEM-RSP720-SP2G=

This publication describes how to upgrade the dynamic random-access memory (DRAM) dual inline memory modules (DIMMs) on the Supervisor Engine 720.

Contents

This publication consists of these sections:

•

Removing the Supervisor Engine 720

•

Removing and Installing the DRAM DIMMs

•

Installing the Supervisor Engine 720

•

Preventing Electrostatic Discharge Damage

•

Obtaining Documentation and Submitting a Service Request

Safety Overview

Safety warnings appear throughout this publication in procedures that may harm you if performed incorrectly. A warning symbol precedes each warning statement.

Statement 1071—Warning Definition

Required Tools

The following tools are required to perform the memory upgrade kit installation:

•

Antistatic mat or foam pad to support and protect the removed supervisor engine

•

3/16-inch flat-blade screwdriver for the captive installation screws on the supervisor engine

•

Your own ESD-prevention equipment or the disposable grounding wrist strap included with all upgrade kits, field-replaceable units (FRUs), and spares

Warning

Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

CautionAlways use an ESD wrist strap when working around chassis, handling modules not protected by antistatic bags, or coming into contact with internal components. See the "Preventing Electrostatic Discharge Damage" section.

Warning

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place.

Statement 1029

Warning

Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

Removing the Supervisor Engine 720

To install the switch processor and route processor DRAM DIMM upgrade, you must first remove the Supervisor Engine 720 from the chassis.

The Supervisor Engine 720 is a required system component. If only one Supervisor Engine 720 is present, removing it while the system is operating causes the system to halt. When two Supervisor Engine 720s are installed, hot swapping allows you to remove and replace one of the supervisor engines without turning off the system power.

To avoid erroneous failure messages, note the current configuration of all interfaces before you remove or replace another switching module, and allow at least 15 seconds for the system to reinitialize after a module has been removed or replaced.

CautionAlways use an ESD wrist strap when handling the Supervisor Engine 720 or coming in contact with internal components.

To remove the Supervisor Engine 720, follow these steps:

Step 1

Attach an ESD grounding strap securely to your wrist and to earth (building) ground.

Note

If you are unsure about the correct way to attach an ESD grounding strap, see the "Preventing Electrostatic Discharge Damage" section for instructions.

Step 2

Disconnect any interface cables attached to the supervisor engine.

Step 3

Verify that the captive installation screws are tightened on all of the modules in the chassis. This action assures that the EMI gaskets on all of the modules are fully compressed preserving the space created by the removed supervisor engine.

Note

If the captive installation screws are loose, the EMI gaskets on the remaining installed modules will expand which reduces the height of the slot opening making it difficult to reinstall the supervisor engine.

Step 4

Disengage the two captive screws on the supervisor engine that is to be removed.

Step 5

Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following sets of steps to remove the supervisor engine from the chassis slot:

Horizontal slots

a.

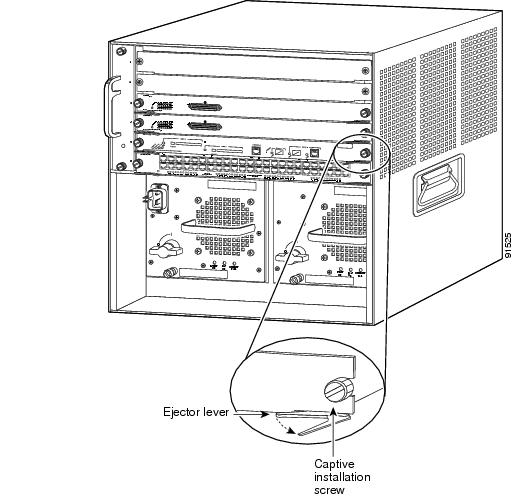

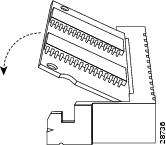

Place your thumbs on the left and right ejector levers, and simultaneously rotate the levers outward to unseat the supervisor engine from the backplane connector. (See Figure 1.)

b.

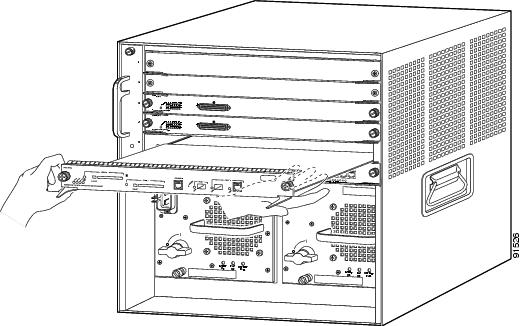

Grasp the front edge of the supervisor engine, and slide the supervisor engine partially out of the slot. Place your other hand under the supervisor engine to support the weight of the module. Do not touch the module circuitry. (See Figure 2.)

