Field Notice: ONS 15454-OC12-4 Connector Seating Issue

Available Languages

Revised August 11, 2004

July 28, 2004

Products Affected

-

15454-OC12-4

Problem Description

ONS 15454-OC12-4 optical boards have been found to exhibit the following mechanical connector issues.

The optical link connected to the OC12-4 card may experience higher optical loss, increased jitter and increased bit error rate (BER) as a result of a connector air gap.

-

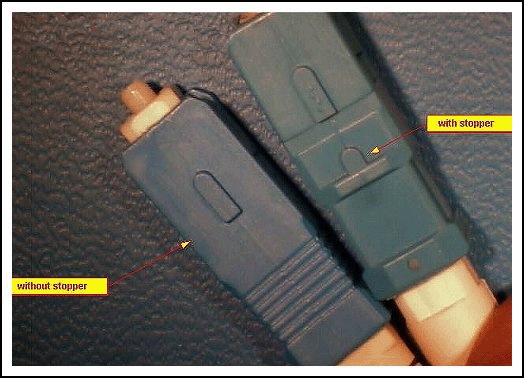

This air gap may result from a male connector cable assembly duplex clip's "stopper" (see Figure 1) that may contact the OC12-4 card's bulkhead connector housing before the connector is fully seated, preventing the connector from latching into place.

-

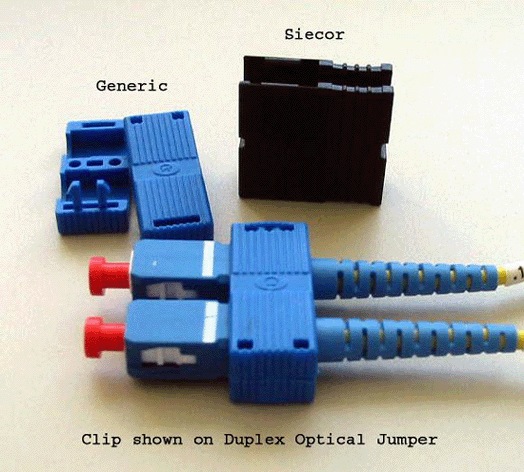

A male connector cable assembly duplex clip (see Figure 2) that may contact the OC12-4 cards bulkhead connector housing before the connector is fully seated, preventing the connector from latching into place.

Issue # 1 - Insufficient engagement due to certain duplex clip interference.

Issue # 2 - Receptacle retainer clip deformation when subjected to high temperatures with connector not fully engaged.

FIGURE 1 - Connector Comparison

FIGURE 2

Background

Issue # 1 - With certain duplex clips, interference between the connector housing and the duplex clip prevent the connector from fully engaging, causing the connector to fail to fully seat and lock into place.

Issue # 2 - If subjected to high temperature (50deg C) with the connector not fully engaged, the retaining fingers within the connector receptacle can become deformed, defeating proper operation.

Problem Symptoms

Issue # 1 - The duplex clip may contact the connector housing before the connector is fully seated, preventing the connector from latching in to place.

Issue # 2 - If, as a result of being subjected to high temperature (50deg C) with the connector not fully engaged, the retaining fingers within the connector receptacle become deformed, the male connector will no longer snap in to place.

Workaround/Solution

Issue # 1 - Ensure that the male connector is fully seated in the bulkhead receptacle and has snapped into place prior to operation. If the connector fails to fully engage due to interference between the duplex clip and the connector housing, remove the duplex clip and reinsert the connectors making sure that they are fully seated.

Issue # 2 - If the receptacle has been subjected to high temperature with the connector not fully engaged and the retaining clips no longer retain a properly inserted male connector, the board will need to be replaced. Contact the Technical Assistance Center as outlined below to obtain a replacement.

Ensure strict adherence to the product documentation and any related release notes.

For More Information

If you require further assistance, or if you have any further questions regarding this field notice, please contact the Cisco Systems Technical Assistance Center (TAC) by one of the following methods:

Receive Email Notification For New Field Notices

Product Alert Tool - Set up a profile to receive email updates about reliability, safety, network security, and end-of-sale issues for the Cisco products you specify.

Contact Cisco

- Open a Support Case

- (Requires a Cisco Service Contract)

Feedback

Feedback