Catalyst 6500 Series Switch Content Switching Module Installation Note Software Release 4.2(x)

Available Languages

Table Of Contents

Catalyst 6500 Series Switch Content Switching Module Installation and Verification Note

Environmental and System Requirements

Cisco Product Security Overview

Reporting Security Problems in Cisco Products

Obtaining Technical Assistance

Cisco Technical Support Website

Definitions of Service Request Severity

Obtaining Additional Publications and Information

Catalyst 6500 Series Switch Content Switching Module Installation and Verification Note

Product Number: WS-X6066-SLB-APC

This publication describes how to install the Content Switching Module (CSM) in the Catalyst 6500 series switches, including the software and hardware requirements.

Contents

This publication contains these sections:

•

Environmental and System Requirements

•

Cisco Product Security Overview

•

Obtaining Technical Assistance

•

Obtaining Additional Publications and Information

Front Panel Description

This section describes the physical attributes of the Content Switching Module.

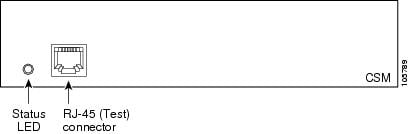

Figure 1 shows the CSM front panel.

Figure 1 Content Switching Module Front Panel

Note

The RJ-45 connector is covered by a removable plate.

Status LED

At startup, the CSM initializes various hardware components and communicates with the supervisor engine. The Status LED indicates the supervisor engine operations and the initialization results. During the normal initialization sequence, the status LED changes from off to red to orange to and green.

Note

For more information on the supervisor engine LEDs, refer to the Catalyst 6500 Series Switch Module Installation Guide.

Table 1 describes the Status LED operation.

Table 1 Content Switching Module Status LED

Off

•

The module is waiting for the supervisor engine to provide power.

•

The module is not online.

•

The module is not receiving power, which could be caused by the following:

–

Power is not available to the CSM.

–

Module temperature is over the limit1 .

Red

•

The module is released from reset by the supervisor engine and is booting.

•

If the boot code fails to run, the LED stays red after startup.

Orange

•

The module is initializing hardware or communicating with the supervisor engine.

•

A fault occurred during the initialization sequence.

•

The module has failed to download its Field Programmable Gate Arrays (FPGAs) at startup but continues with the remainder of the initialization sequence and provides the module online status from the supervisor engine.

•

The module has not received module online status from the supervisor engine. This problem could be caused by the supervisor engine detecting a failure in an external loopback test that it issued to the CSM.

Green

•

The module is operational; the supervisor engine has provided module online status.

Green to orange

•

The module is disabled through the supervisor engine CLI 2 using the set module disable mod command.

1 Enter the show environment temperature mod command to display the temperature of each of four sensors on the CSM.

2 CLI=command-line interface.

RJ-45 Connector

The RJ-45 connector, which is covered by a removable plate, is used to connect a management station device or a test device. This connector is used by field engineers to perform testing and to obtain dump information.

Environmental and System Requirements

This section describes the environmental and system requirements.

Environmental Requirements

Table 2 lists the environmental requirements for the CSM.

System Requirements

Before you install the CSM into the Catalyst 6500 series switch, refer to the Release Notes for Catalyst 6500 Series Content Switching Module to make sure that the switch meets the hardware and software requirements.

CautionYou can use the Multilayer Switch Feature Card (MSFC), which is internal to the Catalyst 6500 series switch, to route traffic on either the client side or the server side of the CSM, but not both simultaneously (unless policy-based routing is used).

Safety Overview

Warning

Only trained and qualified personnel should be allowed to install, replace, or service this equipment. Statement 1030

Warning

Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. Statement 1034

Warning

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

Warning

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself.

Preparing to Install the CSM

Before installing the CSM, make sure that the following items are available:

•

Catalyst 6500 series switch chassis

•

Management station that is available through a Telnet or a console connection to perform configuration tasks

CautionThe WS-X6066-SLB-APC Content Switching Module is not fabric enabled.

Required Tools

These tools are required to install the CSM in the Catalyst 6500 series switches:

•

Flat-blade screwdriver

•

Phillips-head screwdriver

•

Wrist strap or other grounding device

•

Antistatic mat or antistatic foam

Whenever you handle the CSM, always use a wrist strap or other grounding device to prevent electrostatic discharge (ESD).

Installing the CSM

CautionTo prevent ESD damage, handle modules by the carrier edges only.

Note

All modules, including the supervisor engine (if you have redundant supervisor engines), support hot swapping. You can add, replace, or remove modules without interrupting the system power or causing other software or interfaces to shut down. For more information about hot-swapping modules, refer to the Catalyst 6500 Series Switch Module Installation Guide.

Warning

During this procedure, wear grounding wrist straps to avoid ESD damage to the module. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself.

To install a module in the chassis, perform these steps:

Step 1

Choose a slot for the CSM.

Step 2

Verify that there is enough clearance to accommodate any interface equipment that you will connect directly to the module ports. If possible, place modules between empty slots that contain only module filler plates.

Step 3

Verify that the captive installation screws are tightened on all modules installed in the chassis.

This action ensures that the EMI gaskets on all modules are fully compressed to maximize the opening space for the replacement module.

Note

If the captive installation screws are loose, the EMI gaskets on the installed modules will push adjacent modules toward the open slot, reducing the opening size and making it difficult to install the replacement module.

Step 4

Remove the module filler plate by removing the two Phillips pan-head screws from the filler plate. (To remove a module, refer to the "Removing the Module" section.)

Step 5

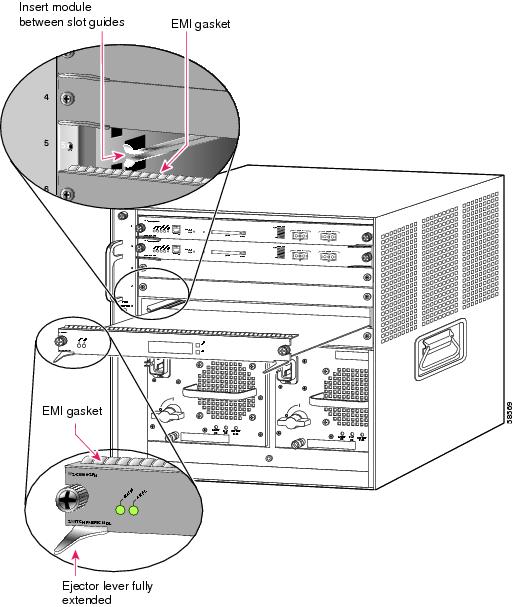

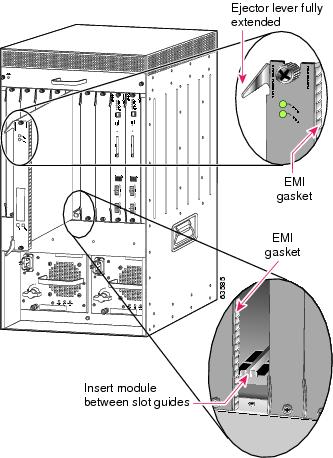

Fully open both ejector levers on the new or replacement module. (See Figure 2.)

Figure 2 Positioning the Module in a Horizontal Slot Chassis

Step 6

Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following sets of substeps:

Horizontal slots

a.

Position the module in the slot. Make sure that you align the sides of the module carrier with the slot guides on each side of the slot. (See Figure 2.)

b.

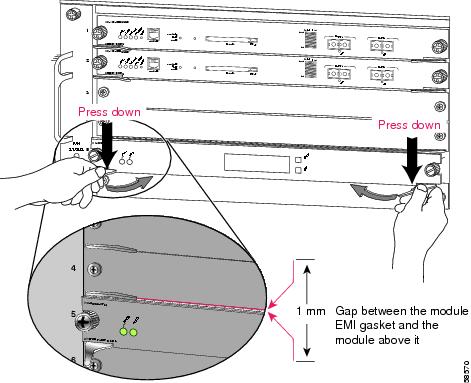

Carefully slide the module into the slot until the EMI gasket along the top edge of the module makes contact with the module in the slot above it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate. (See Figure 3.)

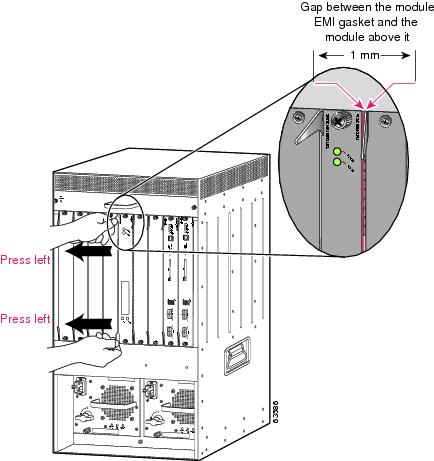

Figure 3 Clearing the EMI Gasket in a Horizontal Slot Chassis

c.

Using the thumb and forefinger of each hand, grasp the two ejector levers and press down to create a small (0.040 inch [1 mm]) gap between the EMI gasket and the module above it. (See Figure 3.)

CautionPressing down too firmly on the levers will bend and damage them.

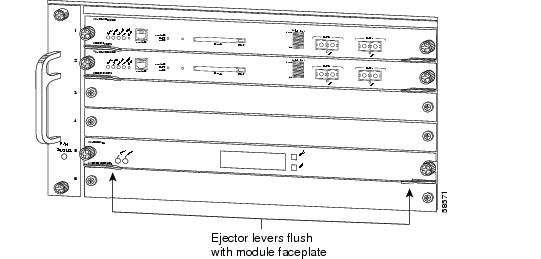

d.

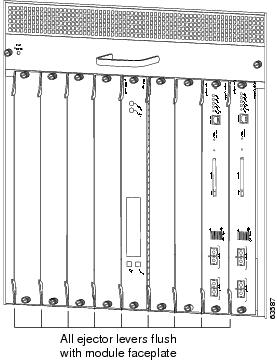

While pressing down, simultaneously close the left and right ejector levers to fully seat the module in the backplane connector. The ejector levers are fully closed when they are flush with the module faceplate. (See Figure 4.)

Figure 4 Ejector Lever Closure in a Horizontal Slot Chassis

Note

Failure to fully seat the module in the backplane connector can result in error messages.

e.

Tighten the two captive installation screws on the module.

Note

Make sure that the ejector levers are fully closed before tightening the captive installation screws.

Vertical slots

a.

Position the module in the slot. (See Figure 5.) Make sure that you align the sides of the module carrier with the slot guides on the top and bottom of the slot.

Figure 5 Positioning the Module in a Vertical Slot Chassis

b.

Carefully slide the module into the slot until the EMI gasket along the right edge of the module makes contact with the module in the slot adjacent to it and both ejector levers have closed to approximately 45 degrees with respect to the module faceplate. (See Figure 6.)

c.

Using the thumb and forefinger of each hand, grasp the two ejector levers and exert a slight pressure to the left, deflecting the module approximately 0.040 inches (1 mm) to create a small gap between the module's EMI gasket and the module adjacent to it. (See Figure 6.)

Figure 6 Clearing the EMI Gasket in a Vertical Slot Chassis

CautionExerting too much pressure on the ejector levers will bend and damage them.

d.

While pressing on the ejector levers, simultaneously close them to fully seat the module in the backplane connector. The ejector levers are fully closed when they are flush with the module faceplate. (See Figure 7.)

Figure 7 Ejector Lever Closure in a Vertical Slot Chassis

e.

Tighten the two captive installation screws on the module.

Note

Make sure that the ejector levers are fully closed before tightening the captive installation screws.

This completes the CSM installation procedure.

Verifying the Installation

When you install the CSM in a Catalyst 6500 series switch, the module goes through a startup sequence that requires no intervention. At the successful conclusion of the startup sequence, the green Status LED will light and remain on. If the Status LED does not show green, or if it shows a different color, refer to Table 1 to determine the status of the module.

Removing the Module

This section describes how to remove an existing module from a Catalyst 6500 series switch chassis slot.

CautionDuring this procedure, wear grounding wrist straps to avoid ESD damage to the module. Do not directly touch the backplane with your hand or any metal tool, or you could shock yourself.

Warning

Invisible laser radiation may be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments. Statement 1051

To remove a module from the chassis, perform these steps:

Step 1

Disconnect any network interface cables that are attached to the module.

Step 2

Verify that the captive installation screws on all of the modules in the chassis are tight.

This step assures that the space that is created by the removed module is maintained.

Note

If the captive installation screws are loose, the electromagnetic interference (EMI) gaskets on the installed modules will push the modules toward the open slot, reducing the opening size and making it difficult to install the replacement module.

Step 3

Loosen the two captive installation screws on the module.

Step 4

Depending on the orientation of the slots in the chassis (horizontal or vertical), perform one of the following sets of substeps:

Horizontal slots

a.

Place your thumbs on the left and right ejector levers, and simultaneously rotate the levers outward to unseat the module from the backplane connector.

b.

Grasp the front edge of the module, and slide the module part of the way out of the slot. Place your other hand under the module to support the weight of the module. Do not touch the module circuitry.

Vertical slots

a.

Place your thumbs on the ejector levers that are located at the top and bottom of the module, and simultaneously rotate the levers outward to unseat the module from the backplane connector.

b.

Grasp the edges of the module, and slide the module straight out of the slot. Do not touch the module circuitry.

Step 5

Place the module on an antistatic mat or antistatic foam, or immediately reinstall it in another slot.

Step 6

If the slot from which you removed the module is to remain empty, install a module filler plate to keep dust out of the chassis and to maintain proper airflow through the chassis.

Warning

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system unless all cards, faceplates, front covers, and rear covers are in place. Statement 1029

Related Documentation

Use this document with the following Cisco documents:

•

Release Notes for the Catalyst 6500 Series Switch Content Switching Module

•

Catalyst 6500 Series Switch Content Switching Module Configuration Note

•

Catalyst 6500 Series Switch Content Switching Module Command Reference

•

Catalyst 6500 Series Switch Cisco IOS Software Configuration Guide

•

Catalyst 6500 Series Switch Software Configuration Guide

Obtaining Documentation

Cisco documentation and additional literature are available on Cisco.com. Cisco also provides several ways to obtain technical assistance and other technical resources. These sections explain how to obtain technical information from Cisco Systems.

Cisco.com

You can access the most current Cisco documentation at this URL:

http://www.cisco.com/cisco/web/psa/default.html?mode=prod

You can access the Cisco website at this URL:

You can access international Cisco websites at this URL:

http://www.cisco.com/web/siteassets/locator/index.html

Documentation DVD

Cisco documentation and additional literature are available in a Documentation DVD package, which may have shipped with your product. The Documentation DVD is updated regularly and may be more current than printed documentation. The Documentation DVD package is available as a single unit.

Registered Cisco.com users (Cisco direct customers) can order a Cisco Documentation DVD (product number DOC-DOCDVD=) from the Ordering tool or Cisco Marketplace.

Cisco Ordering tool:

http://www.cisco.com/en/US/ordering/index.shtml

Cisco Marketplace:

http://www.cisco.com/go/marketplace/

Ordering Documentation

You can find instructions for ordering documentation at this URL:

http://www.cisco.com/en/US/ordering/index.shtml

You can order Cisco documentation in these ways:

•

Registered Cisco.com users (Cisco direct customers) can order Cisco product documentation from the Ordering tool:

http://www.cisco.com/en/US/ordering/index.shtml

•

Nonregistered Cisco.com users can order documentation through a local account representative by calling Cisco Systems Corporate Headquarters (California, USA) at 408 526-7208 or, elsewhere in North America, by calling 1 800 553-NETS (6387).

Documentation Feedback

You can send comments about technical documentation to bug-doc@cisco.com.

You can submit comments by using the response card (if present) behind the front cover of your document or by writing to the following address:

Cisco Systems

Attn: Customer Document Ordering

170 West Tasman Drive

San Jose, CA 95134-9883We appreciate your comments.

Cisco Product Security Overview

Cisco provides a free online Security Vulnerability Policy portal at this URL:

http://www.cisco.com/en/US/products/products_security_vulnerability_policy.html

From this site, you can perform these tasks:

•

Report security vulnerabilities in Cisco products.

•

Obtain assistance with security incidents that involve Cisco products.

•

Register to receive security information from Cisco.

A current list of security advisories and notices for Cisco products is available at this URL:

If you prefer to see advisories and notices as they are updated in real time, you can access a Product Security Incident Response Team Really Simple Syndication (PSIRT RSS) feed from this URL:

http://www.cisco.com/en/US/products/products_psirt_rss_feed.html

Reporting Security Problems in Cisco Products

Cisco is committed to delivering secure products. We test our products internally before we release them, and we strive to correct all vulnerabilities quickly. If you think that you might have identified a vulnerability in a Cisco product, contact PSIRT:

•

Emergencies — security-alert@cisco.com

•

Nonemergencies — psirt@cisco.com

Tip

We encourage you to use Pretty Good Privacy (PGP) or a compatible product to encrypt any sensitive information that you send to Cisco. PSIRT can work from encrypted information that is compatible with PGP versions 2.x through 8.x.

Never use a revoked or an expired encryption key. The correct public key to use in your correspondence with PSIRT is the one that has the most recent creation date in this public key server list:

http://pgp.mit.edu:11371/pks/lookup?search=psirt%40cisco.com&op=index&exact=on

In an emergency, you can also reach PSIRT by telephone:

•

1 877 228-7302

•

1 408 525-6532

Obtaining Technical Assistance

For all customers, partners, resellers, and distributors who hold valid Cisco service contracts, Cisco Technical Support provides 24-hour-a-day, award-winning technical assistance. The Cisco Technical Support Website on Cisco.com features extensive online support resources. In addition, Cisco Technical Assistance Center (TAC) engineers provide telephone support. If you do not hold a valid Cisco service contract, contact your reseller.

Cisco Technical Support Website

The Cisco Technical Support Website provides online documents and tools for troubleshooting and resolving technical issues with Cisco products and technologies. The website is available 24 hours a day, 365 days a year, at this URL:

http://www.cisco.com/cisco/web/support/index.html

Access to all tools on the Cisco Technical Support Website requires a Cisco.com user ID and password. If you have a valid service contract but do not have a user ID or password, you can register at this URL:

http://tools.cisco.com/RPF/register/register.do

Note

Use the Cisco Product Identification (CPI) tool to locate your product serial number before submitting a web or phone request for service. You can access the CPI tool from the Cisco Technical Support Website by clicking the Tools & Resources link under Documentation & Tools. Choose Cisco Product Identification Tool from the Alphabetical Index drop-down list, or click the Cisco Product Identification Tool link under Alerts & RMAs. The CPI tool offers three search options: by product ID or model name; by tree view; or for certain products, by copying and pasting show command output. Search results show an illustration of your product with the serial number label location highlighted. Locate the serial number label on your product and record the information before placing a service call.

Submitting a Service Request

Using the online TAC Service Request Tool is the fastest way to open S3 and S4 service requests. (S3 and S4 service requests are those in which your network is minimally impaired or for which you require product information.) After you describe your situation, the TAC Service Request Tool provides recommended solutions. If your issue is not resolved using the recommended resources, your service request is assigned to a Cisco TAC engineer. The TAC Service Request Tool is located at this URL:

https://tools.cisco.com/RPF/register/register.do

For S1 or S2 service requests or if you do not have Internet access, contact the Cisco TAC by telephone. (S1 or S2 service requests are those in which your production network is down or severely degraded.) Cisco TAC engineers are assigned immediately to S1 and S2 service requests to help keep your business operations running smoothly.

To open a service request by telephone, use one of the following numbers:

Asia-Pacific: +61 2 8446 7411 (Australia: 1 800 805 227)

EMEA: +32 2 704 55 55

USA: 1 800 553-2447For a complete list of Cisco TAC contacts, go to this URL:

http://www.cisco.com/en/US/support/tsd_contact_technical_support.html

Definitions of Service Request Severity

To ensure that all service requests are reported in a standard format, Cisco has established severity definitions.

Severity 1 (S1)—Your network is "down," or there is a critical impact to your business operations. You and Cisco will commit all necessary resources around the clock to resolve the situation.

Severity 2 (S2)—Operation of an existing network is severely degraded, or significant aspects of your business operation are negatively affected by inadequate performance of Cisco products. You and Cisco will commit full-time resources during normal business hours to resolve the situation.

Severity 3 (S3)—Operational performance of your network is impaired, but most business operations remain functional. You and Cisco will commit resources during normal business hours to restore service to satisfactory levels.

Severity 4 (S4)—You require information or assistance with Cisco product capabilities, installation, or configuration. There is little or no effect on your business operations.

Obtaining Additional Publications and Information

Information about Cisco products, technologies, and network solutions is available from various online and printed sources.

•

Cisco Marketplace provides a variety of Cisco books, reference guides, and logo merchandise. Visit Cisco Marketplace, the company store, at this URL:

http://www.cisco.com/go/marketplace/

•

Cisco Press publishes a wide range of general networking, training and certification titles. Both new and experienced users will benefit from these publications. For current Cisco Press titles and other information, go to Cisco Press at this URL:

•

Packet magazine is the Cisco Systems technical user magazine for maximizing Internet and networking investments. Each quarter, Packet delivers coverage of the latest industry trends, technology breakthroughs, and Cisco products and solutions, as well as network deployment and troubleshooting tips, configuration examples, customer case studies, certification and training information, and links to scores of in-depth online resources. You can access Packet magazine at this URL:

http://www.cisco.com/web/about/ac123/ac114/about_cisco_packet_magazine.html

•

iQ Magazine is the quarterly publication from Cisco Systems designed to help growing companies learn how they can use technology to increase revenue, streamline their business, and expand services. The publication identifies the challenges facing these companies and the technologies to help solve them, using real-world case studies and business strategies to help readers make sound technology investment decisions.

•

Internet Protocol Journal is a quarterly journal published by Cisco Systems for engineering professionals involved in designing, developing, and operating public and private internets and intranets. You can access the Internet Protocol Journal at this URL:

http://www.cisco.com/web/about/ac123/ac147/about_cisco_the_internet_protocol_journal.html

•

World-class networking training is available from Cisco. You can view current offerings at this URL:

http://www.cisco.com/web/learning/index.html

This document is to be used in conjunction with the documents listed in the "Related Documentation" section.

Copyright © 2004-2005 Cisco Systems, Inc. All rights reserved.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback