Catalyst 6000 Family Multilayer Switch Feature Card 2 Installation Note

Available Languages

Table Of Contents

Catalyst 6000 Family Multilayer Switch Feature Card 2 Installation Note

Preparing the Supervisor Engine

Removing the MSFC from the Supervisor Engine 1A

Obtaining Documentation and Submitting a Service Request

Catalyst 6000 Family Multilayer Switch Feature Card 2 Installation Note

Product number: WS-F6K-MSFC2=

This publication describes how to install the Catalyst 6000 Family Multilayer Switch Feature Card 2 (MSFC2) on a Supervisor Engine 1A or Supervisor Engine 2.

Contents

This publication contains these sections:

•

Preparing the Supervisor Engine

•

Removing the MSFC from the Supervisor Engine 1A

•

Obtaining Documentation and Submitting a Service Request

Safety Overview

Safety warnings appear throughout this publication in procedures that may harm you if performed incorrectly. A warning symbol precedes each warning statement.

Warning

Only trained and qualified personnel should be allowed to install or replace this equipment.

Features

The MSFC2 ships with 128-MB SDRAM at 100 MHz with Error Checking and Correction (ECC) (single-bit error detection and correction; 2-bit error detection) as the default and is upgradeable to 256 MB or 512 MB.

Table 1 lists the Cisco IOS features available for the MSFC2.

Table 1 Cisco IOS Features

Wire-speed IP, IP multicast, and IPX routing between VLANs (switches running the Cisco IOS for the Catalyst 6000 Family of Switches product can also route between ports)

Support for up to 128,000 entries for IP network prefixes, IP unicast and multicast addresses, IPX network numbers, and MAC addresses1

FIB2 and adjacency database support as defined in other Cisco routers

Destination-based load sharing among equal cost paths

Static IP routing

IP routing protocols: IGRP3 , EIGRP4 , OSPF5 , RIP6 , and RIP-2

IP multicast routing protocols: PIM7 (sparse and dense mode) and DVMRP8 interrupt

IPX routing protocols: RIP, NLSP9 , and EIGRP

IGMP10 v1 and v2

IGMP snooping

CGMP11 server support

Full ICMP12 support

GDP13

IRDP14

MSDP15

MBGP16

Standard DNS17 support

MHSRP20

CDP21

Wire-speed IP standard ACL support

Standard reflexive ACL

Two priority queues for CoS23 -based operation

IP precedence-based IP forwarding

1 An MLS cache larger than 32,000 entries increases the probability that a flow will not be switched by the PFC and will get forwarded to the router

2 FIB = forwarding information base

3 IGRP = Interior Gateway Routing Protocol

4 EIGRP = Enhanced Interior Gateway Routing Protocol

5 OSPF = Open Shortest Path First

6 RIP = Routing Information Protocol

7 PIM = Protocol Independent Multicast

8 DVMRP = Distance Vector Multicast Routing Protocol

9 NLSP = NetWare Link Services Protocol

10 IGMP = Internet Group Management Protocol

11 CGMP = Cisco Group Multicast Protocol

12 ICMP = Internet Control Message Protocol

13 GDP = Gateway Discovery Protocol

14 IRDP = ICMP Router Discovery Protocol

15 MSDP = Multicast Source Discovery Protocol

16 MBGP = Multicast Border Gateway Protocol

17 DNS = Domain Naming System

18 DHCP = Dynamic Host Configuration Protocol

19 BOOTP = Boot Protocol

20 MHSRP = Multigroup Hot Standby Routing Protocol

21 CDP = Cisco Discovery Protocol

22 QoS = Quality of Service

23 CoS = Class of Service

Software Requirements

The software requirements are as follows:

•

For switches with Cisco IOS on the Catalyst 6000 Family of Switches product on both the supervisor engine and the MSFC2:

Cisco IOS Release 12.1(2)E or later on both the supervisor engine and the MSFC2. The image required to support this is c6sup12-*-mz, where * is one of the various versions (such as js, is, ds). When you upgrade from MSFC to MSFC2, you need to upgrade the c6sup-*-mz or c6sup11-*-mz image to the new c6sup12-*-mz image.

•

For switches with Catalyst supervisor engine software on the supervisor engine and Cisco IOS software on the MSFC2:

–

Catalyst 6000 family supervisor engine software release 5.4(3) or later

–

Cisco IOS Release 12.1(2)E or later on the MSFC2

Parts List

These parts are in the replacement kit:

•

One Catalyst 6000 MSFC2 (WS-F6K-MSFC2=)

•

One disposable grounding wrist strap

•

One bag of spare mounting screws

Required Tools

These tools are required to perform the installation of the MSFC2:

•

Antistatic mat or foam pad to support the removed supervisor engine

•

3/16-inch flat-blade screwdriver for the captive installation screws on the supervisor engine

•

Number 1 Phillips screwdriver for the screws and cap nut that fasten the MSFC2 to the supervisor engine

•

Your own ESD-prevention equipment or the disposable grounding wrist strap included with all upgrade kits, field-replaceable units (FRUs), and spares

Refer to the Site Preparation and Safety Guide for ESD details including the locations of the ESD connectors on the Catalyst 6000 family switches.

Installation Guidelines

Follow these guidelines when installing an MSFC2 on a supervisor engine:

•

The hardware on both supervisor engines in a single chassis must be identical. You cannot mix an MSFC and an MSFC2 in the same chassis. You must shut down the switch to install the MSFC2, even if you have redundant supervisor engines.

•

If you have redundant supervisor engines, you must install an MSFC2 on each supervisor engine.

•

The Supervisor Engine 1A with only a PFC cannot be upgraded to MSFC2. There are no standoffs installed for securing the MSFC2 to the supervisor engine.

•

The Supervisor Engine 1A with a PFC and an MSFC (WS-X6K-SUP1A-MSFC) can be upgraded to an MSFC2. You must remove the existing MSFC from the Supervisor Engine 1A. The MSFC2 uses the same standoffs used for the MSFC.

•

The Supervisor Engine 2 with a PFC2 (WS-X6K-SUP2-2GE) can be upgraded to an MSFC2. The supervisor engine has standoffs installed for securing the MSFC2 to the supervisor engine.

Preparing the Supervisor Engine

Note

Review the guidelines in the "Software Requirements" section before you prepare the supervisor engine.

To install the MSFC2 on a Supervisor Engine 1A with a PFC and an MSFC, you must shut down the switch, remove the Supervisor Engine 1A from the chassis, and remove the MSFC from the Supervisor Engine 1A.

To install the MSFC2 on a Supervisor Engine 2, you must shut down the switch and remove the Supervisor Engine 2 from the chassis.

CautionAlways use an ESD wrist strap when handling modules or coming into contact with internal components.

Before you remove a supervisor engine, you should first upload the current configuration to a server. This saves time when bringing the module back online. You can recover the configuration by downloading it from the server to the nonvolatile memory of the supervisor engine. For more information, refer to Chapter 26, "Working with Configuration Files," in the Catalyst 6000 Family Software Configuration Guide.

To prepare the supervisor engine, follow these steps:

Step 1

Upload the current configuration to a server. On any modules running Cisco IOS, save the running configuration.

Step 2

Shut down the switch.

Step 3

Remove the supervisor engine from the Catalyst 6000 family switch. (Refer to the Catalyst 6000 Family Module Installation Guide for removal instructions.)

Step 4

Place the supervisor engine on an antistatic mat or foam.

To remove the MSFC from the Supervisor Engine 1A, see the "Removing the MSFC from the Supervisor Engine 1A" section and follow the instructions for removing the MSFC.

To install the MSFC2 on a Supervisor Engine 2, see the "Installing the MSFC2" section and follow the instructions for installing the MSFC2.

Removing the MSFC from the Supervisor Engine 1A

Note

You must remove the Flash SIMM from the MSFC to access two mounting screws that are located under the SIMM.

CautionHandle the SIMM by its edges only; avoid touching the memory module, pins, or traces (the metal fingers along the connector edge of the SIMM). SIMMs are sensitive components that are susceptible to ESD damage and can be shorted by mishandling.

To remove the MSFC from the Supervisor Engine 1A, follow these steps:

Step 1

Note that the Flash SIMM is located at the rear of the MSFC (see Figure 1). Pull the locking spring clips on both sides of the Flash SIMM outward and tilt the Flash SIMM free of the clips (see Figure 2). Be careful not to break the clips on the Flash SIMM connector.

Figure 1 Flash SIMM Location on the MSFC

Figure 2 Removing the Flash SIMM

Step 2

Hold the SIMM by the edges and gently lift and remove it, placing it on an antistatic mat or foam.

Step 3

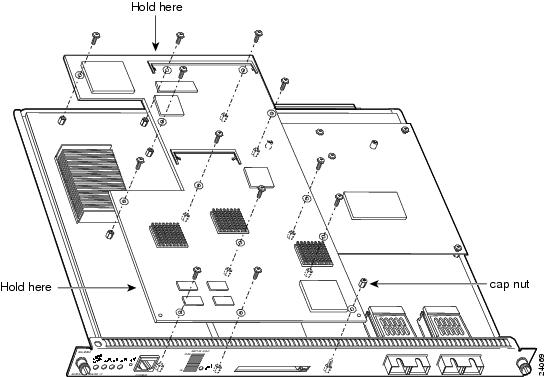

Remove the securing screws and cap nut (see Figure 3).

Figure 3 Removing Securing Screws and Cap Nut

Step 4

Hold the top edge of the MSFC with your right hand and the bottom-left edge with your left hand (see Figure 3). Gently lift the MSFC with both hands simultaneously and remove the MSFC from the supervisor engine.

CautionUse care not to damage the connectors on the supervisor engine. If you damage a connector, you will have to return the supervisor engine to Cisco for repair.

Step 5

Place the MSFC on an antistatic mat or antistatic foam pad.

Installing the MSFC2

Note

The MSFC2 is designed to be installed on a Supervisor Engine 1A and a Supervisor Engine 2. The standoff locations on the different supervisor engines may not be the same. Not all mounting holes on the MSFC2 will be used in all installations. Visually verify that there are standoffs beneath the mounting holes before installing the securing screws.

To install the MSFC2 on the supervisor engine, follow these steps:

Step 1

Remove the MSFC2 from its antistatic bag.

Step 2

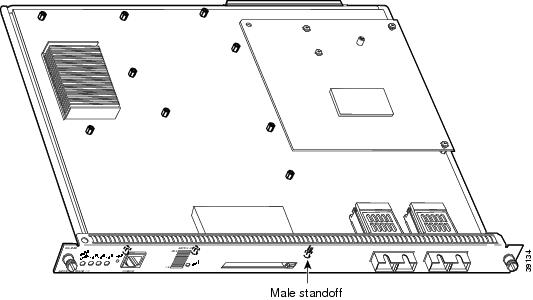

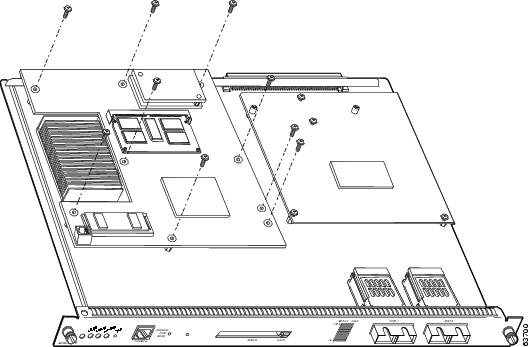

Align the MSFC2 with the standoffs on the supervisor engine. (See Figure 4).

Figure 4 Male Standoff Location on the Supervisor Engine

Step 3

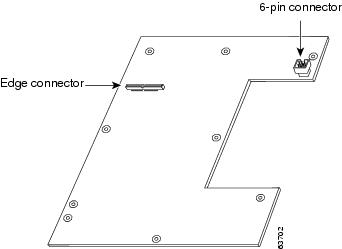

Ensure that the connectors on the MSFC2 (see Figure 5) are aligned with the connectors on the supervisor engine.

Figure 5 MSFC2 Connectors

Step 4

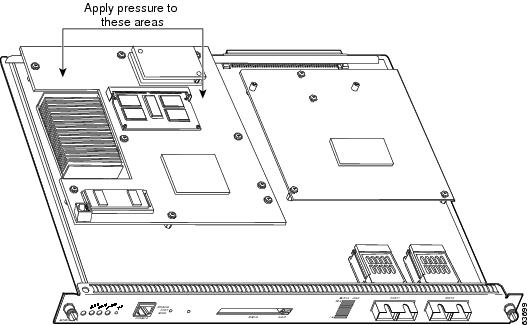

Carefully seat the MSFC2 onto the supervisor engine (see Figure 6).

Step 5

Using your thumbs, apply pressure at the locations shown in Figure 6 to ensure that the MSFC2 is securely seated on the supervisor engine.

CautionEnsure that the MSFC2 is securely seated before you install and tighten the cap nut and securing screws. Using the screws to seat the MSFC2 could warp the card.

CautionUse care not to damage the connectors on the supervisor engine. If you damage a connector, you will have to return the supervisor engine to Cisco for repair.

Figure 6 Seating the MSFC2 on the Supervisor Engine

Step 6

Use a Phillips-head screwdriver to install the screws that secure the MSFC2 to the supervisor engine. (See Figure 7).

CautionYou must install all screws. The screws provide grounding between the MSFC 2 and the supervisor engine. Failure to install all screws will invalidate the safety approvals and can cause fire and electrical hazards.

Figure 7 Installing the Screws

Step 7

Install the supervisor engine in the Catalyst 6000 family switch. (Refer to the Catalyst 6000 Family Module Installation Guide for installation instructions.)

CautionThe hardware on both supervisor engines in a single chassis must be identical. If you have redundant supervisor engines, you must install an MSFC2 on each supervisor engine.

Step 8

If you are installing an MSFC2 on a redundant supervisor engine, go to Step 3 in the "Preparing the Supervisor Engine" section and follow the procedure for removing the supervisor engine.

Step 9

Power up the switch.

Step 10

Depending on the software running on the switch, do one of the following steps to verify the installation:

•

Cisco IOS for the Catalyst 6000 Family of Switches product on the supervisor engine and the MSFC2:

Verify that the switch is online. This indicates that the system acknowledges the new module and has brought it online.

•

Catalyst supervisor engine software on the supervisor engine and Cisco IOS on the MSFC2:

Enter the show module command to verify that the system acknowledges the new module and has brought it online.

This example shows the output of the show module command:

Console> show moduleMod Slot Ports Module-Type Model Status--- ---- ----- ------------------------- ------------------- --------1 1 2 1000BaseX Supervisor WS-X6K-SUP1A-2GE ok15 1 1 Multilayer Switch Feature WS-F6K-MSFC2 ok2 1 2 1000BaseX Supervisor WS-X6K-SUP1A-2GE ok16 1 1 Multilayer Switch Feature WS-F6K-MSFC2 standby.<display text omitted>.Console>

Related Documentation

For additional information on Catalyst 6000 family switches and command-line interface (CLI) commands, refer to the following publications:

•

Regulatory Compliance and Safety Information for the Catalyst 6000 Family Switches

•

Catalyst 6000 Family Installation Guide

•

Catalyst 6000 Family Module Installation Guide

•

Catalyst 6000 Family Software Configuration Guide

•

Catalyst 6000 Family Command Reference

•

Catalyst 6000 Family IOS Software Configuration Guide

•

Catalyst 6000 Family IOS Command Reference

•

System Message Guide—Catalyst 6000 Family, Catalyst 5000 Family, Catalyst 4000 Family, Catalyst 2926G Series, Catalyst 2948G, and Catalyst 2980G Switches

•

Site Preparation and Safety Guide

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional information, see the monthly What's New in Cisco Product Documentation, which also lists all new and revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What's New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free service and Cisco currently supports RSS Version 2.0.

Feedback

Feedback