Vertical slots

a.

Place your thumbs on the ejector levers located at the top and bottom of the supervisor engine, and simultaneously rotate the levers outward to unseat the supervisor engine from the backplane connector.

b.

Grasp the edges of the supervisor engine, and slide the supervisor engine straight out of the slot. Do not touch the module circuitry.

Step 6

Place the removed supervisor engine on an antistatic work mat or antistatic foam.

Figure 1 Opening the Ejector Levers (Horizontal Chassis Shown)

Figure 2 Removing the Module from the Chassis (Horizontal Chassis Shown)

Removing and Installing the DRAM DIMMs

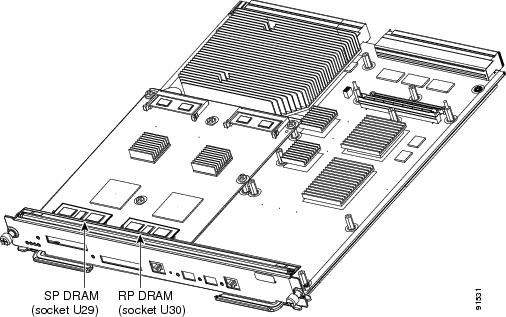

This section covers the removal of the old DRAM DIMMs and the installation of the switch processor and route processor DRAM DIMM upgrade. There are two DRAM DIMMs that must be removed and replaced; the SP DRAM and the RP DRAM. Figure 3 shows the location of the SP and the RP DRAM DIMMs on the Supervisor Engine 720.

CautionBoth the SP and RP DRAM DIMMs are static-sensitive components that are susceptible to ESD damage. To prevent ESD damage, always wear an ESD grounding wrist strap, handle the DIMM by the edges only, and avoid touching the memory modules, pins, or traces (the metal fingers along the connector edge of the DIMM). (See Figure 5.)

Figure 3 SP and RP DRAM DIMM Location on the Supervisor Engine 720

To install the SP and RP DRAM DIMMs, perform these steps:

Step 1

Attach an ESD grounding strap securely to your wrist and to earth (building) ground.

Note

If you are unsure about the correct way to attach an ESD grounding strap, see the "Preventing Electrostatic Discharge Damage" section for instructions.

Step 2

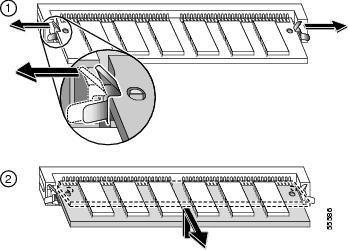

Release the old DRAM DIMM from the DIMM socket by simultaneously pivoting out the two clips on either side of the DIMM socket. (See Figure 4.) The DRAM DIMM will pivot up in the socket. Be careful not to apply too much force to the DIMM connector clips. Exerting too much force on the clips can cause them to break.

Figure 4 Removing the DRAM DIMM

Note

The DIMM shown in Figure 4 is shown for illustration purposes only and might not look exactly like the one installed on your Supervisor Engine 720.

Step 3

Grasp the old DRAM DIMM by its edges with your thumb and forefinger and gently pull the DRAM DIMM completely out of the socket. Immediately place the old DRAM DIMM on a properly grounded antistatic mat or store it in an antistatic bag.

Step 4

Carefully remove the new DRAM DIMM from its antistatic package.

Step 5

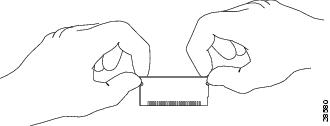

Holding the upgrade DIMM between your thumbs and forefingers, with the connector edge (the metal fingers) down, insert the connector edge of the DIMM into the socket connector. (See Figure 5.)

Figure 5 Handling a DIMM

Step 6

Slide the DIMM into the connector so that none of the metal fingers at the edge of the DIMM are visible under the edge of the connector.

CautionWhen inserting the DIMM, use firm but not excessive pressure. If you damage a socket, you must return the supervisor engine to Cisco for repair.

Step 7

Gently press down on the DIMM edges pivoting the DIMM into the socket until the two socket latches engage the notches on the sides of the DIMM. (See Figure 6.). Verify that both socket latches have engaged the DRAM DIMM.

Figure 6 Installing the DIMM in the Socket

Step 8

Repeat the process for the second DRAM DIMM.

Installing the Supervisor Engine 720

CautionDuring this procedure, wear grounding wrist straps, and handle modules by the carrier edges only to avoid ESD damage to the module.

To reinstall the Supervisor Engine 720 in the chassis, follow these steps:

Step 1

Verify that the captive installation screws are tightened on all modules installed in the chassis. This action assures that the EMI gaskets on all modules are fully compressed to maximize the space for the removed module.

Note

If the captive installation screws are loose, the EMI gaskets on the installed modules will push adjacent modules toward the open slot, reducing the opening size and making it difficult to install the removed module.

Step 2

Fully open both ejector levers on the supervisor engine that you are installing.

Step 3

Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following sets of steps for positioning the supervisor engine in a chassis with either horizontal or vertical slots:

Horizontal slots

a.

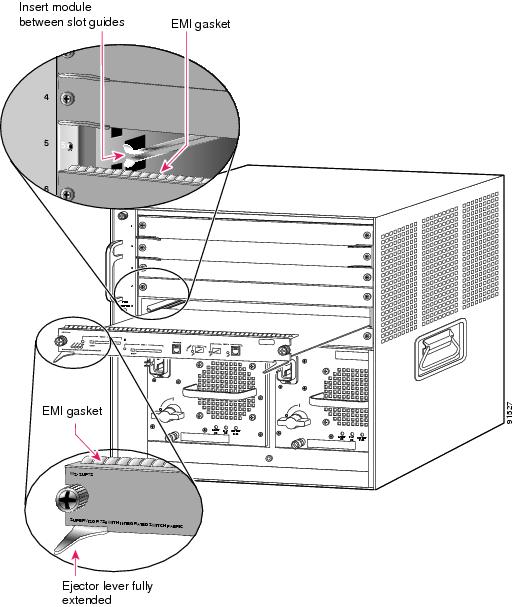

Position the supervisor engine in the slot. (See Figure 7.) Make sure that you align the sides of the module carrier with the slot guides on each side of the chassis slot.

b.

Carefully slide the supervisor engine into the slot until the EMI gasket along the top edge of the module makes contact with the module in the slot above it and both ejector levers have closed to approximately 45 degrees with respect to the supervisor engine faceplate.

Figure 7 Positioning the Supervisor Engine in a Horizontal Slot Chassis

c.

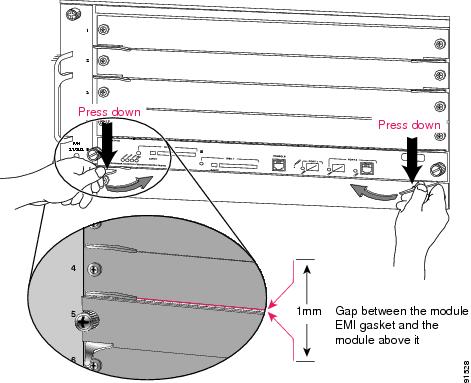

Using the thumb and forefinger of each hand, grasp the two ejector levers, and gently press down to create a small 0.040 inch (1 mm) gap between the supervisor engine's EMI gasket and the module above it. (See Figure 8.)

Note

Do not press down too forcefully on the levers because they will bend and become damaged.

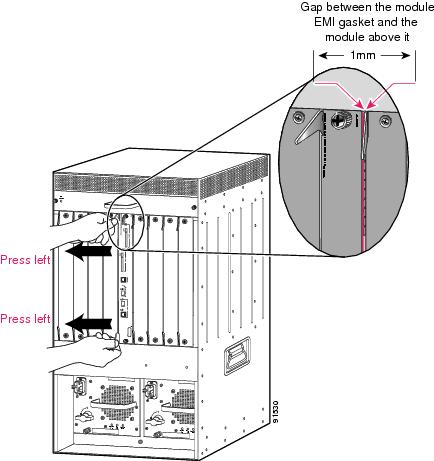

Figure 8 Creating a Gap Above the EMI Gasket (Horizontal Slot Chassis)

d.

While pressing down, simultaneously close the left and right ejector levers to fully seat the supervisor engine in the backplane connector. The ejector levers are fully closed when they are flush with the supervisor engine faceplate. (See Figure 8.)

Note

Failure to fully seat the supervisor engine in the backplane connector can result in error messages.

e.

Tighten the two captive installation screws on the supervisor engine.

Note

Make sure that the ejector levers are fully closed before tightening the captive installation screws.

f.

Verify that the supervisor engine STATUS LED is lit.

Periodically check the STATUS LED. If the STATUS LED changes from orange to green, the supervisor engine has successfully completed the boot process and is now online.

If the STATUS LED remains orange or turns red, the supervisor engine has not successfully completed the boot process and may have encountered an error.Vertical slots

a.

Position the supervisor engine in the slot. (See Figure 9.) Make sure that you align the sides of the module carrier with the slot guides on the top and bottom of the chassis slot.

b.

Carefully slide the supervisor engine into the slot until the EMI gasket along the right edge of the module makes contact with the module in the slot adjacent to it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate.

Figure 9 Positioning the Supervisor Engine in a Vertical Slot Chassis

c.

Using the thumb and forefinger of each hand, grasp the two ejector levers, and exert a slight pressure to the left, deflecting it approximately 0.040 inches (1 mm) creating a small gap between the supervisor engine's EMI gasket and the module adjacent to it. (See Figure 10.)

Note

Do not exert too much pressure on the ejector levers because they will bend and become damaged.

Figure 10 Creating a Gap Adjacent to the EMI Gasket (Vertical Slot Chassis)

d.

While pressing down on the ejector levers, simultaneously close the levers to fully seat the supervisor engine in the backplane connector. The ejector levers are fully closed when they are flush with the supervisor engine faceplate.

e.

Tighten the two captive installation screws on the supervisor engine.

Note

Make sure that the ejector levers are fully closed before tightening the captive installation screws.

f.

Verify that the supervisor engine STATUS LED is lit. Periodically check the STATUS LED.

If the STATUS LED changes from orange to green, the supervisor engine has successfully completed the boot process and is now online.

If the STATUS LED remains orange or turns red, the supervisor engine has not successfully completed the boot process and may have encountered an error.

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) damage, which can occur when modules or other field-replaceable units (FRUs) are improperly handled, results in intermittent or complete failures. Modules consist of printed circuit boards that are fixed in metal carriers. Electromagnetic interference (EMI) shielding and connectors are integral components of the carrier. Although the metal carrier helps to protect the board from ESD, always use an ESD grounding strap when handling modules.

Follow these guidelines for preventing ESD damage:

•

When using an ESD wrist strap make sure that it makes maximum contact with bare skin and with earth ground. ESD grounding straps are available with an adhesive pad, banana plug, metal spring clip, or alligator clip earth ground connector. All Catalyst 6500 series chassis are equipped with a banana plug connector (identified by the ground symbol next to the connector) somewhere on the front panel. This connector should not be confused with the system NEBs ground pad also located on the chassis. If you have an older Catalyst 6500 series chassis equipped with a plastic banana plug connector, we recommend that you use either the supplied ESD grounding wrist strap (with an adhesive pad or a metal clip) or an ESD grounding wrist strap equipped with an alligator clip. If you have a newer Catalyst 6500 series chassis that has a bare metal hole as the banana plug connector (also identified by the ground symbol next to the connector), we recommend that you use a personal ESD grounding strap equipped with a banana plug.

•

If you choose to use the disposable ESD wrist strap supplied with most FRUs or an ESD wrist strap equipped with an alligator clip, you must attach the system ground lug to the chassis in order to provide a proper grounding point for the ESD wrist strap.

Note

This system ground is also referred to as the network equipment building system (NEBS) ground.

•

If your chassis does not have the system ground attached, you must install the system ground.

After you install the system ground, follow these steps to correctly attach the ESD wrist strap:

Step 1

Attach the ESD wrist strap to bare skin as follows:

a.

If you are using the ESD wrist strap supplied with the FRUs, open the wrist strap package and unwrap the ESD wrist strap. Place the black conductive loop over your wrist and tighten the strap so that it makes good contact with your bare skin.

b.

If you are using an ESD wrist strap equipped with an alligator clip, open the package and remove the ESD wrist strap. Locate the end of the wrist strap that attaches to your body and secure it to your bare skin.

Step 2

Grasp the spring or alligator clip on the ESD wrist strap and momentarily touch the clip to a bare metal spot (unpainted surface) on the rack. We recommend that you touch the clip to an unpainted rack rail so that any built-up static charge is then safely dissipated to the entire rack.

Step 3

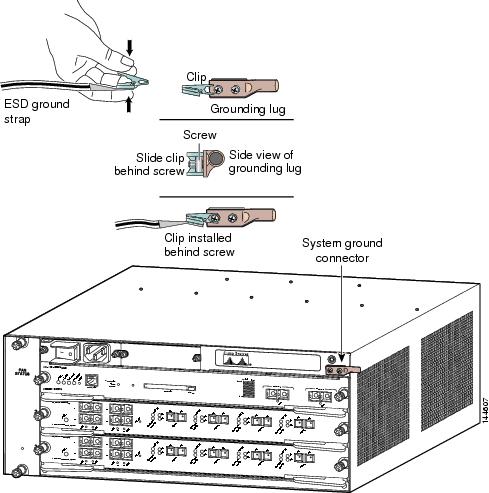

Attach either the spring clip or the alligator clip to the ground lug screw as follows (See Figure 11):

a.

If you are using the ESD wrist strap that is supplied with the FRUs, squeeze the spring clip jaws open, position the spring clip to one side of the system ground lug screw head, and slide the spring clip over the lug screw head so that the spring clip jaws close behind the lug screw head.

Note

The spring clip jaws do not open wide enough to fit directly over the head of the lug screw or the lug barrel.

b.

If you are using an ESD wrist strap that is equipped with an alligator clip, attach the alligator clip directly over the head of the system ground lug screw or to the system ground lug barrel.

Figure 11 Attaching the ESD Wrist Strap Clip to the System Ground Lug Screw

In addition, follow these guidelines when handling modules:

•

Handle modules by the metal carrier or edges only; avoid touching the printed circuit boards or connectors.

•

Place a removed module component board-side-up on a properly grounded antistatic surface or in a antistatic bag. If you plan to return the module to the factory, immediately place it in an antistatic bag.

•

Never attempt to remove the printed circuit board from the metal carrier.

CautionFor safety, periodically check the resistance value of the antistatic strap. The measurement should be between 1 and 10 megohm (Mohm).

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information, see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free service and Cisco currently supports RSS Version 2.0.

CCDE, CCENT, CCSI, Cisco Eos, Cisco HealthPresence, Cisco IronPort, the Cisco logo, Cisco Lumin, Cisco Nexus, Cisco Nurse Connect, Cisco Pulse, Cisco StackPower, Cisco StadiumVision, Cisco TelePresence, Cisco Unified Computing System, Cisco WebEx, DCE, Flip Channels, Flip for Good, Flip Mino, Flipshare (Design), Flip Ultra, Flip Video, Flip Video (Design), Instant Broadband, and Welcome to the Human Network are trademarks; Changing the Way We Work, Live, Play, and Learn, Cisco Capital, Cisco Capital (Design), Cisco:Financed (Stylized), Cisco Store, and Flip Gift Card are service marks; and Access Registrar, Aironet, AllTouch, AsyncOS, Bringing the Meeting To You, Catalyst, CCDA, CCDP, CCIE, CCIP, CCNA, CCNP, CCSP, CCVP, Cisco, the Cisco Certified Internetwork Expert logo, Cisco IOS, Cisco Press, Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Cisco Unity, Collaboration Without Limitation, Continuum, EtherFast, EtherSwitch, Event Center, Explorer, Fast Step, Follow Me Browsing, FormShare, GainMaker, GigaDrive, HomeLink, iLYNX, Internet Quotient, IOS, iPhone, iQuick Study, IronPort, the IronPort logo, Laser Link, LightStream, Linksys, MediaTone, MeetingPlace, MeetingPlace Chime Sound, MGX, Networkers, Networking Academy, Network Registrar, PCNow, PIX, PowerKEY, PowerPanels, PowerTV, PowerTV (Design), PowerVu, Prisma, ProConnect, ROSA, ScriptShare, SenderBase, SMARTnet, Spectrum Expert, StackWise, The Fastest Way to Increase Your Internet Quotient, TransPath, WebEx, and the WebEx logo are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the United States and certain other countries.

All other trademarks mentioned in this document or website are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any other company. (0908R)

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional and coincidental.

© 2009 Cisco Systems, Inc. All rights reserved.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback