Catalyst 6500 Series PFC3B and PFC3BXL Installation Note

Available Languages

Table Of Contents

Catalyst 6500 Series PFC3B, PFC3BXL, PFC3C, and PFC3CXL Installation Note

Preparing the Supervisor Engine 720

Removing the PFC3A from the Supervisor Engine 720

Applying the Label to the Supervisor Engine

Obtaining Documentation and Submitting a Service Request

Catalyst 6500 Series PFC3B, PFC3BXL, PFC3C, and PFC3CXL Installation Note

Product number: WS-F6K-PFC3B=, WS-F6K-PFC3BXL=, WS-F6K-PFC3C=, WS-F6K-PFC3CXL=

This publication describes how to install the Catalyst 6500 Series Policy Feature Card 3B (PFC3B) or PFC3BXL, and Catalyst 6500 Series Policy Feature Card 3C (PFC3C) or PFC3CXL on a Supervisor Engine 720.

Note

To use the PFC3BXL or PFC3CXL, you must also upgrade the switch processor (SP) and route processor (RP) memory on the Supervisor Engine 720 to 1 GB each using the included DRAM DIMMs. For information on upgrading the memory on the Supervisor Engine 720, refer to the Supervisor Engine 720 Switch Processor and Route Processor Memory Installation Note at this URL:

http://www.cisco.com/en/US/docs/switches/lan/catalyst6500/hardware/Config_Notes/OL_20611.html

The Supervisor Engine 720 memory upgrade (MEM-MSFC2-1GB=) is an option when using the PFC3B or PFC3C.

Contents

This publication contains these sections:

•

Preparing the Supervisor Engine 720

•

Removing the PFC3A from the Supervisor Engine 720

•

Installing the PFC3B or PFC3C

•

Applying the Label to the Supervisor Engine

•

Obtaining Documentation and Submitting a Service Request

Safety Overview

Safety warnings appear throughout this publication in procedures that, if performed incorrectly, may harm you. A warning symbol precedes each warning statement.

WarningOnly trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

WarningHazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

WarningBlank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

WarningThis unit is intended for installation in restricted access areas. A restricted access area can be accessed only through the use of a special tool, lock and key, or other means of security. Statement 1017

Parts List

These parts are in the WS-F6K-PFC3B=, WS-F6K-PFC3BXL=, WS-F6K-PFC3C=, or WS-F6K-PFC3CXL=kit:

•

One Catalyst 6500 series PFC3B, PFC3BXL, PFC3C, or PFC3CXL

•

One packet of labels

•

One disposable grounding wrist strap

•

One bag of mounting screws

•

Two 1-GB DRAM DIMMs (to be installed on the Supervisor Engine 720 switch processor and route processor) — PFC3BXL or PFC3CXL only

Required Tools

Note

In this section, the term "PFC3B" refers to the PFC3B and PFC3BXL, and "PFC3C" refers to PFC3C and PFC3CXL unless otherwise noted.

These tools are required to perform the installation of the PFC3B or PFC3C:

•

Antistatic mat or foam pad to support the removed Supervisor Engine 720

•

3/16-inch flat-blade screwdriver for the captive installation screws on the Supervisor Engine 720

•

Number 1 Phillips screwdriver for the screws and cap nut that fasten the PFC3B or PFC3C to the Supervisor Engine 720

•

Your own ESD-prevention equipment or the disposable grounding wrist strap included with all upgrade kits, field-replaceable units (FRUs), and spares

Installation Guidelines

Follow these guidelines when installing a PFC3B, PFC3BXL, PFC3C, PFC3CXL on a Supervisor Engine 720:

•

If you have redundant Supervisor Engine 720s, the hardware on both supervisor engines must be identical. You cannot have a mix of PFC3A, PFC3B, PFC3BXL, PFC3C, or PFC3CXL in the same chassis. You must shut down the switch to install the PFC3B, PFC3BXL, PFC3C or PFC3CXL even if you have redundant supervisor engines.

•

If you have redundant Supervisor Engine 720s, you must install the PFC3B, PFC3BXL, PFC3C, or PFC3CXL on each Supervisor Engine 720.

•

Observe the following cautions:

CautionAlways use an ESD wrist strap when handling modules or coming into contact with internal components.

CautionUse care not to damage the connectors on the supervisor engine. If you damage a connector, you will have to return the supervisor engine to Cisco for repair.

CautionEnsure that the PFC3B, PFC3BXL, PFC3C, or PFC3CXL is securely seated before you install and tighten the cap nut and the securing screws. If you use the screws to seat the PFC3B, PFC3BXL, PFC3C, or PFC3CXL the card might warp.

CautionYou must install all screws. The screws provide grounding between the PFC3B, PFC3BXL, PFC3C, or PFC3CXL and the supervisor engine. Failure to install all screws will invalidate the safety approvals and can cause fire and electrical hazards.

CautionThe hardware on both supervisor engines in a single chassis must be identical. If you have redundant supervisor engines, you must install a PFC3B, PFC3BXL, PFC3C, or PFC3CXL on each Supervisor Engine 720.

Preparing the Supervisor Engine 720

Note

In this section, the term "PFC3B" refers to the PFC3B and PFC3BXL, and "PFC3C" refers to the PFC3C and PFC3CXL and unless otherwise noted.

To install the PFC3B or PFC3C on a Supervisor Engine 720, you must shut down the switch, remove the Supervisor Engine 720 from the chassis, and remove the PFC3A from the Supervisor Engine 720.

CautionAlways use an ESD wrist strap when handling modules or coming into contact with internal components.

Before you remove a supervisor engine, you should first upload the current configuration to a server. This saves time when bringing the module back online. You can recover the configuration by downloading it from the server to the nonvolatile memory of the supervisor engine. For more information, refer to Chapter 26, "Working with Configuration Files," in the Catalyst 6500 Series Software Configuration Guide.

To prepare the Supervisor Engine 720 for the PFC3B or PFC3C, follow these steps:

Step 1

Upload the current configuration to a server. On any modules running Cisco IOS software, save the running configuration.

Step 2

Shut down the switch.

Step 3

Remove the Supervisor Engine 720 from the Catalyst 6500 series switch. (Refer to the Catalyst 6500 Series Switch Module Installation Guide for removal instructions.)

Step 4

Place the Supervisor Engine 720 on an antistatic mat or foam.

Removing the PFC3A from the Supervisor Engine 720

To remove the PFC3A from the Supervisor Engine 720, follow these steps:

Step 1

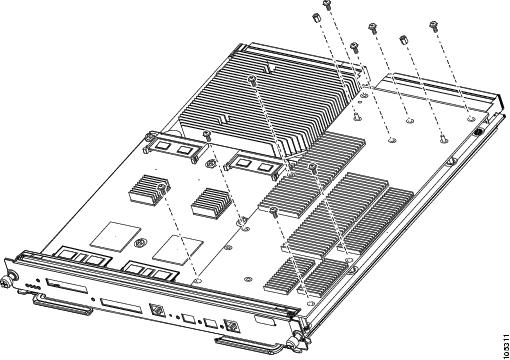

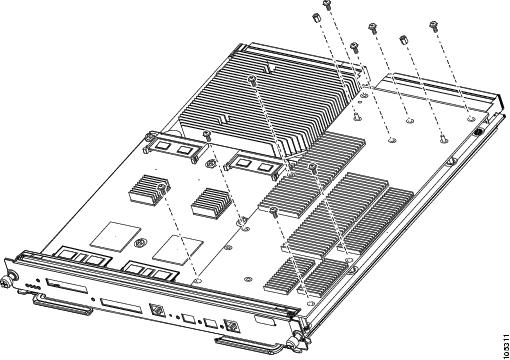

Remove the nine securing screws and two cap nuts. (See Figure 1.)

Note

Set the removed screws and cap nuts aside. Use the supplied screws and cap nuts when securing the PFC3B, PFC3BXL, PFC3C, or PFC3CXL to the Supervisor Engine 720.

Figure 1 Removing Securing Screws and Cap Nuts

CautionUse care not to damage the connectors on the supervisor engine. If you damage a connector, you will have to return the supervisor engine to Cisco for repair.

Step 2

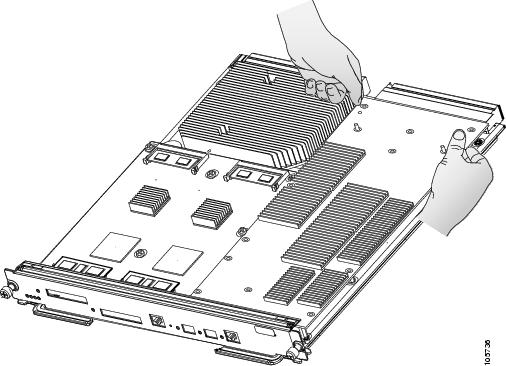

Hold the right edge of the PFC3A with your right hand and the rear left corner with your left hand. (See Figure 2.) Gently lift the PFC3A with both hands simultaneously and remove the PFC3A from the Supervisor Engine 720.

Figure 2 Removing the PFC3A

Step 3

Place the PFC3A on an antistatic mat or antistatic foam pad.

Installing the PFC3B or PFC3C

Note

In this section, the term "PFC3B" refers to the PFC3B and PFC3BXL, and "PFC3C" refers to the PFC3C and PFC3CXL unless otherwise noted.

To install the PFC3B or PFC3C on the Supervisor Engine 720, follow these steps:

Step 1

Remove the PFC3B or PFC3C from its antistatic bag.

Step 2

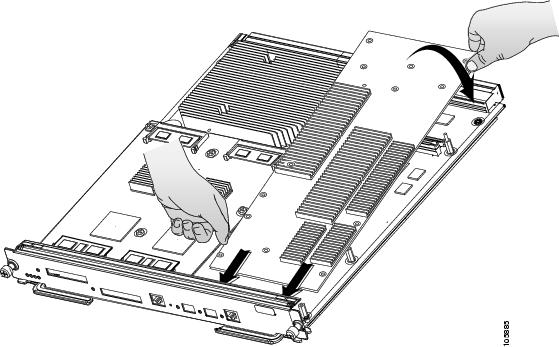

Insert the front edge of the PFC3B or PFC3C under the EMI gasket on the Supervisor Engine 720. (See Figure 3.)

Figure 3 Inserting the PFC3B or PFC3C Under the EMI Gasket

CautionUse care not to damage the connectors on the supervisor engine. If you damage a connector, you will have to return the supervisor engine to Cisco for repair.

Step 3

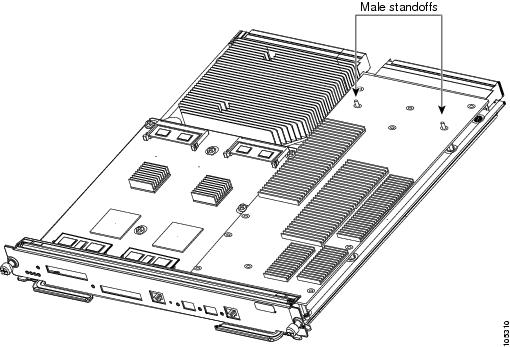

Align the PFC3B or PFC3C with the male standoffs on the Supervisor Engine 720, and carefully seat the PFC3B or PFC3C onto the Supervisor Engine 720. (See Figure 4.)

Figure 4 Male Standoff Location on the Supervisor Engine 720

CautionEnsure that the PFC3B or PFC3C is securely seated before you install and tighten the cap nut and the securing screws. If you use the screws to seat the PFC3B or PFC3C, the card might warp.

CautionUse care not to damage the connectors on the supervisor engine. If you damage a connector, you will have to return the supervisor engine to Cisco for repair.

Step 4

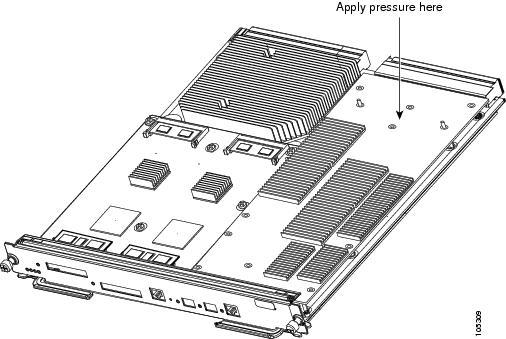

Using your thumbs, apply pressure at the locations shown in Figure 5 to ensure that the PFC3B or PFC3C is securely seated on the Supervisor Engine 720.

Figure 5 Seating the PFC3B or PFC3C on the Supervisor Engine

CautionYou must install all screws. The screws provide grounding between the PFC3B or PFC3C and the supervisor engine. Failure to install and tighten all screws will invalidate the safety approvals and can cause fire and electrical hazards.

Note

Use the supplied screws and cap nuts to secure the PFC3B or PFC3C to the Supervisor Engine 720.

Step 5

Use a Phillips-head screwdriver to install the supplied screws and cap nuts that secure the PFC3B or PFC3C to the Supervisor Engine 720. (See Figure 6.)

Figure 6 Installing the Supplied Screws

Note

To use the PFC3BXL or PFC3CXL , you must also upgrade the switch processor (SP) and route processor (RP) memory on the Supervisor Engine 720 to 1 GB each using the included DRAM DIMMs. For information on upgrading the memory on the Supervisor Engine 720, refer to the Supervisor Engine 720 Switch Processor and Route Processor Memory Installation Note at this URL:

http://www.cisco.com/en/US/docs/switches/lan/catalyst6500/hardware/Config_Notes/OL_20611.html

The Supervisor Engine 720 memory upgrade (MEM-MSFC2-1GB=) is an option when using the PFC3B or PFC3C.

Step 6

If you installed a PFC3BXL or PFC3CXL, upgrade the SP and RP memory on the Supervisor Engine 720 if you have not done so already.

Step 7

Install the Supervisor Engine 720 in the Catalyst 6500 series switch. (Refer to the Catalyst 6500 Series Switch Module Installation Guide for installation instructions.)

CautionThe hardware on both supervisor engines in a single chassis must be identical. If you have redundant supervisor engines, you must install the PFC3B, PFC3BXL, PFC3C, or PFC3CXLon each Supervisor Engine 720.

Step 8

If you are installing a PFC3B or PFC3C on a redundant Supervisor Engine 720, go to Step 3 in the "Preparing the Supervisor Engine 720" section and follow the procedure for removing the supervisor engine.

Step 9

Power up the switch.

Step 10

Depending on the software running on the switch, do one of the following steps to verify the installation:

•

Cisco IOS software on the supervisor engine and the MSFC3

Verify that the switch is online. This indicates that the system acknowledges the new module and has brought it online.

•

Catalyst supervisor engine software on the supervisor engine and Cisco IOS software on the MSFC3

Enter the show module command to verify that the system acknowledges the new module and has brought it online.

This example shows the output of the show module command:

Console> show moduleMod Slot Ports Module-Type Model Sub Status--- ---- ----- ------------------------- ------------------- --- --------1 1 48 10/100BaseTX Ethernet WS-X6248-RJ-45 no ok5 5 2 1000BaseX Supervisor WS-SUP720-BASE yes ok15 5 1 Multilayer Switch Feature WS-SUP720 no ok...Mod Sub-Type Sub-Model Sub-Serial Sub-Hw Sub-Sw--- ----------------------- ------------------- ----------- ------ ------5 L3 Switching Engine III WS-F6K-PFC3BXL SAD073702HH 0.250Console>If the installation is not successful, see the "Troubleshooting" section for troubleshooting information.

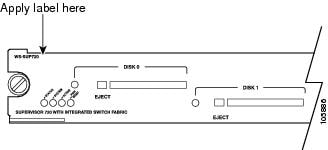

Applying the Label to the Supervisor Engine

The WS-F6K-PFC3B=, WS-F6K-PFC3BXL=, WS-F6K-PFC3C=, or WS-F6K-PFC3CXL= kits include a packet of labels. Apply the "PFC3B", "PFC3BXL", "PFC3C" or "PFC3CXL"label to the upper-left corner of the Supervisor Engine 720 front panel. (See Figure 7.)

Figure 7 Applying the Label

Troubleshooting

Table 1 describes the basic troubleshooting information.

Table 1 Troubleshooting

The supervisor engine fails online diagnostics.

Remove the supervisor engine from the chassis and make sure that all securing screws and cap nuts are tight. See Figure 6 for screw locations.

The supervisor engine experiences a software-forced reset or boots to ROMMON.

The supervisor engine does not boot up (no power to supervisor engine, no console prompt, no STATUS LED).

Remove the supervisor engine from the chassis and reseat the SP and RP memory modules.

If these solutions do not resolve the issue, see the "Obtaining Documentation and Submitting a Service Request" section for information on obtaining technical assistance.

Related Documentation

For additional information on Catalyst 6500 series switches and command-line interface (CLI) commands, refer to the following publications:

•

Regulatory Compliance and Safety Information for the Catalyst 6500 Series Switches

•

Catalyst 6500 Series Switch Installation Guide

•

Catalyst 6500 Series Switch Module Installation Guide

•

Catalyst 6500 Series Switch Software Configuration Guide

•

Catalyst 6500 Series Switch Command Reference

•

Catalyst 6500 Series Switch Cisco IOS Software Configuration Guide

•

Catalyst 6500 Series Switch Cisco IOS Command Reference

•

Catalyst 6500 Series System Message Guide

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information, see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free service and Cisco currently supports RSS Version 2.0.

This document is to be used in conjunction with the documents listed in the "Related Documentation" section.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership relationship between Cisco and any other company. (1110R)

Copyright © 2004-2013 Cisco Systems, Inc. All rights reserved.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback